Tembec Inc.: Exhibit 99.4 - Filed by newsfilecorp.com

Exhibit 99.4

| |

TEMBEC |

| |

FINANCIAL REPORT 2013

|

| |

|

| 01 |

Message to Shareholders |

| |

|

| 04 |

Management’s Discussion and

Analysis |

| |

|

| 48 |

Management Responsibility |

| |

|

| 49 |

Independent Auditors’ Report

|

| |

|

| 50 |

Consolidated Financial Statements

|

| |

|

| 95 |

Directors and Officers |

| |

|

| 96 |

Shareholder Information |

| |

|

| |

APPENDIX |

| |

|

| |

Sustainability Report Summary

|

The covers are printed on 10pt. FSC-certified Kallima® Coated

Cover C2S,

manufactured by Tembec’s Temiscaming, Quebec, coated bleached

board mill.

TEMBEC INC.

©2013 All rights reserved

Printed in

Canada

MESSAGE

TO

SHAREHOLDERS

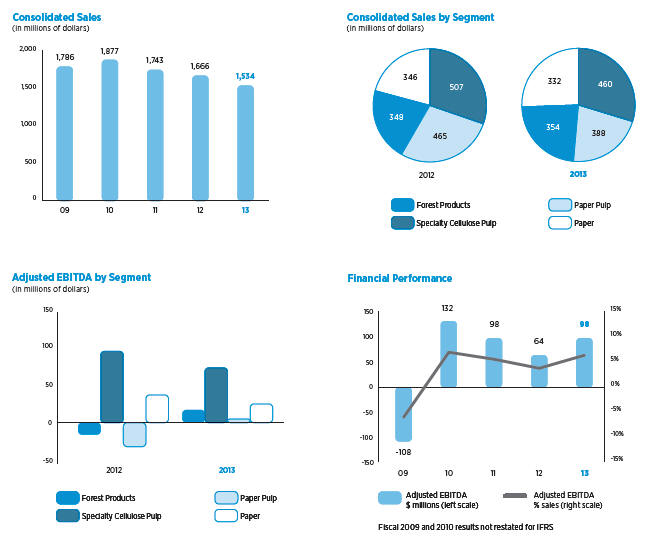

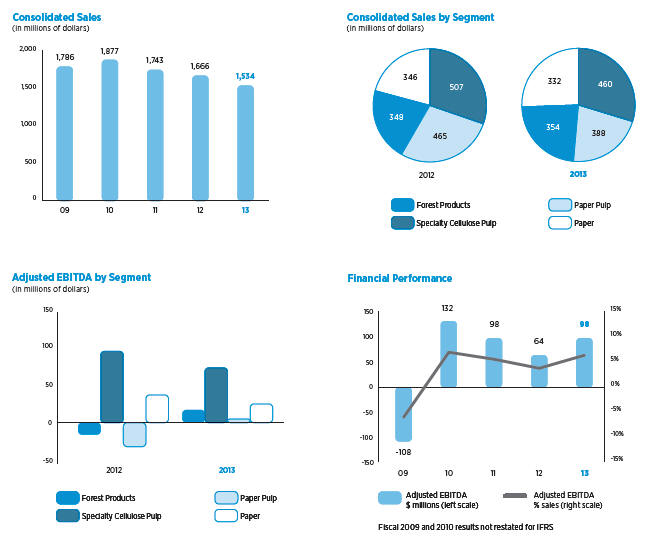

Fiscal 2013 was an important year for the Company as it made

significant strides in the implementation of the Transformation Plan. This

included the divestment of certain non-core businesses and reaching the 50%

completion mark on the Temiscaming Energy Project investment. The completion of

the Transformation Plan will drive further margin improvements and reduce the

volatility of the Company’s earnings.

Tembec continued its journey towards becoming a world-class

Company in health and safety performance by reducing recordable incidents by 16%

in 2013. This follows reductions of 32% in 2012 and 25% in 2011 and now marks

eight consecutive years of improvement in the Company’s health and safety

performance. The commitment and contribution of the Company’s employees have

been critical elements in the sustained improvement.

The financial results were below expectations, but improved

materially over the previous year. Adjusted EBITDA for 2013 was $98 million

versus $64 million in the previous year. The Company’s Specialty Cellulose

business continued to be the main driver of earnings, although market conditions

weakened somewhat throughout the year. The Paper business generated steady

earnings with stable market conditions. The Forest Products business continued a

positive trend that started in late 2012 with prices in a range to allow for

positive adjusted EBITDA. The Paper Pulp business contributed modest earnings in

a fairly stable market.

The Company continued to manage its cash flow judiciously while

continuing with its investment in the $235 million energy project at the

Temiscaming specialty cellulose facility. Additional projects identified in the

Business Improvement Plan have been deferred until cash flow permits, which will

likely occur after the start-up of the Temiscaming Project.

INVESTMENTS

The construction of the new liquor recovery boiler and

50-megawatt (MW) steam turbine that began in 2012 is now more than 50% complete.

The project will replace three obsolete, low-pressure boilers with a new

high-pressure boiler. In addition to the electricity revenue, the project will

provide efficiency benefits to the specialty cellulose mill and reduce

maintenance and capital costs.

The critical element of the Temiscaming energy investment is a

purchase power agreement with Hydro-Quebec that was signed in 2012. The

agreement provides for a guaranteed purchase of electricity produced by the new

turbine at a fixed price of $106 per MW/hour (based on 2012 rates), which is

adjusted for inflation annually, for a 25 year-term.

The construction budget for the Temiscaming Project was revised

from $190 million to $235 million in 2013. The higher cost was due to the

decision to increase the capacity of the boiler by 20% over the initial design.

This was done to accommodate a future capacity expansion of the specialty

cellulose mill. The projected benefit was also increased from $42 million to $48

million per year.

While capital expenditures were limited throughout the year,

the Company did complete a low consistency refiner project at the Kapuskasing

newsprint mill to reduce electricity consumption. The project was partially

funded by Ontario’s “Industrial Accelerator Program”. The Company also began

installing the first of four new autograders at sawmill sites.

Tembec Financial Report 2013

1

Message to Shareholders

Defined Benefit Pension Plans

The Company administers several defined benefit pension plans

on behalf of current and past employees. As highlighted in last year’s report,

the rapid and significant declines in interest rates over the last several years

created significant deficits in the plans, requiring large increases in the

Company’s contributions. Throughout this period, investments in the plans

continued to generate very good returns.

Fortunately, the negative trend for the pension plan deficits

and ensuing contributions has ended, and positive conditions are now converging

to rectify the situation. Long-term interest rates have increased, which has

reduced the deficits. This, combined with another year of good investment

performance and the high level of contributions made by the Company, has

significantly reduced the deficits of the various registered plans. The deficit

decreased from $200 million in September 2012 to $34 million at the end of

fiscal 2013.

The declining deficit will allow the Company to significantly

reduce contributions in 2014 and the trend should continue in subsequent

years.

Forest Products

The lumber business showed signs of recovery in 2012 with

increased demand and improved prices. Economic conditions and housing

affordability in the United States have created an improved environment for new

home construction. Strong demand for lumber in China continued throughout the

year, drawing a large volume of product from the North American markets. These

items helped to keep the lumber markets in relative balance, which led to

improved product prices.

U.S. housing starts did improve materially from 2012 to 2013.

However, the housing starts remain substantially below normalized levels. In

2013, the housing starts trended towards 1 million per year, but this is below a

trend line number of approximately 1.5 million per year. This indicates that

there is a strong probability for further increases in lumber demand as the

economic recovery continues. The Company anticipates that a full housing

recovery will not occur until 2016.

Chinese lumber demand from North America has been a significant

boost for producers and has partially mitigated the low demand for new home

construction. However, the Chinese demand has been mainly for random lengths and

has not had much effect on stud lumber. For this reason, the selling price of

stud lumber dropped significantly below random length prices in the second half

of 2013. This has had an impact on the financial results for Eastern Canadian

producers, such as ourselves, who produce large volumes of stud lumber. It is

believed that part of this price gap is seasonal and will decline during the

peak home construction season.

Specialty Cellulose

The Company has made the Specialty Cellulose business the

center piece of its Transformation Plan. This business has the potential to

generate superior margins with considerably lower volatility than other segments

of the forest products industry. Favorable long-term trends exist for the

products and there are large barriers of entry for new entrants. For these

reasons, the Company has decided to focus its capital investments in the two

specialty cellulose mills.

The initial focus of investment in the specialty mills was on

the Tartas, France, operation. Over the last decade, the mill was converted from

fluff pulp grades to 100% specialty cellulose grades. This required substantial

investments in process changes, environmental improvements and most recently,

green energy. The investments and transformation have made the Tartas mill a

world-class facility in both product quality and cost structure among mills in

this sector.

The Company has now turned its focus to the Temiscaming

specialty cellulose facility with the objective of duplicating the results at

Tartas. This mill has been a producer of specialty cellulose for decades and

provided the product technology to convert the French facility. However, certain

sections of the mill are in need of upgrades. The first in a two-step investment

plan is the aforementioned energy investment, which will not only significantly

reduce manufacturing costs, but will improve process reliability and product

quality. The second investment will involve new digesters and related

equipment.

2 Tembec Financial Report

2013

Message to Shareholders

After several good years of demand growth and price increases,

certain specialty cellulose markets experienced softness in demand in 2013. This

was most prevalent in the “ether” grades for construction related materials.

Other specialty grades remained relatively stable. Markets have been impacted by

poor economic conditions in Europe and generally lackluster global economic

growth. These conditions are likely to continue for the next 12-24 months. The

Specialty Cellulose business is expected to drive the Company’s profitability

through this period.

Paper Pulp

The Company sold its Skookumchuck NBSK mill in 2013, further

reducing its exposure to the paper pulp sector. It now operates two high-yield

pulp mills in Quebec. This is part of the ongoing refocusing of the Company

driven by the Transformation Plan. The lower margins and higher volatility of

this sector do not meet the objective of generating higher margins with reduced

volatility.

The markets for hardwood paper pulp could be challenging in the

short and medium-term due to the anticipated start-up of over 4 million tonnes

of new capacity in Brazil. There is a risk of excess supply of pulp and downward

pressure on price. The Company has been preparing for this eventuality by

focusing on a product differentiation strategy with its maple pulp and on cost

reduction efforts in the pulp mill operations.

Paper

The coated bleached board and newsprint operations have been

consistent generators of profitability for the Company. The coated bleached

board business has been stable with relatively firm pricing. The newsprint

business continues to experience demand decline in North America and prices have

declined over the last year. Future capacity reduction will be required in order

to maintain adequate prices.

TRANSFORMATION PLAN

The Company’s Management and Board of Directors continue with

its ambitious multi-year Transformation Plan, with the objective of improving

margins, reducing earnings volatility and ultimately driving shareholder value.

This has taken place during a period of challenging business conditions that

presented some unexpected issues as highlighted in this report.

The Transformation Plan targets the Specialty Cellulose

business as the key core business of the Company, and focuses investment on

green energy projects within these operations. The Plan also contemplates

strategic options for the other businesses to maximize the value to

shareholders. The divestment of certain assets has occurred as a result of this

Plan.

LIGHT AT THE END OF THE TUNNEL

Managing cash flow and generating profitability has been

challenging during the implementation of the Transformation Plan. However, the

Company believes that significant improvements will occur throughout 2014 to

enhance financial performance and cash flow. The Temiscaming Energy Project will

be concluded within the year, drastically reducing capital expenditures, and the

operating cash flow will improve with the start-up of the boiler and turbine by

the Fall of 2014. The sale of approximately $75 million of land in British

Columbia is anticipated in 2014. The Company’s contributions to the defined

benefit pension plans will drop in 2014 and continue to rapidly taper down

thereafter. All these events are expected to converge and favorably impact the

cash flow, profitability, and balance sheet of the Company. Other parts of the

Transformation Plan will also be executed as conditions allow. It is expected

that shareholders will be rewarded for their patience as the Company works

toward completion of the Transformation Plan.

|

|

| JAMES M. LOPEZ |

JAMES V. CONTINENZA |

| President and Chief Executive Officer |

Executive Chairman of the Board

|

Tembec Financial Report 2013

3

MANAGEMENT’S

DISCUSSION

AND ANALYSIS

as at November 29, 2013

The Management’s Discussion and Analysis (MD&A) section

provides a review of the significant developments and issues that influenced

Tembec Inc.’s financial performance during the fiscal year ended September 28,

2013, as compared to the fiscal year ended September 29, 2012. The MD&A

should be read in conjunction with the audited consolidated financial statements

for the fiscal year ended September 28, 2013. Financial data has been prepared

in accordance with International Financial Reporting Standards (IFRS) as issued

by the International Accounting Standards Board (IASB). All financial references

are stated in Canadian dollars, unless otherwise noted. All references to

quarterly information relate to Tembec’s fiscal quarters. Adjusted EBITDA, net

debt to total capitalization, free cash flow and certain other financial

measures utilized in the MD&A are non-IFRS financial measures. As they have

no standardized meaning prescribed by IFRS, they may not be comparable to

similar measures presented by other companies. Non-IFRS financial measures are

described in the section “Use of non-IFRS financial measures”.

The MD&A includes “forward-looking statements” within the

meaning of securities laws. Such statements relate, without limitation, to the

Company’s or management’s objectives, projections, estimates, expectations or

predictions of the future and can be identified by words such as “may”, “will”,

“could”, “anticipate”, “estimate”, “expect”, and “project”, the negative or

variations thereof, and expressions of similar nature. Forward-looking

statements are based on certain assumptions and analyses made by the Company in

light of its experience, information available to it and its perception of

future developments. Such statements are subject to a number of risks and

uncertainties, including, but not limited to, changes in foreign exchange rates,

product selling prices, raw material and operating costs and other factors

identified in the Company’s periodic filings with securities regulatory

authorities. Many of these risks are beyond the control of the Company and,

therefore, may cause actual actions or results to materially differ from those

expressed or implied herein. The forward-looking statements contained herein

reflect the Company’s expectations as of the date hereof and are subject to

change after such date. The Company disclaims any intention to update or revise

any forward-looking statements, whether as a result of new information, future

events or otherwise, unless required by applicable securities legislation. The

information in this MD&A is as at November 29, 2013. Disclosure contained in

this document is current to that date, unless otherwise stated.

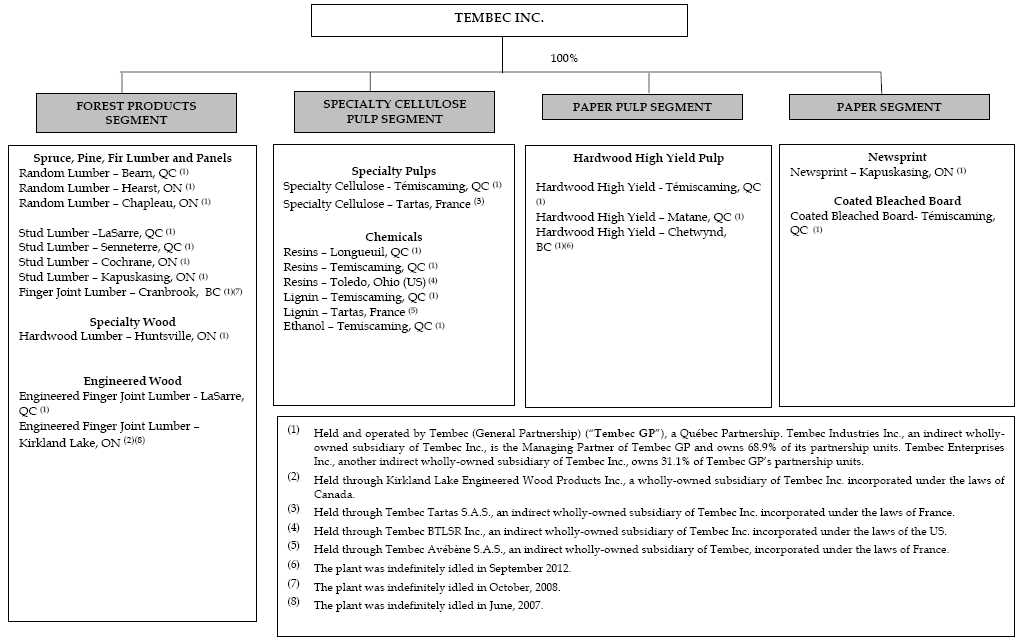

Throughout the MD&A, “Tembec” or “Company” means Tembec

Inc. and its consolidated subsidiaries. Tembec’s operations consist of five

reportable business segments: Forest Products, Specialty Cellulose Pulp, Paper

Pulp, Paper and Corporate. On September 28, 2013, the Company had approximately

3,500 employees, as compared to 3,700 at the end of the prior fiscal year. The

Company operates manufacturing facilities in Quebec, Ontario, British Columbia,

the state of Ohio as well as in Southern France. Principal facilities are

described in the subsequent sections of the MD&A.

Tembec Financial Report 2013 4

Management’s Discussion and Analysis

2013 vs. 2012

| FINANCIAL SUMMARY

|

|

|

|

|

|

|

| (in millions of

dollars, unless otherwise noted) |

|

2012

|

|

|

2013 |

|

| Sales |

|

1,666 |

|

|

1,534 |

|

| Freight and other deductions |

|

232 |

|

|

201 |

|

| Lumber export taxes |

|

7 |

|

|

3 |

|

| Cost of sales (excluding depreciation and

amortization) |

|

1,290 |

|

|

1,159 |

|

| SG&A |

|

74 |

|

|

72 |

|

| Share-based

compensation |

|

(1 |

) |

|

1 |

|

| Adjusted EBITDA

|

|

64

|

|

|

98 |

|

| Depreciation and amortization |

|

46 |

|

|

40 |

|

| Other items

|

|

50

|

|

|

29 |

|

| Operating earnings

(loss) |

|

(32 |

) |

|

29 |

|

| Interest, foreign exchange and other |

|

41 |

|

|

28 |

|

| Exchange

loss (gain) on long-term debt |

|

(13 |

) |

|

14 |

|

| Loss before income

taxes |

|

(60 |

) |

|

(13 |

) |

| Income tax

expense |

|

22

|

|

|

21 |

|

| Net loss |

|

(82 |

) |

|

(34 |

) |

| Basic and diluted

net loss in dollars per share |

|

(0.82 |

) |

|

(0.34 |

) |

| Total

comprehensive earnings (loss) |

|

(131 |

) |

|

115 |

|

| |

|

|

|

|

|

|

| Total assets (at

year-end) |

|

1,059

|

|

|

1,021 |

|

| Total long-term

debt (at year-end) (1) |

|

339

|

|

|

385 |

|

| Total long-term

liabilities (at year-end) |

|

627

|

|

|

509 |

|

| (1) Includes current portion |

|

|

|

|

|

|

Business segments

During the December 2012 quarter, the Company reorganized its

internal reporting structure, which impacted segment disclosure included in the

financial statements and MD&A. Prior to the change, the Company had reported

the results of the Skookumchuck, British Columbia (BC), Northern Bleached

Softwood Kraft (NBSK) pulp mill as part of the Specialty Cellulose and Chemical

Pulp segment. Subsequent to the organizational change, the mill was regrouped

with the high-yield pulp mills in a new segment called Paper Pulp. The Specialty

Cellulose and Chemical Pulp segment was renamed Specialty Cellulose Pulp.

Comparative prior year segment information has been restated in the financial

statements to conform to the new presentation.

Tembec Financial Report 2013 5

Management’s Discussion and Analysis

| SALES |

|

| |

|

|

|

|

|

|

|

Total |

|

|

Price |

|

|

Volume & mix |

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

|

variance |

|

|

variance |

|

|

variance |

|

| Forest Products |

|

432 |

|

|

420 |

|

|

(12 |

) |

|

43 |

|

|

(55 |

) |

| Specialty Cellulose Pulp |

|

507 |

|

|

460 |

|

|

(47 |

) |

|

3 |

|

|

(50 |

) |

| Paper Pulp |

|

507 |

|

|

418 |

|

|

(89 |

) |

|

9 |

|

|

(98 |

) |

| Paper |

|

346 |

|

|

332 |

|

|

(14 |

) |

|

(9 |

) |

|

(5 |

) |

| Corporate |

|

13 |

|

|

12 |

|

|

(1 |

) |

|

- |

|

|

(1 |

)

|

| |

|

1,805 |

|

|

1,642 |

|

|

(163 |

) |

|

46 |

|

|

(209 |

) |

| Less: intersegment

sales |

|

(139 |

) |

|

(108 |

) |

|

31 |

|

|

|

|

|

|

|

| Sales |

|

1,666

|

|

|

1,534 |

|

|

(132 |

) |

|

|

|

|

|

|

Tembec Financial Report 2013 6

Management’s Discussion and Analysis

Sales decreased by $132 million as compared to fiscal 2012.

Currency was not a significant factor as the Canadian dollar averaged US $0.985,

a 0.7% decrease from US $0.992 in the prior year. Forest Products segment sales

decreased by $12 million as a result of lower shipments, partially offset by

higher prices. Specialty Cellulose Pulp segment sales decreased by $47 million

due to lower shipments. Paper Pulp segment sales decreased by $89 million due to

lower shipments. Paper segment sales decreased by $14 million due to lower

prices and shipments.

In terms of geographical distribution, the U.S. remained the

Company’s principal market with 39% of consolidated sales in fiscal 2013, as

compared to 37% in the prior year. Canadian sales represented 19% of sales, as

compared to 18% in the prior year. Sales outside of the U.S. and Canada

represented the remaining 42% in fiscal 2013, as compared to 45% a year ago.

| ADJUSTED EBITDA |

|

| |

|

|

|

|

|

|

|

Total |

|

|

Price |

|

|

Cost & volume |

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

|

variance |

|

|

variance |

|

|

variance |

|

| Forest Products |

|

(16 |

) |

|

17 |

|

|

33 |

|

|

43 |

|

|

(10 |

) |

| Specialty Cellulose Pulp |

|

95 |

|

|

73 |

|

|

(22 |

) |

|

3 |

|

|

(25 |

) |

| Paper Pulp |

|

(32 |

) |

|

5 |

|

|

37 |

|

|

9 |

|

|

28 |

|

| Paper |

|

37 |

|

|

25 |

|

|

(12 |

) |

|

(9 |

) |

|

(3 |

) |

| Corporate |

|

(20 |

) |

|

(22 |

) |

|

(2 |

) |

|

- |

|

|

(2 |

)

|

| |

|

64 |

|

|

98 |

|

|

34 |

|

|

46 |

|

|

(12 |

)

|

Adjusted EBITDA of $98 million was $34 million higher than the

prior year. Forest Products segment adjusted EBITDA was up $33 million from the

prior year as a result of higher prices, partially offset by higher costs.

Specialty Cellulose Pulp segment adjusted EBITDA declined by $22 million due to

higher costs and lower volumes. Paper Pulp segment adjusted EBITDA improved by

$37 million due to lower costs and higher prices. Paper segment adjusted EBITDA

declined by $12 million due to lower prices and higher costs.

| OPERATING EARNINGS (LOSS) |

|

| |

|

|

|

|

|

|

|

|

|

|

Adjusted |

|

|

|

|

|

Other |

|

| |

|

|

|

|

|

|

|

Total |

|

|

EBITDA |

|

|

Depreciation |

|

|

items |

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

|

variance |

|

|

variance |

|

|

variance |

|

|

variance |

|

| Forest Products |

|

(4 |

) |

|

8 |

|

|

12 |

|

|

33 |

|

|

1 |

|

|

(22 |

) |

| Specialty Cellulose Pulp |

|

84 |

|

|

59 |

|

|

(25 |

) |

|

(22 |

) |

|

(3 |

) |

|

- |

|

| Paper Pulp |

|

(105 |

) |

|

(33 |

) |

|

72 |

|

|

37 |

|

|

9 |

|

|

26 |

|

| Paper |

|

35 |

|

|

22 |

|

|

(13 |

) |

|

(12 |

) |

|

(1 |

) |

|

- |

|

| Corporate |

|

(42 |

) |

|

(27 |

) |

|

15 |

|

|

(2 |

) |

|

- |

|

|

17 |

|

| |

|

(32 |

) |

|

29 |

|

|

61 |

|

|

34 |

|

|

6 |

|

|

21 |

|

Tembec Financial Report 2013 7

Management’s Discussion and Analysis

The Company generated operating earnings of $29 million

compared to an operating loss of $32 million in fiscal 2012.

The Forest Products segment generated operating earnings of $8

million, as compared to an operating loss of $4 million in fiscal 2012. In

addition to the previously noted improvement in adjusted EBITDA, the sale of the

BC sawmills and the hardwood flooring operations in fiscal 2012 led to lower

depreciation expense. During the prior fiscal year, the Company recorded a gain

of $24 million related to the sale of the BC sawmills. The Company also sold its

Toronto, Ontario, hardwood flooring plant and concurrently closed its

Huntsville, Ontario, hardwood flooring plant. The combined effect was a charge

of $2 million.

The Specialty Cellulose Pulp segment generated operating

earnings of $59 million compared to operating earnings of $84 million in the

prior year. The previously noted decline in adjusted EBITDA led to the lower

operating earnings.

The Paper Pulp segment generated an operating loss of $33

million compared to an operating loss of $105 million in the prior year. In

addition to the previously noted improvement in adjusted EBITDA, the segment saw

depreciation expense decline by $9 million due to the sale of the Skookumchuck,

BC, NBSK pulp mill. The prior year operating results included a $50 million

asset impairment charge relating to the Chetwynd, BC, high-yield pulp mill. The

current year included a $22 million asset impairment charge and a subsequent $2

million loss on sale related to the Skookumchuck pulp mill.

The Paper segment generated operating earnings of $22 million

compared to operating earnings of $35 million in the prior year. The previously

noted decline in adjusted EBITDA led to the lower operating earnings.

Corporate segment results improved by $15 million, primarily

due to “Other items”. In fiscal 2013, the Company generated a $2 million gain

related to the sale of the Cranbrook, BC, office. The prior year included a $16

million loss relating to the impairment of a loan receivable from Temlam Inc.

The latter is currently under creditor protection and owns an idled laminated

veneer lumber (LVL) facility located in Amos, Quebec. The Company has a 50%

secured interest in the facility. The prior year also included a gain of $4

million relating to the sale of a minority equity interest in two dissolving

pulp mills.

Tembec Financial Report 2013 8

Management’s Discussion and Analysis

SEGMENT REVIEW – 2013 vs. 2012

| FOREST PRODUCTS

|

|

|

|

|

|

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

| Sales (1) |

|

432 |

|

|

420 |

|

| Freight and other deductions |

|

41 |

|

|

39 |

|

| Lumber export taxes |

|

7 |

|

|

3 |

|

| Cost of sales (1) |

|

385 |

|

|

350 |

|

| SG&A |

|

15

|

|

|

11 |

|

| Adjusted EBITDA |

|

(16 |

) |

|

17 |

|

| Adjusted EBITDA

margin on sales |

|

(3.7 |

)% |

|

4.0% |

|

| Depreciation and amortization |

|

10 |

|

|

9 |

|

| Other items: |

|

|

|

|

|

|

| Gain on sale of BC sawmills |

|

(24 |

) |

|

- |

|

| Loss

on sale/closure of flooring operations |

|

2 |

|

|

- |

|

| Operating earnings

(loss) |

|

(4 |

) |

|

8 |

|

| Identifiable

assets (excluding cash) |

|

216

|

|

|

155 |

|

| (1) Includes intersegment sales eliminated on

consolidation |

The Forest Products segment is divided into two main areas of

activity: forest resource management and manufacturing operations.

The Forest Resource Management group is responsible for

managing all of the Company’s Canadian forestry operations. This includes the

harvesting of timber, either directly or by contractual agreements, and all

silviculture and regeneration work required to ensure a sustainable supply for

the manufacturing units. The group is also responsible for third party timber

purchases, which are needed to supplement total requirements. The group’s main

objective is the optimization of the flow of timber into various manufacturing

units. As the Company’s forest activity in Canada is conducted primarily on

Crown lands, the Forest Resource Management group works closely with provincial

governments to ensure harvesting plans and operations comply with established

regulations and that stumpage charged by the provinces is reasonable and

reflects the fair value of the timber being harvested. During fiscal 2013, the

Company’s operations harvested and delivered 3.2 million cubic metres of timber,

compared to 3.9 million cubic metres in the prior year. Additional supply of

approximately 0.6 million cubic metres was secured mainly through purchases and

exchanges with third parties, compared to 0.8 million cubic metres in the prior

year.

The Forest Products segment includes operations located in

Quebec and Ontario. At the end of the March 2012 quarter, the Company sold its

two BC sawmills. The sawmills had a capacity of 450 million board feet of

lumber, which represented approximately 29% of the Company’s total SPF lumber

capacity at that time. The SPF lumber operations can produce approximately 880

million board feet of lumber. The specialty wood operations can annually produce

30 million board feet of hardwood lumber. During the December 2011 quarter, the

Company sold its Toronto, Ontario, hardwood flooring plant and announced the

closure of its Huntsville, Ontario, hardwood flooring plant. The two operations

had a combined capacity of 20 million square feet of hardwood flooring. The

Company’s engineered wood operations consist of two finger joint lumber

operations, which were idle for all of fiscal 2012 and fiscal 2013.

Tembec Financial Report 2013 9

Management’s Discussion and Analysis

The following summarizes the current annual capacity of each

facility by product group:

| SPF LUMBER |

mbf |

| Stud lumber - La Sarre, QC |

135,000 |

| Stud lumber - Senneterre, QC |

100,000 |

| Stud lumber - Cochrane, ON |

110,000 |

| Stud lumber - Kapuskasing, ON |

105,000 |

| |

|

| Random lumber - Béarn, QC |

110,000 |

| Random lumber - Chapleau, ON |

135,000 |

| Random lumber - Hearst, ON |

160,000 |

| |

|

| Finger joint lumber - Cranbrook, BC |

25,000 |

| |

880,000 |

| |

|

| |

|

| SPECIALTY

WOOD |

mbf |

| Hardwood lumber - Huntsville, ON |

30,000 |

| |

|

| |

|

| ENGINEERED

WOOD |

mbf |

| Engineered finger joint lumber - La Sarre,

QC |

60,000 |

| Engineered finger joint lumber - Kirkland Lake, ON |

30,000 |

| |

90,000 |

The segment is dominated by SPF lumber, which represented 97%

of building material sales in fiscal 2013, compared to 94% in the prior year.

The volume of SPF lumber sold in fiscal 2013 decreased by 92 million board feet

or 11%. The sale of the Company’s two BC sawmills at the end of the March 2012

quarter had a significant impact on shipments and volumes. Shipments of lumber

from the two sawmills during the first two quarters of the prior year totalled

172 million board feet. Lumber shipments from the Company’s Eastern sawmills

increased by 80 million board feet, partially offsetting the previously noted

decrease. Shipments were equal to 82% of capacity, up from 73% in fiscal 2012.

Market conditions for lumber improved and this translated into increased demand

and prices. US $ reference prices for random lumber were up by US $71 per mbf on

average while stud lumber increased by US $51 per mbf. Currency was not a

significant factor as the Canadian dollar averaged US $0.985, a 0.7% decrease

from US $0.992 in the prior year. The combined result was a $59 per mbf price

increase from a year ago.

Tembec Financial Report 2013 10

Management’s Discussion and Analysis

Specialty wood represented 3% of building material sales in

fiscal 2013, down from 6% in the prior year. The decline was due to the sale of

the Toronto, Ontario, hardwood flooring plant and the closure of the Huntsville,

Ontario, hardwood flooring plant.

There were no engineered wood sales in fiscal 2012 and 2013.

The two finger joint facilities were idle for all of fiscal 2012 and fiscal

2013.

The Forest Products segment produced and shipped approximately

870,000 tonnes of wood chips in fiscal 2013, 67% of which were directed to the

Company’s pulp and paper operations. In 2012, the segment produced 977,000

tonnes and shipped 80% of this volume to the pulp and paper mills. The internal

transfer price of wood chips is based on current and expected market transaction

prices.

Total sales for this segment reached $420 million, a decrease

of $12 million over the prior year. After eliminating internal sales, the Forest

Products segment generated 23% of Company consolidated sales, up from 21% in the

prior year. The segment’s main market is North America, which represented 100%

of consolidated sales in fiscal 2013, compared to 97% in the prior year.

| |

|

Sales |

|

|

Shipments |

|

|

Selling prices |

|

| |

|

($ millions) |

|

|

(000 units |

) |

|

($ / unit) |

|

| |

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

| SPF lumber

(mbf) |

|

282

|

|

|

295 |

|

|

835.7 |

|

|

743.8 |

|

|

337 |

|

|

396 |

|

| Specialty wood |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Hardwood (mbf) |

|

8 |

|

|

9 |

|

|

12.7 |

|

|

13.6 |

|

|

629 |

|

|

662 |

|

| Hardwood

flooring (000 square ft) |

|

10 |

|

|

- |

|

|

2.2 |

|

|

- |

|

|

4,545 |

|

|

- |

|

| |

|

18 |

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Engineered Wood |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Engineered

finger joint lumber (mbf) |

|

- |

|

|

- |

|

|

- |

|

|

- |

|

|

- |

|

|

- |

|

| Total building

materials |

|

300

|

|

|

304 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Wood chips,

logs and by-products |

|

132

|

|

|

116 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Total sales

|

|

432

|

|

|

420 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Internal

wood chips and other sales |

|

(84 |

) |

|

(66 |

) |

|

|

|

|

|

|

|

|

|

|

|

|

| Consolidated

sales |

|

348

|

|

|

354 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Tembec Financial Report 2013 11

Management’s Discussion and Analysis

Markets

The Company markets its lumber with its own internal sales

force.

The benchmark random length Eastern SPF average lumber price

(#2 and better delivered Great Lakes) increased from US $370 per mbf to US $441

per mbf in 2013. The reference price for stud lumber also increased with the

Eastern average lumber price (delivered Great Lakes) up from US $353 per mbf to

US $404 per mbf. The prices were driven by an improving U.S. housing market.

Housing starts in the U.S. on a seasonally adjusted basis averaged 906,000 units

in fiscal 2013, an increase over the 729,000 units in fiscal 2012. However,

these remain below the 2 million unit mark experienced in the 2004-2006 period

and the +1.2 million average that would be indicative of normal market

conditions. While the Company recognized several years ago that U.S. housing

starts could not maintain the 2 million unit per year run rate, and that a

degree of market correction would likely occur at some point, the duration of

the correction has been significantly longer than those of prior cycles. The

negative effects of the sub-prime mortgage difficulties, the latter having

fuelled the strong demand in 2004-2006, have been much greater in terms of

impact than originally anticipated. During fiscal 2013, the Company shipped

388,800 mbf into the U.S. market from its Eastern sawmills. In the prior year,

shipments to the U.S. from the Eastern sawmills were 295,000 mbf and shipments

from the two Western sawmills were 77,200 mbf in the first six months of fiscal

2012. The improved U.S. market conditions drove the 32% increase in Eastern

lumber shipments to the U.S.

While the U.S. housing market improved, this was not the case

for the Canadian housing market. Housing starts in Canada on a seasonally

adjusted basis averaged 190,000 units, an 11% decline from 214,000 units in the

prior year. The weaker Canadian demand for lumber did not affect prices, which

are determined primarily by the much larger U.S. market. During fiscal 2013, the

Company shipped 355,000 mbf into the Canadian market from its Eastern sawmills.

In the prior year, Canadian shipments from the Eastern sawmills totalled 369,200

mbf and shipments from the two Western sawmills were 94,300 mbf in the first six

months of fiscal 2012.

The Company’s financial performance continued to be impacted by

export taxes on lumber shipped to the U.S. Effective October 12, 2006, the

governments of Canada and the United States implemented an agreement for the

settlement of the softwood lumber dispute. The Softwood Lumber Agreement (SLA)

requires that an export tax be collected by the Government of Canada, which is

based on the price and volume of lumber shipped. Since that date, the Company’s

Eastern Canadian sawmills have been subject to export quota limitations and a 5%

export tax on lumber shipped to the U.S. The SLA provides that during periods of

relatively high prices, as was the case during the spring and summer months of

2013, the export tax rate declines. In fiscal 2013, the average tax rate on

Eastern lumber shipped to the U.S. was 1.9% and the total cost was $3 million.

In fiscal 2012, the average tax rate on Eastern lumber shipments to the U.S. was

4.8% and the total cost was $4 million. The rate decline was due to the higher

prices. The impact of the lower rate was partially offset by the increased

shipments to the U.S. market.

The Company sold its two British Columbia sawmills in March

2012. As such, the MD&A data includes the mills financial results for the

first six months in fiscal 2012. The BC sawmills were subject to a 15% export

tax, but shipments were not quota limited. In fiscal 2012, the average rate on

shipments was 15% and the total cost was $3 million.

Tembec Financial Report 2013 12

Management’s Discussion and Analysis

Operating Results

The following summarizes adjusted EBITDA variances by major

element:

| |

|

Variance - favourable (unfavourable) |

|

| |

|

|

|

|

|

|

|

|

|

|

Inventory |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

Export |

|

|

Mill |

|

|

NRV |

|

|

|

|

|

|

|

|

|

|

| (in millions of

dollars) |

|

Price

|

|

|

taxes

|

|

|

costs

|

|

|

adjustments |

|

|

Freight |

|

|

Other

|

|

|

TOTAL

|

|

| SPF lumber |

|

43 |

|

|

1 |

|

|

(12 |

) |

|

(3 |

) |

|

(3 |

) |

|

6 |

|

|

32 |

|

| Other segment

items |

|

- |

|

|

- |

|

|

- |

|

|

- |

|

|

- |

|

|

1 |

|

|

1 |

|

| |

|

43 |

|

|

1 |

|

|

(12 |

) |

|

(3 |

) |

|

(3 |

) |

|

7 |

|

|

33 |

|

In fiscal 2013, adjusted EBITDA was $17 million compared to

negative adjusted EBITDA of $16 million in the prior year. SPF lumber adjusted

EBITDA improved by $32 million. The previously noted higher selling prices for

lumber increased adjusted EBITDA by $43 million. The higher prices were assisted

by currency as the Canadian dollar averaged US $0.985, a 0.7% decrease from US

$0.992 in the prior year. The previously noted decline in export taxes on

Eastern lumber shipped to the U.S. increased adjusted EBITDA by a further $1

million. Sawmill manufacturing costs increased by $12 million, primarily due to

increased fibre costs. In the prior year, the segment had benefited from a $3

million favourable adjustment to the carrying values of logs and lumber

inventories. There was no net realizable value adjustment in fiscal 2013. The $6

million positive variance in “Other” related primarily to the two BC sawmills.

In the first six months of the prior year, the sawmills had generated negative

adjusted EBITDA of $5 million. The adjusted EBITDA margin to total sales was

4.0% compared to negative 3.7% in the prior year.

The following summarizes operating results variances by major

element:

| |

|

|

|

|

|

|

|

Variance

|

|

| |

|

|

|

|

|

|

|

favourable |

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

|

(unfavourable) |

|

| Adjusted EBITDA |

|

(16 |

) |

|

17 |

|

|

33 |

|

| Depreciation and amortization |

|

10 |

|

|

9 |

|

|

1 |

|

| Other items (gain) |

|

(22 |

) |

|

- |

|

|

(22 |

) |

| Operating earnings

(loss) |

|

(4 |

) |

|

8 |

|

|

12

|

|

The Forest Products segment generated operating earnings of $8

million, as compared to an operating loss of $4 million in fiscal 2012. In

addition to the previously noted improvement in adjusted EBITDA, the sale of the

BC sawmills and the hardwood flooring operations led to lower depreciation

expense. During the prior fiscal year, the Company recorded a gain of $24

million related to the sale of the BC sawmills. The Company sold its Toronto,

Ontario, hardwood flooring plant and concurrently closed its Huntsville,

Ontario, hardwood flooring plant. The combined effect was a charge of $2

million.

Tembec Financial Report 2013 13

Management’s Discussion and Analysis

| SPECIALTY

CELLULOSE PULP |

|

|

|

|

|

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

| Sales - Pulp |

|

407 |

|

|

360 |

|

| Sales - Chemicals

|

|

100

|

|

|

100 |

|

| |

|

507 |

|

|

460 |

|

| |

|

|

|

|

|

|

| Freight and other deductions |

|

40 |

|

|

36 |

|

| Cost of sales |

|

352 |

|

|

331 |

|

| SG&A |

|

20

|

|

|

20 |

|

| Adjusted EBITDA |

|

95 |

|

|

73 |

|

| Adjusted EBITDA

margin on sales |

|

18.7%

|

|

|

15.9% |

|

| Depreciation and

amortization |

|

11

|

|

|

14 |

|

| Operating earnings

|

|

84

|

|

|

59 |

|

| Identifiable

assets (excluding cash) |

|

544

|

|

|

538 |

|

The Specialty Cellulose Pulp segment consists of two

manufacturing facilities, which produce specialty cellulose pulps.

The specialty cellulose pulp mills have an annual capacity of

310,000 tonnes per year. The pulp produced at the two pulp mills is a high

purity cellulose utilized in a wide variety of specialized products such as

pharmaceuticals, food additives, and industrial chemicals. The Temiscaming mill

also produces “viscose” grade pulp, which is utilized in the production of

viscose staple fibre, which in turn is used to produce rayon for the textile

industry.

The specialty cellulose mills generate lignin as a by-product

of the sulphite process, which is sold to third parties. The Temiscaming mill

also includes a facility that produces ethanol as a by-product that is also sold

to third parties.

The segment also includes a stand-alone resin business, which

produces powder and liquid phenolic resins at two operating sites in Quebec:

Temiscaming and Longueuil. The Company also operates a third facility located in

Toledo, Ohio, which manufactures powder and liquid amino-resins. The chemical

business periodically purchases and re-sells third party pulp mill by-product

chemicals.

The following summarizes the annual operating capacity of each

facility:

| SPECIALTY CELLULOSE |

|

tonnes |

|

| Specialty cellulose - Temiscaming, QC |

|

160,000 |

|

| Specialty cellulose - Tartas, France |

|

150,000 |

|

| |

|

310,000 |

|

| |

|

|

|

| |

|

|

|

| CHEMICALS

|

|

|

|

| Resin and related products - Temiscaming

and Longueuil, QC; Toledo, Ohio |

|

170,000 |

|

| Lignin - Temiscaming, QC; Tartas, France |

|

190,000 |

|

| Ethanol - Temiscaming, QC (million litres)

|

|

12.1 |

|

Total sales for the Specialty Cellulose Pulp segment were $460

million, a decrease of $47 million from the prior year. The decrease was due to

lower shipments of specialty grades. The Specialty Cellulose Pulp segment

generated 30% of Company consolidated sales, unchanged from the prior year. The

Specialty Cellulose Pulp segment is a global business. In 2013 and fiscal 2012,

62% of consolidated sales were generated outside of Canada and the U.S.

Tembec Financial Report 2013 14

Management’s Discussion and Analysis

| |

|

Sales |

|

|

Shipments |

|

|

Selling prices |

|

| |

|

($ millions) |

|

|

(000 units |

) |

|

($ / unit) |

|

| |

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

| Specialty pulp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Specialty cellulose (tonnes) |

|

353 |

|

|

318 |

|

|

215.1 |

|

|

186.3 |

|

|

1,641 |

|

|

1,705 |

|

|

Viscose grade (tonnes) |

|

54 |

|

|

43 |

|

|

42.3

|

|

|

44.9 |

|

|

1,264 |

|

|

951 |

|

| |

|

407

|

|

|

361 |

|

|

257.4

|

|

|

231.2 |

|

|

|

|

|

|

|

| Chemicals |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Resin and related products (tonnes) |

|

55 |

|

|

56 |

|

|

55.7 |

|

|

50.6 |

|

|

987 |

|

|

1,107 |

|

| Lignin (tonnes) |

|

29 |

|

|

26 |

|

|

132.4 |

|

|

94.8 |

|

|

219 |

|

|

274 |

|

|

Ethanol (000 litres) |

|

9 |

|

|

9 |

|

|

10.0

|

|

|

10.3 |

|

|

900

|

|

|

874 |

|

| |

|

93 |

|

|

91 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Other sales

|

|

7 |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Consolidated

sales |

|

507

|

|

|

460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Markets

The Company markets its pulp on a world-wide basis, primarily

through its own sales force. Permanent sales offices are maintained in Toronto,

Canada and Dax, France. Contractual arrangements with third party

representatives are also utilized.

The shipments to capacity ratio for specialty pulp was 75% in

fiscal 2013 versus 83% in the prior year. The decrease in shipment ratio was due

primarily to a decrease of 28,800 tonnes in specialty grade pulp shipments.

During fiscal 2012 and 2013, both mills operated as planned and no production

curtailments were taken for market conditions. However, demand for specialty

grades was weaker in fiscal 2013 and as a result the mills operated at a reduced

rate, producing 16,700 fewer tonnes than in the prior year. Despite the lower

demand, realized prices increased by $64 per tonne, assisted by a Canadian

dollar that was weaker versus the euro and the US dollar. Market conditions in

the viscose grade continued to weaken from the record levels reached in 2011 and

prices declined by $313 per tonne. The viscose grade market continues to suffer

from excess production capacity brought on by the very high prices reached in

2011. The Company has a strategy of gradually reducing its exposure to the

viscose market by producing additional specialty grade volume. Unfortunately,

the weaker specialty market conditions experienced in fiscal 2013 did not permit

the Company to make any progress with this strategy. In fiscal 2013, viscose

grade shipments totalled 44,900 tonnes, compared to 42,300 tonnes in the prior

year.

Tembec Financial Report 2013 15

Management’s Discussion and Analysis

Operating Results

The following summarizes adjusted EBITDA variances by major

element:

| |

|

Variance - favourable (unfavourable) |

|

| |

|

|

|

|

Mill |

|

|

Inventory NRV |

|

|

|

|

|

|

|

|

|

|

| (in millions of

dollars) |

|

Price

|

|

|

costs

|

|

|

adjustments |

|

|

Mix

& volume |

|

|

Other

|

|

|

TOTAL

|

|

| Specialty cellulose |

|

(2 |

) |

|

(10 |

) |

|

(1 |

) |

|

(12 |

) |

|

1 |

|

|

(24 |

) |

| Chemicals |

|

5 |

|

|

(3 |

) |

|

- |

|

|

- |

|

|

- |

|

|

2 |

|

| |

|

3 |

|

|

(13 |

) |

|

(1 |

) |

|

(12 |

) |

|

1 |

|

|

(22 |

) |

Fiscal 2013 adjusted EBITDA was $73 million compared to $95

million in the prior year, a decrease of $22 million. Higher realized prices for

specialty grades increased adjusted EBITDA by $12 million. But this was more

than offset by the significant decline in viscose grade prices, which reduced

adjusted EBITDA by $14 million. Manufacturing costs at the two specialty pulp

mills increased by $10 million, primarily for chemicals and under-absorption of

fixed costs as the two mills produced 16,700 fewer tonnes in fiscal 2013. During

the current year, the segment also absorbed a net realizable value charge of $1

million on the carrying value of its viscose grade pulp inventories as pricing

ended the year at levels that were less than total estimated delivered cost.

Adjusted EBITDA was also negatively impacted by a volume variance of $12 million

caused by lower shipments of specialty grade pulp.

The $5 million favourable chemicals price variance was due to

higher lignin and resin prices. However, resin raw material costs increased by

$4 million and resin profitability declined by $2 million. The increase of $2

million in chemicals adjusted EBITDA was due to the Canadian lignin business,

which experienced higher prices and lower costs.

The Temiscaming specialty cellulose mill purchased

approximately 305,700 bone dry tonnes of wood chips in fiscal 2013, down from

370,200 in the prior year. Of this amount, approximately 73% was supplied by the

Forest Products segment, compared to 66% in the prior year. The remaining

requirements were purchased from third parties under contracts and agreements of

various durations. The pulp mill located in Southern France purchased 284,000

bone dry tonnes of wood in fiscal 2013 as compared to 287,000 bone dry tonnes in

the prior year. The fibre is sourced from many private landowners.

Overall, lower viscose grade prices and higher manufacturing

costs reduced adjusted EBITDA margins from 18.7% in 2012 to 15.9% in 2013.

The following summarizes operating results variances by major

element:

| |

|

|

|

|

|

|

|

Variance

|

|

| |

|

|

|

|

|

|

|

favourable |

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

|

(unfavourable) |

|

| Adjusted EBITDA |

|

95 |

|

|

73 |

|

|

(22 |

) |

| Depreciation and

amortization |

|

11

|

|

|

14 |

|

|

(3 |

) |

| Operating earnings

|

|

84

|

|

|

59 |

|

|

(25 |

) |

The Specialty Cellulose Pulp segment generated operating

earnings of $59 million during the most recently completed fiscal year, compared

to operating earnings of $84 million in the prior year. The previously noted

decline in adjusted EBITDA led to the lower operating earnings.

Tembec Financial Report 2013 16

Management’s Discussion and Analysis

| PAPER PULP |

|

|

|

|

|

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

| Sales (1) |

|

507 |

|

|

418 |

|

| Freight and other deductions |

|

105 |

|

|

80 |

|

| Cost of sales (1) |

|

427 |

|

|

325 |

|

| SG&A |

|

7 |

|

|

8 |

|

| Adjusted EBITDA |

|

(32 |

) |

|

5 |

|

| Adjusted EBITDA

margin on sales |

|

(6.3 |

)% |

|

1.2% |

|

| Depreciation and amortization |

|

23 |

|

|

14 |

|

| Other item: |

|

|

|

|

|

|

| Chetwynd impairment loss |

|

50 |

|

|

- |

|

| Skookumchuck asset impairment loss |

|

- |

|

|

22 |

|

| Loss

on sale of Skookumchuck |

|

- |

|

|

2 |

|

| Operating loss |

|

(105 |

) |

|

(33 |

) |

| |

|

|

|

|

|

|

| Identifiable

assets (excluding cash) |

|

156

|

|

|

142 |

|

|

(1) Includes intersegment sales eliminated on

consolidation

|

The Paper Pulp segment consisted of four market pulp

manufacturing facilities. Prior to May 2013, the Company owned and operated a

chemical softwood kraft (NBSK) paper pulp mill located in Skookumchuck, BC. The

mill had a capacity to produce 270,000 tonnes per year. Its financial results

are included in the segment’s results for all of fiscal 2012 and for

approximately eight months in fiscal 2013. The remaining three facilities are

hardwood high-yield pulp mills. They produce pulp with a combination of

mechanical and chemical processes. The Company produces hardwood grades made

from maple, aspen and birch. High-yield pulps have a lower tensile and tear

strength than kraft pulps but they offer advantages on bulk and opacity. They

compete against other hardwood or “short fibre” grades, with Bleached Eucalyptus

Kraft (BEK) being the most prominent. The Chetwynd, BC, mill has been idle since

September 2012 due to relatively low prices resulting from significant new

capacity start-ups of BEK pulp mills in the Southern hemisphere.

The following summarizes the annual capacity of each facility:

| HIGH-YIELD PULP |

tonnes |

| Hardwood high-yield - Temiscaming, QC |

315,000 |

| Hardwood high-yield - Matane, QC |

250,000 |

| Hardwood high-yield - Chetwynd, BC |

240,000 |

| |

805,000 |

This segment shipped 542,700 tonnes of high-yield pulp in

fiscal 2013 compared to 640,700 tonnes in the prior year. The Chetwynd, BC, pulp

mill did not operate in fiscal 2013, reducing shipments by 175,800 tonnes. This

reduction was partially offset by higher shipments from the Company’s two other

high-yield pulp mills. NBSK pulp shipments declined by 58,400 tonnes as a result

of the sale of the Skookumchuck pulp mill in mid-May 2013.

High-yield pulp shipments include 61,600 tonnes consumed by the

Company’s paperboard operations, as compared to 60,100 tonnes in the prior year.

The paperboard operations did not utilize any internally produced NBSK in fiscal

2013, as compared to 17,300 tonnes consumed in the prior year.

Total sales for the Paper Pulp segment were $418 million, a

decrease of $89 million from the prior year. After eliminating internal sales,

the Paper Pulp segment generated 25% of Company consolidated sales, as compared

to 28% in the prior year. The Paper Pulp segment is more export oriented than

the other business segments within the Company. In 2013, 86% of consolidated

pulp sales were generated outside of Canada and the U.S., as compared to 87% in

the prior year. China alone accounted for 44% of sales compared to 38% in the

prior year.

Tembec Financial Report 2013 17

Management’s Discussion and Analysis

| |

|

Sales |

|

|

Shipments |

|

|

Selling prices |

|

| |

|

($ millions) |

|

|

(000 tonnes |

) |

|

($ / tonne) |

|

| |

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

| Hardwood high-yield pulp |

|

352 |

|

|

308 |

|

|

640.7 |

|

|

542.7 |

|

|

549 |

|

|

568 |

|

| NBSK pulp |

|

155

|

|

|

110 |

|

|

222.5

|

|

|

164.1 |

|

|

697

|

|

|

670 |

|

| Total sales |

|

507 |

|

|

418 |

|

|

863.2 |

|

|

706.8 |

|

|

|

|

|

|

|

|

Internal sales |

|

(42 |

) |

|

(30 |

) |

|

(77.4 |

) |

|

(61.6 |

) |

|

|

|

|

|

|

| Consolidated

sales |

|

465

|

|

|

388 |

|

|

785.8

|

|

|

645.2 |

|

|

|

|

|

|

|

Markets

The Company markets its pulp on a world-wide basis, primarily

through its own sales force. Sales offices are maintained in Toronto, Canada and

Dax, France. Contractual arrangements with third party representatives are also

utilized.

The shipments to capacity ratio for high-yield pulp was at 96%

versus 80% in the prior year. The fiscal 2013 ratio does not include the

capacity of the Chetwynd pulp mill, which has been indefinitely idled since

September 2012 due to relatively weak demand and pricing for high-yield pulp.

While the reference price for BEK increased by US $53 per tonne, the increase in

high-yield pricing was a more modest US $14 per tonne. Currency was relatively

unchanged as the Canadian dollar averaged US $0.985, a 0.7% decline from US

$0.992 in the prior year. Overall, Canadian dollar prices for high-yield pulp

increased by $19 per tonne. Inventory levels ended the year at 22 days of supply

as compared to 35 days at the end of fiscal 2012.

The shipments to capacity ratio for NBSK pulp was 96% in fiscal

2013, up from 82% in the prior year. In fiscal 2012, the Skookumchuck mill

productivity had been adversely affected by 17 days of unplanned downtime to

effect repairs on its recovery boiler. The benchmark price (delivered China)

increased by US $1 per tonne. However, discounts to reference prices increased

year-over-year and NBSK price realizations declined by $27 per tonne.

Tembec Financial Report 2013 18

Management’s Discussion and Analysis

Operating Results

The following summarizes adjusted EBITDA variances by major

element:

| |

|

Variance - favourable (unfavourable) |

|

| |

|

|

|

|

Mill |

|

|

Inventory NRV |

|

|

|

|

|

|

|

| (in millions of

dollars) |

|

Price

|

|

|

costs

|

|

|

adjustments |

|

|

Other

|

|

|

TOTAL

|

|

| High-yield pulp |

|

13 |

|

|

(8 |

) |

|

5 |

|

|

11 |

|

|

21 |

|

| NBSK pulp |

|

(4 |

) |

|

19 |

|

|

2 |

|

|

1 |

|

|

18 |

|

| Other segment items |

|

- |

|

|

- |

|

|

- |

|

|

(2 |

) |

|

(2 |

) |

| |

|

9 |

|

|

11 |

|

|

7 |

|

|

10 |

|

|

37 |

|

Fiscal 2013 adjusted EBITDA was $5 million compared to negative

$32 million in the prior year. The previously noted increase in high-yield pulp

selling prices increased adjusted EBITDA by $13 million. This was partially

offset by a $4 million reduction due to weaker NBSK prices. Mill level costs at

the two high-yield pulp mills increased by $8 million, primarily due to higher

chemical costs. Manufacturing costs at the NBSK mill improved significantly. In

the prior year, the mill had absorbed costs related to 17 days of unplanned

downtime to repair its recovery boiler. The segment also benefited from a

favourable variance of $7 million on the net realizable value (NRV) of finished

goods inventories. In the prior year, low pulp selling prices in the September

2012 quarter had generated a charge of $3 million on the estimated NRV of

finished goods inventories. During the fiscal 2013, pricing gradually improved

and the Company recorded a gain of $4 million relating to NRV adjustments on the

carrying value of finished goods inventories. The $11 million favourable

variance in “Other” category relates primarily to the Chetwynd high-yield pulp

mill, which generated negative adjusted EBITDA of $12 million in the prior year.

The pulp mills purchased approximately 834,500 bone dry tonnes

of wood chips in fiscal 2013, down from 1,189,000 in the prior year. The decline

was due to the idling of the Chetwynd high-yield pulp mill and the sale of the

Skookumchuck NBSK pulp mill. Of this amount, approximately 20% was supplied by

the Forest Products segment, compared to 29% in the prior year. The remaining

requirements were purchased from third parties under contracts and agreements of

various durations.

Overall, higher high-yield pulp prices and lower NBSK costs

increased profitability with an adjusted EBITDA margin of 1.2% compared to

negative 6.3% in the prior year.

The following summarizes operating results variances by major

element:

| |

|

|

|

|

|

|

|

Variance

|

|

| |

|

|

|

|

|

|

|

favourable |

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

|

(unfavourable) |

|

| Adjusted EBITDA |

|

(32 |

) |

|

5 |

|

|

37 |

|

| Depreciation and amortization |

|

23 |

|

|

14 |

|

|

9 |

|

| Other items |

|

50

|

|

|

24 |

|

|

26

|

|

| Operating loss |

|

(105 |

) |

|

(33 |

) |

|

72

|

|

The Paper Pulp segment generated an operating loss of $33

million during the most recently completed fiscal year, compared to an operating

loss of $105 million in the prior year. In addition to the previously noted

improvement in adjusted EBITDA, the segment saw depreciation expense decline by

$9 million due primarily to the sale of the Skookumchuck pulp mill. The prior

year operating results included a $50 million asset impairment charge relating

to the Chetwynd high-yield pulp mill. The current year included a $22 million

asset impairment charge and a subsequent $2 million loss on sale related to the

Skookumchuck pulp mill.

Tembec Financial Report 2013 19

Management’s Discussion and Analysis

| PAPER |

|

|

|

|

|

|

| (in millions of

dollars) |

|

2012

|

|

|

2013 |

|

| Sales |

|

346 |

|

|

332 |

|

| Freight and other deductions |

|

46 |

|

|

46 |

|

| Cost of sales |

|

252 |

|

|

250 |

|

| SG&A |

|

11

|

|

|

11 |

|

| Adjusted EBITDA |

|

37 |

|

|

25 |

|

| Adjusted EBITDA

margin on sales |

|

10.7%

|

|

|

7.5% |

|

| Depreciation and

amortization |

|

2 |

|

|

3 |

|

| Operating earnings

|

|

35

|

|

|

22 |

|

| |

|

|

|

|

|

|

| Identifiable

assets (excluding cash) |

|

120

|

|

|

137 |

|

The Paper segment currently includes two paper manufacturing

facilities with a total of three paper machines. The mill located in

Kapuskasing, Ontario, produces newsprint on two machines. The facility located

in Temiscaming, Quebec, produces multi-ply coated bleached board on one machine.

The board mill is partially integrated with a high-yield pulp mill. The total

capacity of the Paper segment is 420,000 tonnes.

The following summarizes the products and capacity of each

facility:

| COATED BLEACHED BOARD |

tonnes |

| Temiscaming, QC |

180,000 |

| |

|

| NEWSPRINT

|

|

| Kapuskasing, ON |

240,000 |

Coated bleached board shipments represented 44% of Paper

segment shipments in fiscal 2013, unchanged from the prior year. As a percentage

of total segment sales, coated bleached board represented 61% of sales compared

to 59% in the prior year.

Newsprint shipments represented 56% of Paper segment shipments

in fiscal 2013, unchanged from the prior year. In terms of total segment sales,

newsprint represented 39% of sales compared to 41% in the prior year.

Sales for the Paper segment totalled $332 million, as compared

to $346 million in the prior year. The segment generated 22% of Company

consolidated sales, as compared to 21% in fiscal 2012. The focus of the paper

business is North America, which accounted for 94% of consolidated sales in

2013, unchanged from the prior year. The U.S. alone accounted for 74% of sales

in fiscal 2013, as compared to 77% in the prior year.

| |

|

Sales |

|

|

Shipments |

|

|

Selling prices |

|

| |

|

($ millions) |

|

|

(000 tonnes |

) |

|

($ / tonne) |

|

| |

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

|

2012

|

|

|

2013 |

|

| Coated bleached board (rolls and sheets) |

|

204 |

|

|

201 |

|

|

171.2 |

|

|

169.9 |

|

|

1,192 |

|

|

1,183 |

|

| Newsprint |

|

142

|

|

|

131 |

|

|

221.8

|

|

|

215.9 |

|

|

640 |

|

|

608 |

|

| Consolidated

sales |

|

346

|

|

|

332 |

|

|

393.0

|

|

|

385.8 |

|

|

|

|

|

|

|

Tembec Financial Report 2013 20

Management’s Discussion and Analysis

Markets

The benchmark reference price for coated bleached board rolls