Exhibit 99.2

TASMAN METALS LTD.

MANAGEMENT’S DISCUSSION AND ANALYSIS

FOR THE THREE MONTHS ENDED NOVEMBER 30, 2015

This discussion and analysis of financial position and results of operation is prepared as at January 11, 2016 and should be read in conjunction with the unaudited condensed consolidated interim financial statements for the three months ended November 30, 2015 of Tasman Metals Ltd. (“Tasman” or “the Company”). The following disclosure and associated financial statements are presented in accordance with International Financial Reporting Standards (“IFRS”). Except as otherwise disclosed, all dollar figures included therein and in the following management discussion and analysis (“MD&A”) are quoted in Canadian dollars.

Forward Looking Statements

Certain statements found in this discussion may constitute forward-looking statements as defined in the U.S. Private Securities Litigation Reform Act of 1995 or forward-looking information within the meaning of applicable Canadian securities laws (collectively, “forward-looking statements”). Forward-looking statements reflect the speaker’s current views with respect to future events and financial performance and include any statement that does not directly relate to a current or historical fact. Such statements reflect the current risks, uncertainties and assumptions related to certain factors including, without limitations, competitive factors, general economic conditions, customer relations, uncertainties related to the availability and costs of financing, the implementation of the Norra Kärr amended and restated pre-feasibility study, changes in corporate goals, unexpected expenditures, unexpected geological conditions, success of future development initiatives, imprecision in resource estimates, ability to obtain necessary permits and approvals, relationships with vendors and strategic partners, the interest rate environment, governmental regulation and supervision, seasonality, technological change, changes in industry practices, changes in world metal markets, changes in equity markets, environmental and safety risks, and one-time events. Should any one or more of these risks or uncertainties materialize, or should any underlying assumptions prove incorrect, actual results may vary materially from those described herein. Forward-looking statements cannot be guaranteed and actual results may vary materially due to the uncertainties and risks, known and unknown, associated with such statements. Shareholders and other readers should not place undue reliance on forward-looking statements as such statements speak only as of the date of this discussion. Except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events, results or otherwise.

Historical results of operations and trends that may be inferred from this MD&A may not necessarily indicate future results from operations. In particular, the current state of the global securities markets may cause significant reductions in the price of the Company’s securities and render it difficult or impossible for the Company to raise the funds necessary to continue operations.

All of the Company’s public disclosure filings, including its most recent management information circular, Form 20-F (in lieu of an Annual Information Form), material change reports, press releases and other information, may be accessed via www.sedar.com, www.sec.gov, or the Company’s website at www.tasmanmetals.com and readers are urged to review these materials, including the technical reports filed with respect to the Company’s mineral properties.

Cautionary Note Regarding Reserve and Resource Disclosure

The terms “mineral reserve,” “proven mineral reserve” and “probable mineral reserve” are Canadian mining terms as defined in accordance with National Instrument 43-101 - Standards of Disclosure for Mineral Projects (“NI 43-101”) and the Canadian Institute of Mining, Metallurgy and Petroleum (the “CIM”) - CIM Definition Standards on Mineral Resources and Mineral Reserves, adopted by the CIM Council, as may be amended from time to time by the CIM. These definitions differ from the definitions in the United States Securities and Exchange Commission (the “SEC”) Industry Guide 7 (“SEC Industry Guide 7”) under the U.S. Securities Act of 1933 (the “U.S. Securities Act”). Under SEC Industry Guide 7 standards, a “final” or “bankable” feasibility study is required to report reserves, the three year history average price is used in any reserve or cash flow analysis to designate reserves and the primary environmental analysis or report must be filed with the appropriate governmental authority.

- 1 -

In addition, the terms “mineral resource,” “measured mineral resource,” “indicated mineral resource” and “inferred mineral resource” are defined in and required to be disclosed by NI 43-101; however, these terms are not defined terms under SEC Industry Guide 7 and normally are not permitted to be used in reports and registration statements filed with the SEC. Investors are cautioned not to assume that any part or all of mineral deposits in these categories will ever be converted into reserves. “Inferred mineral resources” have a great amount of uncertainty as to their existence, and great uncertainty as to their economic and legal feasibility. It cannot be assumed that all or any part of an inferred mineral resource will ever be upgraded to a higher category. Under Canadian rules, estimates of inferred mineral resources may not form the basis of an economic analysis, except a preliminary economic assessment provided certain additional disclosure requirements are met. Investors are cautioned not to assume that all or any part of an inferred mineral resource exists or is economically or legally mineable. Disclosure of “contained ounces” in a resource is permitted disclosure under Canadian regulations; however, the SEC normally only permits issuers to report mineralization that does not constitute “reserves” by SEC Industry Guide 7 standards as in place tonnage and grade without reference to unit measures.

Unless otherwise indicated, all mineral resource estimates included in this document have been prepared in accordance with NI 43-101 and the CIM classifications system. Accordingly, information contained in this document containing descriptions of the Company’s mineral deposits may not be comparable to similar information made public by U.S. companies subject to the reporting and disclosure requirements under the United States federal securities laws and the rules and regulations thereunder.

Company Overview

The Company was incorporated under the laws of the Province of British Columbia on August 27, 2007. On October 22, 2009 the Company completed a statutory amalgamation with Lumex Capital Corp. and Ausex Capital Corp. and the surviving corporation continued under the name of Tasman Metals Ltd. On November 3, 2009 the Company commenced trading on the TSX Venture Exchange (“TSXV”) under the symbol “TSM”. On December 2, 2011 the Company commenced trading on the NYSE MKT (formerly the NYSE AMEX) under the symbol “TAS”.

The Company is a junior resource company engaged in the acquisition and exploration of unproven REE properties and also holds interests in tungsten properties in Scandinavia and is considered an exploration stage company. As at November 30, 2015 the Company has not earned any production revenue, nor found proven reserves on any of its mineral interests.

The Company’s main focus continues to be the exploration and assessment of the Company’s Norra Kärr property. The Company filed an amended and restated pre-feasibility study (the “PFS”) on July 10, 2015. See also “Exploration Projects - REE Projects, Sweden, Norra Kärr” in this MD&A.

On October 1, 2013 the Company filed a final short form base shelf prospectus with certain Canadian and U.S. securities regulatory authorities. The shelf prospectus allowed the Company to offer, from time to time over a 25-month period, up to $25,000,000 of common shares, units and warrants. The Company did not sell any securities under the prospectus which expired on November 1, 2015.

Exploration Projects

As of the date of this MD&A the Company is the 100% owner of eight exploration claims and one mining lease for rare earth elements in Sweden and holds a 100% interest in eight exploration claims for tungsten in the Bergslagen district of Sweden.

REE Projects

Sweden

In Sweden Tasman holds eight exploration claims and one mining lease, considered prospective for REEs. REE consumption is growing globally, being essential in the production of hybrid/electric cars, solar panels, wind turbines, compact florescent lighting, high-energy magnets, mobile phones and computers. Tasman is well placed as the European Union is actively supporting policies to promote the domestic supply of REEs to secure high-tech industry.

- 2 -

Norra Kärr

Norra Kärr lies in south-central Sweden, 15km NNE of the township of Gränna and 300km SW of the capital Stockholm in mixed forestry and farming land. The project is 100% owned by Tasman, with a 25-year Mining Lease in place surrounded by an extensive area of exploration licences. Norra Kärr is proximal to road, rail, power and operating ports, plus skilled personnel, minimizing the need for offsite infrastructure to be built by the Company in a development scenario.

Norra Kärr is a zirconium (Zr) and heavy REE enriched peralkaline nepheline syenite intrusion which covers 450m x 1,500m in area. The deepest extents of the REE mineralized intrusion exceed 350m. The rock units comprising the Norra Kärr intrusion include mineral phases that are comprised of or associated with REEs, Zr, Nb, Y and Hf.

Mineralogical studies show nearly all of the REE in the deposit is found within the mineral eudialyte, with only trace britholite and mosandrite. Eudialyte at Norra Kärr is relatively rich in REE’s compared to most other similar deposits globally, and also contains a very high proportion of high value heavy REE’s.

The first phase drill program by Tasman at Norra Kärr commenced in mid-December 2009. A total of 121 exploration holes have now been completed, typically on 50m sections.

In May 2013 the Swedish Mining Inspectorate (Bergsstaten) granted a Mining Lease (the “ML”) to Tasman covering Norra Kärr, valid for 25 years when it is available for renewal.

In July 2015 Tasman filed the PFS which confirmed Norra Kärr to be an economically robust project, with a long mine life, and the capacity to be a major producer of the most critical REE’s, dysprosium (Dy), yttrium (Y), neodymium (Nd) and terbium (Tb). Readers are encouraged to read the entire PFS report available in its entirety on the SEDAR website at www.sedar.com, through EDGAR at www.sec.gov or on the Company’s website at www.tasmanmetals.com. Tasman cautions that there is no certainty that the PFS will be realized.

GBM Minerals Engineering Consultants Limited (“GBM”), an independent engineering consulting group based in Twickenham, UK coordinated and authored the PFS. The PFS addresses in addition to mining and processing, all required on site and off site infrastructure, land access, reagent and fuel transport and storage, power access, water recycling and purification, waste rock and tailings storage, and final closure.

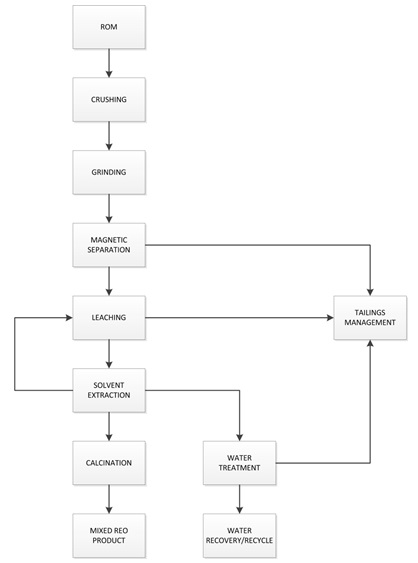

The PFS’ economic assessment is based on conventional open pit mining with crushing, grinding, beneficiation and mineral dissolution occurring in the immediate vicinity of the pit. The PFS includes a new Mineral Resource calculation to provide for a 20-year mine life. An average annual rare earth oxide (REO) output of some 5,100 tonnes is envisaged, reflecting the recommendations of a market study for the most critical REE’s. Mineralized material is processed via a simple flowsheet, comprising crushing, grinding, magnetic separation, sulphuric acid leaching and precipitation of a purified mixed REE-oxalate which is calcined to form a mixed REO product.

Key project and PFS attributes include:

|

|

·

|

After-tax Net Present Value (“NPV”) of US $313 million using a 10% discount rate

|

|

|

·

|

Internal Rate of Return (“IRR”) of 24% pre-tax and 20% after tax using a 10% discount rate

|

|

|

·

|

Initial capital cost of US $378 million including contingency - low for long mine life heavy REE producer

|

|

|

·

|

Major exposure to the most critical REE’s, with 74% of revenue from magnet metals Dy, Nd, Pr, Tb, Sm

|

|

|

·

|

Project able to produce more than 200 tonnes of dysprosium oxide per year for at least 20 years

|

|

|

·

|

No requirement in flowsheet or economic model for proprietary or commercially untested technologies

|

|

|

·

|

Attractive location with extensive transport/power/water infrastructure in place and close to major European REE consumers

|

|

|

·

|

High leverage to anticipated increase in REE prices. Most revenue from Dy, Nd, Tb - the most in demand metals. Only 2.6% of revenue from cerium (Ce) and lanthanum (La) which are forecast to remain in long term oversupply

|

- 3 -

PFS Key Financial and Operating Metrics

Key results and operational assumptions of the Norra Kärr PFS are provided in Tables 1 and 2 below.

Table 1: PFS Financial Results, Norra Kärr Project

|

FINANCIAL RESULT

|

VALUE

|

|

Initial capital cost (million)

|

US $378

|

|

Pre-tax / After-tax IRR

|

24% / 20%

|

|

Pre-tax / After-tax NPV at 10% discount rate (million)

|

US $456 / US $313

|

|

After-tax payback period

|

4.9 years

|

|

Mine life

|

20 years

|

|

TREO basket price/kg

|

US $64.57

|

|

Average annual operating cash flow (after-tax) (million)

|

US $96

|

Table 2: PFS Operating Assumptions, Norra Kärr Project

|

OPERATIONAL METRICS

|

VALUE

|

|

Average annual mineralized material mining rate (million tonnes)

|

1.18

|

|

Average Annual Total Rare Earth Oxide (TREO) production (tonnes)

|

5,119

|

|

Average Annual Saleable TREO production (tonnes) (excludes Ho, Er, Tm, Yb)

|

4,733

|

|

Average Mining Grade, % TREO

|

0.59%

|

|

Average Mining Grade, ppm Dy2O3

|

269

|

|

Life of Mine (20 year) Strip ratio (waste to mineralized material)

|

0.73 : 1

|

|

Beneficiation Plant recovery rate

|

89%

|

|

Hydrometallurgical Average annual Feed Rate (tonnes)

|

5,235

|

|

Hydrometallurgical Recovery Rate

|

86%

|

|

Overall Recovery

|

77%

|

|

Separation Charge per kg TREO (Converting Mixed to Individual REO’s)

|

US $19

|

|

Operating cost per tonne processed, including REO separation

|

US $179.60

|

|

Operating cost per kg TREO, including REO separation

|

US $39.69

|

Demand for high-strength magnets are widely forecast to grow at 5-10% annually and the REE’s used in these magnets (Nd, Pr, Dy, Tb, Sm) presents the strongest opportunity in the REE sector. Magnet metals comprise 74% by revenue and 26% by volume at Norra Kärr, indicating the project presents strong exposure to this high growth market. The elements identified by the U.S. Department of Energy as critical to “clean energy” with supply uncertainty (Nd, Dy Eu, Tb, Y), comprise 85% by revenue and 49% by volume at Norra Kärr.

Mineral Resource and Mineral Reserve Estimate

Following a supply and demand study of various REE market segments the PFS Mineral Resource and pit was calculated to allow for production of 5,000 tonnes per year of separated REO over a mine life of 20 years. This production rate was chosen due to the globally significant output of dysprosium, yttrium and terbium from Norra Kärr under this scenario.

The optimized pit model provided the in-pit Mineral Resource estimate as given in Table 3. The Mineral Resource estimation was completed using a 3D block modeling approach utilising Datamine Studio 3® software. A TREO cut-off grade of 0.4% shall be considered as the “base case”.

The database used for Mineral Resource calculation contained sample data from 119 diamond drill holes (20,420m) containing 9,986 samples. All work completed by Tasman was considered to be of a high standard, with robust QA/QC protocols in place that demonstrated precision and accuracy of samples.

- 4 -

Cautionary Note to U.S. Investors concerning estimates of Indicated Mineral Resource. This section uses the term “indicated mineral resource”. We advise U.S. investors that while that term is recognized and required by Canadian regulations, the U.S. Securities and Exchange Commission does not recognize it. U.S. Investors are cautioned not to assume that any part or all of an indicated mineral resource will ever be converted into reserves.

Table 3: Indicated Mineral Resource for Norra Kärr Project, Effective Date January 13, 2015.

|

TREO %

Cut-Off

Grade

|

Tonnes

(M)

|

TREO

(%)

|

% HREO

in TREO

|

Dy2O3

(%)

|

Y2O3

(%)

|

Eu2O3

(%)

|

La2O3

(%)

|

Nd2O3

(%)

|

Ce2O3

(%)

|

Gd2O3

(%)

|

Tb2O3

(%)

|

Pr2O3

(%)

|

Sm2O3

(%)

|

Lu2O3

(%)

|

|

0.2

|

36.82

|

0.55

|

53.2

|

0.0253

|

0.2005

|

0.0020

|

0.0519

|

0.0603

|

0.1156

|

0.0183

|

0.00371

|

0.01504

|

0.01647

|

0.00227

|

|

0.4

|

31.11

|

0.61

|

52.6

|

0.0273

|

0.2178

|

0.0022

|

0.0573

|

0.0668

|

0.1282

|

0.0200

|

0.00403

|

0.01668

|

0.01815

|

0.00238

|

|

0.6

|

17.12

|

0.68

|

52.2

|

0.0299

|

0.2429

|

0.0025

|

0.0621

|

0.0769

|

0.1441

|

0.0226

|

0.00447

|

0.01896

|

0.02083

|

0.00251

|

Notes:

|

1.

|

Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability.

|

|

2.

|

Mineral Resources are reported inclusive of any Mineral Reserves.

|

|

3.

|

The Mineral Resources reported have been based on a 20 year pit.

|

|

4.

|

Mineral Resources are reported for combined Migmatitic Grennaite, Pegmatitic Grennaite, Grennaite with Catapleiite and Eudialyte Lakarpite mineralization only

|

|

5.

|

The Mineral Resources reported represent estimated contained metal in the ground and has not been adjusted for metallurgical recovery.

|

|

6.

|

Total Rare Earth Oxides (TREO) includes: La2O3, Ce2O3, Pr2O3, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3.

|

|

7.

|

Heavy Rare Earth Oxides (HREO) includes: Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3.

|

|

8.

|

Preferred Base Case Mineral Resources are reported at a TREO % cut-off grade of 0.4% TREO.

|

|

9.

|

Metal prices used for 20 year pit comprise:

|

|

Cerium Oxide

|

US$/g

|

0.005

|

Neodymium Oxide

|

US$/g

|

0.080

|

|

Dysprosium Oxide

|

US$/g

|

0.575

|

Praseodymium Oxide

|

US$/g

|

0.115

|

|

Erbium Oxide

|

US$/g

|

0.000

|

Samarium Oxide

|

US$/g

|

0.008

|

|

Europium Oxide

|

US$/g

|

0.700

|

Terbium Oxide

|

US$/g

|

0.950

|

|

Gadolinium Oxide

|

US$/g

|

0.040

|

Thulium Oxide

|

US$/g

|

0.000

|

|

Holmium Oxide

|

US$/g

|

0.000

|

Yttrium Oxide

|

US$/g

|

0.025

|

|

Lanthanum Oxide

|

US$/g

|

0.007

|

Ytterbium Oxide

|

US$/g

|

0.000

|

|

Lutetium Oxide

|

US$/g

|

0.900

|

|

10.

|

The potential development of Mineral Resources may be materially affected by legal, political, environmental or other risks.

|

Taking into account of modifying factors (loss/dilution, geotechnics) an open pit mine design was based on the optimized pit shell to provide an estimate of Mineral Reserves.

Cautionary Note to U.S. Investors Concerning Estimates of Proven and Probable Reserves. The references in the following tables to “probable mineral reserves” are Canadian mining terms as defined in accordance with Canadian National Instrument 43-101 - Standards of Disclosure for Mineral Projects and the Canadian Institute of Mining, Metallurgy and Petroleum (the “CIM”) - Standards on Mineral Resources and Mineral Reserves - Definitions and Guidelines, adopted by the CIM Council, as amended. These definitions differ from the definitions in SEC Industry Guide 7 under the United States Securities Act of 1933, as amended. Under SEC Industry Guide 7 standards, mineralization may not be classified as a “reserve” unless the determination has been made that the mineralization could be economically and legally produced or extracted at the time the reserve determination is made. Among other things, all necessary permits would be required to be in hand or issuance imminent in order to classify mineralized material as reserves under the SEC standards. Accordingly, the following information may not be comparable to similar information made public by U.S. companies subject to the reporting and disclosure requirements under the United States federal securities laws and the rules and regulations thereunder.

Probable Mineral Reserves are reported at this stage due to the confidence of Mineral Resources, as provided in Table 4, with a full break down of REE’s in Table 5. Probable Mineral Reserves total 23.6 million tonnes (Mt) of mineralized material at 0.59% TREO. Mined waste totals 17.3 Mt for total 20-year mining of 40.8 Mt, life of mine stripping ratio (total waste : total mineralized material) of 0.73, and an average pit slope angle of 53 degrees. Mineral Reserve estimates have been based on a 20 year mine life.

Table 4: Probable Mineral Reserves for Norra Kärr Project, Effective Date January 13, 2015.

|

Tonnes

(M)

|

TREO

(%)

|

HREO

%

|

% HREO

in TREO

|

Dy2O3

(%)

|

Y2O3

(%)

|

Eu2O3

(%)

|

La2O3

(%)

|

Nd2O3

(%)

|

Ce2O3

(%)

|

Gd2O3

(%)

|

Tb2O3

(%)

|

Pr2O3

(%)

|

Sm2O3

(%)

|

Lu2O3

(%)

|

|

23.6

|

0.592

|

0.314

|

53.1

|

0.0269

|

0.215

|

0.0022

|

0.0551

|

0.0648

|

0.124

|

0.0196

|

0.00396

|

0.0161

|

0.0178

|

0.00234

|

Notes:

|

1.

|

Mineral Reserves are reported based on material contained within the Final Mine Design.

|

|

2.

|

Mineral Reserves are designed for a 20yr mine life.

|

|

3.

|

Mineral Reserves are reported for combined Migmatitic Grennaite and Pegmatitic Grennaite only,

|

|

4.

|

Mineral Reserves reported have been adjusted for mining factors, at 3.5 % dilution and 5.0 % loss.

|

|

5.

|

Mineral Reserves are reported to 3 significant figures.

|

|

6.

|

Total Rare Earth Oxides (TREO) includes: La2O3, Ce2O3, Pr2O3, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3.

|

- 5 -

|

7.

|

Heavy Rare Earth Oxides (HREO) includes: Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3.

|

|

8.

|

Metal prices used for 20yr pit comprise:

|

|

Cerium Oxide

|

US$/g

|

0.005

|

Neodymium Oxide

|

US$/g

|

0.080

|

|

Dysprosium Oxide

|

US$/g

|

0.575

|

Praseodymium Oxide

|

US$/g

|

0.115

|

|

Erbium Oxide

|

US$/g

|

0.000

|

Samarium Oxide

|

US$/g

|

0.008

|

|

Europium Oxide

|

US$/g

|

0.700

|

Terbium Oxide

|

US$/g

|

0.950

|

|

Gadolinium Oxide

|

US$/g

|

0.040

|

Thulium Oxide

|

US$/g

|

0.000

|

|

Holmium Oxide

|

US$/g

|

0.000

|

Yttrium Oxide

|

US$/g

|

0.025

|

|

Lanthanum Oxide

|

US$/g

|

0.007

|

Ytterbium Oxide

|

US$/g

|

0.000

|

|

Lutetium Oxide

|

US$/g

|

0.900

|

|

9.

|

Indicated Mineral Resources are inclusive of Mineral Reserves.

|

|

10.

|

Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

|

|

11.

|

The potential development of Mineral Resources may be materially affected by legal, political, environmental or other risks.

|

Table 5: Composition of TREO in 20-Year Mineral Reserve, Norra Kärr

|

RARE EARTH

OXIDE

|

GRADE

(%)

|

RELATIVE

DISTRIBUTION |

|

|

Lanthanum (La)

|

0.0551

|

9.3%

|

LIGHT REE

|

|

Cerium (Ce)

|

0.1240

|

20.9%

|

|

|

Praseodymium (Pr)

|

0.0161

|

2.7%

|

|

|

Neodymium (Nd)

|

0.0648

|

10.9%

|

|

|

Samarium (Sm)

|

0.0178

|

3.0%

|

|

|

Total Light REO

|

0.2778

|

46.9%

|

|

|

Europium (Eu)

|

0.0022

|

0.37%

|

HEAVY REE

|

|

Gadolinium (Gd)

|

0.0196

|

3.3%

|

|

|

Terbium (Tb)

|

0.0040

|

0.7%

|

|

|

Dysprosium (Dy)

|

0.0269

|

4.5%

|

|

|

Holmium (Ho)

|

0.0059

|

1.0%

|

|

|

Erbium (Er)

|

0.0184

|

3.1%

|

|

|

Thulium (Tm)

|

0.0028

|

0.5%

|

|

|

Ytterbium (Yb)

|

0.0172

|

2.9%

|

|

|

Lutetium (Lu)

|

0.0023

|

0.4%

|

|

|

Yttrium (Y)

|

0.2150

|

36.3%

|

|

|

Total Heavy REO

|

0.3143

|

53.1%

|

|

|

TREO

|

0.5920

|

100%

|

|

Other Metals

|

|||

|

ZrO2

|

1.84

|

||

|

Hf

|

0.0286

|

||

|

U

|

0.0013

|

||

|

Th

|

0.0006

|

Samples submitted by Tasman, used with the Mineral Resource calculation quoted above, were analyzed by the ME-MS81 technique by ALS Minerals’ laboratories in Pitea, Sweden and Vancouver, Canada, where duplicates, repeats, blanks and known standards were inserted according to standard industry practice. Where over-range for ME-MS81, Zr was determined using the ME-XRF10 technique. The Qualified Person for the Company’s exploration projects, Mark Saxon, President and Chief Executive Officer of Tasman and a member of the Australasian Institute of Mining and Metallurgy and Australian Institute of Geoscientists oversaw this data collection.

The beneficiation and hydrometallurgy flowsheet is provided in Figure 1.

- 6 -

Figure 1: Processing Flowsheet for Norra Kärr

The estimated start-up capital cost for the Norra Kärr project is considered low amongst its peer group of heavy REE projects that can support a mine life of 20 years. The extensive existing road/power/rail infrastructure and the presence of a local skilled work force, minimizes the need for off-site infrastructure investment, whilst the ambient temperature and pressure processing conditions reduces the need for high capital cost process equipment.

Initial capital cost for Norra Kärr is estimated to be US $378.3 million, including US $40.1 million in contingency and US $25.3 million in working capital. It is estimated that an additional US $44.3 million shall be required during the life of the project in sustaining capital.

The operating cost estimates for the proposed mine are provided in Table 6. The operating cost estimate assumes a separation or tolling charge of US $19 per kg, following discussion with various potential industry partners. Operating costs are viewed as in keeping with peer heavy REE projects, and includes significant investments in water recycling, purification and efficient storage of tailing and waste rock.

- 7 -

Table 6: Operating Cost for Norra Kärr Project under the PFS

|

OPERATING COSTS

|

AVG ANNUAL

(US $ M)

|

COST PER KG

REO

(US $)

|

% OF TOTAL

OPEX

(%)

|

|

|

MINING COSTS

|

$6.57

|

$1.35

|

3.4%

|

|

|

PROCESSING COSTS

|

||||

|

Labour

|

$8.35

|

$1.71

|

4.3%

|

|

|

Reagents

|

$35.70

|

$7.32

|

18.4%

|

|

|

Maintenance and Consumables

|

$7.89

|

$1.62

|

4.1%

|

|

|

Utilities

|

$12.88

|

$2.64

|

6.7%

|

|

|

Water Treatment and Waste Management

|

$24.40

|

$5.00

|

12.6%

|

|

|

GENERAL AND ADMIN

|

$5.08

|

$1.04

|

2.6%

|

|

|

REFINING/SEPARATION COSTS

|

$92.60

|

$19.00

|

47.9%

|

|

|

TOTAL

|

$193.51

|

$39.69

|

100.0%

|

|

Pricing assumptions used in the PFS financial model were provided by independent consultants and discussions with various industry partners, as provided in Table 7.

Table 7: Rare Earth Oxide Price Assumptions for Norra Kärr’s PFS

|

REE OXIDE

|

PFS Pricing

(US $/kg)

|

Current (Dec 2014)

(US $/kg)

|

Trailing 3 year Avg

(US $/kg)

|

|

Ce2O3

|

5.00

|

4.65

|

11.88

|

|

La2O3

|

7.00

|

4.85

|

11.99

|

|

Pr2O3

|

115.00

|

117.00

|

110.94

|

|

Nd2O3

|

80.00

|

58.00

|

84.32

|

|

Sm2O3

|

8.00

|

16.50

|

27.59

|

|

Eu2O3

|

700.00

|

705.00

|

1,455.48

|

|

Gd2O3

|

40.00

|

46.50

|

65.34

|

|

Tb2O3

|

950.00

|

615.00

|

1,199.23

|

|

Dy2O3

|

575.00

|

340.00

|

670.69

|

|

Ho2O3

|

n/a

|

n/a

|

n/a

|

|

Er2O3

|

n/a

|

n/a

|

n/a

|

|

Tm2O3

|

n/a

|

n/a

|

n/a

|

|

Yb2O3

|

n/a

|

n/a

|

n/a

|

|

Lu2O3

|

900.00

|

n/a

|

n/a

|

|

Y2O3

|

25.00

|

14.00

|

44.40

|

|

NK Basket

|

$64.46

|

$41.42

|

$80.65

|

NI 43-101 Compliance

A technical report supporting the PFS is available in its entirety, on the SEDAR website at www.sedar.com, on the Company’s website at www.tasmanmetals.com or through EDGAR at www.sec.gov. The PFS was prepared by GBM under the guidance of Michael Short, Principal Consultant for GBM who is a “Qualified Person” in accordance with NI 43-101.

The Mineral Resource and Mineral Reserve estimates were completed by Wardell Armstrong International Limited under the supervision of Greg Moseley and Mark Mounde, who are both “Qualified Persons” in accordance with NI 43-101. The process for the integrated processing plant for the PFS was completed by GBM under the supervision

- 8 -

of Thomas Apelt who is a “Qualified Person” in accordance with NI 43-101. The infrastructure design and cost estimation for the PFS was completed by GBM under the supervision of Michael Short who is a “Qualified Person” in accordance with NI 43-101. The environmental and social section and the permitting review for the PFS was completed by Golder Associate Oy under the supervision of Gareth Digges La Touche who is a “Qualified Person” in accordance with NI 43-101.

In December 2015, Tasman reported on the completion of a beneficiation pilot plant test for the Norra Kärr project. The pilot plant was run at the Geological Survey of Finland (GTK) in Outokumpu, with the cost borne by the EURARE project, of which Tasman is a research partner. EURARE is a research project co-funded by the European Commission under the Seventh Framework Programme of the European Community for Research, Technological Development and Demonstration Activities (Grant Agreement NMP2-LA-2012-309373).

A 6.5 tonne sample of representative Norra Karr mineralized rock was collected via drilling during 2014 with the support of EURARE. From this sample 5.6 tonnes was crushed, ground and magnetically separated as per Tasman’s PFS flow sheet. A scavenging magnetic separation stage was also tested, to determine the possibility for enhanced recovery. Greater than 95% of REE’s at Norra Karr are contained within the zirconosilicate mineral eudialyte. Eudialyte is para-magnetic, and concentrates well using wet magnetic separation. Magnetic separation does not require any process chemicals.

Although the optimal magnetic separation equipment selected by Tasman’s previous bench scale work was not available at GTK, the pilot plant performed well, and in line with results from bench scale testing when using similar equipment. The magnetic separation pilot plant was run continuously for 6 hours on each of 3 days, and 79% yttrium (Y) recovery was achieved in a mass of 34.8%.

The pilot plant has produced approximately 1.9 tonnes of eudialyte/REE enriched mineral concentrate. This mineral concentrate is available for scaled up hydrometallurgical testwork by the ERECON team, and Tasman’s other research partners. This work is now being planned and scheduled.

In addition to the REE enriched concentrate, some 3.7 tonnes (65% of original sample) of nepheline and feldspar by-product was also produced. Nepheline and feldspar are industrial minerals with large European market in ceramics, glass, cement, building material and metallurgical industries. Nepheline and feldspar are for example widely consumed in the manufacture of bathroom ceramics, roof and floor tiles, crockery, building fillers, paints, cement and even cosmetics.

Tasman’s previous test work on the nepheline/feldspar by-product from Norra Karr has shown it to be low in iron, and with key characteristics similar to material being used industrially across Europe today. This material is now being subsampled and screened in preparation for product and market development activities to progress commercialization.

Olserum

On October 13, 2011 Tasman announced the acquisition of a 100% interest in a new heavy rare earth element project in southern Sweden, located only 100km east of Tasman’s flagship Norra Kärr project. The Company staked a further five claims surrounding the original Olserum claim in 2012, however, during fiscal 2015 the Company relinquished two of the claims. The other three claims, known as Overum Nr. 1, Overum Nr. 2 and Overum Nr. 3, which continue to form part of Olserum, currently expire in December 2017 (and may be further extended to a maximum date in 2026).

The Company submitted a mining lease application for the Olserum project during 2013. Due to the prolonged downturn in the mining industry, Tasman chose to withdraw from this application during December 2015 and shall continue with exploration on the granted exploration claims.

The REE potential of the Olserum region was first identified by the Swedish Geological Survey (“SGU”) in the early 1990’s, when a number of REE anomalous samples were collected and assayed from several locations. In 2003 the Swedish exploration company IGE Resources AB (“IGE”) claimed the area, concentrating on the iron ore workings at Olserum. During 2004 and 2005 a total of 27 diamond drill holes were drilled by IGE, 24 of which targeted the REE potential.

- 9 -

Drilling discovered a REE mineralized zone 600m in length and up to 100m wide. Drilling was performed on 40m spaced profiles with typically two holes on each profile. REE mineralogy was determined to be simple, with coarse to fine grained xenotime, monazite and rare apatite recognized as the host to all significant REE’s.

Using all available drilling data, the independent resource estimate for Olserum was published in February 2013. The resource estimate was prepared by consulting geologists at ReedLeyton Consulting Pty Ltd (“ReedLeyton”) following site visits, core sampling and geological modelling. Following a review by the BCSC, a revised resource estimate was completed and filed in July 2013. Readers are encouraged to review the entire Olserum technical report available on the SEDAR website at www.sedar.com, on the Company’s website at www.tasmanmetals.com or through EDGAR at www.sec.gov.

Cautionary Note to U.S. Investors Concerning Estimates of Indicated Resources - This section uses the terms “Indicated Mineral Resource” and “Indicated Resource”. We advise U.S. investors that while these terms are recognized and required by Canadian regulations, the U.S. Securities and Exchange Commission does not recognize them. U.S. Investors are cautioned not to assume that any part or all of mineral deposits in these categories will ever be converted into reserves.

Cautionary Note to Investors Concerning Estimates of Inferred Resources. This section uses the term “Inferred Resource” (also referred to as “Inferred Mineral Resource”). We advise U.S. investors that while these terms are recognized and required by Canadian regulations, the U.S. Securities and Exchange Commission does not recognize them. Inferred resources have a great amount of uncertainty as to their existence, and great uncertainty as to their economic and legal feasibility. It cannot be assumed that all or any part of an inferred resource will ever be upgraded to a higher category. Under Canadian rules, estimates of inferred resources may not form the basis of feasibility or pre-feasibility studies, except in rare cases. U.S. investors are cautioned not to assume that all or any part of an inferred resource exists, or is economically or legally mineable.

Mineral Resources were modelled applying six different TREO cut-off grades, with a base-case resource estimated using a TREO cut-off of 0.4% (Tables 8 and 9). At this cut-off, Olserum hosts an Indicated Mineral Resource of 4.5 million tonnes grading 0.60% TREO and an Inferred Mineral Resource of 3.3 million tonnes grading 0.63% TREO, both with 34% of the TREO being the higher value HREO. Table 10 and 11 provide the grade averages for rare earth oxides at the various cut-offs.

Table 8: Indicated Resource Estimate for the Olserum Deposit.

|

TREO %

Cut-off

|

Million

Tonnes

|

TREO

%

|

% of HREO in

TREO

|

Dy2O3

ppm

|

Y2O3

ppm

|

Nd2O3

ppm

|

Tonnes of Contained

TREO

|

|

|

0.7

|

1.0

|

0.89

|

32.3

|

292

|

1800

|

1314

|

8,620

|

|

|

0.6

|

1.7

|

0.78

|

32.9

|

262

|

1610

|

1146

|

13,360

|

|

|

0.5

|

3.0

|

0.68

|

33.3

|

232

|

1420

|

996

|

20,650

|

|

|

0.4

|

4.5

|

0.60

|

33.9

|

209

|

1283

|

878

|

27,260

|

BASE CASE

|

|

0.3

|

6.3

|

0.53

|

34.4

|

187

|

1146

|

769

|

33,530

|

|

|

0.2

|

7.7

|

0.48

|

34.5

|

0.017

|

1042

|

700

|

37,030

|

Table 9: Inferred Resource Estimate for the Olserum Deposit.

|

TREO %

Cut-off

|

Million

Tonnes

|

TREO

%

|

% of HREO in

TREO

|

Dy2O3

ppm

|

Y2O3

ppm

|

Nd2O3

ppm

|

Tonnes of Contained

TREO

|

|

|

0.7

|

0.9

|

0.85

|

31.8

|

288

|

1667

|

1294

|

7,947

|

|

|

0.6

|

1.6

|

0.77

|

32.5

|

264

|

1547

|

1151

|

12,088

|

|

|

0.5

|

2.5

|

0.69

|

33.6

|

242

|

1445

|

1018

|

16,960

|

|

|

0.4

|

3.3

|

0.63

|

33.7

|

222

|

1320

|

925

|

20,770

|

BASE CASE

|

|

0.3

|

4.2

|

0.57

|

33.9

|

202

|

1205

|

841

|

23,820

|

|

|

0.2

|

4.7

|

0.54

|

33.9

|

191

|

1134

|

790

|

25,050

|

Notes:

|

|

1.

|

Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

|

|

|

2.

|

TREO includes: La2O3, Ce2O3, Pr2O3, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3

|

|

|

3.

|

HREO includes: Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3

|

- 10 -

|

|

4.

|

The calculated resource is sensitive to cut-off grade which will be influenced by metallurgical operating costs. Bench scale metallurgical tests were completed on an Olserum composite sample in 2005. Magnetic and gravity separation gave a mineral concentrate of 14% rare earth oxide in only 5% of the mass with a recovery of 59%.

|

|

|

5.

|

The mineral resource estimate was completed by Mr Geoffrey Reed, Senior Consulting Geologist of ReedLeyton, and is based on geological and geochemical data supplied by Tasman, as audited by Mr Reed. Mr Reed is an independent qualified person for the purposes of NI 43-101 standards of disclosure for mineral projects of the Canadian Securities Administrators.

|

|

|

6.

|

The resource estimate has been classified as an Indicated and Inferred Resource based on the distance-space between sample data within the current deposit outline. Variograms were obtained from a variography study of TREO, with the continuity analysis showing a reasonable fit model in the major and semi major direction for the mineralised domains.

|

|

|

7.

|

The resource estimate is based on:

|

|

|

§

|

A database of 31 “In Resource” drill holes totalling 5,297m of diamond drilling completed by Tasman and previous project owner IGE since 2004 where samples were composited on 1m lengths. All assays by both Tasman and IGE were completed at laboratories in Vancouver, British Columbia.

|

|

|

§

|

Specific gravity (SG) has an overall mean of 2.80 g/cc from 458 SG readings. The mean of the mineralisation of 2.82 g/cc was used in the estimate and a mean of the host rock of 2.67 g/cc was used in the estimate

|

|

|

§

|

Block model was estimated by ordinary kriging interpolation method on blocks 5m (x) x 20m (y) x 10m (z).

|

|

|

§

|

Metallurgical test work at Olserum is in progress and no information was available at the time of this resource calculation.

|

ReedLeyton completed a mining optimisation exercise to demonstrate the mineralization has a reasonable expectation of being mined. As the mining concept for the Olserum Deposit is currently surface mining, Whittle® software was used to generate a conceptual pit shell. Notwithstanding the pit optimisation exercise, it has not resulted in an engineered and operational open-pit mine design. Operating assumptions used for the Whittle® pit shell were based from the Norra Kärr PEA. The economic assumptions used to derive the optimised pit shell include:

|

|

·

|

Stripping Cost $/tonne mined US $3.66

|

|

|

·

|

Mining Cost $/tonne mined US $3.66

|

|

|

·

|

Processing Cost $/tonne mineralized material US $41.48

|

|

|

·

|

REO Recovery 80.0%

|

|

|

·

|

Discount to TREO Basket Price 38.0% (accounts for REO separation charge)

|

|

|

·

|

Discounted TREO Price US $31.0 kg

|

|

|

·

|

5 percent mining loss, 5 percent for mining dilution

|

Overall, ReedLeyton considered these assumptions are fair for the purpose of determining reasonable prospects for economic extraction of the Olserum deposit but do not demonstrate that the mineralization is economic, since the exercise is not at the level of a preliminary economic assessment and does not conform to the studies required for a preliminary economic assessment.

Table 10: Indicated Resource Estimate Rare Earth Oxide Grade Averages for the Olserum Deposit.

|

TREO %

Cut-off

|

La2O3

|

Ce203

|

Pr203

|

Nd203

|

Sm203

|

Eu203

|

Gd203

|

Tb203

|

Dy203

|

Ho203

|

Er203

|

Tm203

|

Yb203

|

Lu203

|

Y203

|

|

0.7

|

0.125

|

0.281

|

0.034

|

0.131

|

0.029

|

0.001

|

0.029

|

0.005

|

0.029

|

0.006

|

0.017

|

0.002

|

0.015

|

0.002

|

0.180

|

|

0.6

|

0.109

|

0.244

|

0.030

|

0.115

|

0.026

|

0.001

|

0.026

|

0.004

|

0.026

|

0.005

|

0.015

|

0.002

|

0.014

|

0.002

|

0.161

|

|

0.5

|

0.094

|

0.212

|

0.026

|

0.100

|

0.023

|

0.001

|

0.023

|

0.004

|

0.023

|

0.005

|

0.014

|

0.002

|

0.012

|

0.002

|

0.142

|

|

0.4

|

0.083

|

0.186

|

0.023

|

0.088

|

0.020

|

0.001

|

0.021

|

0.004

|

0.021

|

0.004

|

0.012

|

0.002

|

0.011

|

0.002

|

0.128

|

|

0.3

|

0.072

|

0.163

|

0.020

|

0.077

|

0.018

|

0.000

|

0.018

|

0.003

|

0.019

|

0.004

|

0.011

|

0.002

|

0.010

|

0.001

|

0.115

|

|

0.2

|

0.065

|

0.147

|

0.018

|

0.070

|

0.016

|

0.000

|

0.017

|

0.003

|

0.017

|

0.004

|

0.010

|

0.001

|

0.009

|

0.001

|

0.104

|

Table 11: Inferred Resource Estimate Rare Earth Oxide Grade Averages for the Olserum Deposit.

|

TREO %

Cut-off

|

La2O3

|

Ce203

|

Pr203

|

Nd203

|

Sm203

|

Eu203

|

Gd203

|

Tb203

|

Dy203

|

Ho203

|

Er203

|

Tm203

|

Yb203

|

Lu203

|

Y203

|

|

0.7

|

0.118

|

0.270

|

0.033

|

0.129

|

0.030

|

0.001

|

0.029

|

0.005

|

0.029

|

0.006

|

0.016

|

0.002

|

0.014

|

0.002

|

0.167

|

|

0.6

|

0.105

|

0.241

|

0.030

|

0.115

|

0.027

|

0.001

|

0.026

|

0.005

|

0.026

|

0.005

|

0.015

|

0.002

|

0.013

|

0.002

|

0.155

|

|

0.5

|

0.093

|

0.213

|

0.026

|

0.102

|

0.024

|

0.001

|

0.024

|

0.004

|

0.024

|

0.005

|

0.014

|

0.002

|

0.012

|

0.002

|

0.145

|

|

0.4

|

0.084

|

0.194

|

0.024

|

0.093

|

0.022

|

0.001

|

0.022

|

0.004

|

0.022

|

0.005

|

0.013

|

0.002

|

0.011

|

0.002

|

0.132

|

- 11 -

|

TREO %

Cut-off

|

La2O3

|

Ce203

|

Pr203

|

Nd203

|

Sm203

|

Eu203

|

Gd203

|

Tb203

|

Dy203

|

Ho203

|

Er203

|

Tm203

|

Yb203

|

Lu203

|

Y203

|

|

0.3

|

0.077

|

0.176

|

0.022

|

0.084

|

0.020

|

0.000

|

0.020

|

0.003

|

0.020

|

0.004

|

0.012

|

0.002

|

0.010

|

0.001

|

0.121

|

|

0.2

|

0.072

|

0.166

|

0.020

|

0.079

|

0.018

|

0.000

|

0.019

|

0.003

|

0.019

|

0.004

|

0.011

|

0.002

|

0.010

|

0.001

|

0.113

|

In 2013, the Company announced results of the first phase of metallurgical testing on representative mineralization samples from Olserum. Magnetic separation and flotation tests produced a mineral concentrate with REE recovery in excess of 90% within a concentrate mass between 6% and 7% of the original sample. This represents a very encouraging increase in REE grade of approximately 14 times. A very high grade magnetite concentrate was also produced as a by-product during testing.

As anticipated, the low intensity magnetic separator (“LIMS”) was extremely efficient in the separation of magnetite from other minerals present. In test 8 the magnetic concentrate comprised 2.93% of the rock mass and showed a grade of Fe 65.5%, being very close to the iron content of pure magnetite. The best REE recovery results were obtained where highest REE recovery was achieved in the lowest concentrate mass (mass pull) as described in Table 12:

Table 12: REE recovery for various tests from Olserum

|

Test

|

Concentrate Mass

(Mass Pull)

|

Ce Recovery

(%)

|

La Recovery

(%)

|

Y Recovery

(%)

|

|

3A

|

6.80%

|

88.4 %

|

88.8 %

|

92.7 %

|

|

3B

|

8.42%

|

89.6 %

|

90.1 %

|

93.8 %

|

|

8

|

5.99%

|

87.9 %

|

85.3 %

|

91.2 %

|

The Company has not been incurring significant costs on the Olserum project and does not intend to incur significant costs until a further financing is completed. The Company is, however, continuing with certain minor costs mainly through continued metallurgical research, the bulk of which are being funded through our participation in a European Union funding initiative studying the supply of critical materials (EURARE).

Tungsten Projects

Sweden

On October 7, 2013 Tasman purchased a portfolio of tungsten projects in the Bergslagen mining district of south-central Sweden. In addition, during fiscal 2015, Tasman staked one additional tungsten claim. This portfolio includes several of the largest known tungsten occurrences in Scandinavia, including the former Yxsjöberg mine which accounts for more than 90% of the tungsten previously produced in Sweden.

The acquired tungsten projects are approximately centered on the Yxsjöberg historical mine where a mill and tailings dam remains on site. Simple road access links all project areas. The data from the mines is historical in nature and was compiled prior to the implementation of NI 43-101 reporting standards. Tasman has not completed sufficient exploration to verify the estimates and is not treating them as NI 43-101 defined resources or reserves verified by a qualified person; the historical estimate should not be relied upon.

Yxsjöberg

The Yxsjöberg historical mine is the by far largest known tungsten mineralization in Sweden, from which more than 90% of all tungsten produced in the country emanates. The deposit is of a skarn-hosted tungsten-copper-beryllium- fluorite style consisting of three mineralized material bodies (Kvarnåsen, Nävergruvan, Finngruvan) which lie in the same folded, skarn altered limestone horizon. Earliest records of mining date back to 1728 and small scale mining for copper continued intermittently until the 19th century. The tungsten mineral scheelite (CaWO4) was first identified in 1862 and the earliest recorded production of tungsten in 1918. A new concentrator was built in 1937, and a roasting furnace and gravity separator added in 1951. A circuit for the production of fluorite concentrate was added in 1956. Fluorite remains a potential by-product to any future operation.

The price of tungsten fell in the early 1960s, and the mine was closed in 1963 and subsequently allowed to flood. By the end of the 1960s however, the tungsten price had recovered and interest was renewed. In 1969 the Swedish

- 12 -

State-owned mining company, AB Statsgruvor, acquired the mine and constructed a new concentrator and head frame. This new plant began with gravity separation, but was converted to selective flotation in 1977. The mine and plant were closed again in 1989 due to low tungsten prices, when the deepest levels of the mine had reached approximately 600m. A total of more than 5 million tonnes of mineralized material averaging approximately 0.35% WO3 (with additional copper and fluorite) were extracted during the life of the Yxsjöberg mine. Significant mineralization remained in situ at the final closure in 1989.

Apart from remediation and environmental management, the plant has largely been left untouched since the closure of the mine, as have two large tailings dams estimated to contain a total of 4.6 million metric tonnes of material.

Other

The other tungsten projects include Wigström, Sandudden, Gensgruvan, Gussarvet, and Gustavsberg.

Tasman is compiling historic data for this tungsten portfolio and completing low intensity surface prospecting and sampling activity. Sampling and mapping have been undertaken and results are being interpreted.

Chromite Projects

During 2014, Tasman purchased at the cost of claiming, the Akanvaara and Koitelainen chromite projects from Kipu Metals Corp. These projects were comprised of both granted claims and claim applications.

Due to the prolonged downturn in the mining industry, Tasman chose to relinquish all granted claims and withdraw from the claim applications in full. The Company recorded an impairment charge of $45,529 during the three months ended November 30, 2015.

Qualified Person

The qualified person for Tasman’s projects, Mr. Mark Saxon, the Company’s President and Chief Executive Officer, a Fellow of the Australasian Institute of Mining and Metallurgy and a Member of the Australian Institute of Geoscientists, has reviewed and verified the contents of this document.

Selected Financial Data

The following selected financial information is derived from the unaudited condensed consolidated interim financial statements of the Company prepared in accordance with IFRS.

|

Fiscal 2016

|

Fiscal 2015

|

Fiscal 2014

|

||||||

|

Three Months Ended

|

Nov. 30,

2015

$

|

Aug. 31,

2015

$

|

May 31,

2015

$

|

Feb. 28,

2015

$

|

Nov. 30,

2014

$

|

Aug. 31,

2014

$

|

May 31,

2014

$

|

Feb. 28,

2014

$

|

|

Operations:

|

||||||||

|

Revenues

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

|

Expenses

|

(310,836)

|

(307,371)

|

(317,782)

|

(394,274)

|

(457,724)

|

(449,118)

|

(578,083)

|

(638,057)

|

|

Other items

|

(46,405)

|

17,483

|

16,041

|

8,491

|

15,996

|

(2,287)

|

(33,713)

|

15,157

|

|

Net loss

|

(357,241)

|

(289,888)

|

(301,741)

|

(385,783)

|

(441,728)

|

(451,405)

|

(611,796)

|

(622,900)

|

|

Other comprehensive gain(loss)

|

218

|

20,731

|

(23,410)

|

219

|

(1,668)

|

16,744

|

(10,141)

|

3,014

|

|

Comprehensive loss

|

(357,073)

|

(269,157)

|

(325,151)

|

(385,564)

|

(443,396)

|

(434,661)

|

(621,937)

|

(619,886)

|

|

Basic and diluted loss per share

|

(0.00)

|

(0.00)

|

(0.00)

|

(0.01)

|

(0.01)

|

(0.01)

|

(0.01)

|

(0.01)

|

|

Dividends per share

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

|

Balance Sheet:

|

||||||||

|

Working capital

|

2,034,082

|

2,478,303

|

2,982,098

|

3,401,657

|

4,347,099

|

5,403,122

|

7,160,151

|

7,056,411

|

|

Total assets

|

14,943,059

|

15,340,805

|

15,535,415

|

15,956,698

|

16,451,844

|

17,375,571

|

17,470,818

|

16,682,588

|

|

Total long term liabilities

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

Nil

|

- 13 -

Results of Operations

As the Company is in the exploration stage of investigating and evaluating its unproven mineral interests, it has no revenue.

Three Months Ended November 30, 2015 Compared to the Three Months Ended August 31, 2015

During the three months ended November 30, 2015 (the “Q1/2016”) the Company reported a net loss of $357,241 ($0.00 per share), compared to a net loss of $289,888 ($0.00 per share) for the three months ended August 31, 2015 (the “Q4/2015”), an increase in loss of $67,353. The increase was attributed primarily to the recognition of $45,529 in impairment of exploration and evaluation assets during Q1/2016.

Three Months Ended November 30, 2015 Compared to the Three Months Ended November 30, 2014

During the three months ended November 30, 2015 (the “2015 period”), the Company reported a net loss of $357,241 ($0.00 per share) compared to a net loss of $441,728 ($0.01 per share) for the three months ended November 30, 2014 (the “2014 period”). The $84,487 decrease in loss during the 2015 period was primarily due to a $48,138 reduction in professional fees, from $114,641 during the 2014 period to $66,503 during the 2015 period, and the recognition of $51,300 of share-based compensation during the 2014 period. No share-based compensation expense was recognized during the 2015 period.

Expenses with significant fluctuations are as follows:

|

(i)

|

a total of $23,922 (2014 - $35,006) was incurred for accounting and administrative services of which $11,500 (2014 - $22,150) was provided by Chase Management Ltd.(“Chase”), a private corporation owned by a director of the Company and $12,422 (2014 - $12,856) provided by an external accounting service provider in Sweden. Accounting and administrative services provided by Chase were lower during the 2015 period compared to the 2014 period due to reduced corporate activities conducted;

|

|

(ii)

|

general exploration activities were limited in the 2015 period and as a result $24,391 was incurred compared to $38,998 in the 2014 period;

|

|

(iii)

|

professional fees of $66,503 (2014 - $114,641) were incurred of which $45,563 (2014 - $67,490) was charged by current and former directors and officers of the Company and $20,940 (2014 - $47,151) was charged by independent consultants for general corporate services. The decrease in professional fees of $48,138 was due to the resignation of Mr. Jim Powell in February 2015 as the Company’s Vice-President of Corporate Development and the decision to reduce corporate activities during this current economic period. See also “Transactions with Related Parties”;

|

|

(iv)

|

rent expense of $2,194 (2014 - $10,033) was incurred for office premises in Canada and Sweden. During the 2014 period, the Company relocated to a smaller office premise in Sweden; and

|

|

(v)

|

during the 2014 period the Company recorded $51,300 for share-based compensation for the immediate vesting of 135,000 share options granted. During the 2015 period no share options were granted.

|

During the 2015 period the Company reviewed its exploration and evaluation assets portfolio and a decision was made to relinquish its interest in the Chromite Portfolio and record an impairment charge of $45,529. See also “Exploration Projects - Chromite Projects”.

Interest income generated during the 2015 period was $5,317, a decrease of $11,934 from $17,251 earned during the 2014 period. The decrease in interest income during the 2015 period was due to higher levels of cash held during the 2014 period.

Investments

The Company holds 2,647,059 common shares of Hannans Reward Limited (“Hannans”) and 600,000 common shares of Thomson Resources Ltd. (“Thomson”), public companies listed on the Australian Stock Exchange, and have been designated as available-for-sale for accounting purposes. As at November 30, 2015 the quoted market value of the Hannans shares was $7,870 and the Thomson shares was $27,238.

- 14 -

Exploration and Evaluation Assets

During the 2015 period the Company incurred a total of $141,583 (2014 - $677,215) on the acquisition, exploration and evaluation of its unproven resources assets, of which $136,751 (2014 - $657,702) was incurred on the Norra Kärr property and $4,832 (2014 - $19,513) on other properties. The Company also recorded an impairment charge of $45,529 on the decision to relinquish the Chromite Portfolio.

Details of the exploration activities conducted during the 2015 period are described in “Exploration Projects” in this MD&A.

The carrying costs of the Company’s exploration and evaluation assets are as follows:

|

As at November 30, 2015

|

As at August 31, 2015

|

|||||||||||||||||||||||

|

Acquisition

Costs

$

|

Deferred

Exploration

Costs

$

|

Total

$

|

Acquisition

Costs

$

|

Deferred

Exploration

Costs

$

|

Total

$

|

|||||||||||||||||||

|

Rare Earth Properties

|

||||||||||||||||||||||||

|

Norra Kärr

|

103,260 | 11,509,531 | 11,612,791 | 103,260 | 11,372,780 | 11,476,040 | ||||||||||||||||||

|

Olserum

|

182,058 | 581,111 | 763,169 | 182,058 | 581,111 | 763,169 | ||||||||||||||||||

|

Other Properties

|

127,287 | 68,825 | 196,112 | 168,281 | 68,528 | 236,809 | ||||||||||||||||||

| 412,605 | 12,159,467 | 12,572,072 | 453,599 | 12,022,419 | 12,476,018 | |||||||||||||||||||

Exploration and evaluation activities incurred during fiscal 2015 and the three months ended November 30, 2015 are as follows:

|

Rare Earth Element Properties

|

Other

|

|||||||||||||||

|

Norra Kärr

$

|

Olserum

$

|

Properties

$

|

Total

$

|

|||||||||||||

|

Balance at August 31, 2014

|

9,982,080 | 732,669 | 151,904 | 10,866,653 | ||||||||||||

|

Exploration costs

|

||||||||||||||||

|

Consulting

|

381,013 | 5,326 | 6,148 | 392,487 | ||||||||||||

|

Drilling

|

107,857 | - | - | 107,857 | ||||||||||||

|

Exploration site

|

1,641 | - | 200 | 1,841 | ||||||||||||

|

Geochemical

|

35,346 | - | 2,955 | 38,301 | ||||||||||||

|

Geological

|

72,494 | - | - | 72,494 | ||||||||||||

|

Maps

|

- | 1,158 | 2,673 | 3,831 | ||||||||||||

|

Recovery

|

(52,670 | ) | - | - | (52,670 | ) | ||||||||||

|

Salaries

|

44,255 | 1,903 | 17,501 | 63,659 | ||||||||||||

|

Surface rights

|

106,278 | - | - | 106,278 | ||||||||||||

|

Technical report

|

784,944 | - | - | 784,944 | ||||||||||||

|

Travel

|

2,339 | - | - | 2,339 | ||||||||||||

| 1,483,497 | 8,387 | 29,477 | 1,521,361 | |||||||||||||

|

Acquisition costs

|

||||||||||||||||

|

Mining rights

|

10,463 | 29,267 | 9,899 | 49,629 | ||||||||||||

|

Acquisiton

|

- | - | 45,529 | 45,529 | ||||||||||||

| 10,463 | 29,267 | 55,428 | 95,158 | |||||||||||||

|

Impairment

|

- | (7,154 | ) | - | (7,154 | ) | ||||||||||

|

Balance at August 31, 2015

|

11,476,040 | 763,169 | 236,809 | 12,476,018 | ||||||||||||

|

Exploration costs

|

||||||||||||||||

|

Consulting

|

81,477 | - | - | 81,477 | ||||||||||||

|

Exploration site

|

399 | - | - | 399 | ||||||||||||

|

Geochemical

|

4,779 | - | 297 | 5,076 | ||||||||||||

|

Salaries

|

18,822 | - | - | 18,822 | ||||||||||||

|

Surface rights

|

30,577 | - | - | 30,577 | ||||||||||||

|

Travel

|

697 | - | - | 697 | ||||||||||||

| 136,751 | - | 297 | 137,048 | |||||||||||||

- 15 -

|

Rare Earth Element Properties

|

Other

|

|||||||||||||||

|

Norra Kärr

$

|

Olserum

$

|

Properties

$

|

Total

$

|

|||||||||||||

|

Acquisition costs

|

||||||||||||||||

|

Mining rights

|

- | - | 4,535 | 4,535 | ||||||||||||

|

Impairment

|

- | - | (45,529 | ) | (45,529 | ) | ||||||||||

|

Balance at November 30, 2015

|

11,612,791 | 763,169 | 196,112 | 12,572,072 | ||||||||||||

Financial Condition / Capital Resources

The Company manages its capital structure and makes adjustments to it, based on the funds available to the Company, in order to support the acquisition and exploration of mineral properties. The Board of Directors does not establish quantitative return on capital criteria for management, but rather relies on the expertise of the Company’s management to sustain future development of the business. The Company defines capital that it manages as share capital, cash and cash equivalents and short-term investments. The Company will continue to assess new properties and seek to acquire an interest in additional properties if it feels there is sufficient geologic or economic potential and if it has adequate financial resources to do so. Management reviews its capital management approach on an ongoing basis and believes that this approach, given the relative size of the Company, is reasonable.

To date the Company has not conducted any borrowing outside of its accounts payable and accrued liabilities incurred for operations and exploration activities. The Company maintains its cash primarily in Canadian currency in a major Canadian financial institution. The funds are held in interest-bearing accounts. The Company is not exposed to significant credit or interest rate risk although cash is held in excess of federally insured levels.

The Company advances funds to its subsidiary as required to satisfy ongoing levels of operations. There are no legal or economic restrictions on the ability of the Company’s subsidiary to transfer funds to the Company in the form of cash dividends, loans or advances.

As at November 30, 2015 the Company had working capital of $2,034,082. Due to the global financial down-turn and deterioration in the capital markets for junior exploration financing, the Company has focused on reducing costs and expenditures where possible to preserve its working capital until the financial markets recover. The Company has prepared a budget of approximately $1,500,000 for the fiscal year ending August 31, 2016. Although the Company has sufficient financial resources to meet estimated corporate administration costs for the ensuing twelve months, it will need additional financing to conduct further exploration programs. The Company has relied solely on equity financing to raise the requisite financial resources. While it has been successful in the past, there can be no assurance that the Company will be successful in raising future financing.

Contractual Commitments

The Company has no contractual commitments.

Off-Balance Sheet Arrangements

The Company has no off-balance sheet arrangements.

Proposed Transactions

The Company has not entered into any proposed transactions.

Critical Accounting Estimates

Critical Judgments and Sources of Estimation Uncertainty

The preparation of the consolidated financial statements requires management to make certain estimates, judgments and assumptions that affect the reported amounts of assets and liabilities at the date of the consolidated financial statements and reported amounts of expenses during the reporting period. Actual outcomes could differ from these

- 16 -

estimates. These consolidated financial statements include estimates which, by their nature, are uncertain. The impacts of such estimates are pervasive throughout the consolidated financial statements, and may require accounting adjustments based on future occurrences. Revisions to accounting estimates are recognized in the period in which the estimate is revised and future periods if the revision affects both current and future periods. These estimates are based on historical experience, current and future economic conditions and other factors, including expectations of future events that are believed to be reasonable under the circumstances.

Critical Judgments

The following are critical judgments that management has made in the process of applying accounting policies and that have the most significant effect on the amounts recognized in the consolidated financial statements:

|

(i)

|

The determination of categories of financial assets and financial liabilities has been identified as an accounting policy which involves judgments or assessments made by management.

|

|

(ii)

|

Management is required to assess the functional currency of each entity of the Company. In concluding that the Canadian dollar is the functional currency of the parent and its subsidiary companies, management considered the currency that mainly influences the cost of providing goods and services in each jurisdiction in which the Company operates. As no single currency was clearly dominant the Company also considered secondary indicators including the currency in which funds from financing activities are denominated and the currency in which funds are retained.

|

|

(iii)

|

Management is required to assess impairment in respect of exploration and evaluation assets. The triggering events are defined in IFRS 6. In making the assessment, management is required to make judgments on the status of each project and the future plans towards finding commercial reserves. The nature of exploration and evaluation activity is such that only a proportion of projects are ultimately successful and some assets are likely to become impaired in future periods.

|

|

(iv)

|

Although the Company takes steps to verify title to exploration and evaluation assets in which it has an interest, these procedures do not guarantee the Company’s title. Such properties may be subject to prior agreements or transfers and title may be affected by undetected defects.

|