UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 6-K

REPORT OF FOREIGN PRIVATE ISSUER PURSUANT TO RULE 13a-16 OR 15d-16 UNDER THE SECURITIES EXCHANGE ACT OF 1934

For the month of August, 2016

______________

Commission File Number: 001-13742

ISRAEL CHEMICALS LTD.

(Exact name of registrant as specified in its charter)

Israel Chemicals Ltd.

Millennium Tower

23 Aranha Street

P.O. Box 20245

Tel Aviv, 61202 Israel

(972-3) 684-4400

(Address of principal executive office)

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F:

| Form 20-F | X |

Form 40-F |

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1):

| Yes | No | X |

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7):

| Yes | No | X |

ISRAEL CHEMICALS LTD.

| 1. | Corporate Responsibility Report |

Item 1

ICL Corporate Responsibility Report 2015

Where needs take us

Letter from ICL's Sustainability Officer For the global sustainability community, governments, nonprofits and businesses alike, 2015 was marked by the 21st summit of the United Nations Convention on Climate Change and Paris Agreements reached in December, as well as the process leading up to these forward-looking accords. A cornerstone of the process has been the Sustainable Development Goals ("SDGs"), adopted by the UN General Assembly in September. There are 17 goals with 169 targets covering a broad range of sustainable development issues. These include ending poverty and hunger, improving health and education, making cities more sustainable, combating climate change, and protecting oceans and forests. The SDGs serve governments and businesses and guide both strategy and action. ICL, seeking to identify and act upon the most fundamental needs of humanity, has chosen to use the SDGs as a context for its 2015 Sustainability Report. ICL's global presence and vertical integration serve us well in meeting a number of key challenges, making humanity's needs and goals our business. The second SDG is indeed the core of our business: "ending hunger, achieving food security and improving nutrition and promoting sustainable agriculture." We also have key roles to play in a number of SDGs focused on reducing environmental impacts, such as those relating to energy and climate change: "ensure access to affordable, reliable, sustainable and clean energy for all" (SDG 7) and "take urgent action to combat climate change and its impacts" (SDG 13). Thus, this year's Sustainability Report is, above all, an offering for discussion and engagement with our stakeholders, to ensure we hold true to the journey on which ICL has embarked: "Where Needs Take Us". Mr. Tzachi Mor, ICL Sustainability and ERM Tzachi.Mor@icl-group.com ICL Corporate Responsibility Report 2015 3

inviting you to further explore our corporate responsibility related activities We invite you to review our 2015 CSR Report. As our objective is to provide you with the means to locate the information most relevant to you, we have published specific information on a dedicated website which allows for an in-depth look at aspects that are mentioned in this report, and the ability to 'zoom in' on relevant issues. We have also integrated videos which are available by either scanning a QR code or by clicking on the link (if reading online). Please download a free QR code reader from your favorite app store in order to scan the QR codes appearing throughout this report. For ICL's website where you can find a wealth of information about the company, including corporate responsibility reports from previous years, scan the QR code or press the QR code. * Relevant information regarding the scope of the limited assurance performed in regard to the specified parts is detailed throughout the report. All relevant marks should be reviewed according to the Limited Assurance report on pages 5-7 in this report. 4 ICL Corporate Responsibility Report 2015

Somekh Chaikin KPMG Millennium Tower 17 Ha'arba'a Street, PO Box 609 Tel Aviv 61006, Israel +972 3 684 8000 (1) The mark included as part of a given paragraph, refers to the information and/or data included in the relevant sentence only. 09 August 2016 Independent Limited Assurance Report to the users/ readers of Israel Chemicals Ltd. 2015 Corporate Responsibility Report. We were engaged by the management of Israel Chemicals Ltd. (further referred to as "ICL") to provide limited assurance on the specified parts as mentioned in the table below (further referred to as "Specified parts"), marked(1) with in the report, regarding the information presented on ICL's 2015 Corporate Responsibility Report for the year ended 31 December 2015 (further referred to as "The Report"). Management is responsible for A. the preparation and the presentation of the report in accordance with the Sustainability Reporting Guidelines (G4) of the Global Reporting Initiative (GRI) as described in pages 194-201 of the Report, and the information and assertions contained within it B. for determining ICL's objectives in respect of sustainable development performance and reporting, including the identification of stakeholders and material issues for reporting C. for establishing and maintaining appropriate performance management and internal control systems from which the information is derived, to be free from omissions and material misstatements whether due to fraud or error. Our responsibility is to provide a limited assurance engagement and to express a conclusion based on the work performed. We conducted our engagement in accordance with International Standard on Assurance Engagements (ISAE) 3000, Assurance Engagements other than Audits or Reviews of Historical Financial Information, issued by the International Auditing and Assurance Standards Board. That Standard requires that we comply with applicable ethical requirements, including independence requirements, and that we plan and perform the engagement to obtain limited assurance about whether the Report is free from material misstatement. A limited assurance engagement, regarding data and information in the specified parts on the corporate responsibility report, consists of making interviews and inquiries, primarily of persons responsible for the preparation of information presented in the report, and applying analytical and other evidence gathering procedures, as appropriate. These procedures included: Examination of the specified parts in the report, for the purpose of performing a limited assurance, based on public information sources, knowledge of ICL business and other comparative information of similar organizations. Somekh Chaikin, an Israeli partnership and a member firm of KPMG network of independent member firms affiliated with International Cooperative ("KPMG International"), a Swiss entity. ICL Corporate Responsibility Report 2015 5

G4-33 Inquiries of management to gain an understanding of ICL processes for determining the material issues for ICL key stakeholder groups. Inquiries of management to gain an understanding regarding the specified parts. Interviews with senior management and relevant staff at group level and selected business unit level concerning corporate responsibility strategy and policies for specified parts, and the implementation of these across the business. Interviews with relevant staff at corporate and business unit level responsible for providing the information in the Report. Visits to the ICL's Spain and UK sites (Iberpotash site and Cleveland Potash site), on the basis of a risk analysis including the consideration of both quantitative and qualitative criteria regarding the specified parts. Visits and communication with the company sites located in Israel, and the Company Tel Aviv headquarters on the basis of a risk analysis including the consideration of both quantitative and qualitative criteria regarding the specified parts. Comparing the information regarding the specified parts presented in the Report to corresponding information in the relevant underlying sources to determine whether all the relevant information contained in such underlying sources has been included in the report. Where relevant, conducting interviews regarding the calculation, aggregation and methods used to collect and report the specified parts in the report. Reading the information presented in the Report to determine whether it is in line with our overall knowledge of, and experience with, the corporate responsibility performance of ICL group. Limited assurance is less than absolute assurance and reasonable assurance. A limited assurance engagement is substantially less in scope that a reasonable assurance engagement in relation to both the risk assessment procedures, including an understanding of internal control, and the evidence-gathering procedures performed in response to the assessed risks, which vary in nature from and are substantially less in scope than for a reasonable assurance engagement. As a result, the level of assurance obtained in a limited assurance engagement is substantially lower than the assurance that would have been obtained had we performed a reasonable assurance engagement. We believe that the procedures we have performed and the evidence we have obtained is sufficient and appropriate to provide a basis for our conclusion. Conclusion Based on the limited assurance procedures performed and the evidence we have obtained, described in this report, nothing has come to our attention to indicate that the specified parts as mentioned in the table below, Somekh Chaikin, an Israeli partnership and a member firm of KPMG network of independent member firms affiliated with International Cooperative ("KPMG International"), a Swiss entity. 6 ICL Corporate Responsibility Report 2015

G4-33 (2) Material issues assurance included relevant steps performed by the company in its material assessment, as described in the report, only. 3 Specific parts related to information based on the research "The scope of ICL's economic influence on the Israeli economy as a whole, as well as on the Beer Sheva area, in particular" were assured based on the information publicly published in the research only. (4) Limited Assurance procedures performed in regad to ICL's Spain and UK sites (Iberpotash site and Cleveland Potash site) data only. in ICL's 2015 Corporate Responsibility Report are not presented, in all material respects, in accordance with the GRI-G4 and ICL's reporting criteria. Our limited assurance report is made solely to ICL in accordance with the terms of our engagement. Our work has been undertaken so that we might state to ICL those specified parts we have been engaged to state in this limited assurance report and for no other purpose or in any other context. We do not accept or assume responsibility to anyone other than ICL for our work, for this limited assurance report, or for the conclusions we have reached. Somekh Chaikin Certified Public Accountants Tel Aviv, Israel August 9th, 2016 Subject Page ICL's 2015 operating segments business mix 18 Material Issues(2) 34-37 ICL's selected financial information 62 ICL's impact on the Negev, Israeli economy and balance of payments(3) 63 ICL's 2015 total expenses and investments in environmental protection 68 ICL Iberia Iberpotash 2015 mining royalties 93 ICL UK CPL 2015 mining royalties 93 ICL's 2015 Total RandD Expenses 107 ICL's 2015 total indirect energy consumption(4) 137 ICL's 2015 total natural gas direct energy consumption(4) 137 ICL's 2015 Scope 2 market based GHG Emissions 141 ICL's Carbon Disclosure Project disclosure scores and performance bands 143 ICL's 2015 total Europe potable water consumption(4) 148 ICL's 2015 total Europe non potable water consumption(4) 148 ICL's 2015 total wastewater discharged(4) 150 ICL's 2015 total non-hazardous global solid waste(4) 151 ICL's 2015 total charitable contribution 176 Somekh Chaikin, an Israeli partnership and a member firm of KPMG network of independent member firms affiliated with International Cooperative ("KPMG International"), a Swiss entity.

Contents 10 A Message from ICL's Chairman and CEO 12 ICL Corporate Overview About ICL 15 ICL at a Glance 16 One ICL 18 Looking Back - Moving Forward 22 ICL's story: "Where Needs Take Us" 25 Goals, Performance and Next Steps Forward 28 Material Issues 34 40 Governance and Economic Responsibility Corporate Governance 42 Corporate Responsibility 43 Sustainable Development Policy 45 Global Distribution 46 Board of Directors 47 Focusing on Core Business Activities 52 Organizational and business culture 43 Conducting Business Fairly 44 Professional and Industry-Related Involvments 58 Voluntary External Standards 58 Transparency and Stakeholders Dialogue 59 Engaging Our Stakeholders 60 Economic Responsibility 62 Selected Financial Information 62 ICL's Impact on State Economics 63 8 ICL Corporate Responsibility Report 2015

66 Environmental Responsibility Environmental Policy 68 Sustainability Throughout Our Products' Lifecycle 73 Stage 1: Raw Materials and Materials Extraction 75 Stage 2: Product Development 106 Stage 3: Production and Operations 113 Stage 4: Logistics and Distribution 118 Stage 5: Product Use Stage 122 Stage 6: End of Life for Our Products 132 Environmental Performance 136 Energy Consumption 137 GHG and Climate Change 140 Air Quality 145 Water Consumption 148 Wastewater and Wsate 150 154 Social Responsibility Fair and Responsible Employment 158 Employee Empowerment 163 Protection of Human Rights 166 Occupational Health and Safety 167 Maintaining a Safe and Healthy Environment 167 Changing Safety Culture 196 Security 174 Engaging our Communities 176 Israel 177 Europe 183 The Americas 185 188 About the Report 193 GRI G4 Content Index ICL Corporate Responsibility Report 2015 9

A Message from ICL's Chairman and CEO Letter from the Chairman and CEO Corporate Overview Governance and Economic Responsibility Environmental Responsibility Social Responsibility About the Report Mr. Stefan Borgas President and CEO Mr. Nir Gilad Chairman of the Board Our commitment to manage ICL responsibly is clearer than ever and serves as a beacon for decision making within the company. We are pleased to present our 2015 Corporate Responsibility report documenting ICL's focus and progress on addressing humanity's global challenges and needs. The past year at ICL has been marked by events that highlight the truly global nature of our company: we launched new operations in China and Ethiopia, inaugurated our new European headquarters in the Netherlands, strengthened our operations in Spain and Brazil and embarked on intensive agricultural outreach in India and Ethiopia. ICL has brought its recognized global sustainability expertise into all of these operations and projects. We continued to implement our broad-based strategy aimed at creating a more balanced, integrated and efficient company focused on specialty end markets. Ecological, financial and social sustainability is an integral part of this strategy. ICL fulfills essential needs in three core end markets - Agriculture, Food and Engineered Materials - by utilizing an integrated global value chain that is based on specialty minerals. These markets are at the forefront of acute global challenges, such as food security and climate change. The creation of Sustainable Development Goals (SDGs) in 2015 includes 17 goals and 169 specific targets adopted by the 193 countries of the UN General Assembly. They range from preventing poverty and hunger to reducing climate change and increasing the availability of potable water. We view these sustainable development goals as an important compass for providing direction in our journey. G4-1 10 ICL Corporate Responsibility Report 2015

A Message from ICL's Chairman and CEO Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report ICL integrates sustainability considerations into our strategy and our operations by creating a collaborative, efficient and innovative environment for our 13,500 valued employees, enabling them to address evolving needs in our core markets. Some early results of this approach are reviewed in this report: For instance, our new Polysulphate product is a natural, sustainable, organic fertilizer with a low environmental impact (see page 126). Other initiatives are in progress to improve our financial and ecological efficiency and enable us to build sustainable platforms that will make ICL more flexible, resilient and productive. In parallel we are increasing our transparency about our sustainability performance and goals. This is essential to create the suitable corporate environment for excellence in sustainability, as well as for effective engagement with our stakeholders worldwide. One of the many examples of the progress we have achieved in this area is the recognition we received from the Carbon Disclosure Project regarding our transparency and performance. There is increasing uncertainty in the financial markets regarding the willingness -- and the ability -- of many nations to confront several of the world's most pressing challenges, and to overcome their own social and financial problems. Throughout this period, ICL has remained committed to reducing our environmental footprint, enhancing the sustainability of our products throughout the value chain, and developing next generation products in energy storage, balanced fertilization, food additives and environmentally-friendly flame retardants. In this report, we present a window into our activities and achievements and present our roadmap for the future. We will continue to engage our customers, employees and stakeholders throughout the world, aware of our commitment to manage ICL sustainably and responsibly. We hope this report provides you with a greater understanding of our social responsibility activities and we encourage you, our stakeholders, to share your ideas and concerns with us on these issues which are essential to us all. Mr. Nir Gilad Mr. Stefan Borgas Chairman of the Board President and CEO G4-1 ICL Corporate Responsibility Report 2015 11

Letter from the Chairman and CEO Corporate Overview Governance and Economic Responsibility Environmental Responsibility Social Responsibility About the Report ICL Corporate Overview

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Putting food on the table: healthy and plentiful for all. ICL's fertilizers and specialty fertilizers help farmers cope with diverse agricultural conditions and provide improved, high-quality and durable produce.

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Fulfilling Humanity's Essential Needs 14 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report About ICL ICL Overview- Fulfilling Essential Need: Vision and Strategy by Our CEO: G4-3, G4-4, G4-7, G4-9 ICL is a global manufacturer of products based on specialty minerals that fulfill humanity's essential needs in three core markets: Agriculture, Food and Engineered Materials. ICL produces approximately a third of the world's bromine and is the sixth largest potash producer, as well as the leading provider of pure phosphoric acid. It is a major manufacturer of specialty fertilizers, specialty phosphates and flame retardants. ICL's mining and manufacturing activities are located in Israel, Europe, the Americas and China, and are supported by global distribution and supply networks. The agricultural products that ICL produces help to feed the world's growing population. The potash and phosphates that it mines and manufactures are used as ingredients in fertilizers and serve as an essential component in the pharmaceutical and food additives industries. The food additives that ICL produces enable people to have greater access to more varied and higher quality food. ICL's water treatment products supply clean water to millions of people as well industry around the world. Other substances, based on bromine and phosphates, help to create energy that is more efficient and environmentally friendly, prevent the spread of forest fires and allow the safe and widespread use of a wide variety of products and materials. ICL operates within a strategic framework of sustainability that includes a commitment to the environment, support of communities in which ICL's manufacturing operations are located and where its employees live, and a commitment to all its employees, customers, suppliers and other stakeholders. ICL (Israel Chemicals Ltd.) is a public company whose shares are dual listed on the New York Stock Exchange and the Tel Aviv Stock Exchange (NYSE and TASE: ICL). 46.2% of ICL's equity is held by Israel Corp., 13.9% by Potash Corporation of Saskatchewan and the remainder by the public. The company employs approximately 13,500 people worldwide, and its sales in 2015 totaled $5.4 billion. ICL Corporate Responsibility Report 2015 15

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Minerals Assets Potash (potassium chloride) is one of the three major nutrients required for plant growth. It is vital for the physiological processes of plant growth, and improves the durability of the produce it fertilizes, helping agricultural products survive storage and transportation and prolonging their shelf life. There are currently no artificial substitutes for potassium. Derived from phosphate rock, phosphate is one of the three major nutrients required for plant growth. Phosphorus directly contributes to a wide range of physiological processes in a plant and accelerates the growth rate of crops. There are currently no artificial substitutes for PhosphorUS Bromine, a member of the halogen family, is known for its diverse uses in many industries. Bromine is rarer than about 75% of elements in the Earth's crust and is found in seawater and underground brine deposits. Due to its high concentration of salt, the Dead Sea is a major source of the world's Bromine. Magnesium is the eighth most abundant element in the earth's crust and plays an important role in plant and animal life. Resources Fully Integrated and Diversified Value Chain Dead Expertise Segments Sea Mining Fertilizers UK/ Spain Mines Formulation Performance Products Negev Desert Chemistry Industrial Global Products opportu- nities RandD Minerals Assets 16 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Potash Agriculture Bulk Phosphate Fertilizers Markets Specialty Fertilizers Polysulphate[] Industrial Solutions Food Advanced Additives phosphates and End phosphorus-based Food Specialties Flame Retardants bromine-and phosphorus- based Engineered Industrial Solutions Materials Advanced Additives phosphates and phosphorus-based G4-4, G4-12 ICL Corporate Responsibility Report 2015 17

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report One ICL Limited assurance procedures performed for ICL's 2015 Business Mix, as described in the report, only. ICL: G4-8, G4-DMA Commodity Business Our Commodity Business provides bulk potash and phosphate fertilizers, phosphate rock and phosphoric acid to agriculture markets and provides raw materials for our backward-integrated Specialty Business. Specialty Business Our Specialty Business serves all three of our end markets: Agriculture, Food and Engineered Materials. For Agriculture, our mineral raw materials are used to produce specialty fertilizers that enhance yields, improve crop quality, save water and protect the environment. Our Food Specialties products are used to improve the texture, stability and shelf life of products for the meat, bakery, dairy and soft-drink industries, while maintaining and even improving the food nutritional values. For Engineered Materials markets, we produce downstream products such as flame retardants for the electronics automotive and construction industries, clear bromine-based brine fluids for the oil and gas drilling industry and advanced additives for a host of industrial and consumer products in various industries including motor oils, paints and coatings, electronics, construction, asphalt and firefighting. Operating Segments We are a leading multinational company that operates mainly in the areas of fertilizers and specialty chemicals, in three segments: Fertilizers, Industrial Products and Performance Products. In addition, we have other operations that include water desalination and magnesium manufacturing. Business Mix (Based on FY2015 Adj. Operating Income) Fertilizers Segment Industrial Products Performance Products 14% 14% 72% 18 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report One ICL Target 2.4 By 2030, ensure sustainable food production systems and implement resilient agriculture practices that increase productivity and production, help maintain ecosystems, strengthen capacity for adaptation to climate change, extreme weather, drought, flooding and other disasters, and that progressively improve land and soil quality. G4-DMA Fertilizers Our Fertilizers segment develops, manufactures, markets and sells fertilizers that are based primarily on potash (potassium chloride) and phosphate. Nitrogen, phosphorus and potassium (N, P and K) constitute the three major nutrients required for plant growth. Each of these three nutrients plays a different role in plant development. Without these nutrients, crops cannot achieve their growth potential. Potassium also enhances a plant's ability to withstand drought and cold, improves the efficient use of nitrogen and other nutrients necessary for plant development, and improves the durability of agricultural produce in storage and transportation. There are currently no artificial substitutes for phosphorus and potassium. These three nutrients are present in the ground, however the continued use of the soil for agricultural crops depletes the concentration of these fundamental elements in the ground over time, and could result in a decline in crop yields, and must be replenished from external sources through the use of fertilizers. We sell phosphorus-based and potassium-based products. Performance Products Our Performance Products segment primarily develops, produces, markets and sells a broad range of specialty phosphates for different applications as well as whey proteins for the food ingredient industry. Industrial Products Our Industrial Products segment develops, manufactures markets and sells bromine phosphorus and magnesium based flame retardants for the electronics, automotive and construction industries, bromine compounds for industrial and agricultural uses, clear bromine based brine fluids for the oil and gas drilling industry, and biocides for water treatment. These products are principally based on bromine, magnesia, chlorine and salts from the Dead Sea and phosphorus and chlorine purchased from third parties.

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report One ICL G4-DMA, G4-4, G4-8 End Markets Over 98% of our revenue is derived from three core end-markets. End Market (Based on FY2015 Revenue) Agriculture (Bulk and Speciality Fertilizers) Food Engineered Materials Other 2% 9% 33% 56% Agriculture The demand for fertilizers is driven and influenced by the growth of the world's population, the increase in the standard of living and a shortage of arable land, which are creating an increasing demand for food. The agricultural products that ICL produces help to feed the world's growing population by providing essential nutrients that help farmers increase the quantity and quality of their crops. ICL is also an expert in the area of specialty fertilizers meeting the needs of specific crops and climates in order to maximize their productivity and quality. Potash #2 in Western Europe and #6 Worldwide PK fertilizers (complex fertilizers based on potash and phosphate) #1 in Western Europe Specialty fertilizers CRF and MKP #1 Worldwide in MAP/MKP soluble fertilizers, #1 (tied) in Europe in controlled release fertilizers and #2 in the United States in controlled release fertilizers 20 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report One ICL G4-DMA, G4-4, G4-8 Food ICL is a leader in supplying effective and innovative products to the food and beverage industries. The Company's portfolio and expertise allow it to provide customers with products specifically tailored to the needs of their industry. Phosphate-based food additives Top 3 Worldwide Specialty phosphates Top 2 Worldwide (Food and Engineered Materials) Engineered Materials ICL is a global leader in industrial additives and materials, including a broad range of flame retardants, phosphate salts and specialty phosphate blends, purified phosphoric acid and electronic-grade specialty phosphoric acids. The Company is also a leading provider of magnesium alloys for the automobile industry. ICL's strong technical support team works closely with customers across the globe to provide customized high-performance applications. These materials help to create more efficient and environmentally friendly energy, prevent the spread of forest fires, and allow the safe and broad use of hundreds of products and materials. Elemental bromine #1 Worldwide Phosphorus-based flame retardants #1 Worldwide Forest fire retardants #1 Worldwide Other activities include ICL Dead Sea Magnesium which produces, markets and sells pure magnesium and magnesium alloys. It also produces dry carnallite and related by products, including chlorine and sylvinite. DSM is the second largest magnesium producer in the Western world. ICL Corporate Responsibility Report 2015 21

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report LOOKING BACK - MOVING FORWARD Business driven Sustainability driven * All CSR reports mentioned are GRI reports except for the first corporate CSR report in 2009. 1968 ICL established by the State of Israel as a government-owned company. 1992 The beginning of the Israeli government's privatization of ICL, listing its shares on the Tel-Aviv Stock Exchange (TASE) and issuing a special non-transferable "State Share" to the State of Israel to protect the government's vital interests. 2001-2015 During the past decade, the Company has expanded significantly, primarily by increasing its production capacity and global distribution, establishing regional offices and joint ventures, and investing in acquisitions. 2006 Expanding stakeholders dialogue 1975 ICL expanded through the consolidation of additional government-owned entities, including Dead Sea Works, the companies that comprised Rotem Amfert Negev, Bromine Compounds and TAMI (IMI), ICL's research arm. 1995-2000 The state of Israel completes the privatization of ICL and sells its controlling interest to Israel Corp. As of Dec. 31, 2015, Israel Corporation holds approx. 48.8% of ICL's outstanding ordinary shares. 2001-2005 Initiating CAPs (Community Advisory Panels) Introducing VECAP -- Voluntary Emissions Control Action Program for flame retardants 2007 First ICL company-level CSR Report (Bromine Compounds)

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report 2009 First corporate CSR Report * Developing a Sustainability Index for Product RandD Completing full Carbon Footprint assessments for first 5 ICL products (over 60 assessments concluded so far) 2011 Purchasing two new companies (Everris and Fuentes) and establishing the specialty-fertilizers business sub-segment, significantly expanding ICL's activity in sustainable agriculture, through controlled and slow-release fertilizers. First ICL CDP Carbon report- score of 90B, inclusion in CDLI (climate disclosure leadership index) First annual GHG inventory reported to the voluntary reporting scheme in Israel 2015 Completing formation of China phosphate joint venture with Yunnan Yuntinhua First runner-up in the Green Leaf award for ICL Rotem[]s innovative activity in the reclamation of phosphate mines. First ICL company (ICL DSM) to receive gold sustainability rating by EcoVadis -- Supplier Sustainability Rating Start of implementation for the new ICL SoFi IT system- for sustainability data collection, management and reporting ICL-IP launch Systematic Assessment for Flame Retardants (SAFR[]) 2008 First ICL segment level CSR Report (ICL IP) Presenting Merquel([R]), a breakthrough product for reducing mercury emission from coal-based power plants. Sponsoring a green chemistry event in Israel Adopting a sustainability strategy Becoming a signatory member of the Responsible Care Charter 2010 First corporate CSR Report based on the GRI G3 guidelines Starting the transition to natural gas combustion in ICL Israel. This will result in significant emissions reductions in the next years. First ICL owned building reconstructed according to Green Building standards (Beit-Maklef, Beer-Sheba, Israel). 2012 Commercial production of Polysulphate First Readiness Assessment process for external verification of ICL sustainability data First full Life Cycle assessments for ICL IP products completed 2014 Trading on the New York Stock Exchang First corporate GRI-G4 CSR Report; first partial external verification completed. First Sustainability Report (GRI G4) by ICL Iberia Iberpotash Reaching []A[], the highest performance score in the CDP report, and is the first Israeli-based company to be included in the CPLI (climate performance leadership index) Promoting grass-roots community sustainability initiatives by engaging the community: First "Thinking, Doing" initiative started in Yeruham, Israel. Where needs take us ICL Corporate Responsibility Report 2015 23

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report 24 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report ICL'S STORY: WHERE NEEDS TAKE US Based on our commitment to provide essential needs to humanity, ICL is attentive to the needs of its customers, its employees, the communities in which it operates and it's other stakeholders. As social and environmental needs and technologies change, ICL must be able to meet these new challenges and opportunities. We search for opportunities throughout our products life cycles, and our aim is to take the next step forward. Aligning with the UN Sustainability Development Goals Sustainable development is a global goal, but the path is full of challenges. There are worldwide concerns, from poverty and unemployment to global health threats and natural resource depletion. On September 2015, countries adopted a set of goals to end poverty, protect the planet and ensure prosperity for all as part of a new sustainable development agenda. The 17 Sustainable Development Goals and 169 targets seek to build on the Millennium Development Goals and realize the human rights of all and to achieve gender equality and the empowerment of all women and girls. Each goal has specific targets to be achieved over the next 15 years. The goals and targets will stimulate action over the next years in areas of critical importance for humanity and the planet. They are integrated and indivisible and balance the three dimensions of sustainable development: economic, social and environmental. ICL's core business activities are directly connected to Goal 2 of ending hunger, achieving food security and improving nutrition and promoting sustainable agriculture. Our strategy and operations support other goals such as ensuring access to affordable, reliable, sustainable and modern energy for all (Goal 7), combat climate change (Goal 13) and others. We also strive to excel and achieve other goals such as gender equality and empowering all women and girls (Goal 5). The SDGs serve governments and businesses alike as a beacon that guides both strategy and action. It is therefore no coincidence that ICL, seeking to identify and act upon the most fundamental needs for humanity, has chosen to use the SDGs as a context for its 2015 sustainability report. ICL Corporate Responsibility Report 2015 25

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report ICL'S STORY: WHERE NEEDS TAKE US 26 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report End hunger, achieve food security and improved nutrition and promote sustainable agriculture Ensure inclusive and equitable quality education and promote lifelong learning opportunities for all Achieve gender equality and empower all women and girls Ensure availability and sustainable management of water and sanitation for all Ensure access to affordable, reliable, sustainable and modern energy for all Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation Ensure sustainable consumption and production patterns Take urgent action to combat climate change and its impacts* Conserve and sustainably use the oceans, seas and marine resources for sustainable development Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss Promote peaceful and inclusive societies for sustainable development, provide access to justice for all and build effective, accountable and inclusive institutions at all levels ICL Corporate Responsibility Report 2015 27 For more information regarding a specific SDG click on the icon.

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report GOALS, PERFORMANCE and NEXT STEPS FORWARD Sustainable Products and Services products Goals Increase sales of Polysulphate[], an environmentally-friendly fertilizer, by 30%-50% and produce about 1,000,000 tonnes by the year 2020. Create a science-based assessment tool for flame retardants. Achievements ICL is the first and only producer to mine polyhalite, which it markets as Polysulphate[]. Commercial production commenced in 2012. ICL's Systematic Assessment for Flame Retardants (SAFR[]) assesses the sustainability profile of individual flame retardants based on hazard criteria and potential exposure in their application. Assessments conducted on 100% of ICL's (flame retardants using SAFR[])ICL's flame retardants using SAFR[]. Next Steps Forward Develop additional Polysulphate-based products. Expand into additional markets through customer education and support both in agronomy and production, large scale field trials and providing additional results of research regarding the product's capabilities Complete global registration process of Polysulphate[] new fertilizer and complete organic fertilizer registration in relevant countries. Promote the adoption of the methodology throughout the value chain, where it will enable purchasing decisions based on the sustainable use of a flame retardant for specific applications ICL will release a second version of SAFR[] by the end of 2016. G4-DMA, G4-2 28 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report GOALS, PERFORMANCE and NEXT STEPS FORWARD Sustainable Products and Services Goals Introduce a Sustainability Index for Product Development for all of ICL's relevant business units by the end of 2016 Include all BFRs sold by ICL Industrial Products under the VECAP program. Achievements The Sustainability Index tool is fully implemented at ICL Industrial Products. In 2015, global coverage by VECAP included 73% of all BFRs sold by ICL Industrial Products. Next Steps Forward Adaptation of the Sustainability Index for the RandDs of the relevant business units. Incorporate the Sustainability Index in day-to day practices of our RandD units to enable the development of sustainable products and thereby increase ICL's offerings of these products. Create a system of customer "sustainability" ranking and report on best practices. G4-DMA, G4-2 ICL Corporate Responsibility Report 2015 29

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report GOALS, PERFORMANCE and NEXT STEPS FORWARD Goals Focus on new products and new technologies development, new applications and formulations in ICL Strategy fields: agriculture, food and engineered materials. Advance and share ICL's knowledge in plant nutrition by sharing our knowledge and supporting hundreds of research studies worldwide related to various crops, soils and climates. Achievements ICL invested $318 million in RandD since 2012. During 2015 three projects were transferred from ICL Innovation to ICL business unit (ICLSF) for further development and commercialization. In 2015, ICL significantly expanded research activities with third parties in our strategy fields: Agro, Food, EM. ICL established the Center for Fertilization and Plant Nutrition (CFPN) in cooperation with the Israel Agricultural Research Organization (ARO; Volcani Center), a research center for fertilizer and plant nutrition knowledge. RandD center for Phosphorous derivate applications was established in Yunnan China. Next Steps Forward Boost our new products and new technologies portfolio. Promote activities to improve process production in our manufacturing facilities, operational excellence and cultivate technological human capital. Initiate collaborations with external parties for disruptive innovation. Allocate approximately $2 million per year to advance research of plant nutrition. G4-2 30 ICL Corporate Responsibility Report 2015

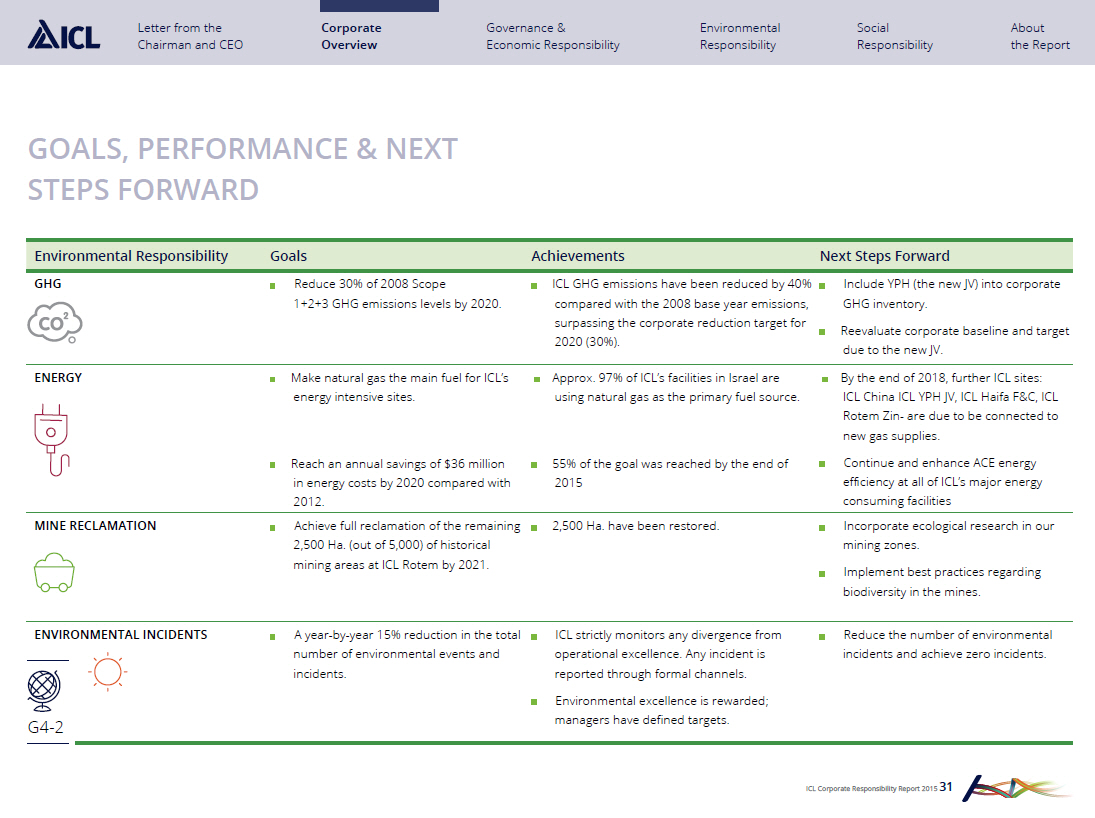

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report GOALS, PERFORMANCE and NEXT STEPS FORWARD Environmental Responsibility GHG ENERGY MINE RECLAMATION environmental incidents G4-2 Goals Reduce 30% of 2008 Scope 1+2+3 GHG emissions levels by 2020. Make natural gas the main fuel for ICL's energy intensive sites. Reach an annual savings of $36 million in energy costs by 2020 compared with 2012. Achieve full reclamation of the remaining 2,500 Ha. (out of 5,000) of historical mining areas at ICL Rotem by 2021. A year-by-year 15% reduction in the total number of environmental events and incidents. Achievements ICL GHG emissions have been reduced by 40% compared with the 2008 base year emissions, surpassing the corporate reduction target for 2020 (30%). Approx. 97% of ICL's facilities in Israel are using natural gas as the primary fuel source. 55% of the goal was reached by the end of 2015 2,500 Ha. have been restored. ICL strictly monitors any divergence from operational excellence. Any incident is reported through formal channels. Environmental excellence is rewarded; managers have defined targets. Next Steps Forward Include YPH (the new JV) into corporate GHG inventory. Reevaluate corporate baseline and target due to the new JV. By the end of 2018, further ICL sites: ICL China ICL YPH JV, ICL Haifa FandC, ICL Rotem Zin- are due to be connected to new gas supplies. Continue and enhance ACE energy efficiency at all of ICL's major energy consuming facilities Incorporate ecological research in our mining zones. Implement best practices regarding biodiversity in the mines. Reduce the number of environmental incidents and achieve zero incidents. ICL Corporate Responsibility Report 2015 31

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report GOALS, PERFORMANCE and NEXT STEPS FORWARD Social Responsibility HEALTH and SAFETY MANAGEMENT STANDARDS DIVERSITY Goals A year-by-year 20% reduction in the total number of accidents and IR index. Implement ISO 9001, ISO 14001 and OHSAS-18001 (or equivalent) at all of ICL's production sites by 2020. Accredit all ICL's significant energy consuming sites with ISO 50001 by 2020 Promote women in leadership roles and increase the number of women in senior management positions to 30% by the year 2020. Achievements 26.6% Decrease in Incident Rate from 2011-2015 About 80% of ICL's production sites have implemented and certified these three standards or their equivalents. Five production site worldwide have been certified for ISO 500001 for energy management. ICL has appointed two women to every strategic committee in ICL. Seeking candidates for senior leadership positions. Next Steps Forward Achieve zero accidents. Implementing programs for changing safety culture. Complete the implementation of standards in all of ICL's relevant operations. Incorporate ISO 50001 at relevant sites. By 2017 certify all production sites in Israel. Update recruitment and promotion procedures to increase diversity. Create an internal global forum to promote diversity. 32 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report ICL Corporate Responsibility Report 2015 33

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Material Issues ICL continually strives to monitor and evaluate issues of materiality relating to the Company and its stakeholders, and to adjust its strategies and disclosure accordingly. In 2015, the Company conducted a Materiality analysis to assess the economic, environmental and social issues that are of highest concern to its stakeholders and that could significantly affect the Company's ability to execute its business strategy. The scope of this report covers ICL's efforts company-wide and globally, in relation to the material issues identified in the analysis. The materiality analysis was based on the framework developed by the Global Reporting Initiative (GRI). Process Material issues were identified using a three phase process: Internal and List of Matrix of List of material external Phase 1 relevant Phase 2 material Phase 3 issues to be documentation, Identification topics to be Prioritization issues by Validation included in the analysis, considered priority report studies and benchmarketing Material issues assurance included the relevant steps performed by the company in its material assessment, as described in the report, only. 34 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report 1. Identification In the first phase, a list of relevant topics was compiled from the following perspectives: Perspective Relevance for business Relevance for stakeholders Emerging issues for the chemical and mining sectors Local and national economic, social and environmental context Sources ICL's Enterprise Risk Management (ERM) Corporate strategy Identification of stakeholders through executives' questioners Commissioned questionnaires completed by ICL's executives Tracking publicly-available information Regular engagement with key stakeholders Monitoring questions submitted to the Company's QandA website and to various ICL department (e.g. Investors relations, Sustainability) Material issues for relevant organizations and reporting bodies (e.g. IFA, ICMM, GRI, CDP, MAALA) Benchmarking of best practices by world-class peers Media and social networks review 2. Prioritization The topics compiled in the previous stage were evaluated to determine which were material to ICL, through both qualitative and quantitative analysis as well as discussions on whether, and to what degree, they reflect a significant economic, environmental and social impact on ICL or substantively influence the assessments and decisions of ICL's stakeholders. The issues were then classified in a matrix with the material issues for ICL on an X-axis and the material issues for ICL's stakeholders, on a Y-axis. The material issues with high importance for ICL ( X axis) were defined and prioritized using the Company's Enterprise Risk Management (ERM) system as well as by evaluating and weighing the data compiled from the commissioned ICL Corporate Responsibility Report 2015 35

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Material Issues questionnaires completed by a group of ICL's executives who represent the Company's various activities, geographies and perspectives. The ERM, compiled by Ernst and Young, identifies risks at the corporate as well as company levels. Key sustainable concerns were selected from among the identified risks according to the principles for defining report content. In addition, issues that were on the Company's agenda during the reporting period, i.e. issues that were addressed in a relatively extensive manner by the Board of Directors and the Company's executives; policies and procedures that were instituted or amended; or significant investments that were made or involvement by the Company related to a particular issue, were given added weight. The material issues of high importance to ICL's stakeholders (represented on the Y Axis) were compiled from stakeholders' requests for information, published materials and other forms of engagement, relevant to the sector in general and to ICL in particular. Further review and evaluation was executed by the Sustainability Team operated by the office of the COO, in consultation with relevant corporate departments. 1 2 3 4 5 6 Economic Payment to Indirect Diversity Training Security and Performance Governments Economic and Equal and Emergency Impacts Opportunity Education Management 7 8 9 10 11 12 Human Product Mining - Community Compliance Biodiversity Rights Innovation Remediation, Relations and Nature Reclamation and Conservation decommissioing 13 14 15 16 17 18 Product Safety and Employment and Raw Business Workforce Responsibility Environmental Labor Relations Materials Ethics Health, Safety and Stewardship Well-being of Chemicals 19 20 21 22 23 Effluents, Air Energy Water Greenhouse Waste and Quality Management Management Gas Emissions Hazardous Material Management 36 ICL Corporate Responsibility Report 2015

Material Issues High 23 20 21 17 1 Stakeholders 22 19 18 11 for ICL's 14 15 16 Importance 12 13 10 7 8 9 5 6 4 2 3 High Low Importance for ICL ICL Corporate Responsibility Report 2015 37

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report 3. Validation The matrix of material issues which resulted from the previous phase was discussed and analyzed by the team in accordance with Completeness and Stakeholder Inclusiveness principles. The material issues in this report are the result of this final matrix. G4-18 38 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report ICL Corporate Responsibility Report 2015 39

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Corporate Governance and Economic Responsibility

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Securing the building blocks of the digital age. ICL's polymer flame retardants are used to produce fire-resistant and environmentally friendly electronic devices.

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report ICL is committed to practicing good corporate governance. This includes close oversight of its business strategy and fiscal accountability, ethical corporate behavior and fairness to its shareholders and stakeholders. Accordingly, the Company abides by advanced principles of corporate governance that define the relationships between the Company's management, Board of Directors, shareholders and stakeholders. ICL is incorporated in Israel and therefore complies with various corporate governance requirements under the Israeli Companies Law, 1999. These are in addition to requirements which apply to ICL as a publicly traded company on the Tel Aviv Stock Exchange and the New York Stock Exchange. Furthermore, the Company has adopted, and will continue to adopt as necessary, voluntary rules to ensure maximum transparency towards all its stakeholders, as well as an enforcement plan that ensures its strict compliance with both the law and with internal regulations. CORPORATE GOVERNANCE 42 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Corporate Responsibility Corporate Responsibility: G4-DMA, G4-36 ICL recognizes its corporate responsibility to its shareholders, customers, suppliers, employees, the community and its other stakeholders. It is strongly committed to managing its business in ways that lead to sustainable growth, balancing current needs with those of future generations while fulfilling all of its regulatory and moral duties. Where there is no legislation to regulate its activities, ICL strives to voluntarily adopt accepted global industry standards as a guide for its actions. ICL places a strong emphasis on its corporate responsibilities. This has led the Company to substantially increase its environmental, social and community activities, and, most importantly, to internalize a commitment to responsible business practices that guides it on a daily basis. ICL's Sustainability Development Policy embodies the Company's commitment to good corporate governance and ensures it conducts business in a way that will lead to sustainable growth while balancing the needs of its various stakeholders. This commitment begins with ICL's CEO, its Global Compliance Officer and its senior management and extends throughout the organization. The Company's Board of Directors and the Group's management, take various measures to ensure that ICL conducts its business in accordance with the Guidelines. The company has created committees dedicated to monitoring and enforcing high standards of environmental and social responsibility. These committees regularly consult with independent experts to evaluate the Company's economic, social and environmental impact and to ensure compliance with all of its legal obligations. The Company's Board of Directors has appointed the Company's Deputy CEO and COO to serve as the Company's Chief Risk Manager responsible for environmental, safety, occupational health and security issues. The COO reports to ICL's CEO and, periodically on his behalf, to the Board of Directors, on activities in these areas.

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report Sustainable Development Policy Target 12 Encourage companies, especially large and transnational companies, to adopt sustainable practices and to integrate sustainability information into their reporting cycle. Corporate Responsibility Policies and Objectives: G4-DMA The Company applies an overall policy of sustainable development that integrates social, economic and environmental considerations into all of its business activities. The policy stresses social responsibility, which includes taking responsibility for the safety and well-being of its employees, reducing environmental impacts, and creating a dialogue and transparent communication channel with the authorities, community service, as well as other matters in the area of sustainability. This policy includes, among other things, the following items: responsible use of natural and land resources; rehabilitation of streams, restoration and preservation of mining and quarrying regions and returning them to the State after completion of the activities the land was designated for by the State and in accordance with the provisions of law governing the matter; reducing at source (in terms of flow) the quantity of waste produced in ICL companies and increasing the recycling of treatable waste. These activities are performed in ongoing cooperation with manufacturers, suppliers, research institutes, customers and other users for purposes of development and application of methods for the safe production and use of products, while reducing or eliminating injury to users and the environment; and safe transport -- selection and instruction of responsible transporters, use of an emergency system for handling transport problems, strict care with respect to safe and correct packaging and assurance that only proper and orderly means of shipment are used. ICL has a policy of involvement and investment in the society and the community, which was formulated and approved by our Board of Directors in 2001 and amended in 2014. ICL focuses on its cooperation with the community and its involvement in the communities in and outside of Israel from which its employees come and in which it operates. ICL focuses its activities on physically and mentally challenged children and youth, women and children at risk, education and instilling excellence in students in the areas of chemistry, computers, young entrepreneurs, assistance to populations in harsh socioeconomic conditions, and populations in need, including special medical needs. Some of our guiding principles regarding corporate responsibility are: Work to maintain the highest standards of integrity and corporate governance, ethics and honesty in all of the Company's businesses. Operate in compliance with applicable laws, regulations and permits in all areas of activities and seek to voluntarily adopt the industry's best practices and evolving global standards around the world. Constantly strive for excellence, quality, competency and efficiency, and encourage innovation and creativity throughout all of the Company's activities. Ensure all administrative and financial resources required to implement and assimilate corporate responsibility policy are in place to achieve outstanding CR performance. 44 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report G4-14, G4-DMA Establish procedures and implement advanced monitoring systems to identify, assess and control risks in the organization and throughout the product lifecycle (i.e. Product Stewardship). Promote an ongoing dialogue and engagement with each set of stakeholders, maintained in a spirit of transparency and good faith and ensure that the Company's efforts match their priorities. Exercise utmost vigilance in using natural recourses and protect the environment, and constantly seek ways to minimize environmental impact wherever the Company operates. Strive to exceed regulatory requirements in the Company's environmental performance. Utilize the Company's assets and know-how to develop sustainable products and unique tailored integrated formulations to add value to the Company's customers in its end markets. Strive to provide lasting benefits to the communities where the Company operates by supporting sustainable initiatives to develop the communities' social, economic and institutional fabric. Seek to maximize employment, business and economic opportunities for local communities from the Company's existing operations and new ventures. Conduct all activities in accordance with accepted standards for the protection and promotion of human rights. Ensure at all times the Company's provision of a healthy and safe work environment. Provide a rewarding and meaningful livelihood to employees, and strive to be an "employer of choice". Risk Management and The Precautionary Principle As part of the strategic planning required to implement sustainable business activities, an organizational risk management structure was established at ICL, including structured programs to promote the issue. In addition, the Company maintains an Ecology Center of Excellence, which serves as the Company's arm for managing, reducing and controlling environmental risk. Through this structured process which identifies risks and opportunities, ICL applies the precautionary principle to environmental and economic issues. An Enterprise Risk Management (ERM) system to identify existing and future risks, was created by ICL in cooperation with Ernst and Young. The ERM identifies, measures, manages and reduces risks, including integration of procedures required to implement the policy. This system relates to strategic, operational, statutory and economic risks in all aspects of the organization's operations, including its impact on the environment, the economy and society at large. Regarding the environment, ICL's commitment to the principles of the Responsible Care Global Charter serves to integrate the precautionary principles. ICL Corporate Responsibility Report 2015 45

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report GLOBAL DISTRIBUTION Europe USA 22% 26% China 10% Other countries Israel 25% 4% India 4% Sales in 2015 Brazil Manufacturing plant 9% Distribution center Global HQ Sales office Regional HQ G4-5, G4-6 46 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report BOARD OF DIRECTORS Board of Directors: G4-39, G4-43, G4-34, G4-36, G4-38, G4-42, G4-48 Board Responsibilities and Practices In addition to their legal responsibilities, ICL policy requires the Board to approve some of the Company's and its subsidiaries' operations, including investments that exceed a specified amount, organizational changes, and mergers and acquisitions. The Chairman of the Board and the CEO have distinct responsibilities and the positions are held by separate individuals. This is also true of the Board of Directors and the Company's officers who are not directors. The Company does not have contracts with its current directors, excluding the CEO and Executive Chairman. Directors are elected each year at the Annual General Meeting (except external directors, whose term is set by law at three years). New Board members receive information about ICL and its operations, and all directors receive periodic training on relevant issues when there are significant changes. Board Activities Involving Corporate Responsibility and Sustainability At least once a year, ICL's Board of Directors convenes a designated meeting to discuss corporate responsibility and sustainability, employee safety, ecology, etc. In 2015, this meeting was held in May and included presentations on the Company's environmental quality, ecology and safety policies, as well as the implementation of these policies. This Report, approved by the Board of Directors, outlines the Company's Guidelines for Corporate Responsibility and documents the Company's continuing global progress. Board Committees Each committee of the Board operates in accordance with a written charter that sets forth the committee's structure, operations, membership requirements, responsibilities and authority to engage advisors. ICL's Board of Directors has established the following committees: audit and accounting committee; human resources and compensation committee; environment, safety and public affairs committee; operations committee and financing committee. ICL Corporate Responsibility Report 2015 47

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report BOARD COMPOSITION Board Committees: G4-LA12, G4-34, G4-38 * An additional director was designated as an "independent director" under the Israeli Companies Law Board of Directors 11 9 9 In 2015, icl's board of directors convened 13 4 times. 2 2 1 Minority groups members - 0 Directors Independent External Accounting and Over 50 Between Female directors directors* financial expertise years old the ages members of 30-50 Audit and Accounting Committee 3 3 The committee held 7 2 meetings in 2015 1 All members are over 50 years old (not including officers) Directors Officers Audit committee Female (Not including financial experts an officer) Human Resources and Compensation Committee 3 The committee held 11 2 meetings in 2015 1 All members are over 50 years old (not including officers) Directors Officers Female (Not including an officer) 48 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report BOARD COMPOSITION Environment, Safety and Public Affairs Committee 4 The committee 3 held 4 meetings in 2015 1 All over 35 years old Directors Officers Female (Not including an officer) Operations Committee 6 The committee 5 held 6 meetings in 2015 All over 35 1 years old Directors Officers Female (Not including an officer) Financing Committee The committee 5 was established in march 2016 3 and held its first meeting in June. 1 All over 35 years old Directors Officers Female (Not including an officer) G4-LA12, G4-38 ICL Corporate Responsibility Report 2015 49

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report EXECUTIVE COMPENSATION G4-51 ICL offers its Executive Officers a compensation package that maintains a balance between fixed and variable components, using a profit sharing mechanism. Pursuant to Amendment 20 of Israel's Companies Law, the General Meeting of Shareholders of ICL approved the Compensation Policy for ICL officeholders in August 2013. The policy was amended in December 2014. The compensation package includes: Base salary The base salary may vary between the Executive Officers in ICL and is individually determined according to some or all of the following considerations: Educational background, qualifications, skills, specializations, prior professional and business experience, past performance and achievements Position and scope of responsibility Previous compensation agreements Comparable compensation agreements within ICL In addition to the considerations above, and to ensure that ICL offers Executive Officers competitive compensation packages so that it can attract and retain highly skilled professionals, ICL established a base salary that is competitive with the base salaries paid to Executive Officers in similar positions, in both global and local companies, as appropriate for each position. Fringe benefits ICL's Executive Officers may be entitled to fringe benefits as mandated or afforded by law, or that are customary in the Company and that the authorized parties deem advisable to provide a competitive employment package. Annual cash bonus ICL's Executive Officers are entitled to a cash bonus in accordance with an Annual Bonus Plan. The Annual Bonus Plan aims to create an alignment between the compensation of the Executive Officers and the Company's annual and long term goals. Quantitative and qualitative performance indicators are used to determine bonus eligibility and the annual bonus for each Executive Officer is calculated separately for each measurable category and for competency key performance indicators. Equity-based compensation From time to time, ICL may offer its Executive Officers equity-based compensation in order to retain them for the long-term. The amount of equity-based compensation granted to an Executive Officer is determined by each Executive Officer's position, responsibilities, achievements and skills. Equity-based compensation is subject to a vesting period of at least three (3) years. 50 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report EXECUTIVE COMPENSATION PROCEDURE FOR TRANSACTIONS WITH INTERESTED PARTIES G4-41, G4-51, G4-SO6 Retirement and termination arrangements All of the Executive Officers are entitled to pension benefits and severance pay that they accumulated while working for ICL. If there is a discrepancy between the money Executive Officers have accumulated, and the amount owed to the Executive Officer based on his/her base salary and years of seniority at ICL, the Executive Officer will be paid the full amount he/she is due. In 2013 ICL approved a procedure for conducting transactions where ICL stakeholders have a personal interest. The provisions and guidelines for detecting, identifying and approving transactions where interested parties, such as controlling shareholders or executive directors, are concerned, include detailed processes for collecting the relevant information about the contracting parties and reporting and disclosure requirements for these transactions. This procedure is intended to add to, and not to detract from, any other legal obligation regarding the approval of such transactions. To implement this procedure, ICL has developed a computerized system that aids in the identification of transactions with interested parties that require this type of disclosure and reporting. Officers and controlling shareholders are required to complete a semi-annual questionnaire to identify and list all the entities in which they have a personal interest. The list of interested parties is then entered into the computerized system. The system issues a real-time alert before transactions (above a certain sum) are made with an interested party, enabling ICL to follow the correct procedure for approving the transaction. Moreover, ICL does not make contributions, financial or otherwise, to politicians or to political bodies. ICL Corporate Responsibility Report 2015 51

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report FOCUSING ON CORE BUSINESS ACTIVITIES As part of its growth strategy, ICL intends to use its cash flow to further expand its specialty and value added products organically and through acquisitions. In October 2015, we completed the formation of the ICL YPH JV with YPC. The ICL YPH JV, which includes a world-scale phosphate rock mine producing approximately 2.5 million tonnes of phosphate annually and a large-scale phosphate operation, is expected to be a leading player in China's phosphate sector, operating an integrated, world-scale phosphate platform across the value chain. It will include upstream mining, bulk fertilizers and downstream businesses in specialty fertilizers, as well as in specialty phosphates for the food and engineered materials markets. In April 2015, AkzoNobel Industrial Chemicals and the Company signed an agreement for production of high quality vacuum salt. The vacuum salt will be manufactured by the Company and will be sold by AkzoNobel by means of an "offtake" agreement for acquisition of the partnership's products. Pursuant to the agreement, the Company will finance and construct two production facilities at its mining site in Suria, in Catalonia, Spain. In 2015, ICL completed the acquisition of ICL Austria Hartberg, a leading European company that manufacturers milk proteins for the food and beverage industry. In 2015, ICL completed the divestment of its aluminum, paper, and water businesses (APW), its thermoplastic products business for the footwear industry (Rhenoflex), its pharmaceutical and gypsum businesses (PCG), and its Medentech and hygiene products business for the food industry (Anti-Germ). 52 ICL Corporate Responsibility Report 2015

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report ORGANIZATIONAL AND BUSINESS CULTURE Corporate Governance: Code of Ethics: G4-DMA, G4-56 ICL's corporate culture rests on core values that include conducting its business activities fairly and transparently, assuming responsibility for its actions, striving for excellence, respecting others, and a steadfast commitment to safety, to the environment and to the wellbeing of the communities where ICL facilities are located. These values, together with the Company's commitment to comply with all laws, regulations, compliance programs and procedures, are vital for ICL's continued growth and success. Code of Ethics ICL's Code of Ethics incorporates the core values of the Company and establishes appropriate ethical guidelines for employees at all levels and positions. The Code is global, uniform and serves as a framework and the foundation for compliance programs currently in effect with respect to securities, restrictive trade practices, anti-bribery and corruption practices, fraud prevention, antitrust, safety and health, environmental protection, and a safe working environment. ICL's Board of Directors have adopted the Code, and it applies to the Board, senior management and employees, including ICL's principal executive officer, principal financial officer, principal accounting officer or controller and any other persons who perform similar functions for the Company. ICL views with importance that the Code become a part of the Company's day to day activities; the Code has been distributed to all of the Company's employees throughout the world. In addition, ICL has trained all of its employees and provided guidance to local Ethics Committees and Compliance Officers through the implementation of internal reporting procedures and mechanisms in order to integrate the Code's principles and values. Responsibility Fairness in business Respect Excellence towards and constant others improvement Commitment Commitment to the to safety environment Compliance with the law ICL Corporate Responsibility Report 2015 53

Letter from the Corporate Governance and Environmental Social About Chairman and CEO Overview Economic Responsibility Responsibility Responsibility the Report conducting business fairly Target 16 Substantially reduce corruption and bribery in all their forms. G4-DMA, G4-41, G4-SO4, G4-SO3 Integrity, fairness and prevention of bribery and corruption are central values of ICL's organizational culture, and as a leading global company, ICL is careful to comply with trade regulations and preventing bribery and corruption. For this reason, the Company's compliance policies and programs are characterized by a high standard of caution, adopting heightened European and American standards. Preventing Bribery, Corruption and Fraud In 2014, the Board of Directors approved two new compliance programs for preventing bribery and corruption, including anti-money laundering. ICL implements a global Gift and Entertainment Policy. The policy requires all employees to obtain prior approval for gifts and entertainment for higher value items and for those which involve government officials. The Gift and Entertainment Policy applies to all ICL employees wherever they are located and has been widely distributed to them. As part of the roll out of this policy and to train employees about it, ICL has provided a short video and infographic about this concept to all employees who have internet or email access and published guidelines in ICL's global employees magazine. In December 2014, ICL launched a Fraud Prevention Program in accordance with ICL's Code of Ethics, which seeks to prevent various types of fraud and provides guidance and training about how to identify and prevent fraud. In addition, ICL has several control mechanisms to minimize regulatory risks and prevent corruption (e.g. prevention of money laundering, financing terrorism and providing or receiving bribes): As part of its Trade Program, ICL has implemented a control mechanism for prevention of financing of terrorism and compliance with international commercial law -- a global computerized process which scans all of the Company's potential transactions in order to check the identity of potential customers and vendors against sanctions lists prepared by the US, Europe, the UN and others. The system issues warnings and can even block a transaction with entities suspected of being on one of the above lists. All ICL transactions worldwide are monitored by this program. The Company educates its employees about "red flags" which assist employees in identifying potential high risks in their transactions.