Exhibit 96.1

TECHNICAL REPORT SUMMARY FOR THE

SLEEPER GOLD-SILVER PROJECT,

HUMBOLDT COUNTY, NEVADA, USA

TECHNICAL REPORT SUMMARY FOR THE SLEEPER GOLD-SILVER PROJECT,

HUMBOLDT COUNTY, NEVADA, USA

SK1300 REPORT RSI(RNO)-M0144.21001 REV 7

PREPARED FOR

Paramount Gold Nevada

665 Anderson Street

Winnemucca, Nevada, USA 89445

PREPARED BY

RESPEC

210 South Rock Boulevard

Reno, Nevada, USA 89502

|

EFFECTIVE DATE: JUNE 30, 2023

REPORT DATE: AUGUST 31, 2023

Project Number M0144.21001

RESPEC.COM |

| |||

TABLE OF CONTENTS

| 1.0 |

EXECUTIVE SUMMARY |

1 | ||||||

| 1.1 |

Property Description and Ownership |

1 | ||||||

| 1.2 |

Geology and Mineralization |

1 | ||||||

| 1.3 |

Status of Exploration, Development and Operations |

2 | ||||||

| 1.4 |

Metallurgical Testing and Mineral Processing |

2 | ||||||

| 1.5 |

Mineral Resource Estimate |

4 | ||||||

| 1.6 |

Conclusions and Recommendations |

5 | ||||||

| 2.0 |

INTRODUCTION |

6 | ||||||

| 2.1 |

Sources of Information |

6 | ||||||

| 2.2 |

Personal Inspections |

6 | ||||||

| 2.3 |

Effective Date |

7 | ||||||

| 2.4 |

Units of Measure and Frequently Used Acronyms |

7 | ||||||

| 3.0 |

PROPERTY DESCRIPTION AND LOCATION |

10 | ||||||

| 3.1 |

Property Location |

10 | ||||||

| 3.2 |

Property Area and Claim Types |

11 | ||||||

| 3.3 |

Mineral Rights |

11 | ||||||

| 3.4 |

Significant Encumbrances and Permitting |

12 | ||||||

| 3.5 |

Royalties |

13 | ||||||

| 3.6 |

Significant Factors and Risks |

14 | ||||||

| 4.0 |

ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY |

15 | ||||||

| 4.1 |

Topography, Elevation and Vegetation |

15 | ||||||

| 4.2 |

Access to the Property |

15 | ||||||

| 4.3 |

Climate and Length of Operating Season |

15 | ||||||

| 4.4 |

Infrastructure |

15 | ||||||

| 5.0 |

HISTORY |

16 | ||||||

| 5.1 |

Historical Production |

16 | ||||||

| 5.1.1 |

Early mining: 1914 to 1982 |

16 | ||||||

| 5.1.2 |

AMAX: 1982 to 1996 |

16 | ||||||

| 5.2 |

Historical Exploration |

17 | ||||||

| 5.2.1 |

AMAX 1982 - 1998 |

21 | ||||||

| 5.2.2 |

X-Cal Resources Ltd 1993 - 1997 |

21 | ||||||

| 5.2.3 |

Placer Dome 1997 |

22 | ||||||

| 5.2.4 |

X-Cal 1998 - 2003 |

22 | ||||||

| 5.2.5 |

New Sleeper Gold 2004 - 2006 |

23 | ||||||

| 5.2.6 |

X-Cal 2006-2010 |

24 | ||||||

| 5.2.7 |

Evolving Gold 2007 - 2008 |

27 | ||||||

|

i

RSI(RNO)-M0144.21001 REV 5 |

| 5.2.8 |

Montezuma Mines 2009-2012 |

28 | ||||||

| 5.2.9 |

Paramount Gold and Silver Corp. Acquisition 2010 |

28 | ||||||

| 5.3 |

Historical Mineral Resource Estimates |

28 | ||||||

| 6.0 |

GEOLOGIC SETTING, DEPOSIT TYPE, AND MINERALIZATION |

30 | ||||||

| 6.1 |

Regional Geologic Setting |

30 | ||||||

| 6.2 |

District and Local Geology |

30 | ||||||

| 6.3 |

Mineralization |

37 | ||||||

| 6.4 |

Deposit Types |

39 | ||||||

| 7.0 |

EXPLORATION |

41 | ||||||

| 7.1 |

Paramount Geophysical Surveys 2010 - 2013 |

41 | ||||||

| 7.1.1 |

2012 Gravity 2012 |

41 | ||||||

| 7.1.2 |

Induced Polarization Survey 2012 |

42 | ||||||

| 7.1.3 |

Airborne Magnetic Survey 2015 |

42 | ||||||

| 7.2 |

Paramount Drilling 2010 - 2013 |

43 | ||||||

| 7.2.1 |

2010-2011 Paramount Drill program |

44 | ||||||

| 7.2.2 |

2012-2013 Paramount Drill program |

45 | ||||||

| 7.2.3 |

2021 Paramount Drilling |

45 | ||||||

| 7.3 |

Paramount Exploration Assessment 2020 |

46 | ||||||

| 7.4 |

Hydrogeology |

46 | ||||||

| 7.5 |

Geotechnical Data |

46 | ||||||

| 8.0 |

SAMPLE PREPARATION, ANALYSIS, AND SECURITY |

47 | ||||||

| 8.1 |

Historical Sample Preparation, Analysis, Quality Assurance/Quality Control Procedures and Historical Sample Security |

47 | ||||||

| 8.1.1 |

AMAX, Placer DOME, and X-Cal 1983 - 2002 |

47 | ||||||

| 8.1.2 |

New Sleeper Gold 2004 - 2005 |

48 | ||||||

| 8.1.3 |

X-Cal 2003 - 2007 |

49 | ||||||

| 8.1.4 |

Evolving Gold 2009 |

51 | ||||||

| 8.1.5 |

Montezuma Mines 2011 - 2012 |

51 | ||||||

| 8.2 |

Paramount Sample Preparation, Analyses, Sample Security and Quality Assurance/Quality Control Procedures |

51 | ||||||

| 8.3 |

Quality Assurance/Quality Control Results |

54 | ||||||

| 8.3.1 |

X-Cal Historical Quality Assurance/Quality Results |

58 | ||||||

| 8.3.1.1 CRMs 2003-2007 |

58 | |||||||

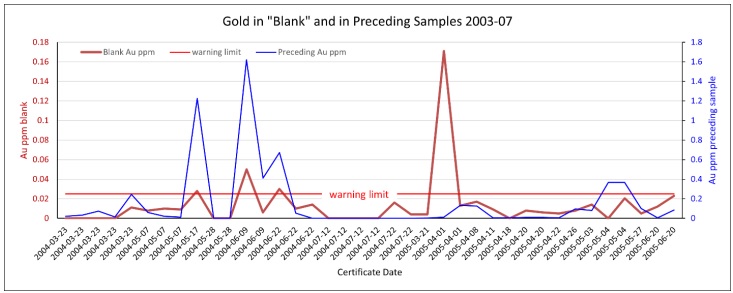

| 8.3.1.2 Blanks 2003 - 2007 |

58 | |||||||

| 8.3.1.3 Duplicates 2003 - 2007 |

59 | |||||||

| 8.3.2 |

Paramount Quality Assurance/Quality Control Results |

63 | ||||||

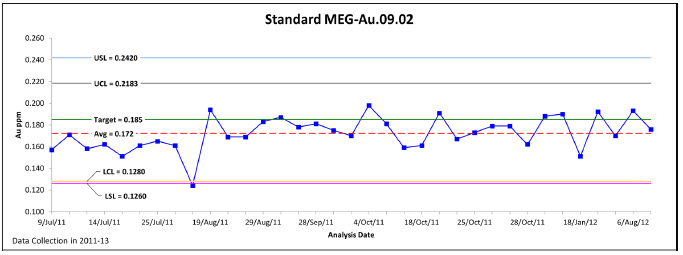

| 8.3.2.1 CRMs 2010-2013 |

63 | |||||||

| 8.3.2.2 Blanks 2010-2013 |

66 | |||||||

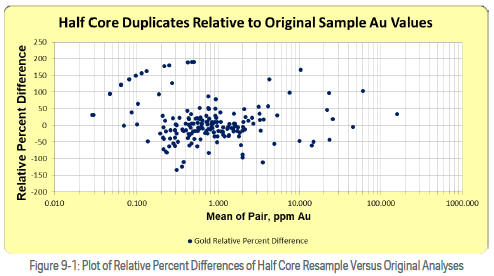

| 8.3.2.3 Paramount Duplicates |

67 | |||||||

| 8.4 |

Adequacy of Sample Preparation, Analyses and Security |

69 | ||||||

|

ii

RSI(RNO)-M0144.21001 REV 5 |

| 9.0 |

DATA VERIFICATION |

70 | ||||||

| 9.1 |

Site Visit |

70 | ||||||

| 9.2 |

Drilling Database Verification |

70 | ||||||

| 9.2.1 |

Phase 1 – Logic Tests |

70 | ||||||

| 9.2.2 |

Phase 2 – Collar, Survey and assay Verification |

71 | ||||||

| 9.2.2.1 Drill Collar Locations |

71 | |||||||

| 9.2.2.2 Down-Hole Surveys |

71 | |||||||

| 9.2.2.3 Drilling Assay Database |

71 | |||||||

| 9.2.3 |

Resampling Programs |

72 | ||||||

| 9.2.4 |

Down-Hole Contamination |

73 | ||||||

| 9.2.5 |

Geologic Data |

74 | ||||||

| 9.3 |

Adequacy of Data |

74 | ||||||

| 10.0 |

MINERAL PROCESSING AND METALLURGICAL TESTING |

75 | ||||||

| 10.1 |

Parmount Metallurgical Tests |

75 | ||||||

| 10.1.1 |

Test Series #1 |

75 | ||||||

| 10.1.2 |

Test Series #2 |

76 | ||||||

| 10.2 |

Discussion |

79 | ||||||

| 10.2.1 |

Test Series #1 |

79 | ||||||

| 10.2.2 |

Test Series #2 |

85 | ||||||

| 10.3 |

Conclusion and Recommendations |

93 | ||||||

| 10.3.1 |

Test Series #1 |

93 | ||||||

| 10.3.2 |

Test Series #2 |

94 | ||||||

| 10.3.3 |

Recovery Projections |

95 | ||||||

| 10.3.4 |

Hybrid Process Recommendations |

95 | ||||||

| 10.4 |

Summary Statement for Paramount Metallurgical testing |

95 | ||||||

| 11.0 |

MINERAL RESOURCE ESTIMATES |

96 | ||||||

| 11.1 |

Introduction |

96 | ||||||

| 11.2 |

Database |

97 | ||||||

| 11.2.1 |

Drill hole Database |

97 | ||||||

| 11.2.2 |

Topography |

98 | ||||||

| 11.3 |

Deposit Modeling Relevant to Resource Estimation |

98 | ||||||

| 11.4 |

Geologic Modeling |

99 | ||||||

| 11.5 |

Oxidation Modeling |

100 | ||||||

| 11.6 |

Density Modeling |

100 | ||||||

| 11.7 |

Gold and Silver Modeling |

101 | ||||||

| 11.7.1 |

Mineral Domains |

101 | ||||||

| 11.7.2 |

Assay Coding, Capping, and Compositing |

107 | ||||||

| 11.7.3 |

Block Model Coding |

112 | ||||||

| 11.7.4 |

Grade Interpolation |

113 | ||||||

|

iii

RSI(RNO)-M0144.21001 REV 5 |

| 11.8 |

Mineral Resources |

115 | ||||||

| 11.8.1 |

Classification |

122 | ||||||

| 11.9 |

Discussion of Resources |

123 | ||||||

| 12.0 MINERAL RESERVE ESTIMATES |

125 | |||||||

| 13.0 MINING METHODS |

126 | |||||||

| 14.0 PROCESSING AND RECOVERY METHODS |

127 | |||||||

| 15.0 INFRASTRUCTURE |

128 | |||||||

| 16.0 MARKET STUDIES |

129 | |||||||

| 17.0 ENVIRONMENTAL STUDIES, PERMITTING, AND PLANS, NEGOTIATIONS, OR AGREEMENTS WITH LOCAL INDIVIDUALS OR GROUPS |

130 | |||||||

| 18.0 CAPITAL AND OPERATING COSTS |

131 | |||||||

| 19.0 ECONOMIC ANALYSIS |

132 | |||||||

| 20.0 ADJACENT PROPERTIES |

133 | |||||||

| 21.0 OTHER RELEVANT DATA AND INFORMATION |

134 | |||||||

| 22.0 INTERPRETATIONS AND CONCLUSIONS |

135 | |||||||

| 22.1 |

Adequecy of the data used in Estimating the project Mineral Resources |

135 | ||||||

| 22.2 |

Geology and Mineralization |

135 | ||||||

| 22.3 |

Metallurgy and Processing |

136 | ||||||

| 22.4 |

Mineral Resources, Mining Methods, and Mine Planning |

136 | ||||||

| 22.5 |

Exploration Potential |

136 | ||||||

| 23.0 RECOMMENDATIONS |

137 | |||||||

| 23.1 |

Resource Update and Preliminary Economic Analysis |

137 | ||||||

| 23.2 |

Infill Drilling Program |

137 | ||||||

| 23.3 |

Metallurgical Test Work |

137 | ||||||

| 23.4 |

Pre-Feasibility Study |

138 | ||||||

| 24.0 REFERENCES |

139 | |||||||

| 25.0 RELIANCE ON INFORMATION PROVIDED BY THE REGISTRANT |

142 | |||||||

| APPENDIX A LIST OF UNPATENTED LODE MINING CLAIMS OF THE SLEEPER PROPERTY |

1 | |||||||

|

iv

RSI(RNO)-M0144.21001 REV 5 |

LIST OF TABLES

| TABLE |

PAGE | |||

| Table 1-1 Sleeper Total In-Pit Gold and Silver Resources – Measured & Indicated |

4 | |||

| Table 1-2. Cost Estimate for the Recommended Program |

5 | |||

| Table 2-1. List of Units, Acronyms, and Abbreviations |

7 | |||

| Table 3-1. Summary of Annual Property Holding Costs |

12 | |||

| Table 5-1. Summary of Sleeper Deposit Drilling in RESPEC Database |

18 | |||

| Table 5-2. Geophysical Surveys Conducted at the Sleeper Property |

20 | |||

| Table 5-3. 2004 and 2005 Drill Footage Summary |

23 | |||

| Table 5-4. Summary of Historical Mineral Resource Estimates, Sleeper Property |

29 | |||

| Table 7-1. Paramount Drilling in 2010 - 2013 |

43 | |||

| Table 8-1. Paramount Blank Materials for 2010-2013 |

53 | |||

| Table 8-2. Summary Counts of Sleeper QA/QC Analyses |

56 | |||

| Table 8-3: Summary of Results for X-Cal Historical and Paramount Field Duplicates |

57 | |||

| Table 8-4. Summary of Results for Blanks 2003 - 2013 |

58 | |||

| Table 8-5. X-Cal Blank Failures and Preceding Samples 2003-2007 |

58 | |||

| Table 8-6: CRMs used by Paramount |

63 | |||

| Table 8-7. Summary of Sleeper Gold Results for Certified Reference Materials 2010-2013 |

64 | |||

| Table 8-8. Gold Failures in the 2010-2013 Drill Program |

64 | |||

| Table 8-9. Summary of Sleeper Silver Results for Certified Reference Materials, 2010-2013 |

66 | |||

| Table 10-1. Waste Dump Composite Make-Up Information |

79 | |||

| Table 10-2. Summary Metallurgical Results, Agitated Cyanidation Tests, Sleeper Waste Dump Composites, P80 19mm |

||||

| Feeds |

80 | |||

| Table 10-3. Summary Metallurgical Results, Bulk Sulfide Flotation Tests (for Ro. Concs.), North Waste Dump |

||||

| Composites, P80 75µm Feeds |

80 | |||

| Table 10-4. West Wood and Facilities Composite Make-Up Information |

81 | |||

| Table 10-5. Summary Metallurgical Results, Agitated Cyanidation Tests, Westwood and Facilities Core Composites, |

||||

|

P80 19mm Feeds and P80 75µm Feeds |

82 | |||

| Table 10-6. Summary Metallurgical Results, Bulk Sulfide Flotation Tests (for Ro. Concs.), Westwood and Facilities Core |

||||

| Composites, P80 75µm Feeds |

83 | |||

| Table 10-7. Summary Column Percolation Leach Test Results, |

85 | |||

| Table 10-8. Sleeper Project Composite Make-Up Information |

86 | |||

| Table 10-9. Metallurgical Scope of Work Summary, Sleeper Project Core Composites |

87 | |||

| Table 10-10. Summary Metallurgical Results, Bottle Roll Tests, Sleeper Project Core Composites, Varied Feed Sizes |

87 | |||

| Table 10-11. Summary Metallurgical Results, Column Leach Tests, Sleeper Project Core Composites, P80 37.5 and P80 |

||||

| 19mm Feeds (BT Results Included for Comparison) |

89 | |||

|

v

RSI(RNO)-M0144.21001 REV 5 |

| Table 10-12. Summary Metallurgical Results, Cyanidation (CIL) Tests, Sleeper Drill Core Composites, 80%-45µm Feed |

||||

| Size |

90 | |||

| Table 10-13. Summary Metallurgical Results, Continuous Column Leach Tests, Sleeper Drill Core Composites |

91 | |||

| Table 11-1. Summary of Drilling in the Database for the Sleeper Deposit Resource Estimate |

97 | |||

| Table 11-2. Descriptive Statistics of Sample Assays in Sleeper Drill hole Database |

98 | |||

| Table 11-3. Sleeper Deposit Applied Densities and Tonnage Factors |

100 | |||

| Table 11-4. Approximate Grade Ranges of Gold and Silver Domains |

101 | |||

| Table 11-5. Sleeper Gold and Silver Assay Caps by Domain |

107 | |||

| Table 11-6. Descriptive Statistics of Sleeper Coded Gold Assays |

107 | |||

| Table 11-7. Descriptive Statistics of Sleeper Coded Silver Assays |

109 | |||

| Table 11-8. Descriptive Statistics of Sleeper Gold Composites |

111 | |||

| Table 11-9. Descriptive Statistics of Sleeper Silver Composites |

112 | |||

| Table 11-10. Sleeper Search-Ellipse Orientations and Maximum Search Distances by Estimation Area |

113 | |||

| Table 11-11. Sleeper Estimation Parameters |

114 | |||

| Table 11-12. Pit Optimization Parameters |

115 | |||

| Table 11-13. Sleeper Gold and Silver Mineral Resources |

117 | |||

| Table 23-1 Paramount’s Recommended Work Program |

137 | |||

|

vi

RSI(RNO)-M0144.21001 REV 5 |

LIST OF FIGURES

| FIGURE |

PAGE | ||||

| Figure 3-1. Location Map for the Sleeper Property |

10 | ||||

| Figure 3-2: Sleeper Property Location Map |

12 | ||||

| Figure 3-3. Map of Sleeper Property Subject to Applicable Production Royalties |

14 | ||||

| Figure 5-1: Map of Historical Drilling Locations |

19 | ||||

| Figure 6-1: Regional Geologic Map of the Sleeper Project Area |

32 | ||||

| Figure 6-2: Stratigraphic Column for the Sleeper Property |

34 | ||||

| Figure 6-3: Geologic Map of the Sleeper Volcanic Center |

36 | ||||

| Figure 6-4: Cross-Section looking North through the Sleeper mine area |

37 | ||||

| Figure 6-5: Schematic Cross-Section Model of the Sleeper Deposit |

39 | ||||

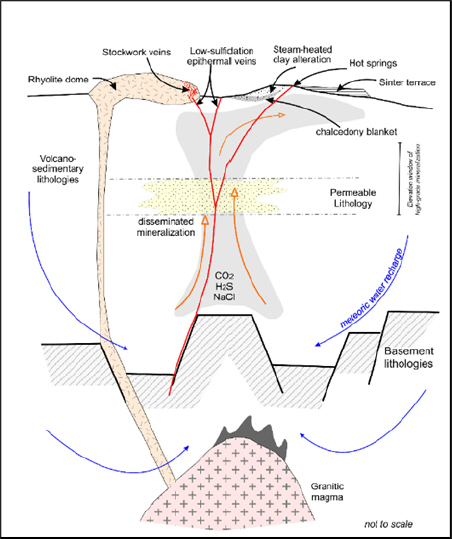

| Figure 6-6: Schematic Model of Low-Sulfidation Epithermal Precious-Metal Systems |

40 | ||||

| Figure 7-1: Map of Drill Holes Within the Sleeper Deposit |

44 | ||||

| Figure 7-2: Map of 2021 Drill Collar Locations |

46 | ||||

| Figure 8-1: X-Cal Gold in Blanks and Preceding Samples 2003-2007 |

59 | ||||

| Figure 8-2: X-Cal Gold Core Preparation Duplicates, Relative Differences 2003-2007 |

60 | ||||

| Figure 8-3: X-Cal Gold Core Preparation Duplicates, Relative Differences 2003-2007 |

60 | ||||

| Figure 8-4: X-Cal Gold RC Field Duplicates, Relative Differences 2003-2007 |

61 | ||||

| Figure 8-5: X-Cal Gold RC Field Duplicates, Absolute Values of the Relative Differences 2003-2007 |

62 | ||||

| Figure 8-6. Gold Control Chart for MEG-Au.09.02 |

65 | ||||

| Figure 8-7 Gold Values of Paramount Coarse Blanks and Preceding Samples |

67 | ||||

| Figure 8-8: Paramount Gold RC Field Duplicates, Relative Differences 2010-2013 |

68 | ||||

| Figure 8-9: Paramount Gold Core Field Duplicates, Relative Differences 2010-2013 |

68 | ||||

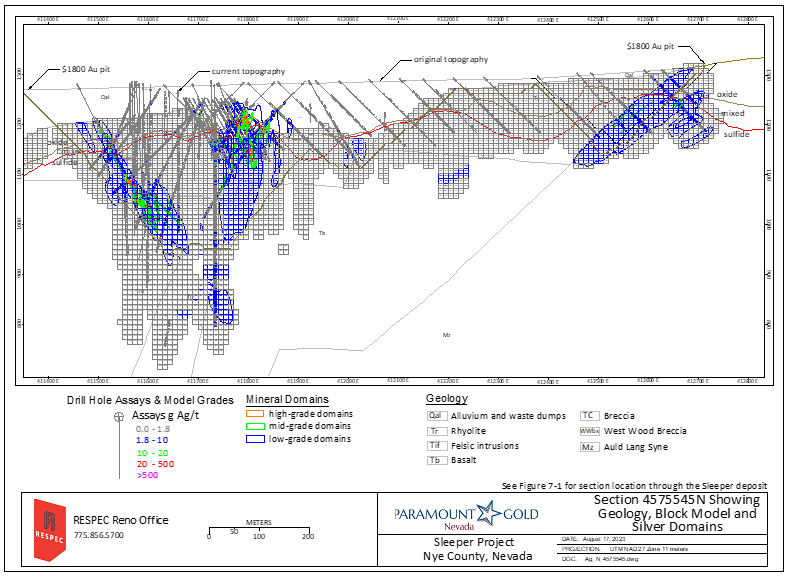

| Figure 11-1. East-West Cross-Section 4575545N Showing Gold Domains and Geology |

103 | ||||

| Figure 11-2. East-West Cross-Section 4575545N Showing Silver Domains and Geology |

104 | ||||

| Figure 11-3. East-West Cross-Section 45756175N Showing Gold Domains and Geology |

105 | ||||

| Figure 11-4.. East-West Cross-Section 45756175N Showing Silver Domains and Geology |

106 | ||||

| Figure 11-5. East-West Cross-Section 4575545N Showing Gold Grades in the Block Model |

118 | ||||

| Figure 11-6. East-West Cross-Section 4575545N Showing Silver Grades in the Block Model |

119 | ||||

| Figure 11-7. East-West Cross-Section 4576175N Showing Gold Grades in the Block Model |

120 | ||||

| Figure 11-8. East-West Cross-Section 4576175N Showing Silver Grades in the Block Model |

121 | ||||

|

vii

RSI(RNO)-M0144.21001 REV 5 |

RESPEC Company LLC (“RESPEC”) has prepared this technical report summary on the Sleeper gold-silver project at the request of Paramount Gold Nevada Corp. (“Paramount”), a United States (“U.S.”) listed company (PZG: NYSE American) based in Winnemucca, Nevada. The Sleeper gold-silver project is located in Humboldt County, Nevada, and was the site of historical open pit mining from 1986 to 1996 when a total of approximately 1.66 million ounces of gold and 2.3 million ounces of silver were produced. This report provides a technical summary and a current estimate of gold and silver mineral resources for the project under the U.S. Securities and Exchange Commission (“SEC”) Regulation S-K.

| 1.1 | PROPERTY DESCRIPTION AND OWNERSHIP |

The Sleeper property consists of 2,474 unpatented Federal lode mining claims covering approximately 18,177 hectares in parts of Sections 3 to 11, 14 to 23 and 26 to 36, inclusive, in Township 40 North, Range 35 East, Sections 1 to 12 15 to 21 and 29-33, Township 39 North, Range 35 East, Sections 1, 2, 11 and 12, Township 38 North, Range 34 East, Sections 2, 4, 8, 16 and 28, Township 37 North, Range 35 East, Sections 24 and 36, Township 37 North, Range 34 East, and Section 2, Township 36 North, Range 34 East, inclusive, Mount Diablo Base and Meridian, Humboldt County, Nevada. The main historical mine workings are centered at Lat: 41° 20’ N, Long: 118° 03’ W.

Paramount and two 100%-owned subsidiaries, Sleeper Mining LLC and New Sleeper LLC., own 100% of the mining claims comprising the Sleeper property. Ownership of the unpatented mining claims is in the name of the holder (locator), subject to the overall title of the United States of America. Under the Mining Law of 1872, the locator has the right to explore, develop, and mine minerals on unpatented mining claims without payments of production royalties to the U.S. government. The 2,474 unpatented lode claims include rights to all locatable subsurface minerals. Currently, annual claim-maintenance fees of $165 per claim are the only federal payments related to unpatented mining claims. As of the effective date of this report, these fees have been paid in full to September 1, 2024.

| 1.2 | GEOLOGY AND MINERALIZATION |

The Sleeper gold-silver deposit was discovered by AMAX Gold Inc. (“AMAX”) in late 1984. The Sleeper mine was constructed by AMAX in the mid-1980s as an open pit operation that produced approximately 1.658 million ounces of gold from 1986 to the end of production in 1996. Silver production totaled approximately 2.3 million ounces.

The deposit is located on the western flank of the Slumbering Hills and is largely covered by Quaternary gravels, alluvium, colluvium, and a surficial sequence of eolian sand. Gold-silver mineralization is situated nearly entirely in the hanging wall of a major, northwest-trending, west-dipping range-bounding normal fault that separates Mesozoic metasedimentary rocks of the Auld Lang Syne Group in the footwall from middle Miocene lavas, flow breccia, and lesser

|

RESPEC.COM |

RSI(RNO)-M0144.21001 REV 5 |

epiclastic and tuffaceous rocks in the hanging wall. The principal host rocks for the deposit are a sequence of middle Miocene basalt and rhyolite lavas, domes, and small-volume tuffs.

Prior to mining, the Sleeper deposit consisted of four spatially overlapping types of gold-silver mineralization: a) banded quartz-adularia-electrum-(sericite) veins; b) silica-pyrite-marcasite cemented breccias; c) quartz-pyrite-marcasite stockworks; and d) alluvial gold-silver placers in Pliocene gravels.

The Sleeper veins generally dip to the west at moderate to high angles, but some secondary hanging-wall offshoots of the principal vein structures dip steeply to the east. Significant zones of mineralization at Sleeper extended for about 1,500 meters along strike, about 600 meters of width, and from near the pre-mining surface to depths of more than 610 meters. At least eleven veins with bonanza grades were mined historically. The Sleeper Main vein produced more than 0.5 Moz of gold from a single bonanza ore shoot, which had a strike length of 850 meters and width ranging from 0.3 to 4.6 meters. Most discrete bonanza zones consisted of a series of sheeted chalcedonic quartz veins distributed over cumulative widths of 10 to 25 meters. Individual veins ranged in thickness from a few centimeters to locally 5 meters.

The post-mining Sleeper deposit is predominantly characterized by extensive, low-grade stockwork mineralization hosted within the Sleeper rhyolite and underlying basalts. The stockwork mineralization has numerous, randomly oriented quartz-pyrite-marcasite veinlets peripheral to mid- to high- grade veins and breccias. The mid-grade mineralization consists of clast-supported breccias and narrow veins which extend down-dip from previously mined high-grade veins. These mid-grade narrow veins typically assay between 3 and 34 g Au/t, whereas the stockwork assays usually result in grades less than 3 g Au/t.

The West Wood area to the southwest of the Sleeper pit contains high-grade mineralization within a hydrothermal breccia body associated with faults and a felsic porphyritic intrusive. This zone likely represents a down-faulted block that was continuous or parallel to the West vein mined in the pit. The West Wood breccia is highly silicified with abundant sulfides, but localized veins within the breccia can exceed 100 g Au/t.

| 1.3 | STATUS OF EXPLORATION, DEVELOPMENT AND OPERATIONS |

Paramount is not engaged in development or operations at the Sleeper project as of the effective date of this report. Exploration conducted by Paramount from 2010 through 2013, and in 2021, is summarized in Section 7.0.

| 1.4 | METALLURGICAL TESTING AND MINERAL PROCESSING |

The oxide and transition materials of the various Sleeper areas are amenable to heap leach processing with an expected recovery:

|

2

RSI(RNO)-M0144.21001 REV 5 |

| Material Type | Heap Leach Recovery | |||||||||

| Au | Ag | |||||||||

| Alluvium | 72% | 8% | ||||||||

| Mine Dumps | 72% | 43% | ||||||||

| Facilities | 79% | 8% | ||||||||

| Mixed | 68% | 20% | ||||||||

| Sleeper | 85% | 10% | ||||||||

| Westwood | 72% | 9% | ||||||||

For the refractory ore types, a hybrid processing method is recommended. This methos involves grinding the material suitable for froth flotation to generate a flotation concentrate. Treatment of the concentrate by biooxidation followed by cyanidation is expected to recover 75% of the gold and 48% of the silver. Cyanide leaching of the flotation tailings is expected to recover an additional 15 % and 22 % of the gold and silver respectively, for an overall recovery of 90% of gold and 70% of silver of the flotation feed material.

| Process | Au Recovery | Ag Recovery | ||||||||

| Flotation Rec | 80% | 60% | ||||||||

| Concentrate Biox/Leach |

94% | 80% | ||||||||

| Net Flot/Biox/Leach | 75% | 48% | ||||||||

| Flot Tails to Leach | 20% | 40% | ||||||||

| Flot Tails Leach Rec | 75% | 55% | ||||||||

| Net Flot Tails Lech Rec | 15% | 22% | ||||||||

| Combined Flot Con/Tails Rec |

90% | 70% | ||||||||

|

3

RSI(RNO)-M0144.21001 REV 5 |

| 1.5 | MINERAL RESOURCE ESTIMATE |

Measured and Indicated resources, effective June 30, 2023, consist of a total of 163,239,000 tonnes with an average gold grade of 0.361 g Au/t and an average silver grade of 4.05 g Ag/t, for 1,897,000 contained ounces of gold and 21,231,000 contained ounces of silver. The resources are constrained within an optimized pit, reflecting the potential for open pit mining and heap-leach processing of the present Sleeper deposit. The in-pit resources are reported at cutoffs of 0.14 g Au/t for oxide and mixed materials, and 0.17 g Au/t for sulfide material. The cutoff for unoxidized materials reflects the potential for flotation with biooxidation processing.

Table 1-1 Sleeper Total In-Pit Gold and Silver Resources – Measured, Indicated & Inferred

(Metric units)

| Cutoff | ||||||||||||

| g Au/T | K Tonnes | g Au/T | K oz Au | g Ag/T | K oz Ag | |||||||

| Measured | Variable | 4,902 | 0.537 | 85 | 3.61 | 570 | ||||||

| Indicated | Variable | 158,337 | 0.356 | 1,812 | 4.06 | 20,661 | ||||||

| Inferred | Variable | 119,909 | 0.315 | 1,214 | 2.45 | 9,454 | ||||||

(Imperial units)

| Cutoff | ||||||||||||

| Oz Au/t | K tons | Oz Au/t | K oz Au | Oz Ag/t | K oz Ag | |||||||

| Measured | Variable | 5,403 | 0.016 | 85 | 0.105 | 570 | ||||||

| Indicated | Variable | 174,535 | 0.010 | 1,812 | 0.118 | 20,661 | ||||||

| Inferred | Variable | 132,176 | 0.009 | 1,214 | 0.071 | 9,454 | ||||||

Notes:

| • | The estimate of mineral resources was done by RESPEC in metric tonnes. |

| • | Mineral Resources comprised all model blocks at a 0.14 g Au/t cut-off for Oxide and Mixed, 0.17 g Au/t for Sulfide within an optimized pit and 0.14 g Au/t for dumps. |

| • | The average grades of the Mineral Resources are comprised of the weighted average of Oxide, Mixed, Sulfide, and dumps mineral resources. Alluvium mineralized materials are not included in the mineral resources. |

| • | Mineral Resources within the optimized pit are block-diluted tabulations. Dumps mineral resources are undiluted tabulations. |

| • | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| • | Mineral Resources potentially amenable to open pit mining methods are reported using a gold price of US$1,800/oz, a silver price ofUS$22/oz, a throughput rate of 30,000 tonnes/day, assumed metallurgical recoveries of 84.6% for Au and 52.3% for Ag, mining costs of US$2.40/tonne mined, heap leach processing costs of US$3.08/tonne processed, flotation with biooxidation processing costs of US$8.52/tonne processed, general and administrative costs of $0.46/tonne processed. Gold and silver commodity prices were selected based on analysis of the three-year running average at the end of July 2023. |

| • | The effective date of the estimate is June 30, 2023. |

| • | Rounding may result in apparent discrepancies between tonnes, grade, and contained metal content. |

|

4

RSI(RNO)-M0144.21001 REV 5 |

| 1.6 | CONCLUSIONS AND RECOMMENDATIONS |

The current Sleeper mineral resources are principally comprised of the substantial volumes of the lower-grade mineralization that envelops the Sleeper veins both vertically and laterally. This lower-grade envelope is dominated by stockwork mineralization, but moderate- to high-grade mineralization within it includes the down-dip extensions of the mined-out Sleeper high-grade veins as well as other secondary and tertiary structural zones that host hydrothermal breccias of moderate grades. The unmined West Wood occurrence also lies within the low-grade halo mineralization. West Wood is comprised of mid- to high-grade gold mineralization hosted within an easterly dipping, sulfidic hydrothermal breccia that is related to a felsic porphyritic intrusion, and it lies to the southwest of the AMAX pit limits.

It is recommended to advance the current technical report summary to an initial assessment (“IA”) to assess the preliminary project economics. If the results of the recommended IA are favorable, an infill drill program of approximately 7,600 meters of drilling is recommended. However, RESPEC recommends that core drilling be substituted for a portion of the RC drilling due to the emerging understanding of the importance of narrow high-grade veins and steeply dipping structural controls to the remaining higher-grade mineralization, and to avoid the demonstrated down-hole contamination that has occurred below the water table. Core drilling would also provide opportunities to collect information regarding geotechnical data, hydrology, metallurgical testing, and validate historical RC drilling. Increased drill density is required in some areas to provide confidence needed to potentially upgrade Inferred resources to Measured and Indicated classifications.

Table 1-2. Cost Estimate for the Recommended Program

| Category | Estimated Cost ($) | |||

| Initial Assessment | $150,000 | |||

| Infill RC Drilling (7,600 meters at $132/m) | $1,000,000 | |||

| Metallurgy including biooxidation test work | $250,000 | |||

| Pre-Feasibility Study | $2,500,000 | |||

| Total | $3,900,000 | |||

|

5

RSI(RNO)-M0144.21001 REV 5 |

| 2.0 | INTRODUCTION |

RESPEC Company LLC (“RESPEC”) has prepared this technical report summary on the Sleeper gold-silver project at the request of Paramount Gold Nevada Corp. (“Paramount”), a United States (“U.S.”) listed company (PZG: NYSE American) based in Winnemucca, Nevada. The Sleeper gold-silver project is located in the Awakening mining district of Humboldt County, Nevada, and was the site of historical open pit mining from 1986 to 1996 when a total of approximately 1.66 million ounces of gold and 2.3 million ounces of silver were produced.

The purpose of this report is to provide a technical summary and an updated, current estimate of gold and silver mineral resources for the project in support of Paramount’s regulatory obligations under the U.S. Securities and Exchange Commission (“SEC”) and Code of Federal Regulations subpart 229.1300 of Regulation S-K (“S-K 1300”). The Sleeper property is considered a material property under S-K 1300. This technical report summary supersedes the most recent technical reports and estimated resources for the Sleeper project prepared for Paramount by RESPEC in 2022.

| 2.1 | SOURCES OF INFORMATION |

The scope of this technical report summary included a review of pertinent technical reports and data provided to RESPEC by Paramount relative to the general setting, geology, project history, exploration activities and results, methodology, quality assurance, interpretations, drilling programs, and metallurgy. RESPEC has fully relied on the data and information provided by Paramount for the completion of this report, drawing most significantly on the reports of Wilson et al. (2015) and Wilson et al. (2017), as well as other sources of information cited specifically in portions of this technical report summary and listed in Section 24 References. RESPEC has also utilized information derived from work done by Paramount’s predecessor operators of the project, and on observations made by RESPEC geologists during their site visits. RESPEC has reviewed much of the available data and has made judgments about the general reliability of the underlying data. Where deemed either inadequate or unreliable, the data was either eliminated from use or procedures were modified to account for lack of confidence in that specific information. RESPEC has made such investigations as deemed necessary in their professional judgment to be able to reasonably present the conclusions discussed herein.

| 2.2 | PERSONAL INSPECTIONS |

RESPEC conducted multiple site visits to the Sleeper project guided by Mr. Glen Van Treek, Mr. Michael McGinnis, and/or other representatives of Paramount on five separate occasions: April 19 and November 18, 2021, March 2 and May 11, 2022, and August 14, 2023. RESPEC examined the property infrastructure, reviewed representative drill core and RC cuttings, evaluated the status of drill sample pulps stored on site, and measured the coordinates of selected drillhole collar locations. The geology of the Sleeper deposit was reviewed through an examination of drill core from selected drill holes and printouts of Paramount’s cross-sections.

|

6

RSI(RNO)-M0144.21001 REV 5 |

| 2.3 | EFFECTIVE DATE |

The effective date of the current mineral resources is June 30, 2023, and the effective date of this technical report summary is August 31, 2023. In this report, measurements are generally reported in metric units. Where information was originally reported in Imperial units (U.S. customary units), RESPEC has made the conversions as shown below. Units of measure, and conversion factors used in this report include:

| 2.4 | UNITS OF MEASURE AND FREQUENTLY USED ACRONYMS |

| Linear Measure |

||||

| 1 centimeter |

= 0.3937 inch |

|||

| 1 meter |

= 3.2808 feet |

= 1.0936 yard | ||

| 1 kilometer |

= 0.6214 mile |

|||

| Area Measure |

||||

| 1 hectare |

= 2.471 acres |

= 0.0039 square mile | ||

| Capacity Measure (liquid) |

||||

| 1 liter |

= 0.2642 US gallons |

|||

| Weight |

||||

| 1 tonne (metric) |

= 1.1023 short tons |

= 2,205 pounds | ||

| 1 kilogram |

= 2.205 pounds |

|||

| 1 troy ounce (oz) |

=31.1034768 grams |

|||

Currency: Unless otherwise indicated, all references to dollars ($) in this report refer to currency of the United States.

Frequently used acronyms and abbreviations are listed in Table 2-1.

Table 2-1. List of Units, Acronyms, and Abbreviations

| AA | atomic absorption spectrometry |

|||

| Ag |

silver |

|||

| Ai | abrasion index |

|||

| Au |

gold |

|||

| AV | absolute value |

|||

| BWi | bond ball mill work index |

|||

| cm |

centimeters |

|||

| CBA | complete bouguer anomaly |

|||

| core | diamond core-drilling method |

|||

| CRMs |

certified reference material |

|||

| oC | degrees centigrade |

|||

| °F |

degrees Fahrenheit |

|||

|

7

RSI(RNO)-M0144.21001 REV 5 |

Table 2.1. List of Units, Acronyms, and Abbreviations (continued)

| ft | foot or feet |

|||

| g Au/t | grams per tonne |

|||

| g/cm3 | grams per cubic centimeter |

|||

| g/cc | grams per cubic centimeter |

|||

| gpm | gallons per minute |

|||

| hp |

horsepower |

|||

| Hz |

Hertz |

|||

| ICP |

inductively coupled plasma analytical method |

|||

| ICP-AES |

inductively coupled plasma - atomic emission spectroscopy method |

|||

| ICP-OES |

inductively coupled plasma - optical emission spectroscopy method |

|||

| ICP-MS |

inductively coupled plasma – mass spectrometry method |

|||

| ID | inverse distance |

|||

| IP | induced polarization |

|||

| in | inch or inches |

|||

| kg |

kilograms |

|||

| km |

kilometers |

|||

| kv |

kilovolt |

|||

| kW |

kilowatt |

|||

| lbs |

pounds |

|||

| LCL | lower control limit |

|||

| LSL | lower specification limit |

|||

| µm |

micron |

|||

| m |

meters |

|||

| Ma | million years old |

|||

| mi | mile or miles |

|||

| mm |

millimeters |

|||

| Moz | million troy ounces |

|||

| MT |

magnetotelluric |

|||

| NN | nearest neighbor |

|||

| NSR | net smelter return |

|||

| oz | troy ounce |

|||

| oz Au/ton | troy ounce per imperial short ton |

|||

| opt | troy ounce per imperial short ton |

|||

|

8

RSI(RNO)-M0144.21001 REV 5 |

Table 2.1. List of Units, Acronyms, and Abbreviations (continued)

| P80 | nominal size at 80 percent |

|||

| ppm | parts per million |

|||

| QA/QC | quality assurance and quality control |

|||

| R or Res |

resistivity |

|||

| RC |

reverse-circulation drilling method |

|||

| Resource Pit |

optimized pit shell for the Sleeper Deposit Resources |

|||

| RPD | relative percent difference |

|||

| RQD |

rock-quality designation |

|||

| RTK |

real-time kinematic |

|||

| RTP | reduced to the pole |

|||

| SWIR |

short-wave infrared |

|||

| t | metric tonne or tonnes |

|||

| T | imperial short ton (2,000lb) |

|||

| Tph | imperial short ton per hour |

|||

| UCL | upper control limit |

|||

| USL | upper specification limit |

|||

| VD |

vertical derivative |

|||

|

9

RSI(RNO)-M0144.21001 REV 5 |

| 3.0 | PROPERTY DESCRIPTION AND LOCATION |

RESPEC is not an expert regarding legal, environmental, and social matters such as the validity of mining claims and agreements and environmental permitting. RESPEC has relied fully on Paramount for the information in Section 3.1 through Section 3.6 as summarized in Section 25.0.

| 3.1 | PROPERTY LOCATION |

The Sleeper property is located in Desert Valley and the adjoining Slumbering Hills in Humboldt County, Nevada, U.S.A. The claims cover parts of Sections 3 to 11, 14 to 23 and 26 to 36, inclusive, in Township 40 North, Range 35 East, Sections 1 to 12 15 to 21 and 29-33, Township 39 North, Range 35 East, Sections 1, 2, 11 and 12, Township 38 North, Range 34 East, Sections 2, 4, 8, 16 and 28, Township 37 North, Range 35 East, Sections 24 and 36, Township 37 North, Range 34 East, and Section 2, Township 36 North, Range 34 East, inclusive, Mount Diablo Base and Meridian, Humboldt County, Nevada, U.S.A. The property location is shown on Figure 3-1. The main historical mine workings are centered at Lat: 41° 20’ N, Long: 118° 03’ W (Figure 3-2).

Figure 3-1. Location Map for the Sleeper Property

(from Gustin and Fleming, 2004)

|

10

RSI(RNO)-M0144.21001 REV 5 |

| 3.2 | PROPERTY AREA AND CLAIM TYPES |

The Sleeper property (Figure 3-2) comprises 2,474 unpatented Federal lode mining claims covering approximately 18,177 hectares. This includes 152 unpatented mining claims identified as the RO and SH group of claims, located 5.6 kilometers southwest of the main Sleeper pit, acquired by Paramount on March 31, 2021. Appendix A contains a list of the individual lode claims that comprise the Sleeper property.

Paramount’s ownership of the Sleeper project commenced in 2010 when a predecessor company known then as Paramount Gold and Silver acquired X-Cal Resources Ltd. (“X-Cal”), which held portions of the Sleeper property. In 2011, Paramount Gold and Silver acquired ICN’s land package in the area south of the Sleeper deposit, and in 2012 Paramount Gold and Silver staked additional claims. In connection with a merger agreement between Paramount Gold and Silver, Coeur Mining, Inc. and Hollywood Merger Sub, Inc., Paramount Gold and Silver spun-off Paramount as a separate, publicly traded company owning 100% of two subsidiaries, Sleeper Mining LLC and New Sleeper LLC., that together with Paramount own 100% of the mining claims comprising the Sleeper property.

| 3.3 | MINERAL RIGHTS |

Ownership of the unpatented mining claims is in the name of the holder (locator), subject to the overall title of the United States of America, under the administration of the U.S. Bureau of Land Management (“BLM”). Under the Mining Law of 1872, which governs the location of unpatented mining claims on federal lands, the locator has the right to explore, develop, and mine minerals on unpatented mining claims without payments of production royalties to the U.S. government, and subject to the surface management regulation of the BLM. The 2,474 unpatented lode claims include rights to all locatable subsurface minerals. Currently, annual claim-maintenance fees of $165 per claim are the only federal payments related to unpatented mining claims. As of the effective date of this report, these fees have been paid in full to September 1, 2024. The annual property holding costs, including claim fees and county recording fees total an estimated $447,705 (Table 3-1).

Surface rights sufficient to explore, develop, and mine minerals on the unpatented mining claims are inherent to the claims as long as the claims are maintained in good standing. The surface rights are subject to all applicable state and federal environmental regulations.

|

11

RSI(RNO)-M0144.21001 REV 5 |

Figure 3-2: Sleeper Property Location Map

(from Paramount, 2022; red lines show outlines of Paramount claim blocks and third-party inliers.)

Table 3-1. Summary of Annual Property Holding Costs

| Type | Annual Claim Fees | Annual County Recording Fees |

Total Annual Costs | |||

|

Unpatented Lode Claims |

$417,945 | $29,760 | $447,705 |

| 3.4 | SIGNIFICANT ENCUMBRANCES AND PERMITTING |

The Sleeper property is owned 100% by Paramount with no significant encumbrances or agreements such as leases, options, or purchase payments known to RESPEC. The project is currently operated as an advanced exploration project. Key BLM and State permits associated with these activities and in place as of the effective date of this report include:

|

12

RSI(RNO)-M0144.21001 REV 5 |

| • | Exploration Reclamation Permit #0219 |

| • | Exploration Plan of Operations #NVN077104 |

| • | The Sleeper Mine #NVN064100 |

| • | Class II Air Quality Operating Permit Surface Area Disturbance #AP1041-2831 |

| • | The reclamation bonds associated with the above activities are: |

| • | Exploration Bond #NVB000444 current obligation -$345,044 |

| • | Reclamation Bond #NVB000330 current obligation $3,966,373- |

There are also numerous other permits in place that are maintained from previous mining activities. These are maintained for ease in updating should a decision be made to reinitiate production at the site. Maintenance of these permits includes monthly, quarterly, and annual monitoring and reporting. These permits include:

| • | Mine Reclamation Permit #0037 |

| • | Water Pollution Control Permit #NEV50006 |

| • | Ground Water Appropriation Permit #53228, #53231 and #53236 |

| • | Hazardous Materials Permit #30473 FDID #08250 Facility #1168-2326 |

| • | Class III Solid Waste Landfill Waiver #SWMI-08-10 |

| • | Industrial Artificial Pond Permit #S34480 |

| • | Mine Plan of Operations #N64100 |

The BLM Nevada State Office currently holds BLM bond number NVB00330 with Sleeper Mining Company LLC, as principal, in the amount of $3,966,373; and BLM bond number NVB00444 with New Sleeper Gold LLC, as principal, in the amount of $345,044. The bonds provide surface reclamation coverage for operations conducted by the principal on NVN064100, the Sleeper Mine, and NVN077104, the Sleeper Gold Exploration Plan, respectively. The current obligation was approved 10/09/2020 and is reviewed every 3 years. Paramount is currently in compliance with all issued permits and is in the process of renewing those permits that require renewal.

| 3.5 | ROYALTIES |

A total of five separate Net Smelter Return (“NSR”) royalties apply to future production from the Sleeper property as follows:

The Snyder Syndicate, a private company, holds a one percent (1%) NSR royalty on 1,044 claims in a mining scenario;

Franco-Nevada U.S. Corporation (“Franco”) holds a two percent (2%) NSR royalty on minerals produced from 2,474 mining claims;

Evolving Gold/Quinton Hennigh holds a 2% NSR royalty;

Dry Lake Placer Association holds a 3% NSR royalty; and

ICN holds a 0.5% NSR royalty on the “SS” and “SP” mining claims as well as a 1.5% NSR royalty on the Blue mining claims.

|

13

RSI(RNO)-M0144.21001 REV 5 |

Figure 3-3. Map of Sleeper Property Subject to Applicable Production Royalties

| 3.6 | SIGNIFICANT FACTORS AND RISKS |

RESPEC is not aware of any significant factors and risks that may affect access, title, or the right or ability to perform work on the property other than those described in Sections 3.1 through 3.5.

|

14

RSI(RNO)-M0144.21001 REV 5 |

| 4.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY |

| 4.1 | TOPOGRAPHY, ELEVATION AND VEGETATION |

The Sleeper gold-silver property is located approximately 50 kilometers northwest of Winnemucca, Nevada on the western flank of the Slumbering Hills. The property covers flat to hilly, grass- and shrub-covered desert, with a few trees present at higher elevations. Elevations range from1,250 meters along the western valley side of the property to 1,646 meters on a hilltop in the southeastern portion of the property.

| 4.2 | ACCESS TO THE PROPERTY |

Access to the Sleeper gold-silver property is via Interstate Highway 80 to Winnemucca, north on Highway 95 for 51.5 kilometers, west on Highway 140 for 22.5 kilometers, and then south on the maintained gravel Sod House Road for 10 kilometers to the project site.

| 4.3 | CLIMATE AND LENGTH OF OPERATING SEASON |

The climate in the Sleeper property area is semi-arid, with temperatures that are cool to cold during the winter, with occasional moderate snowfalls, and warm during the summer with cool nights. The area is dry, with infrequent rains during the summer. Exploration and mining activities can be conducted year-round.

| 4.4 | INFRASTRUCTURE |

An office building, a maintenance building plus assorted equipment are present at the Sleeper project site and are in use for exploration offices, core logging, storage and to support drilling programs. Necessary supplies, equipment, and services to carry out full sequence exploration and mining development projects are available in Winnemucca, Reno, and Elko, Nevada. A trained mining-industrial workforce is available in Winnemucca and other nearby communities. The Sleeper property area is uninhabited. The overall subdued topography that characterizes much of the Sleeper property provides ample ground for the siting of mine facilities, tailings, waste dumps and heap leach facilities.

|

15

RSI(RNO)-M0144.21001 REV 5 |

| 5.0 | HISTORY |

The information summarized in this section is taken largely from Redfern and Rowe (2003), Gustin and Fleming (2004), Thomason et al. (2006), Giroux et al. (2009), Wilson et al. (2015), and Ressel et al. (2020). RESPEC has reviewed this information and believes it is suitable for use in this report.

The Sleeper gold-silver project is located in the Awakening district which has been active since the early 1900s. Early production of gold was associated with gold-bearing quartz veins and the district was significantly revitalized with the discovery of the Sleeper deposit by AMAX in 1982, and subsequent open pit mining from 1986 through 1996. This section summarizes historical mining operations, operators, and exploration and development work undertaken by previous owners and operators.

| 5.1 | HISTORICAL PRODUCTION |

| 5.1.1 | EARLY MINING: 1914 TO 1982 |

Early production of gold in the Slumbering Hills (Awakening district), first recorded in 1914, was associated with gold-bearing quartz veins in Mesozoic metasedimentary rocks. Production increased beginning in 1936 with development of the Jumbo and Alma mines (Nash et al., 1995). Narrow quartz-adularia veins within folded metasedimentary rocks were exploited for gold at the Jumbo mine located approximately six kilometers southeast of the Sleeper mine by open pit and underground methods (Nash et al., 1995). Workings include several shafts, adits, and numerous prospects located within 2 kilometers of the eventual Sleeper mine. These old workings, probably from the 1930s, are in or adjacent to altered and veined Tertiary volcanic rocks. The Sleeper mill was constructed atop one of the historical shafts (Nash, et al., 1995). Willden (1964) tabulated a total of 26,262 ounces of gold produced from the Awakening district between 1932 and 1958.

| 5.1.2 | AMAX: 1982 TO 1996 |

The post-1950s mining history of the Sleeper property, as summarized in Wood and Hamilton (1991), began in 1982 when John Wood, an exploration geologist with AMAX Gold Inc. (“AMAX”), observed iron oxide minerals in a scarp east of what became the Sleeper mine during an aerial geological reconnaissance. AMAX conducted surface geological and geochemical work over the next two years and a drilling program that identified gold mineralization that averaged approximately 1.4 g Au/t. In late 1984, AMAX’s thirty-fourth drillhole stepped out to the west of the previous drilling and intersected 102 meters of silicified breccia with an average grade of 27.8 g Au/t and 61.7 g Ag/t, including one very high-grade quartz vein containing abundant visible gold (Nash et al., 1995).

In February 1985, AMAX formally announced the discovery of the Sleeper gold deposit. Mining began in January 1986 and mill commissioning began the following month. On March 26, 1986, AMAX poured its first gold bar. Although the mine plan called for production of about 40,000 ounces in 1986, the mine produced 126,000 ounces of gold during the year at an average cost of less than $60 per ounce, making it one of the lowest cost gold mines in the world at the time.

|

16

RSI(RNO)-M0144.21001 REV 5 |

AMAX’s initial capital investment was recouped in the first six months of operation. During the first nine months the head grade was 25.7 g Au/t, or more than twice the expected grade, owing to bonanza grades in the Sleeper vein (Redfern and Rowe, 2003). In September 1986, AMAX began processing low-grade material in a heap leach circuit. Production increased to 159,000 ounces in 1987 (the first full year of production) and to 230,000 ounces in 1988 at an average cost of $103 per ounce (Proteus, 2002). Armed guards were hired to protect the high-grade, visible gold in the pit. In 1993, annual production declined to 100,000 ounces of gold at a cash cost of $317 per ounce. Cyprus Minerals and AMAX Inc. merged to form Cyprus AMAX Minerals Co. in 1994. AMAX suspended mining operations at Sleeper in 1996.

The Sleeper operation was designed to treat oxide mineralization by both milling and heap leaching. There was no flotation circuit in the mill to recover gold bearing sulfides. The early pit mill feed was oxide material, but zones of sulfide mineralization were present in the pit. Reported total gold production was 1,219,880 ounces from the mill and 438,609 ounces from heap leaching (Zoutomou, 2007). Silver production totaled approximately 2.3 million ounces.

After production ceased, groundwater infiltrated into the open pit, forming a pit lake. The pit lake surface is within 34 meters below the crest of the original pit limits. The mill and crushing facilities have been removed and the mill area has been reclaimed.

| 5.2 | HISTORICAL EXPLORATION |

The Sleeper deposit was largely overlain by alluvial deposits and was discovered by drilling through only a few meters of unconsolidated post-mineral cover. Over the past 40 years, there have been more than 4,400 exploration holes drilled in and around the Sleeper property by AMAX and numerous other companies. Historical drilling from 1983 through 2012 is summarized in Table 5-1. The majority of drilling has been done with reverse-circulation rotary (“RC”) methods which account for 95% of the holes and 93% of the meters drilled on the property. A map showing historical drill collar locations, to the extent known, is shown in Figure 5-1.

Sleeper exploration data includes more than 2,600 rock-chip geochemical samples, more than 11,300 soil geochemical samples, and at least 21 geophysical surveys within the current project landholdings (Ressel et al., 2020). The historical geophysical surveys included gravity, airborne magnetics, ground magnetics, induced polarization(“IP”)/resistivity(“R”), magnetotelluric (“MT”), and seismic studies, as listed in Table 5-2. Surveys completed for Paramount are described in Section 7.1.

Exploration work carried out by historical operators is summarized chronologically below.

|

17

RSI(RNO)-M0144.21001 REV 5 |

Table 5-1. Summary of Sleeper Deposit Drilling in RESPEC Database

| Year | Company | Core Holes |

Core Meters |

RC Holes | RC Meters |

RC + Core Tail Holes |

RC + Core Tail Meters |

Sonic Holes |

Sonic Meters |

?? Holes | ?? Meters | Total Holes |

Total Meters | |||||||||||||

| 1983 – 1995 | AMAX | 3,670 | 494,789 | 3,670 | 494,789 | |||||||||||||||||||||

| 1989 | NGM | 9 | 438 | 9 | 438 | |||||||||||||||||||||

| 1986 – 1987 | X-Cal | 140 | 27,600 | 140 | 27,600 | |||||||||||||||||||||

| 1997 | Placer Dome | 30 | 6,721 | 11 | 4,243 | 6 | 2,204 | 47 | 13,168 | |||||||||||||||||

| 2002 | X-Cal | 83 | N/A | 83 | N/A | |||||||||||||||||||||

| 2003 – 2007 | X-Cal | 30 | 9,027 | 132 | 35,545 | 8 | 2,776 | 1 | N/A | 171 | 47,347 | |||||||||||||||

| 2004 – 2005 |

New Sleeper Gold |

20 | 8,783 | 45 | 8,541 | 4 | 717 | 69 | 18,041 | |||||||||||||||||

| 2008 | Evolving Gold^ | 34 | 6,636 | 34 | 6,636 | |||||||||||||||||||||

| 2011 – 2012 | Montezuma Mines* |

11 | 1,940 | 11 | 1,940 | |||||||||||||||||||||

| 2010 – 2013 | Paramount | 39 | 14,251 | 100 | 12,201 | 1 | 296 | 9 | 360 | 149 | 27,107 | |||||||||||||||

| 1983 – 2010 | Unknown | 0 | 20 | 781 | — | — | — | 20 | 781 | |||||||||||||||||

| Total Drilling | 100 | 34,001 | 4,180 | 593,251 | 20 | 7,315 | 92 | 360 | 11 | 2,920 | 4,403 | 637,847 | ||||||||||||||

|

?? Signifies unknown hole type; N/A Signifies data not available or not in RESPEC database as of effective date of this report | ||||||||||||||||||||||||||

|

^ Uncertain drill type, probably RC; *southern part of Sleeper property | ||||||||||||||||||||||||||

**Paramount drilling is described in Section7.2; locations of 2009 and 2011-2012 drilling by Evolving Gold and Montezuma Mines, respectively, have not been compiled and are not in the RESPEC drilling database as of the effective date of this report.

|

18

RSI(RNO)-M0144.21001 REV 5 |

Figure 5-1: Map of Historical Drilling Locations

Note: locations of 2009 and 2011-2012 drilling by Evolving Gold and Montezuma Mines, respectively, have not been compiled and are not in the RESPEC drilling database as of the effective date of this report.

|

19

RSI(RNO)-M0144.21001 REV 5 |

Table 5-2. Geophysical Surveys Conducted at the Sleeper Property

(from Ressel et al., 2020; Paramount surveys are discussed in Section 7.1)

| Company | Year | Geophysical Survey | ||||

|

AMAX Gold |

1987 | IP/resistivity |

||||

|

Placer-Dome |

1997 | Airborne magnetics |

||||

|

X-Cal Resources |

2003 |

Gravity |

||||

|

X-Cal Resources |

2004 |

Gravity |

||||

|

X-Cal Resources |

2004 |

IP/resistivity |

||||

|

X-Cal Resources |

2005 |

Magnetotellurics (“Titan”) |

||||

|

X-Cal Resources |

2005 |

IP/resistivity |

||||

|

Evolving Gold |

2007 |

Gravity |

||||

|

Evolving Gold |

2007 |

IP/resistivity |

||||

|

Evolving Gold |

2007 | Ground magnetics |

||||

|

Montezuma Mines |

2009 | Ground magnetics |

||||

|

Signal Exploration |

2010 |

Seismic |

||||

|

Northgate |

2010 |

IP/resistivity |

||||

|

Montezuma Mines |

2010 | Ground magnetics |

||||

|

Montezuma Mines |

2011 |

Gravity |

||||

|

Montezuma Mines |

2011 | Ground magnetics |

||||

|

Montezuma Mines |

2011 |

IP/resistivity |

||||

|

Montezuma Mines |

2011 |

IP/resistivity |

||||

|

Montezuma Mines |

2012 |

Gravity |

||||

|

Paramount |

2012 |

Gravity |

||||

|

Paramount |

2012 |

IP/resistivity |

||||

|

Paramount |

2015 | Airborne magnetics |

||||

|

Paramount |

2015 | Airborne radiometrics |

||||

|

20

RSI(RNO)-M0144.21001 REV 5 |

| 5.2.1 | AMAX 1982 - 1998 |

Exploration efforts by AMAX leading to and following production included surface mapping and geochemical sampling, drilling, and geophysical surveys (e.g., Nash et al., 1995; Wood, 1988; Wood and Hamilton, 1991). From 1983 through 1995, AMAX drilled a total of 494,789 meters in 3,670 RC holes. RESPEC has no information about AMAX’s drilling contractors, specific rig types, sample collection methods, or collar and down-hole surveys.

In May 1984, a time-domain IP survey was conducted by DMW Geophysics for AMAX. AMAX used these IP survey data to delineate conductive rock units such as sulfidic or clay-rich zones locally present, and resistive rock units, such as veined areas with silicification (Wood and Hamilton, 1991). In general, the IP survey showed that sulfidic mineralization in the Sleeper pit area could be correlated with IP highs. An IP high was also present along the Range Front fault east of the open pit.

Paramount’s drilling data compiled by RESPEC for this report includes nine RC holes drilled in 1989 by “NGM”. RESPEC is not aware of the actual name of NGM or its relationship to AMAX. RESPEC has no information about NGM’s drilling contractors, specific rig types, sample collection methods, or collar and down-hole surveys.

AMAX merged with Cyprus Minerals to form Cyprus AMAX Minerals Co. (“Cyprus-AMAX”) in 1994. Mining operations at Sleeper were suspended in 1996 and in 1998 Cyprus-AMAX merged with Kinross Gold Corporation (“Kinross”).

| 5.2.2 | X-CAL RESOURCES LTD 1993 -1997 |

In 1993, X-Cal acquired property around the Alma underground mine in the Awakening District, southeast of the Sleeper pit. X-Cal acquired additional land in 1994 and 1995, extending its holdings to the limit of the AMAX Sleeper property boundary. In April 1996, X-Cal and AMAX formed a joint venture to explore the Sleeper property, which included the land holdings of both X-Cal and AMAX. Upon entry into the district, X-Cal carried out exploration work progressing from comprehensive compilation of all data, analysis of satellite imagery and low-level aerial photography, detailed geologic and structural mapping, surface geochemical sampling, and ground-generated and airborne geophysical surveys.

From 1993 through 1997, a total of 7,599 soil samples and 2,480 rock chip samples were collected from the Sleeper property by X-Cal (Redfern and Rowe, 2003). RESPEC is not aware of the methods and procedures used for these exploration surveys nor the results.

The database compiled by RESPEC from Paramount’s drilling files indicates X-Cal drilled a total of 27,600 meters in 140 holes during 1996 and 1997 (Table 5-1). All of X-Cal’s drilling during this time was done with RC methods. Details of the drilling methods and procedures were summarized in Kornze et al. (2006), but RESPEC is not aware of X-Cal’s drilling contractors, rig types, or how collar and down-hole surveys were conducted. Although X-Cal was a reputable exploration company, this lack of information imparts risk and affects the classification of the current mineral resources presented in Section 11.

|

21

RSI(RNO)-M0144.21001 REV 5 |

| 5.2.3 | PLACER DOME 1997 |

In 1997, X-Cal entered into an option agreement with Placer Dome US Inc. (“Placer Dome”) that granted Placer Dome the right to earn a 50% interest in the Sleeper project. During 1997, Placer Dome reviewed the Sleeper property data in detail, completed a detailed aeromagnetic survey, and drilled a total of 13,168 meters in 47 holes (Table 5-1). The RESPEC database includes six holes of unknown type for 2,204 meters, as well as 11 holes initiated with RC and finished with core tails. The 1997 drilling was an effort to extend known mineralization as well as discover new zones of mineralization. RESPEC has no information about Placer Dome’s drilling contractors, rig types, sample collection methods, or how collar and down-hole surveys were conducted. Although Placer Dome was a reputable exploration company, this lack of information imparts risk and affects the classification of the current mineral resources presented in Section 11.

Pediment and Range Front areas and approximately 60% of other target areas were covered by a detailed airborne magnetic survey completed for Placer Dome. The survey comprised E-W and N-S lines spaced 50 meters apart, with magnetometer recordings every two meters along lines. Local aeromagnetic highs were thought to be associated with volcanic, hypabyssal, or metasedimentary rock units (White, 2003). Placer Dome declined to exercise the option and the property reverted to X-Cal.

In 1997 Mineral Resources Development Inc (”MRDI”) implemented studies of the Sleeper mine tailings and heap leach pads for X-Cal. Six auger holes, approximately 7.6 to 10.7 meters deep, were drilled into the tailings. The depth and degree of oxidation was delineated utilizing data from drill samples. A metallurgical study of the heap leach pads included completion of two RC holes and three auger holes in the heap leach pads. The RESPEC drilling database does not include the 1997 auger drill holes as of the effective date of this report and are not included in Table 5-1.

| 5.2.4 | X-CAL 1998 - 2003 |

Commencing in 1998, X-Cal negotiated a series of options to purchase the Kinross interest in Sleeper. In January 1999, X-Cal carried out a sampling and metallurgical test program on the Sleeper mine tailings (KCA,1999). Ten auger holes (15.2 centimeter in diameter) were drilled in the southeastern end of the tailings pond and samples were obtained from depths of 2.7 to 4.6 meters for metallurgical testing. The RESPEC drilling database does not include the 1999 auger drill holes as of the effective date of this report and are not included in Table 5-1.

In 2002, X-Cal carried out a sampling project to further test the Sleeper mine tailings impoundments. X-Cal drilled 83 sonic drill holes (3.2 to 5.1 centimeters in diameter) to depths of 9.1 to 10.7 meters (the average thickness of the tailings was estimated to range from 12.2 to 13.7 meters). The holes were sampled at intervals of 1.52 meters.

In 2003 a gravity survey was carried out at the Sleeper property by Geophysical and Geodetic Associates Inc. of Reno, Nevada for X-Cal. The survey comprised east-west and north-south lines spaced 500 meters apart with gravity measurements every 200 meters along lines. Interpretations were refined following additional gravity surveys for New Sleeper Gold in 2004 as described in the next section.

|

22

RSI(RNO)-M0144.21001 REV 5 |

| 5.2.5 NEW | SLEEPER GOLD 2004 - 2006 |

In January of 2004, New Sleeper Gold Corp. (“New Sleeper”) formed a 50/50 joint venture with X-Cal Resources by acquiring Kinross Gold’s 50% interest in the Sleeper property. New Sleeper assumed management of the Sleeper property as the “Sleeper JV”. RESPEC’s drilling database attributes a total of 18,041 meters of drilling to New Sleeper in 2004 and 2005. The drilling included 20 core holes, 45 RC holes, and four holes of unknown type. According to Giroux et al. (2009), the New Sleeper drilling also included 688.8 meters of sonic drilling, presumably in the waste dumps or tailings impoundment. The data for this sonic drilling has either been lost or has not been compiled by Paramount. Further uncertainty stems from Giroux et al. (2009), who stated:

“The Sleeper JV drilled a total of 122 holes at Sleeper in 2004 and 2005. Core drilling, reverse circulation drilling and sonic drilling were completed. Table 13.1A below provides footage details of each type of drilling by the Sleeper JV.”

Table 5-3. 2004 and 2005 Drill Footage Summary

(from Giroux et al., 2009)

| Type of Drilling | Number of Holes | Footage | ||

| Core Drilling | 57 | 70,841 | ||

| RC Drilling | 48 | 29,978 | ||

| Sonic Drilling | 17 | 2,260 | ||

| Total | 122 | 103,019 | ||

|

| ||||

RESPEC is unaware of the drilling contractors, rig types, sample collection methods, or how collar and down-hole surveys were conducted in the drilling by New Sleeper. RESPEC recommends that Paramount fully compile and evaluate this information, to the extent it is available.

New Sleeper conducted trenching, electrical geophysical surveys (both IP and MT), ground gravity surveys, ‘Quicksilver’ mercury soil gas surveys, O2/CO2 soil gas surveys, geological mapping, extensive soil geochemical sampling, and aerial photography (Giroux et al., 2009).

Results from the gravity surveys of 2003 (X-Cal) and 2004 showed significant density contrast between the local basement composed of Mesozoic metasedimentary rocks, and the combined package of pediment and Tertiary volcanic rocks, providing depth to basement determinations (Thomason et al., 2006). Additional detailed gravity work in 2005 resulted in improved definition of structures and understanding of the Sleeper deposit. Wright (2005) interpreted residual gravity results to reflect a complex structure involving three primary orientations: north-south, northwest, and northeast. The Sleeper deposit appeared to be located at the intersection of northwest and northeast structural corridors, proximal to a major north-south oriented basement feature.

A natural source MT survey was conducted over the “NW and SW Pediment areas” by Quantech who also modeled results. Additional modeling of these data by Wright (2005) yielded preliminary interpretations of subsurface geology, structure, and possible alteration.

|

23

RSI(RNO)-M0144.21001 REV 5 |

From 2004 through 2006, approximately 55 line-kilometer IP and resistivity surveys were completed by Zonge Geosciences Inc. (“Zonge”) and Quantech Consulting Inc. (“Quantec”). Zonge and Quantech processed their respective data, and calculated 2D model inversions of the results. The inversions were forwarded to Jim Wright for geophysical interpretation (Thomason et al., 2006).

Wilson et al. (2015) stated:

“In 2004 New Sleeper completed 17 sonic drill holes (13 vertical) for a total of 641.6 meters in Leach Pad 1. All holes terminated at least 6.1 meters above the leach pad liner as required by State of Nevada regulations.”

The above is not consistent with the drilling data received from Paramount, or possibly Paramount has not compiled the New Sleeper drilling data completely.

In 1997, Placer Dome conducted a pilot clay mineralogy study on 49 drill holes using Terra Spec ASD short-wave infrared (“SWIR”) spectral analyses. The study identified a strong association between gold mineralization and ammonia minerals including NH4-illite and buddingtonite. In 2004, New Sleeper Gold expanded on Placer Dome’s pilot clay mineralogy study and gathered spectral data from approximately 250 drill holes, but RESPEC is not aware of the results or significance of this work.

Between 2004 and 2005, a variety of surface geochemical surveys were carried out. Two phases of mercury vapor surveys were completed in 2004 and 2005 as a reconnaissance tool to detect possible mineralization beneath the pediment surface. The surveys covered the entire pediment area of the Sleeper property west of and overlapping the interpreted Range Front fault. Rock chip and soil samples were collected during this period, and results were added to existing databases; as of 2006 the databases included a total of 1,762 rock chip samples and 9,866 soil samples from the property area. RESPEC has not evaluated these data and is not aware of the results.

Under the management of New Sleeper, the mill and crusher facilities were removed and the sites where these facilities formerly stood were reclaimed. New Sleeper and X-Cal equally funded work at Sleeper from August 2005 to May 2006, at which time X-Cal purchased New Sleeper’s 50% interest in the project for a combination of cash and X-Cal common stock. The Sleeper property was then consolidated 100% into X-Cal until August 2010.

| 5.2.6 | X-CAL 2006-2010 |

According to Giroux et al. (2009), core drilling procedures used by X-Cal during 2007 were as follows:

“Core was collected by a truck mounted Atlas Copco CS3001 core rig capable of drill depths in excess of 2,000 feet. The drill equipment was owned and operated by EMM Core Drilling of Winnemucca, Nevada. Corrugated waxed cardboard core boxes were provided by the core contractor. Wooden blocks or plastic depth indicators were labeled and placed by the core contractors at the appropriate measured drill depths.

Preferred core size was HQ. Adverse drilling conditions preventing advancement of the HQ tools were remedied by casing the hole down to the problem zone. Occasionally a reduction to NQ tools was needed to continue the drill hole to targeted depth.

|

24

RSI(RNO)-M0144.21001 REV 5 |

Core holes drilled in the West Wood target were pre-collared and cased to bedrock (approximately 160-210 feet) using the RCD rig. Angle and vertical drill hole collar sites were pre-surveyed using a portable GPS positioning device.

Completion of each core hole was preceded by down hole surveys conducted by International Directional Services of Battle Mountain, Nevada. After the completion of the drill hole and down hole survey the hole was abandoned by pumping a bentonite slurry from the bottom of the drill hole to within 10 feet of the surface. The remaining surface plug was ten feet of Portland cement. Desert Mountain Surveying of Winnemucca, Nevada, conducted surface collar surveys for each core hole.

Core boxes filled with core were neatly stacked upon pallets and tarped at the drill site until the full pallet was transported to the core processing facility. The core was washed, geologically logged and sample intervals selected and labeled by the core geologist.

The next procedure was digitally photographing the core in place utilizing scale bars to easily position the exact down hole location within each individual core box. The core boxes were then positioned next to the sheds that contain self-feeding core saws.

Each piece of silicified or hard core is placed in a confinement jig. The maximum length is one foot. The jig positions the core’s central axis producing two nearly exact volumetric halves after the core has been cut. One core half is returned to its origin box and the remaining half is placed into a pre-marked 16”X19” sample bag. The more clay rich core intervals are hand chiseled into halves by the core technician or by a geologist.

The sampling technician independently logged the core sample intervals. Copies of the sample intervals are submitted to the assay lab and a copy is archived into individual core hole folders. In addition, the folders contain copies of the geologic log, down hole survey, assays, hole abandonment sheets and surface collar surveys.”

Giroux et al. (2009) stated that X-Cal’s RC drilling procedures in 2007 were as follows:

“The reverse circulation drilling (RC) programs for both late 2006 and 2007 have utilized a Schramm 685, capable of drill depths in excess of 2,500 feet. The Schramm rig is owned and operated by DeLong Drilling and Construction of Winnemucca, Nevada. The crew consists of one driller and two driller’s helpers. The driller’s helpers have multiple tasks in addition to their mechanical drilling duties which include sample bag numbering (including duplicates), chip tray numbering, sample and chip collection and sample storage at the drill site. All drill hands are responsible for a safe, clean and organized drill site.

The preferred RC drill hole diameter is 5 3⁄4 inches produced by a pneumatic hammer and carbide button bit. If water volumes exceed capacities that prevent the advancement of the hammer tool or adverse conditions warrant the use of a tricone tool, the hammer tool is tripped out of the hole and the appropriate tri-cone diameter is returned to the bottom of the hole.

|

25

RSI(RNO)-M0144.21001 REV 5 |

Occasionally a reduction to a smaller diameter of tri-cone is needed to complete the proposed drill hole.

Depths to bedrock vary according to target location. Shallow bedrock depths (less than 20 feet) require only one 20-foot length of 6 inch inside diameter thick-walled casing. Moderate depths to bedrock (over 20 feet and under 250 feet) are cased using a conventional (weld, hammer drive, weld) casing technique. After recent sediments (sands, basin fill sand and gravels) reach accumulations in excess of 250 feet casing depth is dependent upon the sediment’s integrity (adhesive, cementation and porosity properties) and water volumes encountered. All drill holes drilled atop of mine dumps or other areas previously used as staging areas for ore (crusher sites, mill site, etc.) are cased through the mine dump fill material into bedrock at least 10 feet.

RC samples are collected from the surface every 5 feet. Provided an area has previous drilling results that warrant the over burden not to be sampled, an appropriate estimate to sample depth is provided to the driller. Duplicate samples are collected from the rotary splitter every 150 feet.

The rotary wet splitter (splitter) is attached to the rear passenger side of the Schramm. The splitter is washed down after each completed drill hole. Once surface casing is completed water and on demand drilling mud and hole conditioners are injected to suppress silica dust exposure and maintain the integrity of the drill hole.

The splitter has removable pie shaped platelets that are removed or added to maintain a consistent 20:1 volumetric split product at the exit end of the sample collection port. The sample exits the port straight downward into a 5-gallon plastic bucket. Once the 5 feet drill interval has been completed another clean bucket is placed under the exit port. The sample bucket is poured into a pre-labeled 15 inch by 17-inch sample bag. The sample bucket is rinsed once with fresh water and contents poured into the sample bag. The bag is tied and placed into a collection crib or crate that has been provided to the project by American Assay. The crib provides an additional assurance against contamination by ground exposure. The duplicates taken every 150 feet are collected by similar procedure and placed upon a black plastic sheet for drill site storage.

Drill rod changes have long been suspected for down the hole contamination during RCD drilling on other projects. At Sleeper the end of the 20 feet drill rod cycle is used to ream, clean, and dress the walls of the last 20 feet drilled. The process takes a few moments but is vital in maintaining a clean drill hole. Once the new rod for the next 20 feet is positioned, the rotation is started and down the hole pressures and water levels are allowed to stabilize. A screen is placed at the exit of the splitter and checked for debris that may have its origin from up hole. The sample bucket is re-positioned under the sample port only after the driller observes a clean return in the screen. This method takes additional time and has been proven to be a very effective method in minimizing down the hole contamination.

|

26

RSI(RNO)-M0144.21001 REV 5 |

Completion of each RCD hole was preceded by down hole surveys conducted by International Directional Services of Battle Mountain, Nevada. After the completion of the drill hole and down hole survey the hole was abandoned by pumping a bentonite slurry from the bottom of the drill hole to within 10 feet of the surface. The remaining surface plug was ten feet of Portland cement. Desert Mountain Surveying of Winnemucca, Nevada, conducted surface collar surveys for each RCD and core hole.

Compartmental chip trays (20 compartments) were used to archive drilled material from each 5 feet of drill advancement. Each compartment’s content was pre-washed prior to filling the compartment with the aid of a fitted funnel. The process minimizes any contamination from other 5 feet samples. Prior to completion of an RCD hole, the chip trays were stored and secured by the drillers at the rig site after drilling hours. All chip trays were collected after completion of each specific RCD hole. Note: The fenced compound is locked after day shift ends and remains locked until day shift resumes the following day. During the day period the electric gate is unlocked and accessible to entry only through Sleeper personnel.