UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, DC 20549

Form 10-K |

(Mark One)

ý | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 28, 2013

or

¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file number: 001-35623

__________________________________________

PEREGRINE SEMICONDUCTOR CORPORATION

(Exact Name of Registrant as Specified in its Charter)

__________________________________________

Delaware | 86-0652659 |

(State or Other Jurisdiction of Incorporation or Organization) | (I.R.S. Employer Identification No.) |

9380 Carroll Park Drive San Diego, California | 92121 |

(Address of Principal Executive Offices) | (Zip Code) |

(858) 731-9400

(Registrant’s Telephone Number, Including Area Code)

Securities registered pursuant to Section 12(b) of the Act:

Title of Each Class | Name of Each Exchange on Which Registered |

Common Stock, par value $0.001 per share | The NASDAQ Stock Market LLC |

Securities registered pursuant to Section 12(g) of the Act:

None

__________________________________________

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No ý

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes ¨ No ý

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ý No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

Large accelerated filer | ¨ | Accelerated filer | x | ||||

Non-accelerated filer | ¨ | (Do not check if a smaller reporting company) | Smaller reporting company | ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Securities Exchange Act of 1934). Yes ¨ No ý

As of June 28, 2013, the last business day of the registrant’s most recently completed second quarter, the aggregate market value of the registrant’s common stock held by non-affiliates of the registrant was approximately $290.7 million based on the closing price of the registrant’s common stock as reported on the Nasdaq Global Market of $10.91 per share on June 28, 2013. Shares of common stock held by each executive officer and director and each person who beneficially owns 5% or more of the outstanding common stock have been excluded from this calculation. This determination of affiliate status may not be conclusive for other purposes.

The number of outstanding shares of the registrant’s common stock, par value $0.001 per share, as of February 12, 2014 was 33,055,714.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s proxy statement to be filed with the Securities and Exchange Commission pursuant to Regulation 14A in connection with the registrant’s 2014 Annual Meeting of Stockholders, which will be filed subsequent to the date hereof, are incorporated by reference into Part III of this Form 10-K. Such proxy statement will be filed with the Securities and Exchange Commission not later than 120 days following the end of the registrant’s fiscal year ended December 28, 2013.

Peregrine Semiconductor Corporation

ANNUAL REPORT ON FORM 10-K

FOR THE FISCAL YEAR ENDED DECEMBER 28, 2013

TABLE OF CONTENTS

Page | |||

Item 1. | |||

Item 1A. | |||

Item 1B. | |||

Item 2. | |||

Item 3. | |||

Item 4. | |||

Item 5. | |||

Item 6. | |||

Item 7. | 36 | ||

Item 7A. | |||

Item 8. | |||

Item 9. | |||

Item 9A. | |||

Item 9B. | |||

Item 10. | |||

Item 11. | |||

Item 12. | |||

Item 13. | |||

Item 14. | |||

Item 15. | |||

i

Cautionary Statement Regarding Forward-Looking Information

All statements included or incorporated by reference in this Annual Report on Form 10-K, other than statements or characterizations of historical fact, are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. These forward-looking statements are based on our current expectations, estimates and projections about our industry and business, management’s beliefs, and certain assumptions made by us, all of which are subject to change. Forward-looking statements can often be identified by words such as “anticipates,” “expects,” “intends,” “plans,” “predicts,” “believes,” “seeks,” “estimates,” “may,” “will,” “should,” “would,” “could,” “potential,” “continue,” “ongoing,” similar expressions, and variations or negatives of these words. These statements are not guarantees of future performance and are subject to risks, uncertainties and assumptions that are difficult to predict. Such risks and uncertainties include, but are not limited to, our dependence on a limited number of customers for a substantial portion of our revenues; intellectual property risks; intense competition in our industry; our ability to develop and introduce new and enhanced products on a timely basis and achieve market acceptance of those products; consumer acceptance of our customers’ products that incorporate our solutions; our lack of long-term supply contracts and dependence on limited sources of supply; and potential decreases in average selling prices for our products. Therefore, our actual results could differ materially and adversely from those expressed in any forward-looking statements as a result of various factors, some of which are listed under the section entitled “Risk Factors” in Part I, Item 1A of this Report. These forward-looking statements speak only as of the date of this Report. We undertake no obligation to revise or update publicly any forward-looking statement to reflect future events or circumstances.

Unless the context otherwise requires, we use the terms “Peregrine,” the “company,” “we,” “us,” and “our” in this Report refer to Peregrine Semiconductor Corporation and its subsidiaries.

“Peregrine Semiconductor Corporation,” “Peregrine Semiconductor,” “Peregrine,” “UltraCMOS,” “HaRP,” “DuNE,” “STeP,” and other trademarks or service marks of Peregrine appearing in this Report are the property of Peregrine. This Report contains additional trade names, trademarks, and service marks of ours and of other companies. We do not intend our use or display of other companies’ trade names, trademarks, or service marks to imply a relationship with, or endorsement or sponsorship of us by, these other companies.

1

PART I

Item 1. | Business |

Our Company

We are a fabless provider of high performance radio frequency integrated circuits, or RFICs. Our solutions leverage our proprietary UltraCMOS® technology which enables the design, manufacture, and integration of multiple radio frequency, or RF, mixed signal, and digital functions on a single chip. We believe our products deliver an industry leading combination of performance and monolithic integration. Our solutions target a broad range of applications in the space and military, automotive, broadband, industrial, mobile device, test and measurement equipment, and wireless infrastructure markets. We have shipped over two billion RFICs based on our UltraCMOS technology.

Our UltraCMOS technology combines the ability to achieve the high levels of performance of traditional specialty processes, with the fundamental benefits of standard complementary metal oxide semiconductor, or CMOS, the most widely used semiconductor process technology. UltraCMOS technology utilizes ultra thin silicon on insulating substrate, providing greatly reduced unwanted electrical interaction between the RFIC and the substrate (referred to as parasitic capacitance), which enables high signal isolation and excellent signal fidelity with low distortion over a broad frequency range (referred to as broadband linearity). These two technical attributes result in RF devices with excellent high-frequency performance and power handling performance, and reduced crosstalk between frequencies. In addition, increased broadband linearity provides for faster data throughput and greater subscriber capacity over a wireless network, resulting in enhanced network efficiency. UltraCMOS technology also provides the benefits of standard CMOS, such as high levels of integration, low power consumption, reusable circuit libraries, widely available design tools and outsourced manufacturing capacity, and the ability to scale to smaller geometries. We own fundamental intellectual property, or IP in the UltraCMOS technology consisting of more than 170 U.S. and international issued and pending patents, and over 300 documented trade secrets covering basic circuit elements, RF circuit designs, manufacturing processes, and design know-how.

We leverage our extensive RF design expertise and systems knowledge to develop RFIC solutions that meet the stringent performance, integration, and reliability requirements of the rapidly evolving wireless markets. As of December 28, 2013, we offered a broad portfolio of more than 230 high performance RFICs including switches, digital attenuators, mixers / upconverters, prescalers, digitally tunable capacitors, or DTCs, phase-locked loops, or PLLs, and DC-DC converters, and we are developing power amplifiers, or PAs. During the year ended December 28, 2013, our products were sold to more than 1,700 module manufacturers, original equipment manufacturers, or OEMs, contract manufacturers, and other customers. We believe our RFICs are included in products sold by many of the leading mobile handset OEMs. Our net revenue was $202.3 million, $203.9 million, and $107.8 million for the year ended December 28, 2013, December 29, 2012, and December 31, 2011, respectively. We recorded a net loss of $4.1 million and $9.7 million for the years ended December 28, 2013 and December 31, 2011, respectively, and net income of $7.3 million for the year ended December 29, 2012. As of December 28, 2013, we had an accumulated deficit of $225.0 million.

Corporate Information

Peregrine Semiconductor Corporation (together with its subsidiaries, “Peregrine”, “the Company”, “our”, “we” or “us”) was incorporated in Delaware in February 1990 and founded by Mark Burgener, Rory Moore, and Ron Reedy. Our principal executive offices are located at 9380 Carroll Park Drive, San Diego, California 92121. Our telephone number is (858) 731-9400. Our website address is www.psemi.com. Information contained on our website is not incorporated by reference into this report, and you should not consider information contained on our website to be part of this report or in deciding whether to purchase shares of our common stock. Our Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and amendments to reports filed or furnished pursuant to Sections 13(a) and 15(d) of the Securities Exchange Act of 1934, as amended, are available free of charge on the Investor Relations portion of our web site at www.psemi.com as soon as reasonably practicable after we electronically file such material with, or furnish it to, the SEC. We are an “emerging growth company” under the federal securities laws and will be subject to reduced public company reporting requirements.

Industry Overview

Wireless is Everywhere

Proliferation of wireless devices coupled with rapid advances in RF technologies have significantly enhanced wireless connectivity and revolutionized the mobile wireless, wireless infrastructure, broadband, and satellite communications markets. In addition, an array of other consumer, public safety, aerospace and defense and industrial markets are increasingly incorporating advanced RF functionality into a wide variety of applications.

2

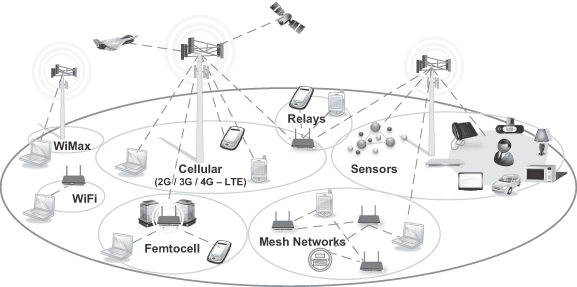

The following graphic shows the broad array of applications in which advanced, high performance RFICs are currently being deployed:

Growing worldwide demand for mobile wireless communications and mobile multimedia applications is driving the proliferation of mobile devices. The evolution of mobile wireless networks from predominantly voice-centric networks to advanced high-speed networks that deliver voice, video, and data, is enabling consumers to access bandwidth intensive rich media content on mobile devices through applications such as videoconferencing, streaming media, and interactive gaming. As a result, mobile devices have evolved from supporting only a single cellular standard, operating on two or three frequencies and utilizing a single antenna, to supporting multiple wireless protocols, supporting greater than 20 frequency bands and integrating multiple antennas.

The combination of an increasing global subscriber base, expansion of advanced wireless networks, and the proliferation of powerful devices offering high-speed wireless Internet access, has dramatically increased mobile data traffic. This increase in data traffic is straining the existing wireless network infrastructure. As a result, operators are expanding their network capacity by acquiring additional wireless spectrum, deploying more third generation, or 3G, base stations, extending coverage with small cell technologies to improve localized coverage, and introducing fourth generation, or 4G, technologies, such as Long Term Evolution, or LTE. The demand for global wireless connectivity is driving operators to deploy network infrastructure in new geographies.

In addition to the mobile wireless handset and infrastructure markets, high performance RFICs are increasingly being deployed in a variety of other wired and wireless market applications. The increasing data transfer requirements of broadband communications, satellite communications, and test and measurement equipment; the high reliability and radiation-hard performance requirements of aerospace and defense communications; and the ruggedness, high temperature, and electrostatic discharge, or ESD, tolerance of automotive and industrial applications have resulted in increased demand for high performance RFICs in these markets. Accordingly, advanced RF semiconductor solutions are evolving to deliver increased functionality, performance, and reliability across a broad array of markets while simultaneously achieving smaller form factors and lower cost per function.

Requirements of the RF Semiconductor Market

Significant market opportunities exist for RFIC suppliers that address the stringent requirements of wireless systems such as:

• | Better Performance. Wireless systems require components that can consistently deliver better signal quality, higher data rates, lower noise and system interference, and less power consumption across a variety of operating conditions and applications. High performance RFICs must interoperate with other wireless system components to avoid performance issues such as dropped calls, slower than expected transfer rates and poor battery life. |

3

• | Increasing Functionality. To enable higher data rates, compatibility with legacy networks, and simultaneous voice and data communications, wireless systems must support multiple protocols and frequency bands. This increases overall design complexity and can increase the number of components, size and power consumption of wireless systems. For example, smartphones often utilize as many as 10 frequency bands to support a variety of wireless protocols and require separate RF components for each band. |

• | Higher Reliability. Module manufacturers and OEMs demand that high performance RFICs perform reliably for long periods of time under a variety of conditions. In particular, manufacturers of wireless network infrastructure, and aerospace and defense products must meet stringent reliability standards that require specialized design, manufacturing, quality assurance, and testing processes. |

• | Smaller Form Factor and More Cost Effective Solutions. High performance RFICs must enable module manufacturers and OEMs to design wireless products with an increasingly smaller form factor while also reducing overall product cost, both of which require increasing levels of integration. |

Challenges Facing RF Semiconductor Suppliers

The need for higher performance wireless solutions, combined with the increased demand for integrated components that reduce costs, overall power consumption and size, has put significant pressure on wireless component suppliers. A typical wireless device contains three primary subsystems – the digital baseband processor, the transceiver, and the RF front-end. Baseband processors, and more recently transceivers, are implemented in standard silicon-based CMOS. However, fundamental physical limitations of silicon have prevented standard silicon-based CMOS solutions from meeting the high frequency and power handling requirements of high performance RF front-ends. As a result, RF front-end semiconductor manufacturers have historically utilized specialty process technologies such as GaAs HBT, GaAs pHEMT, SiGe, or BiCMOS. While discrete RF components produced with these processes can attain sufficient levels of performance, these technologies face one or more of the following significant challenges:

• | Inability to Monolithically Integrate. An RF front-end module consists of a number of discrete components, including PAs, low noise amplifiers, switches, filters, control interfaces, power regulators, diplexers and passive elements, most of which are manufactured using different specialty process technologies. As a result, traditional RFICs cannot monolithically integrate these discrete components, leading to RF front-end modules with higher component counts, greater system design complexity, larger overall form factor, and lower module yields. This inability to monolithically integrate also limits cost reduction opportunities. |

• | Lack of Digital Integration. As the digital content of the RF front-end increases and OEMs demand greater levels of configurability, the inability to monolithically integrate digital logic, memory, and other mixed-signal functions on an RFIC manufactured using specialty process technologies can limit performance improvements and reductions in device size, and result in a higher component count for the same functionality. |

• | Manufacturing Inefficiencies. These processes cannot take advantage of the existing high volume CMOS manufacturing infrastructure, which results in custom fabrication facilities limiting the ability to reduce cost and drive supply chain flexibility. |

• | Lack of Scalability. Manufacturing inefficiencies inherently limited the ability of these processes to scale to smaller geometries as compared to standard CMOS and therefore IC suppliers utilizing these process technologies are increasingly unable to achieve reductions in manufacturing costs and form factors, lower power consumption, or higher performance. |

Advanced wireless system module manufacturers and OEMs continue to implement more complex system architectures to achieve higher levels of performance, which in turn requires them to seek out more integrated solutions that are beyond the capabilities of RFICs produced using specialty process technologies.

Our Solution

We design, develop, market, and sell high performance RFICs based on our proprietary UltraCMOS technology. Our UltraCMOS technology enables us to monolithically integrate multiple RF and mixed signal components and digital circuitry into high performance RFICs. Our UltraCMOS technology provides the fundamental benefits of standard CMOS including high levels of integration, low power consumption, reusable circuit libraries, widely available design tools and outsourced manufacturing capacity, and the ability to scale to smaller geometries. Furthermore, our UltraCMOS technology utilizes an insulating substrate, which enables the low parasitic capacitance, high signal isolation, and excellent broadband linearity required for high frequency and high power RF devices. As of December 28, 2013, we offered a broad portfolio of

4

more than 230 high performance RFICs including switches, digital attenuators, mixers / upconverters, PLLs, prescalers, DTCs, and DC-DC converters, and we are developing PAs.

We leverage our extensive design and process expertise and systems knowledge to develop RFICs that meet the stringent performance, integration, and reliability requirements of the rapidly evolving wireless markets. For example, our monolithic RFICs enable smaller and more power efficient mobile devices. In the wireless base station market, our RFICs enable the management of multiple bands which are driven by growth in 3G and 4G wireless networking protocols.

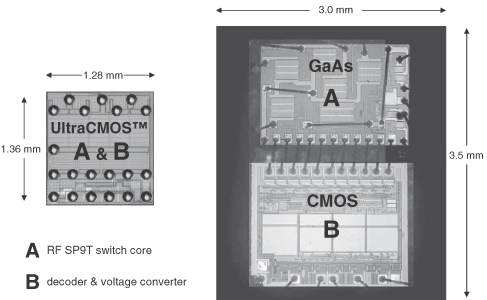

The following graphic illustrates how a 3G antenna switch built using our UltraCMOS technology (shown on the left) is much smaller, eliminates the complexity of wirebonding, and integrates all functionality on a single chip, compared with a similar switch built using a typical GaAs based approach (shown on the right).

Products

Our broad product portfolio includes both highly integrated monolithic RFICs as well as discrete components. Our proprietary UltraCMOS technology enables us to integrate most RF functions as well as analog and digital circuits and high quality factor, or high Q, passive elements on a single chip. We believe we are able to deliver a unique combination of best-in-class RFIC performance, power consumption, monolithic integration, and size required by increasingly advanced wireless communications applications. Our ICs address a broad range of advanced product requirements in the aerospace and defense, broadband, industrial, mobile device, test and measurement equipment, and wireless infrastructure markets. The table below summarizes our product portfolio and target end markets.

5

End Market | |||||||||||||

Product families | Automotive | Space and Military | Broadband | Industrial | Mobile Devices | Test and Measurement | Wireless Infrastructure | ||||||

RF Switches – Antenna | x | ||||||||||||

RF Switches – Broadband and General Purpose | x | x | x | x | x | x | |||||||

Digital Attenuators | x | x | x | x | x | ||||||||

Phase-locked loop | x | x | x | x | |||||||||

Mixers / Upconverters | x | x | x | x | |||||||||

Prescalers | x | x | x | x | |||||||||

Digitally Tunable Capacitors | x | x | x | x | x | ||||||||

DC-DC Converters | x | ||||||||||||

Power Amplifiers | o | ||||||||||||

x = Product in production

o = Product sampling or in development

The following is a brief description of our product families:

• | RF Switches – Antenna. RF Switches are utilized in the RF section of mobile devices to route RF signals between the antenna and the handset core, through one or more signal paths. As the design of the mobile device becomes more complex, more signal paths are required. Our portfolio of RF switches includes products that vary in complexity and performance depending on the design of the application. For mobile handsets, our existing switch products offer up to 16 RF signal paths with integrated digital bus support and onboard voltage regulation. |

• | RF Switches – Broadband and General Purpose. Our broadband and general purpose RF switches deliver an industry leading combination of broadband linearity, settling time, and isolation while routing RF signals to their respective transmit or receive paths. We believe these attributes are being used by the OEMs of LED and plasma digital televisions, or DTVs, set top box, cable infrastructure, test and measurement devices, and high performance wireless applications to replace legacy mechanical relays and GaAs-based designs. |

• | Digital Attenuators. We provide digital step attenuators that are used to control the amplitude of an RF or analog signal. These products include digital control circuitry integrated with an RF attenuator core and are used in 3G and 4G cellular base stations, repeaters, and point-to-point nodes. Our highly linear and configurable digital attenuators reduce design complexity by maintaining excellent performance in both intermediate frequency, or IF, and RF applications and over a range of supply voltages. |

• | Phase-locked loop (PLL). Our frequency PLLs provide an electronic system for generating any of a range of frequencies from a single fixed timebase or oscillator. Our PLLs provide low-power, ultra-low phase noise, programmable frequency PLLs for defense, broadband, industrial, and wireless infrastructure markets. |

• | Mixers / Upconverters. Our mixers / upconverters are used to translate encoded voice/data signals from one frequency to another to enable radio transmission. Our mixers / upconverters are incorporated into leading mixer modules and provide industry leading linearity, which is a key metric to maximizing wireless data transmission rates. These attributes are critical in 3G and 4G cellular base station designs. |

• | Prescalers. Our prescalers operate in the C, X, and Ku bands to divide the frequency of a wireless signal in order to extend the operating range of a PLL beyond its base capability. Our prescalers complement our frequency PLL line, providing our customers with a comprehensive design solution while significantly lowering power consumption. |

• | Digitally Tunable Capacitors. Our DTCs are designed to enable RF circuits to perform optimally at many different frequencies. Our products support a wide range of applications in a variety of end markets, including antenna and filter tuning, and impedance matching between circuits. We believe our DTC products are designed to offer an industry leading combination of power handling, performance, manufacturability, and small form factor. |

6

• | DC-DC Converters. Our frequency-configurable DC-DC converters efficiently perform voltage conversion using a high frequency switching technique that minimizes system noise. Our DC-DC converters are designed to enable a distributed power management architecture designed for satellite applications, replacing inefficient drop out regulators and large central converters. This increases efficiency, reduces weight and form factor, and provides redundant power management. |

• | Power Amplifiers. Our PAs amplify RF signals in order to generate the necessary power required to establish a radio link between a base station and a mobile device. These products are designed to be reconfigurable to optimize efficiency under different load conditions and modulations. We believe this attribute is highly valued by 3G and 4G handset OEMs to address battery life under high data usage conditions. With our UltraCMOS technology we have the ability to integrate our PAs on a single chip with other RF, mixed signal, and digital components. We are currently developing PAs. |

Technology

We have successfully developed and optimized UltraCMOS technology, a proprietary process technology for manufacturing silicon CMOS circuits on insulating substrates. We believe that our fundamental competitive advantage lies in the design and manufacturing of high performance RFIC products using our UltraCMOS technology and have secured broad patent rights covering the significant aspects of our manufacturing processes and circuit designs based on this material system.

Our UltraCMOS Process Technology

The processes that we utilize are all based on SOI substrate materials that provide near perfect electrical insulation. These substrates are then used to build CMOS -based circuit elements using industry standard semiconductor fabrication equipment, while the electrically-insulating substrate results in a broad set of unique physical and electrical properties with particular applicability in RF as well as other areas.

Due to the unique physical characteristics of the UltraCMOS material system, our products are able to overcome the inherent limitations of standard CMOS devices manufactured on bulk silicon substrates, as well as products manufactured using specialty process technologies, while exhibiting the best characteristics of both sets of technologies. Products manufactured using our UltraCMOS technology have advantages in high frequency and high power performance, and can include significantly higher quality passive elements than is possible with bulk silicon CMOS or bipolar devices. In addition, our UltraCMOS technology allows higher levels of monolithic integration, more aggressive technology scaling, and lower power operation than can be achieved with specialty GaAs processes.

The unique combination of performance, integration, and scaling characteristics of our UltraCMOS technology results in numerous key attributes for use in RFICs:

• | extremely low parasitic capacitance, resulting in excellent high-frequency performance, high power handling capability, and low power consumption characteristics; |

• | extremely high signal isolation, leading to minimal crosstalk between different frequencies and the ability to reduce the physical size of the device; |

• | excellent broadband linearity, which results in improved network efficiency, subscriber carrying capacity, and enhanced communication data rates; |

• | ability to integrate multiple analog RF devices and high quality passive devices, such as inductors, along with digital logic, memory, and other mixed-signal functions with a single manufacturing process, which enables monolithically-integrated RFICs with improved performance characteristics and dramatically smaller device size; |

• | ability to scale to advanced process geometries, per Moore’s Law, resulting in further improvements in performance, cost, and reduced product footprint; |

• | excellent tolerance to high-voltage ESD effects, thereby reducing the external protective circuitry required and improving manufacturing yields of module manufacturers, OEMs, and contract manufacturers; |

• | ability to support advanced chip-scale packaging, or CSP, offering dramatically smaller device size and the elimination of undesirable package-related electrical effects; and |

• | high radiation resistance, making our UltraCMOS technology ideal for products used in satellite communications and certain medical applications subjected to single-event and total dose radiation effects. |

7

Comprehensive UltraCMOS RFIC Design Capability

The many unique attributes offered by UltraCMOS technology have provided our product designers with an unmatched level of flexibility to solve many long-standing high performance RFIC design challenges inadequately addressed by prevailing semiconductor technologies. Through our pioneering work in silicon-on-insulator (SOI) based products, we have developed many innovative circuit designs and techniques for which we have secured broad patent rights.

For example, through a patented technique involving the stacking of multiple transistors, we have developed circuits able to handle high power levels not possible using standard CMOS technology. We also have patented design advancements, enabled by our UltraCMOS process, including HaRPTM technology, which significantly improves the harmonic and linearity performance of RF switches, as well as DuNE technology, a patent pending circuit design technique that we have used to develop our advanced DTC products.

We have gained extensive experience and know-how in developing optimized circuit block design techniques and computer-aided design, or CAD, tools that take full advantage of the unique physical and electrical properties of the SOI material system. We have also leveraged the sophisticated CAD tools available to support the standard CMOS design environment, to gain substantial expertise in the use of these tools for the automated design, simulation and design validation of high performance UltraCMOS-based RFICs. As we have grown our portfolio of RFICs over time, we have amassed a significant library of RF circuit “building blocks” that were developed utilizing our CAD tools. Unlike most other RF product suppliers, since all of our products are based on UltraCMOS technology platforms, our library of proven building blocks can quickly be assembled into more complex monolithically integrated RFICs to meet our customers’ expanding system requirements. In addition, we have utilized our extensive system-level expertise to design our RFIC products to work seamlessly in our OEM customers’ system environment.

Research and Development

We view our technology as a competitive advantage, and invest heavily in research and development to ensure our products meet the requirements of module manufacturers and OEMs. Our research and development expense was $42.2 million, $34.1 million, and $22.7 million in 2013, 2012, and 2011, respectively. At December 28, 2013, there were 158 people in our research and development organization, located at our facilities in California, Illinois, and United Kingdom.

We focus our research and development efforts on designing and introducing new products and enhancing our UltraCMOS process technology. Our circuit design efforts are focused on developing products that provide high levels of performance together with integration of RF functions as well as analog, digital, and passive elements on a single chip. Our core team of experienced engineers works closely with a number of our customers to develop and introduce custom products that address the specific requirements of those customers.

We also engage in customer and government sponsored research and development activities. We believe these activities help support the continued development of our core technologies and enhance our relationships with customers and other partners. Our policy is to accept sponsored research and development where it aligns with our other strategies, as well as our technology and product roadmaps, for the enhancement of our UltraCMOS technology and RFICs. We also undertake such activities where we are able to retain proprietary rights with respect to our technology developed in the course of such sponsored research and development activities.

Sales and Marketing

We sell our products worldwide through our direct sales force and field applications engineering staff, our network of domestic and international independent sales representatives, and both worldwide and regional distribution partners. Each of these channels is supported by our customer service and marketing organizations. We have sales and customer support personnel in the U.S., France, China, United Kingdom, Finland, Denmark, South Korea, Taiwan, and Japan.

Our design cycle from initial engagement to volume shipment can be from six months to two years, with product life cycles in the markets we serve ranging from one to five years or more. For many of our products, early engagement with the module manufacturers’ and OEMs’ technical staff is necessary for success. To ensure an adequate level of early engagement, our application and development engineers work closely with the module manufacturers, OEMs, and contract manufacturers to identify and propose solutions to their system challenges.

Our direct sales force and field applications engineers provide our customers technical assistance with the selection and use of our products. Our network of sales representatives and distributors have been selected based on their focus on and knowledge of RFICs, their ability to provide a high level of field application engineering support or their regional logistical support capabilities. We provide ongoing technical training for new products to our sales representatives and distributors to keep them informed of product enhancements and new product releases. We plan to expand our direct sales and support

8

capabilities and our network of independent sales representatives in key regions domestically and internationally. We share product information and technical specifications with our customers using web-based tools.

We maintain an internal marketing organization responsible for the production and distribution of sales and marketing materials, including press releases, product announcements, product brochures, advertisements, and featured articles in trade publications. We also participate in industry tradeshows and conferences to enhance our visibility.

Customers

Our products are sold directly and indirectly to leading companies in each of our target markets, including space and military, broadband, industrial, mobile device, test and measurement equipment, and wireless infrastructure markets. We sell our products through our direct sales force, our network of sales representatives and distributors, as well as to contract manufacturers and module manufacturers who incorporate our products into their modules which are then sold to OEMs. Macnica, Inc. and Richardson Electronics, Ltd. are our primary distributors, and represented 69% and 11%, respectively, of our revenue for the year ended December 28, 2013, 72% and 11%, respectively, of our net revenue for the year ended December 29, 2012, and 48% and 16%, respectively, of our net revenue for the year ended December 31, 2011.

We currently rely, and expect to continue to rely, on a limited number of customers for a significant portion of our net revenue. Sales through our distributor Macnica to module manufacturer Murata Manufacturing Company, Ltd. represented 69%, 69%, and 39% of our net revenue for the year ended December 28, 2013, December 29, 2012, and December 31, 2011, respectively, and we believe substantially all of the products sold by Murata are to a limited number of mobile handset manufacturers. The majority of our business from our largest customers, including sales to Murata through our distributor Macnica, is conducted through standard purchase orders, which provide no contractual guarantees beyond the purchase order itself. No other direct or indirect customer accounted for more than 10% of our total net revenue for the year ended December 28, 2013.

Based on our direct customer sales, and records from our distributors of shipments to their customers, the top 10 end customers of our products represented 82%, 82%, and 66% of our net revenue for the year ended December 28, 2013, December 29, 2012, and December 31, 2011, respectively. For the year ended December 28, 2013, our products were sold to more than 1,700 module manufacturers, OEMs, contract manufacturers, and other customers. We believe our RFICs are included in products sold by many of the leading mobile handset OEMs.

A substantial portion of our net revenue is generated from customers outside of North America, and we anticipate that such net revenue will continue to comprise a significant portion of our net revenue. For the year ended December 28, 2013, 17%, 79%, and 4% of our net revenue was attributable to customers based in North America, Asia, and Europe, respectively. For the year ended December 29, 2012, 17%, 79%, and 4% of our net revenue was attributed to customers based in North America, Asia, and Europe, respectively. For the year ended December 31, 2011, 30%, 61%, and 9% of our net revenue was attributed to customers based in North America, Asia, and Europe, respectively. A summary of our financial information by geographic location is found in Note 11, “Concentrations and Geographic Information,” in the Notes to Consolidated Financial Statements. Our distributor and customer concentration, as well as our international operations and sales, subject us to a variety of risks; see Item 1A, “Risk Factors,” for further discussion.

Competition

The design, development, marketing and sale of high performance RFICs to the space and military, broadband, industrial, mobile device, test and measurement equipment, and wireless infrastructure markets are intensely competitive and characterized by rapid technological change, evolving standards, varying product life cycles, and pricing pressures. We expect competition to intensify as competitors expand their product offerings and as new competitors enter the market. We believe that high performance RFIC providers compete principally on product capabilities, levels of integration, innovation, reliability, price, time-to-market, overall system cost, intellectual property, customer support, reliability of supply, and reputation. We believe we compete favorably with respect to these factors.

We compete with a number of large domestic and international suppliers of RFICs in our target markets. We currently compete in the mobile device and wireless infrastructure markets with Avago Technologies Limited, Hittite Microwave Corporation, Infineon Technologies AG, M/A-COM Technology Solutions Inc., NEC Corporation, Renesas Electronics Corporation, RF Micro Devices, Inc., Skyworks Solutions, Inc., Sony Corporation, Texas Instruments Incorporated, Toshiba Corporation, TriQuint Semiconductor, Inc., and others. In the broadband, test and measurement equipment, and industrial markets, we principally compete with Hittite, Intersil Corporation, M/A-COM, Renesas, Skyworks, and others. Our principal competitors in the space and military markets include Analog Devices, Inc., Hittite, M/A-COM, and others. We also expect that in the future we may face competition from suppliers of RFICs based on new or emerging technologies.

9

Although we have a long operating history, many of our current and potential competitors may have better name recognition, access to a larger customer base and significantly greater financial, sales and marketing, manufacturing, distribution, technical, and other resources than us. As a result, those companies may be able to respond more quickly to changing customer demands or devote greater resources to the development, promotion, and sale of their RFICs than we can. See Item 1A, “Risk Factors,” for further discussion of risks regarding competition.

Manufacturing

We are a fabless semiconductor company and we utilize third-party foundries, wafer preparation suppliers, and packaging contractors, along with a combination of internal and external testing, to manufacture our RFICs. We have accumulated significant materials and we work closely with each of our manufacturing partners to implement our proprietary technologies in order to meet the extremely high quality and reliability standards of our end customers. Our outsourced manufacturing approach allows us to minimize our capital expenditures, scale our business rapidly, and leverage the high volume manufacturing expertise of others. The following is an overview of our manufacturing process:

• | Wafer Procurement. Silicon wafers are a key raw material used in our manufacturing processes. We use both silicon-on-sapphire (SOS) and silicon-on-insulator (SOI) wafers for our products. Worldwide production and availability of synthetic sapphire has risen dramatically in recent years as a number of new producers have entered the market given the widespread use of sapphire as a substrate for blue and white light-emitting diodes, or LEDs. We currently rely on Kyocera Corporation, Rubicon Technology Inc., and Namiki Precision Jewel Co., Ltd. for the supply of our sapphire substrates and are not dependent on any single source. For our SOI wafers we have established a supply relationship with Soitec. In some circumstances we may be required to qualify new sources of sapphire supplies if we, or our third-party foundries, are unable to obtain adequate supplies from our current suppliers. |

• | Wafer Preparation. Our fundamental manufacturing processes for SOS wafers involve the placement of a thin monocrystalline silicon layer onto substrate. The thin silicon layer is either epitaxially grown or bonded onto the substrate. We carefully qualify each of our epitaxial and bonded outside suppliers for wafer preparation. Our principal outside suppliers for epitaxial services are LAPIS Semiconductor Co., Ltd. and Hermes Epitek Corp. Our principal outside supplier for bonded wafers and SOI wafers is Soitec USA, Inc. |

• | Wafer Fabrication. Our RFICs are currently manufactured by third-party CMOS foundries located in Japan, Singapore, South Korea, and Australia. We carefully qualify each of our foundries to ensure their ability to implement our proprietary UltraCMOS technology within their wafer fabrication facilities. Our principal foundries are currently LAPIS Semiconductor, MagnaChip Semiconductor Ltd., and Silanna Semiconductor Pty Ltd for SOS wafers and Global Foundries, Inc. for SOI wafers. |

• | Test and Packaging. Our products are shipped as known-good-die, or KGD, or as packaged products. We test KGD both internally and at third-party subcontractors prior to finishing the product for shipment to customers, while our packaged products are assembled by third-party contractors utilizing industry standard packages prior to testing. We design and control our own test processes, utilizing a combination of both internal and outsourced testing. Our in-house testing provides us with additional insight into the performance of our products and enables faster time-to-market for our new products, while our use of third-party test service providers enables us to balance demand with our internal capacity. We believe our extensive experience in the testing of RFICs, and particularly as required for UltraCMOS technology, is a significant barrier-to-entry. |

The majority of our relationships with our suppliers and manufacturing partners is on a basis which provides limited contractual guarantees of long term supply commitment. It is possible that any of our suppliers could terminate their supplier relationship with us, and in such event, we are typically provided reasonable notice of termination and a last time buy opportunity. See Item 1A, “Risk Factors,” for further discussion of manufacturing risks.

Quality Assurance

We are committed to providing high quality products and services that meet or exceed our customers’ expectations. We have developed and implemented a quality management system to create an organizational environment designed to meet the highest level of quality and reliability standards. Our quality management system has been certified and maintained to ISO 9001 standards since 2001. We achieved AS9100 Quality Management System Standards certification in 2003 to address the strict quality system requirements of the space industry. In early 2012, we further improved the robustness of our quality management system by receiving our ISO/TS 16949:2009 Quality Management System certification by the automotive industry, and during 2013, achieving AEC-Q100 qualification by passing a series of stress tests designed to ensure the quality, reliability, and endurance of semiconductors in automotive applications.

10

Intellectual Property

Our success depends upon our ability to protect our core technology and intellectual property. To accomplish this, we rely on a combination of intellectual property rights, including patents, trade secrets, copyrights and trademarks, as well as customary contractual protections. We plan to pursue and maintain broad intellectual property protection in the U.S. and in our relevant markets worldwide. As of December 28, 2013, we had 71 issued and allowed U.S. patents and 12 issued and allowed international patents. In addition, as of the same date we had 62 pending U.S. patent applications and 30 pending international patent applications. Together, our patents and patent applications protect key aspects of our UltraCMOS technologies. We also rely on copyrights, trade secrets, technical know-how, and continuing innovation to develop and maintain our competitive position. Our 83 issued and allowed patents as of December 28, 2013 have expiration dates ranging from 2014 to 2033 with an average remaining patent life of approximately ten years.

We seek to protect our proprietary information and other intellectual property by generally requiring our employees, consultants, contractors, outside scientific collaborators, and other advisors to execute non-disclosure agreements on commencement of their employment or engagement as well as by documenting and maintaining the confidentiality of our trade secrets and other proprietary and confidential information. See Item 1A, “Risk Factors,” for further discussion of intellectual property risks and Item 3, "Legal Proceedings," for a discussion related to our lawsuit against RFMD alleging infringement of certain of our patents.

Employees

As of December 28, 2013, we had 423 employees, of which 390 were located in the U.S., 17 were located in Asia, and 16 were located in Europe. Of these employees, 158 were in research and development, 140 were in operations and manufacturing operations, 71 were in sales, applications, and marketing, and 54 were in general and administrative functions. Our employees are not covered by any collective bargaining arrangement. We have never had a work stoppage and we consider our employee relations to be good. Subsequent to December 28, 2013, we had a reduction in force of approximately 16% of our total employees.

11

Item 1A. | Risk Factors |

You should carefully consider the following risk factors, as well as the other information in this report, before deciding whether to purchase, hold or sell shares of our common stock. The occurrence of any of the following risks could harm our business, financial condition, results of operations and/or growth prospects or cause our actual results to differ materially from those contained in forward-looking statements we have made in this report and those we may make from time to time. Any of these events could cause the trading price of our common stock to decline. You should consider all of the factors described when evaluating our business.

Risks Related to Our Business and Industry

Our operating results may fluctuate significantly and our future results are difficult to predict, which may cause us to fail to meet the expectations of investors.

We operate in a highly dynamic industry and our future results could be subject to significant fluctuations, particularly on a quarterly basis. Our quarterly net revenue and operating results have fluctuated significantly in the past and may continue to vary from quarter-to-quarter due to a number of factors, many of which are not within our control. As a result, comparing our operating results on a period-to-period basis may not be meaningful. A significant percentage of our net revenue in each quarter is dependent on sales that are booked and shipped during that quarter, typically attributable to a large number of orders placed through our distributors for diverse end users and markets. As a result, accurately forecasting our operating results, including our total net revenue and gross margins, in any quarter is difficult. For example, it is difficult for us to forecast the demand for our products, in part because of the complex supply chain between us and the end users of our products. We have limited visibility into future module manufacturer, OEM, distributor, and contract manufacturer demand and the product mix that they will require, which could adversely affect our net revenue forecasts and operating margins.

In addition, our failure to accurately forecast demand can lead to product shortages that can impede production by the module manufacturers and OEMs, and harm our relationships with them and the distributors of our products. Conversely, our failure to forecast declining demand or shifts in product mix can result in excess or obsolete inventory. The rapid pace of innovation in our industry could also render significant portions of our inventory obsolete. Excess or obsolete inventory levels could result in unexpected expenses or increases in our reserves that could adversely affect our business, operating results, and financial condition. In contrast, if we were to underestimate demand or if sufficient manufacturing capacity were unavailable, we could forego net revenue opportunities, potentially lose market share, and damage our relationships with parties that use or distribute our products.

In addition to the other factors described in this Part I, Item 1A, factors that can contribute to fluctuations in our operating results include:

• | the timing and success of the introduction of new products and technologies by us and our competitors, and the acceptance of our new products by module manufacturers, OEMs, and end users; |

• | our gain or loss of a key module manufacturer, OEM, distributor, or contract manufacturer customers; |

• | the rescheduling, increase, reduction, or cancellation of significant orders or forecasted orders from module manufacturers, OEMs, distributors, or contract manufacturers; |

• | our ability to develop, introduce, and ship in a timely manner new products and product enhancements that meet the requirements of module manufacturers, OEMs, or end users of our products, including performance, functionality, reliability, form factor, and cost requirements; |

• | the rate at which module manufacturers, OEMs, and end users adopt our technologies in our target end markets; |

• | the availability, cost, and quality of materials and components that we purchase from third-party foundries and any problems or delays in the fabrication, wafer preparation, assembly, testing, or delivery of our products; |

• | fluctuations in manufacturing yields associated with new product introductions or changes in process technologies; |

• | the quality of our products and any remediation costs, including costs associated with the return of previously sold products due to manufacturing defects; and |

• | general economic conditions in our domestic and foreign markets. |

12

Due to these and other factors, quarter-to-quarter comparisons of our historical operating results should not be relied upon as accurate indicators of our future performance.

We may be unable to sustain our historical net revenue growth rate and if net revenue growth falls short of our expectations, we may not be able to immediately reduce our operating expenses proportionately, which could eliminate our profitability.

Over our history, we have experienced periods of relatively flat period-over-period growth, as well as periods of more rapid growth. From 2009 through 2013, our annual net revenue has increased at a CAGR of 30%. Our net revenue in the year ended December 29, 2012 increased by 89% over the corresponding period in 2011. However, our net revenue for the year

ended December 28, 2013 decreased by 0.8%, compared to the corresponding period in 2012. We believe that in planning our growth, it is prudent to take into account the cyclical nature of some of the end markets that we serve, as well as the longer term historical patterns in the development of our business. Although we base our planned operating expenses in large part on our expectations of future net revenue, a substantial portion of our expenses is relatively fixed, and cannot immediately be eliminated if our net revenue falls short of our expectations. Thus, if the rate in growth of our net revenue in any quarter is substantially less than we had anticipated, we may be unable to reduce our operating expenses commensurately in that quarter, which could negatively affect our results of operations for that quarter. For instance, for the quarter ended December 28, 2013, our net revenue declined to $43.3 million from $60.0 million for the quarter ended September 28, 2013. In addition, we experienced net losses of $6.8 million, $0.4 million and $1.2 million for the quarters ended December 28, 2013, June 29, 2013, and March 30, 2013, respectively, compared to net income of $5.6 million and $4.4 million for the quarters ended December 29, 2012 and September 28, 2013, respectively.

We rely on a small number of customers for a significant percentage of our net revenue, and the loss of, or a reduction in, orders from these customers could result in a significant decline in net revenue.

Although we have shipped our products to a large number of customers, we have historically depended on a small number of customers for a significant percentage of our annual net revenue. The composition of this group can change from year to year. Net revenue derived from our three largest direct customers as a percentage of our net revenue was 80% and 87% for the three months ended December 28, 2013 and December 29, 2012, respectively, and 83% and 85% for the years ended December 28, 2013 and December 29, 2012, respectively. Included in these percentages for our three largest direct customers are sales to two of our distributors. Based on records from our distributors of shipments to their customers, net revenue derived from our three largest end customers as a percentage of net revenue was 74% and 78% for the three months ended December 28, 2013 and December 29, 2012, respectively, and 73% and 73% for the years ended December 28, 2013 and December 29, 2012, respectively. Sales through our distributor Macnica to module manufacturer Murata represented 64% of our net revenue for the three months ended December 28, 2013 and 69% of our net revenue for the year ended December 28, 2013, and we believe substantially all of the products sold by Murata are to a limited number of mobile handset manufacturers. Any decrease in mobile handset sales by such manufacturers could have a material negative impact on our business, financial condition and results of operations. While the composition of our top customers varies from year to year, we expect that shipments to a limited number of customers will continue to account for a significant percentage of our net revenue for the foreseeable future. As a result of our customer concentration, our financial performance may fluctuate significantly from period to period based on the device release cycles and seasonal sales patterns of the mobile handset manufacturers and the success of their products.

With the exception of a supply and prepayment agreement with Murata, substantially all of our business, including that from our largest customers, is conducted through standard purchase orders, which provide no contractual guarantees beyond the purchase order itself. It is possible that any of our major customers could terminate its purchasing relationship with us or significantly reduce or delay the amount of our products that it orders, purchase products from our competitors, or develop its own products internally. The loss of, or a reduction in, orders from any major customer could cause a decline in net revenue and adversely affect our results of operations. To date, we have not experienced significant risk with respect to customer credit risk, but this could change as we expand our business in size and into new geographies in the future. In addition, during the year ended December 28, 2013, we entered into a royalty agreement with Murata.

We have incurred significant losses in the past and may incur losses in the future.

As of December 28, 2013, we had an accumulated deficit of $225.0 million, and we generated a net loss of $4.1 million for the year ended December 28, 2013. We expect to continue to make significant expenditures related to the development of our business. These include expenditures to hire additional personnel related to the sales, marketing, and development of our products, and to maintain and expand our research and development facilities. We may not have sufficient net revenue growth to offset increased expenses or to achieve or maintain profitability in future periods.

13

The average selling prices of RFICs in our markets have historically decreased over time and will likely do so in the future, which could adversely impact our net revenue and gross profits.

Average selling prices of RFICs in the markets we serve have historically decreased over time and we expect such declines to continue to occur. Our gross profits and financial results will suffer if we are unable to offset reductions in our average selling prices by reducing our costs, developing new or enhanced RFICs on a timely basis with higher selling prices or gross profits, or increasing our sales volumes. Additionally, because we do not operate our own manufacturing or assembly foundries, we may not be able to reduce our costs as rapidly as companies that operate their own facilities, and our costs may even increase, which could also reduce our margins. In the past, we have reduced the prices of our RFICs in anticipation of future competitive pricing pressures, new product introductions by us or our competitors, and other factors. We expect that we will have to continue to do so in the future.

Changes in our product mix and in our manufacturing operations utilization may adversely affect our gross margins and operating results.

Our products have a wide range of gross margins, and our overall gross margin in any period is highly dependent on the percentage of our net revenue attributable to higher or lower margin products in that period. The product mix that module manufacturers, OEMs, distributors, and contract manufacturers will require varies greatly from period-to-period and is difficult for us to predict, and a shift in product mix in any given period to a greater percentage of lower margin products would adversely affect our gross margins and operating results. For example, for the three month period ended December 25, 2010 our gross margin was 48% compared to the three month period ended September 24, 2011 in which our gross margin was 27%. As a result of changes in product mix, our operating results will vary from period-to-period and could be adversely affected. For the quarter ended December 28, 2013 our gross margin was 36%.

In addition, we are generally faced with a decline in the utilization of our manufacturing operations during periods of reduced demand, as a certain portion of our manufacturing costs are relatively fixed. During periods of reduced demand, these overhead costs are allocated over a smaller number of units, which will result in increased product cost. Reduced market demand in the future may adversely affect our utilization and consequently result in lower gross margins for our products. Fluctuations in our gross margins for our products could have a material negative impact on our business, financial condition and results of operations.

The lead time to produce our product is generally longer than the end-customer’s commitment time; therefore, our sales

and operating results in any quarter are difficult to forecast.

We base our production volume on our lead time and forecasts from our customers. Because our typical lead time is longer than customers commitments, they may cancel or reschedule certain orders after we have begun production. Therefore, cancellations, reductions, or delays of orders from any significant customer could have a material adverse effect on our business, financial condition, and results of operations. For instance, during the fourth quarter of fiscal 2013 we wrote off $3.1 million of excess inventory.

If we fail to penetrate key players in our existing markets or fail to penetrate new markets, our net revenue, net revenue growth rate, if any, and financial condition could be materially and adversely affected.

We currently sell most of our products into the space and defense, broadband, industrial, mobile device, test and measurement equipment, and wireless infrastructure markets. Our net revenue growth, if any, will depend in part on our ability to penetrate key customers in these target markets and to continue to develop and broaden our relationships with key players in the wireless ecosystem including wireless network operators, leading device and equipment OEMs, and reference design partners. Each of the markets we serve presents distinct and substantial risks. If any of these markets does not develop as we currently anticipate or if we are unable to penetrate them successfully, it could materially and adversely affect our net revenue and net revenue growth rate, if any.

In addition, the markets for certain of our products, such as DC-DC converters and DTCs, are new, still developing and relatively small. We have sold or provided samples of limited quantities of our products into these markets and cannot predict how or to what extent demand for our products in these markets will develop. If we fail to penetrate these or other new markets upon which we target our resources, our net revenue and net revenue growth rate, if any, likely will decrease over time and our financial condition could suffer.

We recently announced a new product offering referred to as UltraCMOS Global 1 (Global 1) that targets the handset marketplace with products that integrate much of the functionality of the RF portion of the handset. The development of Global 1 requires the monolithic integration of functionality that is currently addressed through discrete components. If we

14

are unsuccessful in integrating the required functionality, or our products take longer to develop than competitive offerings, the Global 1 products may not be successful in the marketplace, and our net revenue and net revenue growth rate, may decrease over time, and our financial condition could suffer. If the market for an integrated RF front end develops, it may make it more difficult for us to sell RF switches and other discrete components that do not integrate the functionality of the RF front end. In addition, if this market does develop it may require us to compete against modem vendors that have the ability to bundle products competitive with our offering, limiting our success in the market. For instance, Qualcomm Incorporated recently announced RF 360, an integrated RF front-end product, which could be bundled exclusively with its transceiver and modem and make it very difficult for us to sell our integrated Global 1 products as well as our other front end discrete products such as RF switches.

If module manufacturers or OEMs do not design our RFICs into their product offerings, or if such module manufacturers’ or OEMs’ product offerings are not commercially successful, we would have difficulty selling our RFICs and our business could be adversely affected.

Our products are sold directly and through our distributors and contract manufacturers to module manufacturers who include one or more of our RFICs in the products they supply to OEMs, and to OEMs who include our RFICs in their products. Our RFICs are generally incorporated into the module manufacturers’ and OEMs’ products at the design stage. As a result, we rely on module manufacturers and OEMs to design our RFICs into the products they sell. Without these design wins or reductions of our RFICs incorporated into module manufacturers’ and OEMs’ products, our business could be materially and adversely affected. We often incur significant expenditures on the development of a new RFIC without any assurance that a module manufacturer or OEM will select our RFIC for design into its own product. Once a module manufacturer or OEM designs a competitor’s semiconductor into its product offering, it becomes significantly more difficult for us to sell our RFICs directly or indirectly to that module manufacturer or OEM because changing suppliers involves significant cost, time, effort, and risk for the module manufacturer or OEM. Furthermore, even if a module manufacturer or OEM designs one or more of our RFICs into its product offering, we cannot be assured that its product will be commercially successful and that we will receive any net revenue from that product. If the module manufacturers’ or OEMs’ products incorporating our RFICs fail to meet the demands of their customers or otherwise fail to achieve market acceptance, we will be unable to achieve broad adoption of our UltraCMOS technology. As a result, our net revenue and business would be adversely affected.

Our failure to comply with U.S. laws and regulations relating to the export and import of goods, technology, and software could subject us to penalties and other sanctions and restrict our ability to sell and develop our products.

We are obligated by law to comply with all U.S. laws and regulations governing the export and import of goods, technology, and services, including International Traffic In Arms Regulations (ITAR), Export Administration Regulation (EAR), regulations administered by the Department of Treasury’s Office of Foreign Assets Control, and regulations administered by the Bureau of Alcohol Tobacco Firearms and Explosives governing the importation of items on the U.S. Munitions Import List. Pursuant to these regulations, we are responsible for determining the proper licensing jurisdiction and export classification of our products, and obtaining all necessary licenses or other approvals, if required, for exports and imports of hardware, technical data, and software, or for the provision of technical assistance or other defense services to or on behalf of foreign persons. We are also required to obtain export licenses, if required, before employing or otherwise utilizing foreign persons in the performance of our contracts if the foreign person will have access to export-controlled technical data or software. The violation of any of the applicable laws and regulations could subject us to administrative, civil, and criminal penalties. In addition, we would also incur substantial legal fees, and our management’s attention and resources would be diverted from operating our business to respond to violations, which could harm our business. For example, during the quarter ended December 28, 2013, we incurred $0.7 million in legal fees for ITAR related matters.

These regulations could restrict our ability to sell existing products and develop new product lines. For example, as a result of ITAR requirements, we are unable to supply certain products to China satellite companies or end users, which comprise a significant part of the overall satellite market. Changes in our products or changes in export and import regulations may create delays in the introduction of our products in international markets, prevent our customers with international operations from deploying our products throughout their global systems or, in some cases, prevent the export or import of our products to certain countries altogether. Any change in export or import regulations or related legislation, shift in approach to the enforcement or scope of existing regulations, or change in the countries, persons, or technologies targeted by such regulations, could result in decreased use of our products by, or our ability to export or sell our products to, existing or potential customers with international operations and decreased revenue. Additionally, failure to comply with these laws could result in sanctions by the U.S. government, including substantial monetary penalties, denial of export privileges, and debarment from government contracts.

Additionally, on November 14, 2013, representatives of the U.S. Department of Homeland Security (DHS), in collaboration with the United States Attorney’s Office for the Southern District of California (USAO), executed a federal search

15

warrant at our San Diego facilities in connection with an investigation into exports and temporary imports of certain products sold in the aerospace market. We are cooperating fully with the USAO and DHS officials.

The U.S. Department of State, Office of Defense Trade Controls Compliance, is conducting a review of our compliance with the Arms Export Control Act (AECA) and the AECA’s implementation of ITAR. Based on this review we could be subject to continued investigation and potential regulatory consequences related to these violations ranging from a no-action letter, government oversight of facilities and export transactions, monetary penalties of up to $0.5 million per violation, and in certain cases, debarment from government contracting, denial of export privileges, and criminal penalties.

The segment of the semiconductor industry in which we participate is intensely competitive, and our inability to compete effectively could adversely affect our business.

The markets for our products are extremely competitive, and are characterized by rapid technological advances, frequent new product introductions, evolving industry standards, price erosion, and the continuously evolving requirements of module manufacturers and OEMs. This competition could result in increased pricing pressure, reduced profit margins, increased sales and marketing expenses, and failure to increase, or the loss of, market share, any of which could adversely affect our business. We compete primarily with other suppliers of high performance RFICs. We currently compete in the mobile device and wireless infrastructure markets with Avago, Hittite, Infineon, M/A-COM, NEC, Renesas, RF Micro Devices, Inc. (RFMD), Skyworks, Sony, Texas Instruments, Toshiba, TriQuint Semiconductor, and others. In the broadband, test and measurement equipment, and industrial markets, we principally compete with Hittite, M/A-COM, Renesas, Skyworks, and others. Our principal competitors in the space and military markets include Analog Devices, Hittite, Intersil, M/A-COM, and others. We expect increased competition from other established and emerging companies if our market continues to develop and expand. For example, a number of competitors now also offer competitive products based on SOI technologies and we expect that this could increase in the future because of the benefits of using SOI. Current or potential competitors have also established or may establish financial and strategic relationships with each other or with existing or potential customers or other third parties to increase the ability of their products to address the needs of our prospective customers. Accordingly, it is possible that new competitors or alliances among competitors could emerge and rapidly acquire significant market share, which would adversely affect our business. In addition, a competitor could acquire a partner to which we have licensed certain rights to sell products using our technology. In addition, we expect increased competition from companies using technologies or competitors using technologies based on standard CMOS. There can be no assurance that we will be able to compete successfully against current or potential competitors, or that competition will not have a material adverse effect on our business, financial condition, and results of operations.

In addition, we may face competition because of the potential risks customers associate with purchasing products from sole sources. Because our products are manufactured using a proprietary technology, customers may be reluctant to purchase some our products because they may view us as a sole source supplier for certain of their component parts. Customers generally prefer to incorporate components into their products that can be sourced from multiple suppliers.

We depend on limited sources of supply for some of the key components and materials in our products, and a limited number of suppliers for wafer preparation, which makes us susceptible to shortages, price fluctuations, and quality risks that could adversely affect our operating results.

We purchase a number of key components and materials used in our products from limited source suppliers. For example, we currently obtain synthetic sapphire substrates from three third-party suppliers, including Kyocera, Rubicon, and Namiki. Our current consumption levels of synthetic sapphire represent less than approximately two percent of worldwide synthetic sapphire production. We believe that our suppliers currently have manufacturing capacity adequate to meet our foreseeable requirements. However, if competition for capacity were to increase, our suppliers could increase the lead times required to deliver materials to us or could seek to increase the prices of materials we purchase from them. For example, competition for synthetic sapphire wafer capacity has increased significantly in recent years due to the use of sapphire as a substrate for blue and white LEDs. This increasing demand for synthetic sapphire for use in LEDs has resulted in substantial increases in the cost of sapphire substrates and could adversely impact our manufacturing costs as well as the availability of sapphire substrate supply. In addition, we and our outside foundries use a limited number of suppliers for wafer preparation. For example, we currently obtain bonded SOS wafers and SOI wafers from Soitec.

If our limited source suppliers and suppliers for wafer preparation were to experience difficulties that affected their manufacturing yields or the quality of the materials they supply to us, our cost of net revenue could be adversely affected. Longer lead times and quality problems experienced by our suppliers could also prevent us from fulfilling the demands of the module manufacturers, OEMs, distributors, and contract manufacturers for our products on a timely basis, and thus adversely affect our net revenue. The ability of our suppliers to meet our requirements could be impaired or interrupted by factors beyond their control, such as earthquakes or other natural phenomena, labor strikes or shortages, or political unrest. In the event one of our suppliers is unable to deliver products to us or is unwilling to sell materials or components to us, our operations may be

16