UNITED STATES

SECURITIES AND EXCHANGECOMMISSION

WASHINGTON, D.C. 20549

FORM

Amendment No. 2

FOR THE FISCAL YEAR ENDED

OR

FOR THE TRANSITION PERIOD FROM __________ TO __________

COMMISSION FILE NUMBER

(Exact name of registrant as specified in its charter) |

| ||

State or other jurisdiction of Incorporation or Organization |

| I.R.S. Employer Identification No. |

|

|

|

| ||

Address of Principal Executive Offices |

| Zip Code |

(

Registrant’s Telephone Number, Including Area Code

________________________________________________________________

Former Name, Former Address and Former Fiscal Year, if Changed Since Last Report

SECURITIES REGISTERED PURSUANT TO SECTION 12(b) OF THE ACT: NONE

SECURITIES REGISTERED PURSUANT TO SECTION 12(g) OF THE ACT:

COMMON STOCK, $0.01 PAR VALUE

Title of each class |

| Trading Symbol(s) |

| Name of each exchange on which registered |

|

| |

| The |

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐

Indicate by check mark whether the registrant (1) has filed all reports required to be filed be Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (Section 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, smaller reporting company, or an emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer,” “smaller reporting company,” and “emerging growth company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer | ☐ | Accelerated filer | ☐ |

☐ | Smaller reporting company | ||

|

| Emerging growth company |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act.

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes

As of December 31, 2022, and as of the date this Form 10-K is filed with the Securities and Exchange Commission, the Registrant’s common stock is trading on the NASDAQ under the ticker symbol “LASE”.

As of December 31, 2022, there were

statements and the notes thereto, the share and per share information reflects a reverse stock split of our outstanding common stock at a ratio of 1-for 6 shares that occurred in December 2021 and is reflected retroactively in the accompanied financial statements in accordance with ASC 260-10-55-12 which requires retroactive presentation.

RECENT IPO

On October 4, 2022, the Company closed on an IPO in which it issued 3,000,000 additional shares of common stock at an offer price of $5.00 per share. The shares trade on the NASDAQ under the ticker symbol, “LASE.” Including this issuance, there were 7,878,419 shares outstanding as of December 31, 2022.

FORWARD LOOKING STATEMENTS

The Private Securities Litigation Reform Act of 1995 provides a “safe harbor” for forward-looking statements, which are identified by the words “believe,” “expect,” “anticipate,” “intend,” “plan” and similar expressions. The statements contained herein which are not based on historical facts are forward-looking statements that involve known and unknown risks and uncertainties that could significantly affect our actual results, performance or achievements in the future and, accordingly, such actual results, performance or achievements may materially differ from those expressed or implied in any forward-looking statements made by or on our behalf. These risks and uncertainties include, but are not limited to, risks associated with our ability to successfully develop and protect our intellectual property, our ability to raise additional capital to fund future operations and compliance with applicable laws and changes in such laws and the administration of such laws. These risks are described below and in “Item 1. Business,” Item 1A “Risk Factors,” “Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations,” and “Item 7A. Quantitative and Qualitative Disclosures About Market Risk” included in this Form 10-K. Readers are cautioned not to place undue reliance on these forward-looking statements which speak only as of the date the statements were made.

| 2 |

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s definitive proxy statement to be filed in connection with the solicitation of proxies for its 2023 annual meeting of stockholders are incorporated by reference into Items 10, 11, 12, 13, and 14 under Part III hereof.

EXPLANATORY NOTE

This Amendment No. 2 on Form 10-K/A (“Amendment No. 2”) amends our Annual Report on Form 10-K for the fiscal year ended March 31, 2023, originally filed on July 14, 2023, and amended on October 30, 2023 (the “Original Filing”). We are filing this Amendment No. 2 to include the clawback policy related to recovery of erroneously awarded executive compensation required to be adopted by December 1, 2023, by Laser Photonics Corporation under Section 10D of the Securities Exchange Act of 1934, as amended, the SEC rules promulgated thereunder and Nasdaq Listing Rule 5608. No changes have been made to the Original Filing other than furnishing the clawback policy attached to this Amendment No. 2 as Exhibit 97.1 and also filing currently dated certifications of our Chief Executive Officer and Chief Financial Officer (Exhibits 31.1, 31.2, and 32.1 and 32.2), as required under Sections 302 and 906 of the Sarbanes-Oxley Act of 2002.

This Amendment No. 2 continues to speak as of the Original Filing date of the Form 10-K, does not reflect events that may have occurred subsequent to the Original Filing date, and does not modify or update in any way disclosures made in the Original Filing.

| 3 |

TABLEOF CONTENTS

| 4 |

| Table of Contents |

PART I

ITEM 1. BUSINESS

OVERVIEW

We are pioneering a new generation of laser blasting technologies focused on disrupting the sandblasting and abrasives blasting markets. We offer a full portfolio of integrated laser blasting solutions for corrosion control, rust removal, de-coating, pre- and post-welding, laser cleaning and surface conditioning. Our solutions span use cases throughout product lifecycles, from product fabrication to maintenance and repair, as well as aftermarket operations. Our laser blasting solutions are applicable in every industry dealing with materials processing, including automotive, aerospace, healthcare, consumer products, shipbuilding, aerospace, heavy industry, machine manufacturing, nuclear maintenance and de-commissioning and surface coating.

We believe that our laser cleaning technology, which we refer to as Laser Blasting™, is one of the most exciting and transformational innovations of our time. It has the capacity to change the way society combats corrosion, nuclear contamination (transmutation), material surface preparation, rust removal, equipment and engine maintenance and repair, as well as myriad number of other industrial processes, currently employing unhealthy, dangerous, and environmentally hazardous old technologies. Our mission is to make laser blasting accessible to operation personnel in every industry involved in any type of material treatment. In doing so, we believe we will empower businesses to adopt radical new approach to design, produce, maintain and repair equipment utilizing cleaner, safer, energy efficient and more cost-effective laser-based technologies to outcompete and outperform competitors using obsolete 19th century technologies. With our state-of- the-art technology, small service companies working in high-growth industries can achieve superior financial results that will propel future global economic growth.

At this moment, “do no harm” corporate social responsibility initiatives have combined with legislative and social initiatives to safeguard the health of workers, while protecting the environment, and lowering carbon emissions. In the case of the world’s largest single market for industrial laser cleaning—the United States—legislative and regulatory crackdown on the use of abrasives blasting, coupled with official government policy requiring government agencies to Buy American products whenever possible are barriers to entry for most companies trying to compete in the industrial laser cleaning equipment market.

By introducing our cleaner, safer, energy efficient, and more cost-effective laser-based technologies to replace antiquated hazard-prone abrasives blasting methods--sandblasting, abrasive blasting, grinding, chemical etching and the use of toxic chemical solvents-- we believe that we are positioned with the right technology, at the right time, and in the right place to provide the solution that will disrupt the abrasives blasting industry.

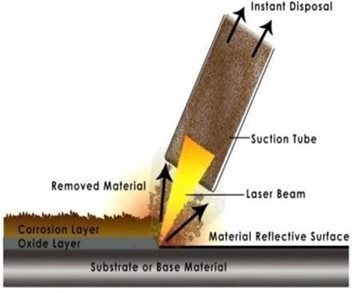

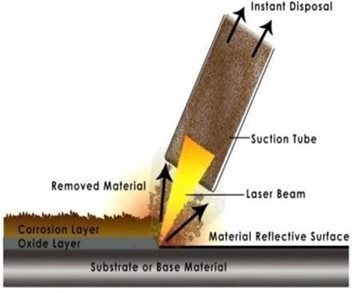

In contrast to abrasive cleaning, laser cleaning is a non-contact and non-abrasive process to remove contaminants or impurities on the surface of metals by physically removing the upper layer of the substrate using laser irradiation and where a desired depth can be achieved with a high degree of accuracy and throughput. We expect to introduce the new laser-based transmutation process into maintenance and decommissioning of nuclear facilities, as studies have shown that metal surfaces in those facilities have been exposed to radiation and that the radioactivity is primarily located in the oxide layer. Accordingly, we propose to develop the decontamination of metallic surfaces by laser ablation which consists of ejecting surface contamination using high energy pulses and trapping ablated matter (the impurities removed from the metal’s surface) in a filter to avoid its release into the environment. We believe that laser cleaning has many advantages over abrasive cleaning methods such as the minimization of secondary waste, the absence of effluents and the reduction of the exposure of workers to toxic waste through automation of the cleaning process.

Our potential to capitalize on this significant opportunity set is rooted in our deep experience in, and our commitment to, research and development. Our engineering efforts are led by a team of world-renowned experts in advanced manufacturing, material science and engineering. Our in-house R&D team is led by Igor Vodopiyanov, a PhD particle physicist who served as a lead subject matter expert at the CERN Large Hadron Collider, and who managed the Hadron Calorimeter Calibration and Condition Group of the CMS Collaboration, members of the particle physics community from across the globe in a quest to advance humanity’s knowledge of the very basic laws of our Universe.

Our announced laser blasting solutions are as follows:

Handheld Laser Blasting™: We offer the widest line of Class IVhandheld laser blasting equipment in the world, from 20W (watt) to 3000W system, including the world’s most powerful production Laser Blaster™ on the market—the Jobsite 2000—to the even more powerful JobSite 3000 which debuts at Aviation Week’s MRO Americas 21 trade show at the end of April 2021. We have under development our most powerful laser blasting equipment, our 4000W handheld system.

Laser Blasting Cabinet: This affordable and safe solution is configured as a fully enclosed Class 1 workspace, designed to replace sandblasting enclosures, along with their noise, dust, media storage, replenishment and clean-up requirements. The Blasting Cabinet is ideal for companies of any size that use abrasive blasting or chemical baths to clean parts or prepare materials.

| 5 |

| Table of Contents |

Class I Laser Blasting Systems: Our Mega Center and Titan lines of Class I Laser Blasting Systems are designed with mass production in mind. These production line-capable systems are designed with automation control and automated materials-loading capabilities to allow for maximum throughput on assembly lines for high production/high precision environments.

Robotic Laser Blasting Cells with AI: Robots are intended to lighten the workload for us humans. We achieve this with user programmable AI (UPAI) driving our C-Robots. Line workers can quickly and easily program these precision robots to complete complex and repetitive tasks in high throughput production environments.

We initiated our sales effort in December 2019. By December 31, 2022, we had gross sales of $5,078,539 and net sales of $4,954,689. We sell our products globally to end users, and principally to Fortune 1000 companies, as well as to agencies of the U.S. Government.

Our vertically integrated operations allow us to reduce development and advanced laser equipment manufacturing time, offer better prices, control quality and protect our proprietary knowhow and technology compared to other laser cleaning companies and companies with competing technologies.

We market our products globally through our direct sales force located in the United States and a few sales representatives located in Europe, Japan and South Asia.

We have an exclusive license agreement with ICT Investments. Under the terms of this agreement, we have a perpetual, worldwide, exclusive license to sell the Laser Photonics™ branded equipment for laser cleaning and rust removal. Through our affiliation with ICT, its portfolio companies and their customers, we have instant access to more than 1,500 high profile Fortune 5000 customer prospects as well as recognition as a global leader in manufacturing premium laser equipment. In addition, through the expertise and reputation of our officers, Board members and advisors, we have the foundation of our technologically advanced, disruptive laser systems specifically suited for most material processes with specific cleaning requirements and challenges.

At our core, we are a company of innovators. We are led by visionary technologists and a team of proven leaders with experience bringing emerging technologies to market across the hardware, materials and software sectors. We believe that our technologies have the potential to empower engineers and designers to adopt laser blasting as the only known alternative to sand blasting and to drive new application discovery as well as to provide manufacturers with reliable and high-performance solutions that will facilitate their production capabilities and maintenance, repair and operations (“MRO”).

Our principal executive offices are located at 1101 N. Keller Rd., Suite G, Orlando, Florida 32810, and our telephone number is (407) 804-1000.

| 6 |

| Table of Contents |

Our Market

Our market encompasses the industrial de-painting, surface preparation, coating and corrosion control space. This includes media blasting or sandblasting, dry ice blasting and laser cleaning or laser blasting. According to Global Market Insights, the laser cleaning market value is estimated at $9 billion in 2021 and projected to be $12 billion by 2025, which includes laser cleaning for maintenance repair operations. Market growth is driven by the increasing demand for robotic cleaning technology, growth in the automotive industry, as well as demand in construction and metalworking industries.

In addition, we see the greatest opportunity for growth in the disruption of the global abrasives blasting media and equipment markets, cumulatively worth

$46 billion. Media blasting is used in nearly every heavy industry, but for health, environmental and safety reasons, media blasting is being regulated into obsolescence. A safer alternative, albeit not without risks, is dry ice blasting. It is expensive to operate, and like media blasting, it is prone to equipment failure.

In light of the regulatory pressures on media blasting and the higher costs of both media blasting and dry ice blasting, we believe that efficient laser cleaning or laser blasting will disrupt the blast cleaning market and emerge as the clean, efficient and low-cost alternative blast cleaning method.

We offer the latest generation of laser material processing equipment for a variety of industrial markets and applications, including for defense, space exploration, aerospace, automotive, medical, industrial, electronic and agriculture markets.

We believe that the laser cleaning equipment market has even a greater potential for growth in light of the size of the $10 billion abrasive cleaning market, and the ancillary $1 billion sandblasting media market, which are being pressured into obsolescence from regulatory agencies and the demands of labor tasked with cleaning industrial equipment. These market pressures, driven by health, safety and environmental concerns, are accelerating the replacement of abrasive blasting and laser cleaning is emerging as the safe, clean, efficient and affordable alternative.

The growth of the laser cleaning market is attributable to the benefits it provides over traditional cleaning methods, such as abrasive media blasting, dry-ice blasting, and chemical cleaning processes, all of which are inherently hazardous to the health of workers, as well as to the environment since they generate a considerable amount of potentially harmful waste.

Our laser cleaning equipment also facilitates our customers’ compliance with the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) regulations to protect the health of workers using conventional abrasive blasting equipment. The current OSHA permissible exposure limit (PEL) for respirable crystalline silica (quartz) is 100µg/m3 as an 8-hour time-weighted average (TWA).

All of our Class I product enclosures are built and labeled to meet or exceed the guidelines established by the Food and Drug Administration’s (FDA) Center for Devices and Radiological Health (CDRH) that regulates the manufacture of radiation emitting electronic products. The CDRH does not issue certificates of compliance. Instead, the CDRH relies on a system of self-certification. That certification of compliance is based on a prescribed testing program that ensures that safety standards have been met. In accordance with HHS Publication FDA 86-8260, COMPLIANCE GUIDE FOR LASER PRODUCTS, we follow the FDA CDRH published reporting guidelines for the testing and certification of laser products. This includes submitting required reports to CDRH, including Annual Reports summarizing required records, including product names, model numbers, and lasers medium or wavelengths. In compliance with CDRH guidelines, we maintain records of each product produced and sold.

| 7 |

| Table of Contents |

Our Market Opportunity

Just one of the global markets, the MRO industry, has a total market value of $150.64 billion as of 2021, with forecast revenue of $178.85 billion for 2028. Annual Pentagon spending on corrosion control alone is forecast to be $22 billion.

The North America MRO distribution market size was valued at $142.65 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 2.9% from 2021 to 2028 according to a report by Grand View Research, Inc. Various initiatives by manufacturers to attain optimum efficiency are expected to drive market growth over the forecast period. MRO distribution is one of the critical components of the industry, which is necessary to eliminate downtime. As a result, industries initiate multiple scheduled and preventive maintenance processes. Industries, where supply activities have little direct accountability, might be driven by stock-outs rather than to any overarching supply chain plan.

Of the anticipated $178.85 billion MRO market in North America in 2028, $46 billion is spent on corrosion control using media blasting and chemical processes that are under regulatory and market pressures to be phased out because of their known harmful effects on workers and the environment. These pressures, driven by health, safety and environmental concerns, are accelerating the replacement of abrasive blasting and laser cleaning is emerging as the safe, clean, efficient and affordable alternative.

Our business is disruptive and in the very beginning of its lifespan and expansion. We have a unique opportunity to displace abrasives and dry-ice blasting with an accepted and readily adopted alternative. We believe that we have taken very effective actions to develop and offer to the market the broadest range of laser cleaning and blasting equipment in the very beginning of the unfolding of this market opportunity. We believe that we will be rewarded for this strategy through explosive growth of sales, together with the expansion of the market in accordance with the wide acceptance of the laser blasting as a new industry standard.

Industry Background

Conventional sandblasting processes have numerous shortcomings. For this reason, the abrasives blasting (sandblasting) market in North America is under extreme pressure to phase out the nineteenth-century sandblasting method of industrial cleaning to safeguard both workers and the environment. In 2019 alone there were 2,500 violations of respirator protection which were included in OSHA’s top ten violations. Government regulators (EPA, FDA and OSHA) all recognize the term “silica” refers broadly to the mineral compound silicon dioxide (SiO2), which can be crystalline or amorphous in molecular structure. The Silica standards apply only to crystalline silica - not amorphous silica. Quartz is the most common form of crystalline silica, and cristobalite is also sometimes encountered in the workplace. OSHA’s focus was on the issues related to the inhalation of respirable dust, which is generally defined as particles that are capable of reaching the pulmonary region of the lung (i.e., particles less than 10 microns (µm) in aerodynamic diameter), in the form of either quartz or cristobalite. Exposure to crystalline forms of silica is associated with a number of health effects, including silicosis derived from the use of abrasive sand blasting are severely curtailing media blasting activities. They are quick to levy hefty fines for non-compliance.

Crystalline Silica dust has been identified by the EPA as a human lung carcinogen. In reaction to the greater awareness of its dangers, OSHA has targeted silica sand blasting as a primary, yet preventable, source for silicosis disease. Their efforts at enforcement of current regulations, as well as new, and tighter laws, mean any contractor attempting to use silica-based media (sand) will be targeted. Accordingly, the use of “sand” blasting has declined over the years. Now, with OSHA’s new standard looming, those that are still relying on this technology are scrambling to find alternatives that meet these new particulate limits. Recently, Levi Strauss & Co. and H&M announced a global ban on sandblasting in all of their product lines, across all of their brands. In addition, some countries, such as the United Kingdom, and major cities, including Victoria, Canada and Queensland, Australia, have banned abrasive sandblasting.

| 8 |

| Table of Contents |

For centuries, the techniques and equipment used for surface cleaning or renewal in industrial applications have remained the same. The demand for improvements, however, has grown dramatically in recent years. Laser technology is now replacing conventional abrasive and chemical processes in many applications, such as rust removal, de-painting, degreasing, activation, restoration, pre-/post-welding joint cleaning, surface preparation, decontamination, and rejuvenation. As a cleaning technique, lasers are increasingly popular because they are precise, controllable, and efficient, and they generate low waste. Additionally, low waste and high efficiency are the primary reasons that laser cleaning is now considered the “greenest” or most environmentally friendly approach to surface cleaning. The only waste created is dust particles, which can be easily collected and removed.

Our Growth Strategy

Our strategy is to expand our product offerings with a focus on integrated solutions that make laser blasting suitable for production applications and accessible to a broad audience. The key elements of our strategy for growth include the following:

New Product Development

We intend to target new applications early in the development cycle and drive adoption by leveraging our strong customer relationships, engineering expertise and competitive production costs.

Multi-market and Multi-product Approach

We intend to develop and manufacture laser systems for a variety of markets to reduce the financial impact that a downturn in any one market would have with an emphasis developing standard systems applicable for variety of markets and applications. We expect to increase sales through an industry recognized expertise in clearly defined markets with substantial sales demand such as rust removal equipment for the shipbuilding industry, laser de-contamination equipment for the nuclear industry and laser blasting cabinets for the general manufacturing industry.

Extend Our Distribution Channels and Reach.

We have an inside sales force actively marketing in the Americas (North, Central and South America). In addition, we have a network of outside sales reps in North America, as well as international representation in Europe (based in Czech Republic), Asia (based in Japan), and the Middle East and North Africa (based in UAE). We intend to add distributers based on geographic coverage and sales capacity, as well as to develop industry-specific expertise to drive penetration in vertical markets such as automotive, aerospace, defense, energy and manufacturing. We expect to continue building out sales channels for capital equipment by partnering with additional volume distributors of equipment and hardware, as well as to expand our internal sales infrastructure and online sales presence. To augment the reach of our distribution network, we intend to grow our direct sales efforts focused primarily on serving major accounts and expanding our footprint within Fortune 500 companies and government organizations worldwide.

Broaden Our Diverse, Global Customer Base.

We expect to develop a global diversified customer base and broaden customer relationships in a variety of industries. We seek to differentiate ourselves from our competitors through superior product pricing, performance and service. We believe that a global presence and investments in application engineering and support will create competitive advantages in serving multinational and local companies.

Promote Awareness Through Training and Education.

As businesses increasingly embrace laser blasting over the next decade, we intend to educate the market on best practices for adoption of the technology across the entire product life cycle. Our leadership position provides a platform to deliver this education both for our existing customers and the market as a whole. Such education is a critical component of our sales and marketing efforts. We believe businesses that are well-informed or that have firsthand experience of the benefits of our laser blasting solutions relative to conventional manufacturing are more likely to purchase and expand their use of our products and services over time. To drive such awareness, we are developing rich laser blasting content and curricula for delivery through both online and in-person media, including classes, programs, certifications, and professional services. We also intend to develop global centers of excellence, leveraging our own headquarters in conjunction with our distribution network’s presences, to serve as showrooms, learning facilities and focal points for laser blasting-focused professional services.

| 9 |

| Table of Contents |

Pursue Strategic Acquisitions and Partnerships.

We intend to selectively pursue acquisitions and/or equity investments in businesses that represent a strategic fit and are consistent with our overall growth strategy. Such partnerships would allow us to accelerate market penetration of our laser blasting solutions by enabling expansion of our product portfolio, access to new markets, and a stronger value proposition for our customers while delivering margin improvements and increased customer lifetime value. We believe that because of our core focus on engineering and technology development as well as our unique distribution network, we will be able to integrate and drive adoption of new technologies and capabilities acquired via strategic partnerships.

Our Competitive Strengths

We are an early pioneer in the laser blasting industry with a mission to make the technology accessible to all material processing manufacturers and maintenance and repair facilities in both commercial and military applications. We believe our collective expertise coupled with the following competitive strengths, will allow us to maintain and extend a leadership position in the next-generation of laser blasting equipment and expand our market opportunities.

We also have established a base of customers among several U.S. Government agencies which we expect to expand. Each branch of the U.S. military, including the Army, Air Force, Navy, Marines, and the Coast Guard, has purchased laser cleaning systems from us. In addition, NASA and the Veteran’s Administration are also among our customers. We believe that our laser cleaning equipment has been well-received by our current U.S. Government customers from which we are already receiving repeat orders. As the only U.S.-based manufacturer of high-powered, portable industrial laser cleaning systems capable of addressing the Pentagon’s never-ending battle with rust, we believe that we are well-positioned to increase our sales to the U.S. Government, especially in light of the Pentagon alone having to spend between $21 billion to $22.9 billion per year on rust control, and corrosion-related repairs on equipment, from trucks and tanks to aircraft and other ships. See https://www.bloomberg.com/news/articles/2011-06-02/the-high-cost-of-waging-war-on-rust The U.S. Navy alone spends $3 billion per year fighting corrosion. See https://www.military.com/daily-news/2020/01/13/battle-against-rust-3-billion-problem-navy.html. The U.S. military is proving to be not only a receptive early adopter of the technology, but also as a proving ground and showcase for our products. This arises from the need to continually maintain, repair and overhaul equipment (MRO) while eliminating maintenance delays that effect force readiness. Corrosion and the lack of spare parts are among the most significant maintenance issues for the Pentagon.

A Recognized Pioneer and Leading Developer of Fiber Laser Material Processing Technology

As a pioneer and technology leader in laser material processing, combined with our deep knowledge of material properties, we are able to develop laser cleaning products that reduce its operating costs for our customers and drive the proliferation of lasers to address existing and new applications.

Track Record of World Class Product Development and Commercialization

Through their combined engineering and operational experience in the laser photonics industry, our C-level management team and board members have accumulated decades of relevant and practical industrial laser equipment development experience. They have developed and advanced a number of materials processing technologies applicable to the laser photonics industry and our vertical markets.

Vertically Integrated Application Center, Equipment Development and Manufacturing

We develop and manufacture most of our critical assemblies, subassemblies and components, including motion systems, integrated lasers, specialty components, frames, cabinets and proprietary optical assemblies. We also develop our software for use with our laser systems. We have our own engineering, procurement, manufacturing and assembly operations as a part of our vertically integrated manufacturing process. Integration of our application and research and development groups with our manufacturing capability provides our customers with a competitive edge in achieving their manufacturing goals using our laser material processing systems.

| 10 |

| Table of Contents |

Accumulated Diversified Expertise

We have extensive know-how in mathematical and physical processes of materials behavior and equipment modeling, industrial electronics, laser systems, materials and computer science which enables us to make our market-specific laser material processing equipment, machine operating software, motion and vision systems and other critical assemblies, subassemblies and components.

Manufacturing Scale

We have invested extensively in our production and lean manufacturing capabilities allowing us to deliver large volumes of lasers systems in short delivery cycles which provides us with a competitive advantage.

Diverse Customer Base, End Markets and Applications

We intend to further develop our diverse customer base, multi-market and multi-product business model given the broad application of our laser cleaning equipment, its competitive pricing and high quality that will not have us dependent on the performance of a specific market sector.

Broad Product Portfolio

Our diverse lines of laser cleaning equipment are used in work environments to improve and promote programs to address significant concerns about the exposure of employees to toxic airborne materials to reduce the risk of lung cancer and silicosis triggered by inhalation of crystalline silica dust released from abrasive blasting. We offer our customers a range of solutions spanning multiple price points, throughput levels, operating environments and technologies to enable businesses to find and use the laser blasting solution for their specific goals. Our broad product portfolio covers a spectrum of use cases, scaling with customer needs from entry-level, office-friendly laser blasting systems for high surface integrity finishing of components to high-end, high throughput industrial laser blasting systems for low-cost mass production applications. In addition, it eliminates the need for customers to source products for different processes from multiple vendors, giving us a market advantage relative to competitors that have a more limited set of products and solutions.

The Only U.S. Manufacturer with a Wide Range of Laser Blasting Equipment

Although no single publication lists all the companies manufacturing industrial laser cleaning equipment, to our knowledge all laser cleaning products of the other companies selling laser cleaning equipment are manufactured abroad. Of our competitors, only Laserax manufactures in North America; but in Canada, not the United States. Our success will depend on investment in marketing resources and the successful implementation of our marketing plan. Our marketing plan may include attendance at trade shows and making private demonstrations, advertising and promotional materials and advertising campaigns in print and/or broadcast media. To our knowledge, only Laser Photonics designs, manufactures, sells, and services industrial laser cleaning onshore in the United States.

On January 25, 2021, President Biden signed an executive order to further his “Buy American” agenda which aims to bolster U.S. manufacturing through the federal procurement process. Our “Made in America” industrial laser systems meet the President’s “Buy American” requirement for U.S. Government agencies to contract with U.S. companies whenever possible. Currently, our products are the only industrial laser cleaning systems designed and built in the United States. As the only industrial laser cleaning equipment manufacturer currently meeting the “Buy American” requirement, we expect to benefit from preferential consideration over the few other companies competing in the laser cleaning systems market.

| 11 |

| Table of Contents |

Diversified and Proprietary Technology Platform and Knowhow

We were able to secure through our affiliation with ICT Investments a diverse portfolio of knowhow, trade secrets and proprietary technologies. We believe that we possess the design documentation for the largest array of laser-based systems for material processing in North America.

Core Technologies Underlying Each Product

Fiber laser cleaning technology or laser ablation which we market under the Laser Blasting™ brand, is a proven, state-of-the-art, 21st Century replacement for hazardous 19th century abrasives blasting (or sandblasting). It is a non-contact, environmentally friendly process that removes surface coatings from metals, concrete and delicate substrates such as composites—with minimal impact on the base material. Laser Blasting works by aiming brief pulses of high-power laser energy (in the µs–ms range) at a surface to be prepared or cleaned of paint, rust, or other contaminants. The energy applied to the layer being removed doesn’t dissipate. Instead, it blasts off the substrate material being cleaned. Most or all of the material being removed is vaporized, resulting in a much cleaner process than other cleaning methods. Whatever removed material has not been vaporized may be suctioned away and filtered out of the air as particle dust.

We are recognized as a pioneer and an industry leader with our CleanTech™ Laser Blasting™ technology. Laser Blasting can replace sandblasting or dry ice blasting in nearly every industry and every application where an abrasive blasting is used. It is effective on glass, ceramics, metals, concrete, plastics and much more, and provides greater control and precision than possible with the legacy technologies it is designed to replace. LP portable Laser Blasting systems incorporate proprietary autofocusing C-Optics technology that allows for greater precision on uneven or contoured surfaces, even from handheld Laser Blasting systems. This innovation expands laser cleaning from the production floor to the field. Laser Blasting is effective on small parts and sensitive materials, as well as surfaces of ships, bridges, aircraft, pipelines, large vehicles and trains, among others.

Our Product Platforms

Since our founding in 2019, and through IP received from ICT Investments, we have developed an extensive portfolio of products based on proprietary technologies that form the foundation of our laser blasting equipment manufacturing solutions, which are comprised of hardware, equipment design documentation, bills of materials, software, materials and service practices.

Designed in-house by industry-recognized laser scientists and inventors, our expansive product portfolio covers a broad spectrum of applications across key industries, including maritime and shipbuilding, oil and gas, automotive manufacturing, rail transport, aerospace, defense and space exploration. Our CleanTech™ line scales with customer needs, starting with low price-point handheld Laser Blasters™ designed to tackle simple cleaning and surface predation jobs, to high-end AI-controlled, user-programmable C-Robotics™ made for complex, precision production environments.

Our state-of-the-art, performance-based “Made in America” Laser Blasting™ products are industrial-grade laser cleaning systems developed to disrupt and displace hazardous legacy abrasives blasting (a.k.a. sandblasting) and chemical cleaning methods that have been in common usage since the 19th century. Laser Blasting is cleaner to operate, more cost effective to own and safer for the worker and the environment. We believe that Laser Blasting is right on time as industry is increasingly coming under pressure to phase out abrasive blasting and chemical cleaning methods in compliance with health, environmental and safety regulations designed to protect laborers and the environment.

Since our founding in 2019, we have developed an extensive portfolio of proprietary equipment and technologies that formed the base for our broad product offering, starting from relatively simple handheld devices to fully automatic and operated by AI robotic systems.

| 12 |

| Table of Contents |

Our diverse lines of laser cleaning equipment are used in a variety of industries to improve and promote programs to address significant concerns about the exposure of employees to toxic airborne materials to reduce the risk of lung cancer and silicosis triggered by inhalation of crystalline silica dust released from abrasive blasting. Laser cleaning uses photons emissions, thus eliminating the need for abrasive media, including silica. The chart below provides information on several industries to indicate the need for laser cleaning equipment and how our technology meets those industries’ requirements. This chart was developed by us in the last few months to allow our salespeople to identify the specific model of our CleanTech laser blasting equipment that matches target industries and the surface integrity parameters familiar to prospective customers. We want to demonstrate our capability to address the specific cleaning applications that such customers require. The industry terminology is explained in our footnotes to the chart.

Below is the description of abbreviations and definitions used in Laser Photonics Laser Blaster products qualification chart:

| • | Roughing-Rough surface condition for thick material |

| • | Mid-Range-Normal level below roughest surface condition for medium material thickness |

| • | Finishing-Least amount of roughness on a surface for thin materials |

| • | Gauge-indication of a measurement of industrial materials |

| • | Grit-indication of roughness to apply to a surface for preparation prior to coating |

| • | CAML-grade of abrasive media used for the sandblasting industry |

| • | DPI-Dots per inch |

| • | LPI-Lines per inch |

| • | Laser Grade-Designated choice of laser for best results |

| • | Strip Rate in Ft Squared per hour is calculated as follow: 2X (laser power in KW) / (coating thickness in mils, where one mill= .001), X 60 minutes. Source: Robotic Laser Coating Removal System ESTCP Project WP- 0526 apps.dtic.mil |

Our current Laser Blasting solutions are as follows:

Handheld Laser Blasting™:

We offer the widest line of Class IV handheld laser blasting equipment in the world, from 20W (watts) to the 3000W system, including the world’s most powerful production Laser Blaster™ on the market—the Jobsite 2000—to a more powerful JobSite 3000 which debuted during Aviation Week’s MRO Americas 21 trade show in April, 2021. We are developing an even more powerful 4000W handheld system. The CleanTech™ 2000-CTH Jobsite is a 2000W handheld laser cleaning machine and surface preparation system designed to remove rust, paint and other impurities from steel, aluminum, iron, and many more surface types. The 2000-CTH Jobsite provides five different pulse laser patterns that provide flexibility when operating the laser in different applications across different surface types.

We also offer the CleanTech™ EZ-Rider Handheld Roughing & Finishing Lasers which are a high-performance, military-grade, fast, and efficient laser cleaning tool. The EZ-RIDER is based on next-generation technology. Laser Photonics designed the EZ-RIDER to be a heavy-duty industrial grade laser cleaning and surface treatment system for large areas requiring cleaning, de-painting and other surface preparations. The system starts immediately when the key is turned ON and the touch screen allows you to choose from five pre-programmed cleaning patterns for control and flexibility. The CleanTech™ EZ-Rider is based on our years of experience building handheld lasers for marking and engraving applications. Our systems are designed to be standalone units, so no personal computer is required. The CleanTech™ EZ-Rider can be coupled with industrial robots and placed inside safety work cells with interlocks for full compliance with OSHA and FDA CDRH regulations.

Laser Blasting Cabinet

The laser blasting cabinet is configured as a fully enclosed Class 1 work space designed to replace sandblasting enclosures, along with their noise, dust, media storage, replenishment and clean-up requirements. The Blasting Cabinet is intended to serve companies of any size that use abrasive blasting or chemical baths to clean parts or prepare materials. The CleanTech™ Laser Blaster Cabinet is a self-contained, industrial-grade laser cleaning machine. This system is the only laser cleaning machine in the world that incorporates the exclusive power of a fiber laser with a handheld laser-blasting head inside a fully enclosed 30” x 26” work space. This system is designed for speed, precision, safety and flexibility. It is the only laser-blasting cabinet manufactured in compliance with CDRH FDA and OSHA regulatory compliance. With the CleanTech™ Laser Blaster Cabinet, companies can eliminate harmful dust, noise, hazardous chemicals and contaminants caused by use of abrasive blasting or chemical baths.

| 13 |

| Table of Contents |

Class I Laser Blasting Systems

Our Mega Center and Titan lines of Class I Laser Blasting Systems are designed with mass production in mind. These production line-capable systems are designed with automation control and automated materials-loading capabilities to allow for maximum throughput on assembly lines for high production, high precision environments. The CleanTech Titan Series Laser Blasting System is a high power, large format laser parts cleaning, rust removal, and surface conditioning system with up to 6′ x12′ working envelope. The industrial, turn-key laser cleaning system operates as a standalone unit or can be easily integrated into a production line environment. Included in the CleanTech product line are the CleanTech Titan Express, CleanTech MegaCenter and the portable CleanTech Handheld which is useful in the field or on the factory floor. The CleanTech Systems operate in full compliance with OSHA, FDA and CDRH staconforming to “Push a Button” laser safety industrial operation. The CleanTech Systems offer CE Certified Class 1 enclosure for the Class 4 lasers.

CleanTech™ Laser Cleaning Robot with AI

With our user programmable AI (UPAI) incorporated in our C-Robots, factory line workers can quickly and easily program these precision robots to complete complex and repetitive tasks in high throughput production environments. The CleanTech™ Laser Cleaning Robot is the first commercially available collaborative, easily programmable, AI-capable laser cleaning system in the United States. Designed for precise positioning and tight focusing of the laser beam, laser cleaning processes are optimized to operate on much lower laser powers than those used by handheld laser cleaners. This allows for dramatic cost reduction of laser cleaning, making it affordable for the majority of industrial companies. It also reduces concerns over safety for the factory line workers since the robot can perform multiple tasks at the same time when equipped with AI module, 3D scanner and visualizer, vision system and Class 1 Safety shroud or enclosure.

Customers

Our intent is to establish additional relationships with Fortune 1000 customers primarily within the United States and with select Fortune 1000 customers around the globe and represent a broad array of industries, including automotive, aerospace, healthcare, consumer products, heavy industry, machine design, research, and others. No single customer has accounted for more than 10% of our total revenue from inception to date.

Research, Development and Engineering

The principal focus of our research and development activity is the development of our proprietary laser-based cleaning equipment to replace global sand blasting and abrasive blasting applications in a large number of markets discussed below.

Marketing and Sales

For the year ended December 31, 2022, we achieved sales of $4,954,689 and employed four salesmen. We have a marketing and sales budget equal to 10% of our gross sales, and a new product promotional budget of $1,000,000 for 2023.

Product Warranty and Support

We offer for sale with our equipment a two-year limited warranty against defects in materials and workmanship under normal use and service conditions following delivery of our equipment to our customers.

We also warrant to the owners of our custom laser systems that they are designed and manufactured in accordance with agreed-upon specifications. In resolving claims under both the defects and performance warranties, we have the option of either repairing or replacing the covered laser cleaning equipment. Our warranties are automatically transferred from the original purchaser of our laser cleaning equipment and optical components to subsequent purchasers upon delivery of our finished laser systems.

| 14 |

| Table of Contents |

In general, our products carry a warranty against defects, depending on the product type and customer negotiations. The costs associated with these warranty obligations are not expected to be significant and no such costs have been recorded in our financial statements.

Competition

In the laser cleaning market, the competition is fragmented with a few competitors that are small or privately owned, or which compete with us on a limited geographic, industry, or application specific basis. Nonetheless, our markets are highly competitive and characterized by rapid advances in technology, evermore demanding customer requirements, and reduced average selling prices as smaller, integrated components replace aging technologies. Our most significant competitors are P-Laser and Clean-Lasersysteme GmbH (operating through the distributor Adapt Laser Systems in the United States) as well as smaller companies, including Laserax and 4 Jet. Some of our competitors are increasing the output powers of their fiber lasers to compete with our high-powered, industrial grade products.

We also compete with end-users who produce laser technology, as well as with manufacturers of non-laser methods and tools, such as traditional abrasives blasting (referred to as sandblasting), non-laser welding, cutting dies, mechanical cutters, and plasma cutters in the materials processing market. Some of our competitors are larger, with considerably more financial, managerial and technical resources, as well as more extensive sales, distribution, and service networks, and greater marketing capacity.

Our primary focus is to provide diversified industrial-grade laser-based cleaning machinery in a variety of markets. Each market has different group of competitors subject to rapidly changing technologies and materials, a customer base with continuously changing requirements and geographical outsourcing challenges.

We believe that our future success is dependent on our flexibility to adapt to changes in the marketplace expanding our existing products and services targeting application specific systems for each industry we serve. We continuously introduce new products and services on a timely and cost-effective basis identifying both standard and niche laser-systems opportunities enhancing our ability to penetrate new customers and new emerging markets.

Primary competitive factors in our markets include:

| • | Price and value |

|

|

|

| • | Ability to design, manufacture, and deliver new products on a cost-effective and timely basis |

|

|

|

| • | Ability of our suppliers to produce and deliver components in a timely manner, in the quantity desired and at the budgeted prices |

|

|

|

| • | Product performance and reliability |

|

|

|

| • | Service support |

|

|

|

| • | Product mix |

|

|

|

| • | Ability to meet customer specifications |

|

|

|

| • | Ability to respond quickly to changes in market demand and technology developments |

| 15 |

| Table of Contents |

In the materials processing market, the competition is fragmented with a large number of competitors that are small or privately owned or compete with us on a limited geographic, industry, or application specific basis including Trumpf GmbH, Clean Laser GMBH, P-Laser. Advanced Laser Technology, Anilox Roll Cleaning Systems, General Lasertronics, IPGPhotonics, Laserax, and White Lion Dry Ice & Laser Cleaning Technology. We believe that none of our competitors compete in all the industries, applications, and geographical markets which we serve and that our products compete favorably with respect to their laser cleaning equipment.

Intellectual Property and License Rights

We believe that our success depends, in part, on our ability to maintain and protect our proprietary technology and to conduct our business without infringing on the proprietary rights of others.

We rely primarily on a combination of trademarks and trade secrets, as well as associate and third-party confidentiality agreements, to safeguard our intellectual property.

With respect to proprietary know-how that is not patentable and processes for which patents are difficult to enforce, we rely on, among other things, trade secret protection and confidentiality agreements to safeguard our interests. We believe that many elements of our laser system manufacturing process, including our unique materials sourcing, involve proprietary know-how, technology, or data that are not covered by patents or patent applications, including technical processes, equipment designs, algorithms, and procedures. We have taken security measures to protect these elements. All of our research and development personnel will have to sign confidentiality and proprietary information agreements with us. These agreements address intellectual property protection issues and require our associates to assign to us all of the inventions, designs, and technologies they develop during the course of employment with us. We also require our customers and business partners to enter into confidentiality agreements before we disclose any sensitive aspects of our modules, technology, or business plans.

Employees and Human Capital

As of February 15, 2022, we had 23 full time employees and one part-time employee. Our human capital resources objectives include, as applicable, identifying, recruiting, retaining, incentivizing and integrating our existing and new employees, advisors and consultants.

Government Regulation

Our current and contemplated activities and the products and processes that will result from such activities are subject to substantial government regulation, both in the United States and internationally.

Government Contracts and Regulations

Our U.S Government business is heavily regulated. We contract with a number of U.S. Government agencies and entities, principally all branches of the U.S. military. We must comply with, and are affected by, laws and regulations relating to the formation, administration and performance of U.S. Government contracts. These laws and regulations, among other things:

| • | require certification and disclosure of all cost or pricing data in connection with certain types of contract negotiations; |

|

|

|

| • | impose specific and unique cost accounting practices that may differ from U.S. generally accepted accounting principles (GAAP); |

|

|

|

| • | impose acquisition regulations, which may change or be replaced over time, that define which costs can be charged to the U.S. Government, how and when costs can be charged, and otherwise govern our right to reimbursement under certain U.S. Government contracts; |

|

|

|

| • | require specific security controls to protect U.S. Government controlled unclassified information and restrict the use and dissemination of information classified for national security purposes and the export of certain products, services and technical data; and compliance with cyber security regulations by our supply chain; and |

|

|

|

| • | require the review and approval of contractor business systems, defined in the regulations as: (i) Accounting System; (ii) Estimating System; (iii) Earned Value Management System, for managing cost and schedule performance on certain complex programs; (iv) Purchasing System; (v) Material Management and Accounting System, for planning, controlling and accounting for the acquisition, use, issuing and disposition of material; and (vi) Property Management System. |

| 16 |

| Table of Contents |

The U.S. Government may terminate any of our government contracts and subcontracts either at its convenience or for default based on our performance. If a contract is terminated for convenience, we generally are protected by provisions covering reimbursement for costs incurred on the contract and profit on those costs. If a contract is terminated for default, we generally are entitled to payments for our work that has been accepted by the U.S. Government or other governments; however, the U.S. Government could make claims to reduce the contract value or recover its procurement costs and could assess other special penalties. For more information regarding the U.S. Government’s right to terminate our contracts and government contracting laws and regulations, see “Risk Factors”.

Radiation Control for Health and Safety Act

We are subject to the laser radiation safety regulations of the Radiation Control for Health and Safety Act administered by the National Center for Devices and Radiological Health, a branch of the United States Food and Drug Administration. Among other things, those regulations require laser manufacturers to file new product and annual reports, to maintain quality control and sales records, to perform product testing, to distribute appropriate operating manuals, to incorporate design and operating features in lasers sold to end-users and to certify and label each laser sold to end-users as one of four classes (based on the level of radiation from the laser that is accessible to users). Various warning labels must be affixed and certain protective devices installed depending on the class of product. The National Center for Devices and Radiological Health is empowered to seek fines and other remedies for violations of the regulatory requirements.

CE Marking

We are subject to certain regulations in Europe as administered by the European Commission. CE Marking is required for products marketed within the European Economic Area (EEA) and confirms that the manufacturer meets certain safety, health and environmental protection requirements administered by the European Union. Non-compliance with these regulations could result in warnings, penalties or fines. We believe that we are currently in compliance with these regulations.

United States Food and Drug Administration

Certain products manufactured by us are integrated into systems by our customers that are subject to certain regulations administered by the United States Food and Drug Administration. We must comply with certain quality control measurements for our products to be effectively used in our customers’ end products. Non-compliance with quality control measurements could result in loss of business with our customers, fines and penalties.

Facility

On December 1, 2019, we entered a sub-lease with ICT Investments for 5,000 sf of manufacturing space on a month-to-month basis at $4,050 per month. In January of 2020, we expanded the lease with ICT Investments to include the entire facility of 18,000 sf. In October of 2021, a direct lease was signed with the landlord for three years, terminating on October 31, 2024. The facility is currently equipped with three of our latest advanced laser cleaning demonstration models. It includes a materials stock room, a ramp and high dock, loading and moving equipment, a machine shop, an electronics room, and an equipment assembly area. The monthly rent for this facility is currently $15,549.

| 17 |

| Table of Contents |

In December of 2022, we entered into an agreement with 2701 Maitland Building Associates to rent 8,000 sf of additional office space nearby the main facility, for our growing sales and marketing program. The monthly rent for this space is currently $14,805.

Our facility is currently equipped with three of our latest advanced laser cleaning demonstration models.

| 18 |

| Table of Contents |

Laser Blaster Systems

Item 1A. RISK FACTORS

Summary of Risk Factors

An investment in our securities involves a high degree of risk. The occurrence of one or more of the events or circumstances described in the section titled “Risk Factors,” alone or in combination with other events or circumstances, may materially adversely affect our business, financial condition and operating results. In that event, the trading price of our securities could decline, and you could lose all or part of your investment. Such risks include, but are not limited to:

| • | We have a limited operating history so there is a lack of historical data on which to determine whether we can be a commercially viable company. |

|

|

|

| • | We are competing in highly competitive market and to compete effectively we must be able to adapt to technology changes and to implement innovative technology applications. |

|

|

|

| • | ICT Investments owns a majority of our outstanding shares and exerts significant control over business decisions as well as matters subject to stockholder approval. |

|

|

|

| • | We depend on the U.S. Government for a portion of our business, which we expect to increase, and changes in government defense spending could have adverse consequences on our financial position, results of operations and business. |

|

|

|

| • | As a U.S. defense contractor, we are vulnerable to security threats and other disruptions that could negatively impact our business. |

|

|

|

| • | Our international business exposes us to geo-political and economic factors, regulatory requirements and other risks associated with doing business in foreign countries. |

|

|

|

| • | Our success may depend on our ability to obtain and protect the proprietary information on which we base our laser-based cleaning equipment. The patent application process is expensive and time-consuming, and we and our current or future licensors and licensees may not be able to prepare, file and prosecute all necessary or desirable patent applications at a reasonable cost or in a timely manner. It is also possible that we or our current licensors, or any future licensors or licensees, will fail to identify patentable aspects of inventions made in the course of development and commercialization activities before it is too late to obtain patent protection on them. |

| 19 |

| Table of Contents |

| • | If we are sued for infringing intellectual property rights of third parties, it will be costly and time consuming, and an unfavorable outcome in that litigation could harm our business. |

|

|

|

| • | Some provisions of our certificate of incorporation and bylaws may deter takeover attempts, which may inhibit a takeover that stockholders consider favorable and limit the opportunity of our stockholders to sell their shares at a favorable price. |

|

|

|

| • | Our indemnification of our officers and directors may cause us to use corporate resources to the detriment of our stockholders. |

|

|

|

| • | Provisions in our certificate of incorporation and bylaws and Delaware law may have the effect of discouraging lawsuits against our directors and officers. |

|

|

|

| • | If our shares of common stock become subject to the penny stock rules, it would become more difficult to trade our shares. If we do not obtain or retain a listing on the Nasdaq Capital Market and if the price of our common stock is less than $5.00 per share, our common stock will be deemed a penny stock. |

Risks Related to our Business and Our Industry

We have an extremely limited operating history.

With respect to the manufacturing and sale of laser-based cleaning equipment, we are still akin to a start-up company with limited historical sales of our laser-based cleaning products. There is little historical basis with which to make judgments regarding the capabilities of our enterprise to produce a widely commercially accepted product leading to ongoing and growing profitability.

We may need to raise additional capital.

While we expect that the funds from our IPO will meet our financing requirements for the next two to three years, if, in the future, we are not able to generate sufficient revenues from operations and our capital resources are insufficient to meet future requirements, we may have to raise additional funds to allow us to continue to commercialize, market and sell our products. We cannot be certain that funding will be available on acceptable terms or at all. To the extent that we raise additional funds by issuing equity securities, our stockholders may experience dilution. Any debt financing, if available, may involve restrictive covenants that may impact our ability to conduct business or return capital to investors. If we are unable to raise additional capital if required or on acceptable terms, we may have to significantly scale back, delay or discontinue the development and/or commercialization of our laser-based cleaning products, restrict our operations or obtain funds by entering into agreements on unattractive terms.

If our proposed marketing efforts are unsuccessful, we may not earn enough revenue to scale the business profitably.

Our success will depend on investment in marketing resources and the successful implementation of our marketing plan. Our marketing plan involves attendance at trade shows, conducting private demonstrations, utilizing promotional materials, and employing advertising campaigns in print and/or broadcast media. We cannot give any assurance that our marketing efforts will be successful. If they are not, revenue may be insufficient to cover our growing fixed costs and we may suffer a reduction in profitability.

We have a large amount of intangible assets, and if these assets become impaired, our earnings would be adversely affected.

We have a substantial amount of intangible assets, representing approximately 15% of our total assets as of December 31, 2022. While we amortize our intangible assets, they may be subject to impairment testing. If we experience any significant impairment to our intangible assets, it may have a material adverse effect on our reported financial results for the period in which the charge is taken and could result in a decrease in the market price of our common stock.

| 20 |

| Table of Contents |

The Coronavirus pandemic could delay or eliminate current and future purchase orders for our laser-based cleaning equipment that could prevent us from achieving our business plan.

As the Covid-19 outbreak and the associated global response continue to evolve, our financial condition, liquidity, and operational results could be jeopardized. Our operations entail the soliciting of additional purchase orders from new and existing customers alike; meanwhile, the Covid-19 outbreak could reduce or eliminate the demand for our equipment as a result of factory closures or slowdowns on the part of our customers, disrupt supply lines, cause employee absences, precipitate travel restrictions, and otherwise impair the demand for our equipment. As a consequence, our sales pipeline could shrink and our business outlook might deteriorate if we are unable to adjust to a reduction in cash flow and raise more capital on acceptable terms.

We may be unable to respond to rapid technology changes and innovative products.

In a constantly changing and innovative technology market with frequent new product introductions, enhancement and modifications, we may be forced to implement and develop new technologies into our products for anticipation of changing customer requirements that may significantly impact costs in order to retain or enhance our competitive position in existing and new markets.

There is intense competition in our market.

There is intense competition amongst manufacturers of crystalline silicon laser modules, thin-film laser modules, solar thermal lasers, and concentrated fiber laser systems. Our management is aware that failure to compete away eventual new entrants will affect overall business prospects and the product itself. Therefore, if we are able to innovate more quickly, we will be better able to defend our pricing power. Competitive factors in this market are all related to product performance, price, customer service, training platforms, reputation, and sales and marketing effectiveness, all of which are factors upon which we believe we can compete successfully but will need greater financial resources to do so.

Future acquisitions may be unsuccessful and may negatively affect operations and financial condition.

We plan to grow organically; however, we will opportunistically pursue potential acquisitions of complementary businesses. Should we acquire other companies, the integration of businesses, personnel, product lines, and technologies might prove to be difficult, time consuming, and risky. Any difficulties could disrupt our ongoing business, distract our management and employees, increase our expenses, and impair our revenue and results of operations.

If we are unable to hire additional personnel, we will have trouble growing our business.

Our future success depends on our ability to attract, retain, and motivate skilled marketing, managerial, operational, and administrative personnel. We plan to hire additional personnel in all areas of our business as we grow. Competition for qualified personnel is intense. As a result, we may be unable to attract and retain qualified personnel. We may also be unable to retain the employees that we currently employ. The failure to attract and retain highly competent personnel could seriously harm our business, financial condition, and operational results.

Our business depends on experienced and highly-skilled technicians and business development personnel, and if we are unable to attract such talent, it will be more difficult for us to manage our business and complete contracts.

The success of our business depends on the skill of our personnel. Accordingly, it is critical that we maintain, and continue to build, a highly experienced management team and specialized workforce, including designers, engineers, and sales professionals. Competition for personnel – particularly those with expertise in government consulting and who possess a security clearance – is high, and identifying candidates with the appropriate qualifications can be costly and difficult. We may not be able to hire the necessary personnel to implement our business strategy given our anticipated hiring needs, or we may need to provide higher compensation or more training to our personnel than we currently anticipate. In addition, our ability to recruit, hire, and indirectly deploy former employees of the U.S. Government is subject to complexlaws and regulations, which may serve as an impediment to our ability to attract such talent.

| 21 |

| Table of Contents |

Our business is labor intensive and our success depends on our ability to attract, retain, train and motivate highly skilled employees, including employees who may become part of our organization in connection with our acquisitions. The increase in demand for consulting, technology integration, and managed services has further increased the need for employees with specialized skills or significant experience in these areas. We may not be successful in attracting and retaining enough employees to achieve our desired staffing and expansion objectives. Furthermore, the industry turnover rates for these types of employees are high and we may not be successful in retaining, training or motivating them. Any inability to attract, retain, train, and motivate skilled talent could impair our ability to adequately manage and complete existing projects, not to mention restrict our ability to accept new client engagements. Such inability may also force us to increase our hiring of independent contractors, which may increase our costs and reduce our profitability on client engagements. We must also devote substantial managerial and financial resources to monitoring and managing our workforce. Our future success will depend on our ability to manage the levels and related costs of our workforce.

In the event we are unable to attract, hire and retain the requisite personnel and subcontractors, we may experience delays in completing contracts in accordance with project schedules and budgets, which may have an adverse effect on our financial results, harm our reputation, and cause us to curtail our pursuit of new contracts. Further, any increase in demand for personnel may result in higher costs, causing us to exceed the budget on a contract, which in turn may have an adverse effect on our business, financial condition, and operating results, as well as harm our customer relationships.

We face a higher risk of failure because we cannot accurately forecast our future revenues and operating results.

The rapidly changing nature of the markets in which we compete makes it difficult to accurately forecast our revenues and operating results. Moreover, we expect our future revenues and operating results to fluctuate due to a number of factors, including the following:

| • | the timing of sales of our products; |

|

|

|

| • | unexpected delays in the introduction of new products; |

|

|

|

| • | increased expenses, whether related to sales and marketing, or administration; and |

|

|

|

| • | costs related to anticipated acquisitions of complementary businesses. |

Our products may suffer defects.

Our products may suffer defects that may lead to substantial product liability, damage, or warranty claims. Given the complexity of the platforms and systems inside our products, the potential for errors and defects is heightened. Significant expenses arising from product liability or warranty claims could have a material adverse effect on our business, financial condition, and operating results.

We need to increase the size and scale of our organization, and we may experience difficulties in managing such growth, which might impair our financial performance.

We need to strengthen our managerial, operational, and accounting infrastructure, in addition to integrating employees retained from other companies that we might acquire. Future growth will impose significant added responsibilities on members of management, including the need to identify, recruit, maintain, and integrate new employees. Our future financial performance and our ability to commercialize our products will depend, in part, on our ability to manage any future growth effectively.

| 22 |

| Table of Contents |

In order to manage our future growth, we will need to continue to effect improvements in our managerial, operational, and accounting controls. All of these measures will require significant expenditures and will demand the attention of management. If we fail to continue making enhancements to our operational and financial controls in support of the growth in our business, we could develop operating and reporting inefficiencies that could increase our costs more than we had planned, as well as impair our competitive position. If we are unable to manage growth effectively, our business, financial condition, and operating results could be adversely affected.

Insurance and contractual protections may not always cover lost revenue, increased expenses or liquidated damages payments, which could adversely affect our financial results.

Although we maintain insurance and intend to obtain warranties from suppliers, obligate subcontractors to meet certain performance levels and attempt, where feasible, to pass risks we cannot control to our customers, the proceeds of such insurance, warranties, performance guarantees or risk sharing arrangements may not be adequate to cover lost revenue, increased expenses or liquidated damages payments that may be required in the future.

Internal system or service failures could disrupt our business and impair our ability to effectively provide our services and products to our customers, which could damage our reputation and adversely affect our revenues and profitability.