TECHNICAL REPORT ON THE

NORRLIDEN RESOURCE ESTIMATION,

SWEDEN

By

Adam Wheeler, C.Eng., Eur.Ing.

Consulting Mining Engineer

May 2006

Adam Wheeler,

Mining Consultant,

Cambrose Farm,

Redruth,

Cornwall, TR16 4HT,

England.

Tel/Fax: (44) 1209-890733

E-mail : adamwheeler@btinternet.com

Ref: NORR/AJW/NO03

| Adam Wheeler |

Norrliden Resource Estimation |

TABLE OF CONTENTS

| Page | |||

| 1 SUMMARY | 1 | ||

| 1.1 | Introduction and Overview | 1 | |

| 1.2 | Database and Resource Estimation | 1 | |

| 1.3 | Conclusions and Recommendations | 2 | |

| 2 INTRODUCTION | 3 | ||

| 2.1 | Introduction | 3 | |

| 2.2 | Terms of Reference | 3 | |

| 2.3 | Sources of Information | 3 | |

| 2.4 | Units and Currency | 4 | |

| 2.5 | Disclaimer | 4 | |

| 3 PROPERTY DESCRIPTION AND LOCATION | 4 | ||

| 4 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES | 7 | ||

| 5 HISTORY | 8 | ||

| 6 GEOLOGICAL SETTING | 8 | ||

| 6.1 | Regional Geology | 8 | |

| 6.2 | Local Geology | 9 | |

| 7 | DEPOSIT TYPES | 10 | |

| 8 | MINERALISATION | 10 | |

| 9 | EXPLORATION | 11 | |

| 10 DRILLING | 11 | ||

| 10.1 | Drillhole database | 11 | |

| 10.2 | Surveying | 12 | |

| 11 SAMPLING METHOD AND APPROACH | 12 | ||

| 11.1 | Sampling Method | 12 | |

| 11.2 | Core logging and recovery | 13 | |

| 11.3 | Bulk Density | 13 | |

| 12 SAMPLE PREPARATION, ANALYSES AND SECURITY | 14 | ||

| 13 DATA VERIFICATION | 14 | ||

| 13.1 | Standards, Blanks and Duplicates | 15 | |

| 13.2 | Analyses by Independent Laboratories | 15 | |

| 13.3 | Independent Review | 15 | |

| 13.4 | Conclusion with respect to Data Verification | 20 | |

| 14 ADJACENT PROPERTIES | 20 | ||

| 15 MINERAL PROCESSING AND METALLURGICAL TESTING | 20 | ||

| 16 MINERAL RESOURCE ESTIMATE | 22 | ||

| 16.1 | General | 22 | |

| 16.2 | Drillhole Data Processing and Interpretation | 23 | |

| 16.3 | Geostatistical Analysis | 32 | |

| 16.4 | Geological Modelling | 34 | |

| 16.5 | Validation | 43 | |

| 16.6 | Evaluation | 45 | |

| 17 OTHER RELEVANT DATA AND INFORMATION | 51 | ||

| 18 CONCLUSIONS AND RECOMMENDATIONS | 52 | ||

| 18.1 | Conclusions | 52 | |

| 18.2 | Recommendations | 53 | |

| 19 REFERENCES | 53 | ||

| 20 DATE AND SIGNATURE PAGE | 53 | ||

| i |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

|

LIST OF TABLES |

|

| Table 13-1. Summary Statistics For Duplicate Samples | 16 |

| Table 13-2. Summary Statistics For Resampling | 18 |

| Table 16-1 Derivation of NSR Parameters | 27 |

| Table 16-2 Drillhole Summary | 28 |

| Table 16-3. Samples' Statistical Summary | 32 |

| Table 16-4. Capping Levels | 33 |

| Table 16-5. Composites' Statistical Summary | 33 |

| Table 16-6. Model Prototype | 34 |

| Table 16-7. Interpolation Parameters | 34 |

| Table 16-8. Resource Classification Parameters | 35 |

| Table 16-9. Comparison of Average Grades | 44 |

| Table 16-10. Resource Evaluation- Base Case Parameters | 46 |

| Table 16-11. Resource Breakdown - By Elevation | 47 |

| Table 16-12. Resource Evaluation - Based On Alternative Economic (LOM) Scenario | 48 |

| Table 16-13. Grade-Tonnage Curve - Just Indicated Resources | 49 |

| Table 16-14. Grade-Tonnage Table - All Resources | 50 |

|

LIST OF FIGURES |

|

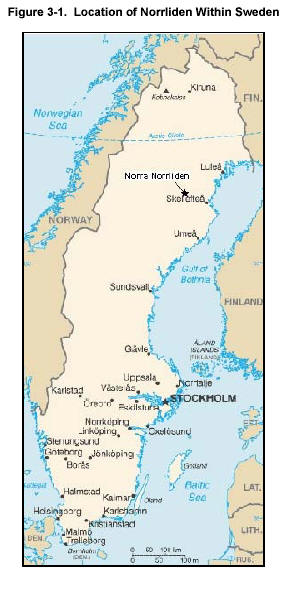

| Figure 3-1. Location of Norrliden Within Sweden | 5 |

| Figure 3-2. Location Norrliden Within Local Area | 6 |

| Figure 3-3. Western Part of Skelleftea Mining District | 6 |

| Figure 16-1. Section Through West Part of Main Zones At X=-60m | 25 |

| Figure 16-2. Section Through East Part of Main Zones At X=+60m | 26 |

| Figure 16-3. West-East Long Section of Main Zones | 29 |

| Figure 16-4. Plan of Drillholes | 30 |

| Figure 16-5. 3D View of Main Zones - Viewed From South-East | 31 |

| Figure 16-6. 3D View of Main Zones - Viewed From South-West | 31 |

| Figure 16-7. Zn Variation, Model Section West, At X= -60m | 36 |

| Figure 16-8. Zn Variation, Model Section East, At X= +60m | 37 |

| Figure 16-9. Cu Variation, Model Section West, At X= -60m | 38 |

| Figure 16-10. Cu Variation, Model Section East, At X= +60m | 39 |

| Figure 16-11. NSR Variation, Model Section West, At X= -60m | 40 |

| Figure 16-12 NSR Variation, Model Section East At X= +60m | 41 |

| Figure 16-13 Extent of Indicated Resources - Long Section of Main Zones | 42 |

APPENDICES

A Statistical Plots

B Decile Analyses

C Model Sections

D Twinned Hole Sections

| ii |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

1 SUMMARY

1.1 Introduction and Overview

Adam Wheeler was retained by Lundin Mining (Lundin) to provide an independent technical report on the mineral resources for the Norrliden polymetallic massive sulphide deposit. These mineral resources were estimated by Adam Wheeler during March 2004, and this study was then subsequently updated in April, 2006, reflecting more recent price parameters. A site visit was undertaken by Adam Wheeler in May 2006.

The Norrliden Zn-Cu deposit is located in northern Sweden, approximately 80km west of Skellefteå,. It is also about 40 road km away from the Storliden Zn-Cu mine, and 50 km east of the town of Malå. No mining activity has taken place at this deposit.

The deposit is a volcanogenic massive sulphide (VMS) occurrence, and was discovered and drilled by the Swedish Geological Survey (SGU) in a period from 1958 to 1974. In 1999, North Atlantic Natural Resources (NAN) initiated a second drilling programme to establish the nature and full extent of the mineralisation. NAN today is a wholly owned subsidiary of Lundin Mining.

Norrliden is situated in the centre of the western end of the Skellefteå mining district and displays the classical characteristics of Skellefteå VMS deposits. The deposit is a massive sulphide orebody with associated stringer zone, hosted by tuffite, sediments and pyroclastics.

The mineralisation is characterised by sulphides occurring in numerous lenses which lie sub-parallel the volcanic stratigraphy in a strongly deformed quartz-sericite rich horizon. Ore mineralogy consists mainly of pyrite, fine-grained sphalerite and chalcopyrite with dispersed galena and minor arsenopyrite. Many samples contain gold values of economic interest.

1.2 Database and Resource Estimation

The Norrliden database used to compile this resource estimate consists of 2092 samples from 92 drillholes; consisting of 52 of the 66 drillholes completed by SGU (those with assay and collar/survey data) and a further 42 diamond drillholes completed by NAN.

The data density (spacing and distribution) is sufficient to establish appropriate levels of geological and grade continuity for the resource estimation techniques used and the resource classification system applied.

The orientation of sampling data relative to the geological structures appears to be appropriate and is not believed to be introducing any bias into the sampling. Similarly, there are no apparent reasons to consider that the available survey data is introducing any bias into the estimates produced. There are no concerns over core recovery that would impact on the resource estimate or classification.

Density (specific gravity) determinations on NAN samples were made by the dry immersion method, which is a widely used and appropriate method. Although unconfirmed, it is believed the same method was used for SGU samples and, overall, sufficient, representative density measurements exist to allow calculation of a bulk density factors.

Sample selection, splitting, preparation and assay were all carried out to industry standards and there are no concerns over sample security or probity.

Although a complete, systematic and thorough quality control programme has not been undertaken for the sample set at Norrliden, the data that is available has not highlighted any significant problems that would compromise the integrity of the database used in the resource estimation.

| 1 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

There is, however, a level of uncertainty in the sample set that makes it inappropriate to use these samples to support measured resources, although sufficient confidence in the assay data does exist to support indicated resources.

Work completed during the original and updated resource estimation studies encompassed:

- Input and validation of drillhole sample data.

- Interpretation and geostatistical analysis of sample data.

- Generation of geological block model.

- Resource evaluation.

There are two distinct zones of mineralization, in the west and east ends of the deposit area. For each of these main zones, sections were interpreted based on a cut-off of SEK120/t. This interpretation was also strongly controlled by previous geological interpretations completed by NAN. The combined SEK value was calculated by consideration of the potential economic contribution of zinc, copper, lead, silver and gold.

Metal grades were interpolated into the block model, using parameters supported by a geostatistical analysis of drillhole composites. This also enabled the definition of pertinent resource classification criteria, relating to search distances, numbers of drillholes and composites, as well as the source of drilling data. Resources were classified according to the JORC code.

1.3 Conclusions and Recommendations

A summary of the resource evaluation is shown in the table below, based on a block cut-off of SEK120/t and a minimum mining width of 3m.

|

CLASS |

Tonnes | Zn | Pb | Cu | Au | Ag |

NSR |

|

|

kt | % | % | % | g/t | g/t |

SEK/t |

|

Indicated |

568 | 4.9 | 0.4 | 0.8 | 0.9 | 59.7 |

452 |

|

|

|

||||||

|

Inferred |

948 | 4.0 | 0.4 | 0.8 | 0.7 | 59.1 |

399 |

Notes . Based on block cut-off of SEK120/t

. NSR calculated using long-term base case prices:

|

|

Zn |

Pb |

Cu |

Au |

Ag |

|

|

|

c/lb |

c/lb |

c/lb |

$/oz |

$/oz |

|

|

|

/% |

/% |

/% |

/g/t |

/g/t |

|

|

Prices |

60 |

33 |

120 |

450 |

6.5 |

|

|

Coefficients |

46.3 |

20.8 |

143.2 |

54.4 |

0.94 |

The following recommendations have been made:

- Further drilling would be required in the main zones

to increase the proportion of indicated resources and to reinforce the

interpretation of peripheral zones.

- Further drilling, to give a closer sample spacing,

would be required in order to classify any of the deposit in a measured

resource category. Corresponding quality control on the sampling and assaying

procedures would need to be demonstrated at a higher standard.

- To allow a reserve estimate, a mine planning study would be required, together with a more detailed consideration of metallurgical and economic parameters.

| 2 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

2 INTRODUCTION

2.1 Introduction

This report presents a resource assessment for the Norrliden copper-zinc project located in the Skelleftea mining district in North Western Sweden. Norrliden is owned by North Atlantic Natural Resources AB (NAN), a wholly owned subsidiary of Lundin Mining Corporation (Lundin), a company listed on the Stockholm and Toronto Stock Exchanges.

The resource assessment is related to operational development of Lundin's Storliden mine, whose processing facility (at Boilden) is located approximately 60 km from Norrliden.

2.2 Terms of Reference

This resource estimation study was commissioned by Lundin and completed by Adam Wheeler, an independent mining consultant, with assistance from Lundin geologists. The majority of the computational work utilised the Datamine mining software system.

Adam Wheeler was retained by Lundin to provide an independent technical report on the mineral resources at Norrliden, as of April 30, 2006.This technical report has been prepared for filing pursuant to National Instrument 43-101and provides information with respect to the exploration activities, resource estimations and technical studies and economic analyses which have been undertaken by Lundin and its consultants.

The Qualified Person responsible for the preparation of this report is Adam Wheeler (C.Eng, Eur.Ing) an independent mining consultant.

Adam Wheeler completed the majority of the geological modelling and resource estimation during the first quarter 2006 and undertook a site visit to Norrliden on May 22nd, 2006. The work has been completed with assistance from Lundin technical personnel. The report was also reviewed internally by Paul Wheeler (BSc) an independent resource estimation geologist with 18 years' industry experience.

2.3 Sources of Information

In conducting this study, Adam Wheeler relied on reports and information prepared by and for Lundin.

The information on which this report is based includes:

- Descriptions of the regional and local geological

setting.

- Drilling, sampling and assay data from diamond drill

holes located on the property, together with details of data verification

procedures.

- Reports prepared by NAN/Boliden and their

consultants reviewing the sampling and assaying protocols, and geological

interpretations developed, including a report on Assay Quality Control by Da

Silva in November 1999.

- Previous reports prepared by Micon International Limited (Micon) and ACA Howe in January 2000; covering respectively the Norrliden Development Concept and a Resource Audit of Norra Norrliden.

Adam Wheeler is pleased to acknowledge the helpful cooperation of the management of Lundin, all of whom made any and all data requested available and responded openly and helpfully to questions and requests for material.

| 3 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

2.4 Units and Currency

Metric units are used throughout this report unless noted otherwise. Currency is primarily United States dollars ("US$") and Swedish kronor or crowns ("SEK"). The currency exchange rate adopted for this study was 8.0 SEK per US$.

2.5 Disclaimer

Adam Wheeler has reviewed and analyzed data provided by Lundin and its consultants and has drawn his own conclusions therefrom. Adam Wheeler has not performed any independent exploration work, drilled any holes or carried out any sampling and assaying.

Adam Wheeler performed the current estimate of the resources at the Norrliden deposit, as of April 30, 2006. Adam Wheeler has also drawn upon previous reports prepared by Micon and ACA Howe (both 2000), as well on a report on quality control prepared by James DaSilva in 1999.

While exercising all reasonable diligence in checking and confirmation, Adam Wheeler has relied upon the data presented by Lundin, and previous reports on the property by Micon, ACA Howe and DaSilva, noted above, in formulating his opinions.

Title to the mineral lands for the Norrliden deposit has not been investigated or confirmed by Adam Wheeler and Adam Wheeler offers no opinion as to the validity of the exploration or mineral title claimed. A description of the property, and ownership thereof, is provided for general information purposes only

3 PROPERTY DESCRIPTION AND LOCATION

The Norrliden deposit is 90% owned by Lundin Mining through their subsidiary NAN and is being evaluated in association with the ongoing development and mining of the Storliden deposit, also controlled by Lundin.

International Gold Exploration AB (IGE) has a 10% interest in the project, subject to making an equivalent contribution to development costs. If IGE decline to fund their share of the project's development, then this interest reverts to a 1.5% Net Smelter Return(NSR) royalty, although the value of the royalty cannot exceed US$5 million.

The deposit lies in the central Skelleftea mining district and is situated 26km north of Norsjö, Våsterbotten county, Swedish Lappland; approximately 50km east of Malå. Swedish National Grid position is grid location 1 643 185 East and 7 239 750 North.The nearest settlement is at Ortråak, 1.5km to the south-east and the coastal towns of Skellefteå and Umeå are approximately 60km and 90km distant respectively.

The location of Norrliden with reference to Sweden is shown in Fig 3.1. The location of Norrliden with reference to the local area is shown in Fig 3.2. The other Lundin concessions are also shown in a plan of part of the Skelleftea mining district, in Fig 3.3.

Norrliden is situated on the exploration permit Malånäset nr 2. An application for a mining permit named Norrliden K nr 1 is currently being processed. The exploration permit will be valid until the mining permit is granted.

The mine and associated site infrastructure would be located on land currently owned either by the Swedish forestry company, Assi Doman AB or by private individuals. Lundin has not yet completed any agreements for the purchase or use of any of these lands.

| 4 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 5 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 6 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

4 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, PHYSIOGRAPHY

The accessibility, climate, local resources, infrastructure and physiography descriptions in this report are taken from the Micon, 2002 report and various internal NAN reports, with the permission of the Lundin Mining Corporation.

The deposit itself is accessible to Adam Wheeler and a site visit was undertaken on May 22nd, 2006.

The deposit is located approximately 50km east of Malå and about 40 road km from Storliden. It is also approximately 60km from the existing processing plant in Boliden. Malå is located 100km inland from Skellefteå, the nearest large population centre, which is served by daily flights from Stockholm, and a well-maintained road and rail system which connects it the rest of Sweden and to Norway.

The climate is sub-arctic. The snow cover, which reaches on average from 50 to 75cm, extends from mid-November to mid-April. Spring is characterized by a 2 month thaw during which time severe damage may occur to un-metalled roads. Average temperatures range from +15o in summer to -15o in winter. Average summer precipitation is 450mm, with 250mm in winter. The prevailing wind directions are west and east with low average velocities of 1m/s. Summer days are long, and in turn winter days are short. Exploration activities can be carried out year-round with the exception of break-up in late April or early May.

The Norrliden deposit is located between 250m and 350m elevations, midway between two lakes, Kotjärnen and Jungfrutjärnen. There are several significant water features in the immediate vicinity. These include three lakes within a 1km radius of the deposit and two drainage courses, one of which traverses the area likely to be disturbed by mining.

The area surrounding the Norrliden deposit and most of the permitted site consists of forestry lands and largely planted coniferous forest. Stands of trees are interspersed with small hollows containing marshes and swamps. The land surface is established on a generally thick (5-20m) layer of glacial till, consisting of sands, clays, gravels and boulders. The forest floor is made up of ferns, mosses, heathers and small trees, with a saturated boggy nature due to the impeded drainage and clayey nature of the till.

The bedrock is formed of strong hard metamorphosed volcanic rocks, which are generally dry impervious and non-porous. It is possible that shear zones of crushed rock, which may be conduits for groundwater movement, exist.

Plans show several existing roads in the immediate vicinity of the deposit and an existing power line of unspecified voltage runs within 600m of the proposed pit. An aerial ropeway formerly used by Boliden approximately parallels the power line.

Population is sparse with the nearest existing dwellings or other structure some 900m from the centre of the deposit. There is a small village at Örträsk, approximately 1.5km south-east. Ortråak is a small tourist/summer village that hosts a funicular railway. This cableway previously used to transport ore from the mines in the west of the county to the concentrator in the town of Boliden.

There are no known areas of archaeological significance on the property. The area is used, as is most of the surrounding countryside, for grazing reindeer herds by the local Lapplanders or Samis.

| 7 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

5 HISTORY

The Norrliden deposit is a volcanogenic massive sulphide occurrence discovered by the Swedish Geological Survey (SGU) in the 1960s following drilling of a geophysical electromagnetic anomaly detected in 1958-59. A total of 66 drill holes were completed during the period 1960 to 1974 totalling 13,257 m.

A preliminary NAN resource estimate made from 40 drill holes drilled by SGU resulted in a resource estimate of 1.4Mt at 4.5% Zn, 0.8% Cu, 0.5% Pb, 79g/t Ag, 0.5g/t Au. In 1999, NAN initiated a drilling programme to establish the nature and full extent of the mineralisation, a programme of re-logging and re-sampling the SGU drill core and metallurgical test work.

The NAN drilling was carried out on sections 20m apart aimed at providing better definition of the geology and resource. A total of 42 diamond drill holes totalling 6,148m were completed.

A mineral resource estimate was prepared for NAN in January 2000 by Micon International Ltd. This culminated in a computerised block model.

Subsequent to this, in March 2000, the Micon study was audited by Mr Richard Parker of A.C.A. Howe, which included a review of the geological procedures, database, and methodology used to compile the Micon resource estimate. During this audit, an alternative resource estimation was also completed by A.C.A. Howe, using a cross-sectional method. This geological resource estimation, at a cut-off gross value of $28/t (gross revenue value), was 774,000t at 7.85% Zn, 0.8% Pb, 0.9% copper, 104g/t Ag and 1.3g/t Au. At the time this resource was classed as Inferred according to international standards.

Following on from the recommendations made by A.C.A. Howe, the interpretation of mineralised zones was revised, to correspond much more closely with the overall geological interpretation. These zone definitions were then used in an updated resource modelling and estimation project by Adam Wheeler during March 2004, with subsequent updates during April 2006.

6 GEOLOGICAL SETTING

6.1 Regional Geology

The regional geology descriptions in this report are taken from the Micon, 2002 report and various internal NAN reports, including a Technical Report on the Storliden Mine, February 2005 by Adam Wheeler. These reports are used with the permission of the Lundin Mining Corporation.

Norrliden is situated in the centre of the western end of the Skellefteå mining district. This district consists of an extensively mineralised Palaeo-Proterozoic (c.1.8-1.9Ga.) belt of mainly felsic submarine volcanics, that is partially covered by younger sediments and intruded by late intrusives.

The Skellefteå district covers an area 120km long by 30km wide, extending from the Baltic coast to west of the town of Malå. More than 85 massive sulphide deposits are known from this belt, of which 52 collectively contained 161Mt before mining with average grades of 0.7% Cu, 3.0% Zn, 47 g/t Ag, 1.9 g/t Au, 0.4% Pb and 0.8% As, often with significant amounts of Sb and Hg (Allen et al., 1996).

The district has been Sweden's main copper, zinc and gold producing region for the last 80 years and a number of mines have been, or currently are, operated, most notably at Boliden whose deposit was mined from 1925 to 1967 and spawned the major mining company of the same name. There are currently four Boliden AB mines in operation in the area, three

| 8 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

underground (Kristineberg, Petiknäs and Renström) and one open pit (Maurliden). In addition, NAN brought the Storliden deposit into production in 2002.

The oldest known rocks in the Skellefte greenstone belt are the 1.88 Ga volcanics of the Skellefte Group, a suite of basaltic to rhyolitic but dominantly felsic extrusive rocks with intercalated, generally fine-grained sediments. Nearly all of the mineral deposits of the Skellefte belt are hosted by this diverse group of volcanic rocks which is overlain by a sedimentary assemblage called the Vargfors Group consisting of fine to coarse-grained sediments and intercalated volcanic rocks.

The Arvidsjaur Group, a younger suite of subaerial volcanics of felsic composition, including ash-fall tuffs, ignimbrites and volcaniclastic sediments, is interpreted to be laterally equivalent to the Vargfors sediments. Intruding these lithologies are various intrusive rocks (Jörn suite) ranging from gabbro to granite in composition but predominantly tonalitic. The late to post-orogenic Revsund granite completes the rock sequence in the Skellefte greenstone belt.

The structure in the Skellefte district is dominated by upright, isoclinal to open folds and numerous shear zones and brittle faults. The main fold axes plunge moderately to the west in the western part, and moderately to steeply to the east in the eastern part, The Skellefte belt was folded and metamorphosed starting at 1.85 Ga, and the metamorphic facies increases outward from greenschist facies in the centre to lower amphibolite grade to the west, south and east, including the Norrlidden area.

The entire area is covered by a persistent veil of glacial deposits, mainly glacial till, that range from a few metres to more than 50m thick and covers not only the low-lying areas but most of the hills as well. As a consequence, outcrop is very scarce, and outside of the mining areas, the regional geology is incompletely known. On a local scale, the accuracy of the published data on bedrock geology is thus subject to change.

6.2 Local Geology

The Norrliden deposit is a massive sulphide orebody hosted by tuffite, sediments and pyroclastics. Narrow dykes and sills of rhyolite and andesite intrude this assemblage. All the lithologies have been regionally metamorphosed to low amphibolite facies and intruded by the Adak granite (ca 1.8 Ga.) which has imparted some contact metamorphic effects.

The deposit is hosted by a volcanic sequence striking about 110° and dipping about 60° south. Rocks within the local volcanic package have been logged as felsites, rhyolites, tuffites and greenstones. Recognition and correlation of these rock types is generally somewhat arbitrary due to their gradational nature and the overprinted alteration. Well-developed alteration halos, mainly above the ore zone, are observed. These are characterised by cordierite, tremolite - actinolite, carbonates, magnetite, silicates and sericite.

Two distinctive rock types do occur, described as very fine grained foliated greenstone, and andesite dyke. The "foliated greenstone" is characterised by delicate laminations which appear to be primary bedding features. It occurs in the immediate hanging wall of the highest massive sulphide lens.

The andesite dyke is recognisable on account of its abundant tabular feldspar phenocrysts. It cross-cuts the central part of the deposit.

| 9 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

7 DEPOSIT TYPES

The Norrliden deposit is a polymetallic, stratabound and stratiform volcanogenic massive sulphide (VMS) deposit. The ore types and their distribution suggest a massive sulphide mineralised zone with an associated stringer zone.

The deposit consists of sub-vertical lenses of massive sulphide up to 30m thick with an east-west strike length of 400m and a depth extent of at least 300m. The deposit is apparently open on the east side at a depth of 300 m. The depth to the top of the deposit is 15 m from the surface.

Norrliden displays the classical characteristics of Skellefteå VMS deposits and this model type and morphology has been used as the basis of the exploration activity to date; consisting of diamond core drilling from surface, with holes angled to intersect the orebody at as normal an angle as possible. As anticipated in deposits of this type, stringer mineralisation generally underlies the massive mineralisation and this zonation has been used to guide the positioning and depths of holes. Gold and lead enrichment is observed but the typical copper-zinc- lead zonation has not been found to date.

Detailed analysis of the facies of the volcanic host rocks to the sulphide deposits in the the Skellefteå mining district indicate that many of them were emplaced by subsea-floor replacement into porous mass flow volcaniclastics, rather than by exhalation onto the sea floor at the time. As a result, they are generally underlain, and often surrounded by, alteration haloes that tend to be larger than their counterparts in the Canadian Shield. These deposits may have genetic affinities to the sub-volcanic replacement deposits in the South American Andes such as Cerro de Pasco. One major difference, however, is that both host rocks and sulphide deposits in the Skellefte belt were folded and metamorphosed starting at around 1.85 Ga.

8 MINERALISATION

The descriptions in this section are taken from the Micon, 2002 report and various internal NAN reports, including a Resource Audit, January 2000 by A.C.A. Howe. These reports are used with the permission of the Lundin Mining Corporation.

The main deposit lies between surface and 200-300m below surface. It consists of a 400m east-west trending massive sulphide ore-body, which varies in thickness and dips at 80o to 85o to the south. The deposit does not outcrop.

The mineralisation is characterised by sulphides occurring in numerous lenses which lie sub-parallel the volcanic stratigraphy, close or at the contact between acid and basic volcanic rocks in a strongly deformed quartz-sericite rich horizon.

The mineralised material consists mainly of pyrite, fine-grained sphalerite and chalcopyrite with dispersed galena and minor arsenopyrite. Many samples contain gold values of economic interest. Pyrite is the dominant sulphide mineral present.

Two main styles of mineralisation are recognised in NAN's geological interpretation: massive to semi-massive sulphides and mineralised, 3-40% sulphides.

The massive to semi-massive sulphides zones comprise banded pyrite and sphalerite +/- minor chalcopyrite, galena and arsenopyrite. Zones categorised as mineralised, 3-40% sulphides includes stringer, disseminated and semi-massive mineralisation, often characterised by silicification and sericitisation. The stringer mineralisation generally underlies the massive mineralisation.

| 10 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

Some metal zonation is apparent. In the western part of the deposit a zinc rich zone is underlain by copper-enriched stringer mineralisation, a pattern which is reversed to some extent in the eastern part of the deposit.

Two main zones of mineralisation, the form of steeply dipping ore lenses, occur for resource modelling purposes: one to the east and one to the west of a relatively barren region of the deposit. A number of other, peripheral zones or lenses have also been defined by geological modelling.

The larger, western group of mineralised lenses is generally characterised by reasonable geological (physical) continuity, reflected by fairly confident correlation of lenses from drillhole to drillhole. The smaller, eastern group of mineralised lenses show less geological continuity, particularly laterally, although vertical continuity is reasonable. The causes of lateral discontinuity are not known. Folding and faulting of sulphide lenses has apparently been reported in some of the core-logs, but their exact role in controlling the distribution of mineral lenses is uncertain.

9 EXPLORATION

The Norrliden deposit was discovered by the Swedish Geological Survey (SGU) in 1968 following drilling of a geophysical electromagnetic anomaly detected in 1958-59. In a period from 1960 to 1974 a total of 66 drill holes were completed totalling 13,257 m.

In 1999, NAN initiated a drilling programme to establish the nature and full extent of the mineralisation, a programme of re-logging and re-sampling the SGU drill core and metallurgical test work.

The NAN drilling was carried out on sections 20m apart and a total of 42 diamond drill holes totalling 6,148m were completed. 29 of the former SGU cores were re-sampled and re-assayed by NAN.

10 DRILLING

10.1 Drillhole database

The Norrliden database as at April 30, 2006 consisted of 94 diamond drillholes which were drilled from surface; 52 SGU drillholes (of which 29 have duplicate assays taken by NAN) and 42 NAN holes. These 94 drillholes have provided 2092 samples for use in the estimation process. The NAN drilling took place between June 1998 and November 1999.

A further 14 SGU initial exploration drillholes have not been used in this study because they were either not assayed (having been used for geophysical not sampling purposes) or (in the case of one hole) because a collar position was not recorded. Their omission does not impact on the resources estimated.

Diamond drilling used conventional drilling equipment and industry standard practices. All NAN's exploration drillcore was geologically logged at NAN's Malå field office.

The data density (spacing and distribution) is sufficient to establish appropriate levels of geological and grade continuity for the resource estimation techniques used and the resource classification system applied.

The orientation of sampling data relative to the geological structures appears to be appropriate and is not believed to have introduced any bias into the sampling.

| 11 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

10.2 Surveying

All drill hole collars have been surveyed, including the old SGU casings, with the surveying work completed by an official surveyor. Drill hole collars were surveyed by NAN using a theodolite and stadia rod and a local surveying contractor, who was engaged to re-survey collar positions using a Global Positioning System (GPS) unit.

The quality and adequacy of topographic control has not been assessed, but Lundin have not indicated any concerns over this issue.

The inclination (dip) of the holes has been measured for most holes. For the NAN drilling, this downhole dip surveying was performed by the drilling company, Kati OY, using an electrical device, which picks up the dip from mercury in a measurement tube. For the NAN holes, which are short and relatively straight, azimuths were not measured down the hole.

The SGU holes were fully surveyed but Lundin staff have expressed concerns over some of the azimuth and dip measurements, particularly for the longer holes. A limited number of holes were re-surveyed using a Maxibore system, however, and Lundin report that the results were satisfactory.

Overall there do not appear to be any significant concerns over drillhole deviation and, while the absence of complete verification data for the surveying of samples does introduce an element of technical risk to this study, a sufficient number of survey readings exist to give reasonable confidence that the survey information is providing reliable three-dimensional positioning of samples.

There are no apparent reasons to consider that the survey data is introducing any bias into the estimates produced. The location of data points appears to be robust in three-dimensions. Zones and lenses identified by the samples produce coherent mineralised envelopes, with the geometric shape and continuity expected from this type of deposit. The relative x,y,z coordinate positions of composites are producing robust semi-variograms that can be modelled, which suggests that relative sample locations have been well defined.

11 SAMPLING METHOD AND APPROACH

11.1 Sampling Method

Details of the SGU sampling method are not available but based on previous experience are assumed to have followed similar practices to those outlined below. There is no reason to suspect that the SGU sampling methodology introduced any bias into the database.

NAN holes were drilled to provide 42 mm diameter core samples. These were placed in wooden boxes which were conveyed to the NAN field office in Malá. The core was logged by a geologist and the core recovery was recorded. Drill core was marked for sampling by the geologist according to the rock types, alteration assemblages, and mineralisation observed in the core during logging.

For the SGU sampling, the commonest sample length was approximately 2m. For the NAN drillholes, sample lengths were generally shorter with the commonest and average sample length of approximately 1m, due principally to greater respect of divisions between copper-rich and zinc-rich zones.

All mineralised intervals selected for sampling from NAN's exploration drillcore were sawn in half at the Malå field office, with the remaining half-core retained for reference. The majority of this core is stored in wooden core boxes inside a heated warehouse adjacent and connected

| 12 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

to NAN's field office and is available for inspection. Bags of core samples were placed in strong boxes and shipped by train to NAN's sample preparation facility in Uppsala.

The SGU re-sampling by NAN was done by taking ¼ of the core, on the same sample lengths. The SGU core is believed to have been retained by the SGU's Malå office and core library.

11.2 Core logging and recovery

Core logging has been carried out by a number of geologists and is of variable quality. Concerns were raised in the A.C.A. Howe report in 2000 that that a lack of consistency and standardisation in logging did not provide an adequate basis for an indicated resource. These comments appear to be of relevance mainly with regard to the SGU drillholes.

Since 2000, further interpretation work and geological modelling has been carried out by NAN geologists and Adam Wheeler is satisfied that the existing geological model and database provides an adequate basis for a resource estimation, including allocation of parts of the main zones as indicated resources (see section 16.4).

Core recovery for the SGU holes was reportedly good and for the NAN holes is over 90% even in the most broken of holes. There are no concerns over core recovery that would impact on the resource estimate or classification.

11.3 Bulk Density

Density (specific gravity) determinations were made for each NAN sample in the database, using a dry immersion method. This is a standard, appropriate method for a project at this stage of exploration and it is believed to have been used for the SGU samples as well.

For NAN samples, density determinations were made by technicians at the Uppsala sample preparation facility using a standard protocol. A representative piece, weighing between 500g-1kg, of sawn drill core was selected from each sample interval and the dry weight of the specimen was recorded. The dry, unsealed specimen was placed in a basket and submerged in a vessel containing water, recording the weight of the specimen in water as quickly as possible to avoid saturation of the sample.

The density of the sample was calculated using the formula:

- Density (t/m3) = dry weight (air) / [dry weight (air) - dry weight (water)]

There is always a concern that density measurements based on core alone may not fully reflect the bulk density of large volumes of rock; due to the inherent variability in fracture spaces and voids and the geological variations in rock masses seen in a bulk mining sense. Massive sulphide deposits, with their variable sulphide mineral contents, also require careful consideration of density in the ore horizons.

Density measurements are available for 1866 out of 2092 samples in the complete database (89%). More importantly, 566 of 579 (98%) samples in the main ore zones and 103 of 106 (97%) samples in the peripheral zones have density measurements. Sufficient measurements clearly exist, therefore, to allow interpolation of density values into blocks (see section 16.4).

Adam Wheeler considers that sufficient, representative density measurements exist to allow calculation of a bulk density factor for the conversion of resource volumes into tonnages.

| 13 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

12 SAMPLE PREPARATION, ANALYSES AND SECURITY

The assay database includes 1628 samples (NAN drillholes and check samples from SGU holes) which were analysed for gold, silver, copper, lead, zinc, bismuth, antimony and arsenic by Cone Geochemical, Colorado. The database also contains original assays only for 464 half-core samples from SGU's holes.

The sawn core samples from NAN's drilling campaigns were transported to the Uppsala preparation laboratory where they were crushed and pulverised. Preparation of drill core samples for analysis involved initial reduction in a jaw crusher followed by pulverisation in a ring grinder. Drill core samples weighing 2-4 kg were crushed to 60% passing a 2mm sieve. A 500g sub-sample was riffled from the crushed material and pulverised to 90% passing 100µm.

A 200-300g sub-sample was riffled from the pulverised material for shipment to the assay laboratory. Coarse reject material was re-bagged and stored for future reference. The pulverised material was split using a rifle splitter and duplicate pulp samples were prepared.

NAN implemented several practises to minimise the potential for contamination during sample preparation. These measures included use of a powerful dust extraction system in the comminution circuit and the use of barren rock to clean crushing and grinding surfaces between each sample. The pulps and coarse rejects of all samples have been retained for future reference.

The 200-300g pulp samples were then sent for assay at the facilities of Cone Geochemical Inc. (Cone), located in Lakewood, Colorado. Assaying was done by standard atomic absorption spectroscopy (AAS) for copper, zinc, lead and silver following digestion in a solution of aqua regia. Gold analyses were accomplished by standard fire assay fusion using a conventional 30g (1 assay ton) sub-sample with an AAS finish. Arsenic values were determined by AAS following a perchloric/nitric acid digestion. Bismuth values were determined using a KClO4/HCl digestion, and antimony values were determined using an organic extraction.

No detailed descriptions are available on the procedures or laboratories used to assay the original SGU samples (see section 13.4). SGU samples were reportedly assayed by Kemiska Laboratoriet over three assaying periods. The Da Silva, 1999 report indicates that two of these batches were considered reliable but a third was not. Any drillholes with assay results based solely on this third batch of samples have been excluded from the resource estimate.

Sample selection, splitting, preparation and assay were all carried out to industry standards and there are no concerns over sample security or probity.

13 DATA VERIFICATION

The descriptions of the quality control (QC) regime given in sections 13.1 and 13.2 are taken from the DaSilva, 1999 report and various internal NAN reports. These reports are used with the permission of the Lundin Mining Corporation.

Adam Wheeler has reviewed and discussed the content of these reports with Lundin/NAN staff and is satisfied that they represent a fair and accurate description of the QC procedures used in the exploration and sampling programmes at Norrliden. Adam Wheeler has then, independently, undertaken a review of data verification issues (section 13.3) and drawn conclusions (section 13.4).

| 14 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

13.1 Standards, Blanks and Duplicates

Quality control (QC) was accomplished by the submission of blank and duplicate samples, totalling some 6.6% of NAN's 1628 sample suite (NAN holes + SGU checks). No details of the QC procedures used to assay the original SGU samples are available (see section 13.4).

QC samples for the NAN suite were inserted at approximately regular intervals into sample batches. Blanks were composed of clean rock (usually unmineralised granite with a low trace element content). Duplicate core samples were chosen at random in the field and the corresponding pulverised reject used to make duplicates with the aid of a Jones splitter.

13.2 Analyses by Independent Laboratories

Within-laboratory repeat assaying was undertaken on duplicates at the facilities of Cone Geochemical Inc. in Colorado. 61 duplicate samples (3.7% of total) were submitted to Cone for re-assay in 1999. Duplicate samples were taken from both SGU-NAN re-sampled holes (16) and NAN's own drillholes (45).

Assay results from duplicates taken from NAN's own drillholes and from SGU holes which NAN re-sampled (i.e. within laboratory repeats), revealed repeatability (precision) of 95% or better for all elements.

No formal, systematic check assaying at a second laboratory was undertaken for samples in the database. For the SGU-NAN re-sampled holes (analysed by Cone), however, results were compared to the original SGU assays (analysed by Kemiska Laboratoriet) to serve as a further quality assurance measure.

The assay results showed repeatability (precision) in excess of 95% for silver, copper and zinc. Gold and lead comparisons revealed a lower degree of repeatability (90%). This is attributed to analytical procedural differences over the 30 plus years between the sets of analyses.

A total of 46 blank samples (3.7% of total), made from preparation lab clean rock, as well as one made from 95% clean rock and 5% high grade material, was also submitted to Cone for within-laboratory check assaying. Results for the suite of blank samples gave an acceptably narrow range of very low or undetectable values. The high grade sample was clearly identifiable in the sample set as an outlier, anomalous to the low background levels of the other blanks.

13.3 Independent Review

Adam Wheeler's review of the Quality Control report by Da Silva, 1999, and discussions with Lundin staff, indicates that drillholes and samples under the control of NAN (including check samples from SGU holes) have been subjected to appropriate quality control procedures and checks with respect to the introduction of duplicates and blanks. A statistical summary of these results is shown in Table 13-1, with corresponding scatter plots in the following charts. For zinc and copper, by far the primary metals for this deposit, 90% of the resampling duplicates have a relative error less or equal to 5%. Very high coefficients of determination are apparent for all metals.

The level of precision within the assay population is good and the accuracy also appears to be good, although a more industry-standard approach would have seen the use of reference materials (standards) as well as blanks in the sample stream to check accuracy. The use of blanks alone has acted as a check for contamination or gross errors in sample handling, rather than specifically checking accuracy.

| 15 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

Table 13-1. Summary Statistics For Duplicate Samples

| Precision Testing | |||

|

|

|

||

|

|

Number of |

|

|

|

Metal |

R2 | Pairs |

Precision |

|

Zn |

96% | 61 |

3% |

|

Cu |

99.9% | 61 |

5% |

|

Pb |

99.9% | 52 |

9% |

|

Ag |

99% | 61 |

11% |

|

Au |

99.9% | 61 |

16% |

|

|

|

SGU |

NAN |

|

Zn |

Mean |

2.20 |

2.30 |

|

|

SD |

4.41 |

4.45 |

|

|

Coeff Var |

2.00 |

1.93 |

|

|

Skewness |

2.49 |

2.35 |

|

Cu |

Mean |

2.20 |

2.30 |

|

|

SD |

4.41 |

4.45 |

|

|

Coeff Var |

2.00 |

1.93 |

|

|

Skewness |

2.49 |

2.35 |

|

Pb |

Mean |

0.32 |

0.32 |

|

|

SD |

0.93 |

0.94 |

|

|

Coeff Var |

2.93 |

2.96 |

|

|

Skewness |

4.33 |

4.38 |

|

Ag |

Mean |

34.03 |

33.05 |

|

|

SD |

66.54 |

61.58 |

|

|

Coeff Var |

1.96 |

1.86 |

|

|

Skewness |

4.60 |

4.27 |

|

Au |

Mean |

1.25 |

1.21 |

|

|

SD |

5.79 |

5.52 |

|

|

Coeff Var |

4.64 |

4.56 |

|

|

Skewness |

7.26 |

7.25 |

Notes

. R2 = coefficient of determination

. R = Pearson product moment correlation coefficient

. Precision determined such that 90% of the corresponding samples have a % relative error < precision value given

. Relative error = (absolute difference from mean or pair)/mean of pair

. All available data used for precision calculations

| 16 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 17 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

In addition, Adam Wheeler independently analysed data from the 472 samples taken by NAN from the remaining half-core from 29 of SGU's original 66 holes. These re-sampled intervals acted as a type of duplicate sampling to help verify the data quality. A statistical summary of these results is shown in Table 13-2, with corresponding scatter plots in the following charts. For zinc and copper, by far the primary metals for this deposit, 90% of the resampling duplicates have a relative error less than 30%. Although this error level seems fairly high, it must be remembered that in many cases, the SGU core had already been resampled previously by Boliden. This meant that core has been cut twice to leave the remaining ¼ of core. Coupled with the small core size (T46), and core loss due to oxidation, this has added to precision errors associated with resampling. Despite this, very good overall correlations have been obtained between zinc and copper. All metals yield very similar overall mean grade and standard deviation values. These results indicate no significant bias for any of the metals.

Table 13-2. Summary Statistics For Resampling

| Precision Testing | |||||

|

|

Total |

|

|

|

|

|

|

Number of |

|

Number of |

|

|

|

Metal |

Pairs |

R2 |

Pairs |

Range |

Precision |

|

Zn |

367 |

96% |

138 |

>0.3% |

30% |

|

Cu |

406 |

95% |

301 |

>0.03% |

25% |

|

Pb |

196 |

92% |

196 |

>0 |

27% |

|

Ag |

359 |

72% |

269 |

>5g/t |

39% |

|

Au |

191 |

46% |

80 |

>0.2g/t |

53% |

|

|

SGU |

NAN |

|

|

Zn |

Mean | 1.98 |

2.03 |

|

|

SD | 5.02 |

5.19 |

|

|

Coeff Var | 2.54 |

2.56 |

|

|

Skewness | 3.73 |

3.49 |

|

Cu |

Mean | 0.52 |

0.51 |

|

|

SD | 0.80 |

0.80 |

|

|

Coeff Var | 1.54 |

1.56 |

|

|

Skewness | 3.07 |

3.03 |

|

Pb |

Mean | 0.44 |

0.44 |

|

|

SD | 0.96 |

0.96 |

|

|

Coeff Var | 2.18 |

2.17 |

|

|

Skewness | 3.54 |

4.07 |

|

Ag |

Mean | 38.06 |

38.43 |

|

|

SD | 68.45 |

84.97 |

|

|

Coeff Var | 1.80 |

2.21 |

|

|

Skewness | 3.73 |

4.92 |

|

Au |

Mean | 0.52 |

0.55 |

|

|

SD | 0.84 |

0.67 |

|

|

Coeff Var | 1.62 |

1.22 |

|

|

Skewness | 3.64 |

2.34 |

Notes

. R2 = coefficient of determination

. R = Pearson product moment correlation coefficient

. Precision determined such that 90% of the corresponding samples have a % relative error < precision value given

. Relative error = (absolute difference from mean or pair)/mean of pair

| 18 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 19 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

The database also contains original assays only for 464 half-core samples from SGU's drillholes, Given the good correlation between re-sampled intervals indicated above, and the known standard of sampling and analytical procedures used elsewhere by the Swedish Geological Survey (SGU), there is no reason to suspect that the use of these samples is introducing any bias into the database.

NAN specifically drilled three twinned holes (i.e. drilled within a few metres of the previous hole) as a check against the older SGU holes. The pairs obtained are summarised below:

| SGU | NAN |

| 63102 | 99005 |

| 60101 | 99006 |

| 63109 | 99008 |

| 63107 | 99007 |

Sections displaying the zinc and copper grades obtained with the 4 different sets of twinned holes are shown in Appendix D. These show very good correspondence between the higher grade intersections of both zinc and lead.

13.4 Conclusion with respect to Data Verification

Although a complete, systematic and thorough quality control programme has not been undertaken for the sample set at Norrliden, the data that is available has not highlighted any significant problems that would compromise the integrity of the database used in the resource estimation.

The absence of complete quality control data does, however, create a level of uncertainty in the sample set and, to reflect this, it is considered inappropriate to use these samples to support measured resources. Sufficient confidence in the assay data does exist to support classification of indicated resources where this is also justified by other appropriate factors, such as data density and search parameters.

14 ADJACENT PROPERTIES

There are no exploration or mining properties currently active in the immediate vicinity of Norrliden. There is no data available on adjacent properties that would materially affect the assessment of this resource estimate.

The Storliden VMS deposit is some 45 road km to the northwest of Norrliden, and Lundin has an existing mine there. The mine commenced production in April, 2002 and remains in operation today. Boliden AB is providing milling services for the Storliden ore at its concentrator located near the town of Boliden, some 90km from Storliden. Facilities at Storliden and the Boliden concentrator may be used in development of Norrliden; but information relating to Storliden is not necessarily indicative of the mineralisation on the Norrliden property.

15 MINERAL PROCESSING AND METALLURGICAL TESTING

The descriptions in this section are taken from the Micon, 2002 report and various internal NAN reports. These reports are used with the permission of the Lundin Mining Corporation. The anticipated metallurgical performances have been discussed and agreed with Lundin staff and form the basis of the NSR parameters determined in section 16.2.

| 20 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

The relatively small size of the deposit does not appear to justify a dedicated concentrator plant to upgrade ore at the site. It is therefore anticipated that ore from Norrliden will be transported to an existing concentrator some distance away.

A limited metallurgical testwork programme conducted by Lakefield Research Limited suggested that Norrliden ore is generally finer grained than Storliden ore. In particular, the degree of liberation of galena and the occurrence of pyrrhotite and arsenopyrite inclusions in sphalerite indicate that the metallurgical response of Norrliden ore is likely to be closer to that of other copper/lead/zinc ore with similar head grades from the SkeIIeftea area, which is currently processed by Boliden AB at their Boliden concentrator..

At the time of writing, the anticipated recoveries to concentrate and concentrate grades are:

| Product | Conc. Grade | Recovery |

| Zinc concentrate | 54% Zn | 85% |

| Copper concentrate | 29% Cu | 85% |

| Lead concentrate | 70% Pb | 70% |

In addition some silver reports to the lead concentrate; both silver and gold report to the copper concentrate. Only the precious-metal content of the copper concentrate is considered in the NSR calculations (section 16.2). Pyrrhotite and arsenopyrite inclusions will affect concentrate grade and the penalty levels of iron and arsenic but this has not been quantified in this study.

| 21 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

16 MINERAL RESOURCE ESTIMATE

16.1 General

This resource estimation stems from an initial geological block modelling project complted in March 2004. This study was then subsequently updated in April, 2006, reflecting more recent price parameters. This report section describes the work completed during the original and updated studies, which can be summarised as:

- Input and validation of drillhole sample data.

- Interpretation and geostatistical analysis of sample

data.

- Generation of geological block model.

- Resource evaluation.

There are two distinct zones of mineralization, in the west and east ends of the deposit area. For each of these main zones, sections were interpreted based on a cut-off of SEK120/t (combining contributions from all main metals). This interpretation was also strongly controlled by previous geological interpretations completed by NAN (North Atlantic Resources).

Stemming primarily from these main zones' interpretations, a block model was created. Additional peripheral blocks were also created outside of the main structures, based on sectional perimeters as well as three-dimensional projection from other intercepts.

Metal grades were interpolated into the block model, using parameters supported by a geostatistical analysis of drillhole composites. This also enabled the definition of pertinent resource classification criteria, relating to search distances, numbers of drillholes and composites, as well as the source of drilling data.

Resources were classified according to the JORC code. A summary of the resource evaluation is shown in the table below, based on a block cut-off of SEK120/t and a minimum mining width of 3m.

Resource Summary

|

ZONE |

Tonnes |

Zn |

Pb |

Cu |

Au |

Ag |

NSR |

|

|

kt |

% |

% |

% |

g/t |

g/t |

SEK/t |

|

Indicated |

568 |

4.9 |

0.4 |

0.8 |

0.9 |

59.7 |

452 |

|

Inferred |

948 |

4.0 |

0.4 |

0.8 |

0.7 |

59.1 |

399 |

|

Total |

1,516 |

4.3 |

0.4 |

0.8 |

0.8 |

59.3 |

419 |

Notes . Based on block cut-off of SEK120/t

. NSR calculated using long-term base case prices:

|

Zn |

Pb |

Cu |

Au |

Ag |

|

|

c/lb |

c/lb |

c/lb |

$/oz |

$/oz |

|

|

/% |

/% |

/% |

/g/t |

/g/t |

|

|

Prices |

60 |

33 |

120 |

450 |

6.5 |

|

Coefficients |

46.3 |

20.8 |

143.2 |

54.4 |

0.94 |

| 22 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

16.2 Drillhole Data Processing and Interpretation

The available drillhole data was compiled in Excel spreadsheets, with separate sheets for assays, survey and collar data. This data was imported into Datamine, combined and then desurveyed, where the central coordinates of each sample were calculated. This data was then examined in plan, section and 3D views.

The drillholes came from two sources - SGU and NAN (North Atlantic Resources AB). Many of the much older SGU holes had also been re-assayed by NAN. All of the data from these sources were imported, and then merged in such a way as to ensure the most recent assay data was utilised. A drillhole collar plot is shown in Fig 16-1.

Based on up-to-date parameters associated with the nearby Boliden processing operations, as well as revised long-term metal prices, coefficients were determined to enable the calculation of contained NSR values for both the sample and model data. These parameters and calculations are summarised in Table 16-1, for the long term base case prices. Similar parameters for an alternative LOM price scenario were also derived. The resultant parameters for these different price scenarios are summarised below:

|

Zn |

Pb |

Cu |

Au |

Ag |

||

|

c/lb |

c/lb |

c/lb |

$/oz |

$/oz |

||

|

/% |

/% |

/% |

/g/t |

/g/t |

||

|

Long Term |

Prices |

60 |

33 |

120 |

450 |

6.5 |

|

Base Case |

Coefficients |

46.3 |

20.8 |

143.2 |

54.4 |

0.94 |

|

LOM |

Prices |

90 |

35 |

180 |

500 |

9 |

|

Scenario |

Coefficients |

71.2 |

22.6 |

221.4 |

60.5 |

1.3 |

Having used the base case coefficients to calculate an updated NSR value in combined sample data, 20m spaced sections were examined. As well as viewing the sample data, previous NAN geological interpretation strings were also superimposed, imported from MicroStation files.

With this data background, two main zones were interpreted (east and west), based on a cutoff value of SEK120/t (for base case prices). The main east and west zones are either side of a barren corridor. This SEK120/t cut-off level was chosen as being relevant for potential economic considerations. Typical sections showing drillholes and the resultant mineralised zone interpretations are shown in Figs 16-2 and 16-3, for the west and east end, respectively. This zone definition was defined so as to conform to the existing NAN geological interpretation, characterised by numerous lense-type structures sub-parallel to the volcanic stratigraphy. Both the geological interpretations, as well as the mineralised zone models defined in this study, are shown in the model sections shown in Appendix C.

| 23 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 24 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 25 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 26 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

Table 16-1 Derivation of NSR Parameters

| Long Term Metal Prices |

Zinc Concentrate Value |

|||||||

|

|

zinc | copper | gold | silver | lead |

Zinc recovery (planned) |

85.00% | |

|

$/tonne |

1,322.76 | 2,645.52 | 727.52 |

Zinc Concentrate grade (planned) |

54.00% | |||

|

c/lb |

60.00 | 120.00 | 33.00 |

Zinc Concentrate ratio = tonnes Zn concentrate / tonnes feed |

||||

|

$/oz |

450.00 | 6.50 |

therefore 7.90%*0.85%/0.54% |

0.124352 | ||||

|

|

||||||||

| Exchange Rate |

Net Smelter Return (NSR) value |

|||||||

| Swedish Kroner (SEK) | 8.00 SEK/US$ |

Payment terms = 85% (min deduction 8 units) |

||||||

|

Payment per tonne zinc concentrate in SEK/tonne Zn conc |

||||||||

| Average Deposit Feed Grades |

payment x price x grade x exchange rate |

|||||||

| zinc | copper | gold | silver | lead |

85% x 1,146.39 x 54% x 8 = |

4,857 | SEK/tonne conc | |

| % Zn | % Cu | g/t Au | g/t Ag | %Pb |

Treatment charge $160/tonne x SEK/$ |

-1,280 | ||

| 7.9 | 0.9 | 1.3 | 104 | 0.8 |

Escalator if price > $1,000, then add 16c/$ |

|||

|

$1,146-$1,000=$146 x $0.16 x 8.0 SEK/$ |

-413 | |||||||

| Lead Concentrate Value |

Penalties, freight, handling, insurance etc |

-222 | ||||||

|

Lead recovery (planned) |

70.00% |

|

2,942 | SEK/tonne Zn conc | ||||

|

Lead Concentrate grade (planned) |

70.00% |

multiplied by Zinc Concentrate ratio |

366 | SEK/tonne feed | ||||

|

Lead Concentrate ratio = tonnes Pb concentrate / tonnes feed |

NSR factor for Zinc |

46.31 | SEK/tonne feed/% Zn | |||||

|

therefore |

0.80%*0.70%/0.70% |

0.008 |

|

|||||

|

Copper Concentrate Value |

||||||||

| Net Smelter Return (NSR) value |

Copper recovery (planned) |

85.00% | ||||||

| Payment terms = 95% (min deduction 8 units) |

Copper Concentrate grade (planned) |

29.00% | ||||||

| Payment per tonne lead concentrate in SEK/tonne Pb conc |

Gold recovery to Cu concentrates |

50.00% | ||||||

| payment x price x grade x exchange rate |

Silver recovery to Cu concentrates |

60.00% | ||||||

| 95% x 661.38x 70% x 8 = | 3,870 SEK/tonne conc |

Copper Concentrate ratio = tonnes Cu concentrate / tonnes feed |

||||||

| Treatment charge | $130/tonne x SEK/$ | -1,280 |

therefore 0.9% x 85% / 29% = |

0.026379 | ||||

| Escalator if price > $500, then add 16c/$ |

Gold in Cu concs g/t Cu conc |

24.64 | ||||||

| $1,146-$500=$146 x $0.16 x 8.0 SEK/$ | -291 |

grade (1.3g/t) x recovery (50%) / Cu conc ratio |

||||||

| Penalties, freight, handling, insurance etc | -222 |

Silver in Cu concs g/t Cu conc |

2,365 | |||||

| 2,077 SEK/tonne Pb conc |

grade (104g/t) x recovery (60%) / Cu conc ratio |

|||||||

| multiplied by Lead Concentrate ratio | 17 SEK/tonne feed |

Net Smelter Return (NSR) value |

||||||

| NSR factor for Lead (481/11.2% Zn) | 20.77 SEK/tonne feed/% Pb |

refining charge 101.4 US$/tonne |

||||||

|

payment deduct 1% Cu, pay for balance x copper price(US$) less refining charge |

||||||||

| Payment for gold | 2,681 SEK/tonne conc |

escallator if US$ copper price > $1,984, then additional charge of 10c for every $ over $1,984 |

||||||

| (Au in Cu concs - 1g/t) x 98% x price ($350/oz/31.1034) x exch rate |

treatment charge $55 per DMT |

|||||||

| NSR factor for Gold | 54.41 SEK/tonne feed/g Au |

gold credit deduct 1 g/t x gold price x 98% |

||||||

| (121 / Au grade (1.3g/t) x Cu conc ratio) |

silver credit deduct 30 g/t x silver price x 95% |

|||||||

|

gold refining no charge |

||||||||

| Payment for Silver | 3,709 SEK/tonne conc |

silver refining no charge |

||||||

| (Ag in Cu concs - 30g/t) x 95% x price ($5.0/oz/31.1034) x exch rate |

Payment for Copper |

5,551 | SEK/tonne conc | |||||

| NSR factor for Silver | 0.94 SEK/tonne feed/g Ag |

Cu conc grade (29-1)% x ((price-refining)-0.1 x (price-1984)) x exch rate (8.0) |

||||||

| (178 / Au grade (104g/t) x Cu conc ratio) |

Treatment charge |

-440 | SEK/tonne conc | |||||

|

Penalties, freight, handling, insurance etc |

-225 | |||||||

|

total |

4,886.0 | SEK/tonne Cu conc | ||||||

|

multiplied by Copper Concentrate ratio |

129 | SEK/tonne feed | ||||||

|

NSR factor for Copper (417/3.5% Cu) |

143.21 | SEK/tonne feed/% Cu | ||||||

| 27 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

The Norrliden deposit could conceivably be mined by either open-pit or underground. The cut-off grade levels used for subsequent evaluation are discussed in more detail in Section 16.6. Statistics of the contained NSR values (Appendix A) do not show any particularly natural breaks. A minimum thickness of 3m was also applied.

On some sections, internal waste splits were also defined. The strings defining the mineralised envelopes were also snapped directly onto the relevant sample boundaries. This is very important because many of the intercepts are long way off the actual 20m section lines. This can be seen from a long section, shown in Fig 16-4, and a plan view of the drillhole traces, shown in Fig 16-5. These main zone perimeters were then linked together to form three-dimensional wireframe envelopes. There are displayed in 3D views in Figs 16-6 and 16-7.

All of the samples belonging to these main zones were then isolated. A summary of the drillhole data overall, and intersecting the main zones, is shown in Table 16-2. This data summary only pertains to those holes which intersected mineralization.

Some peripheral zones were also defined with individual perimeters on intercepts whose NSR value was greater than SEK120/t.

| Table 16-2 Drillhole Summary | ||||

|

|

|

No. of |

Re-Assayed |

No. of |

|

|

Drilled By |

Holes |

By NAN |

Samples |

|

All Zones |

SGU |

52 |

29 |

752 |

|

|

NAN |

42 |

|

1340 |

|

|

Total |

94 |

|

2092 |

|

Main Zones |

SGU |

20 |

18 |

151 |

|

|

NAN |

28 |

|

422 |

|

|

Total |

48 |

|

573 |

| 28 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 29 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 30 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| 31 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

16.3 Geostatistical Analysis

A summary of the statistical parameters for the metal grades and derived NSR values, for all samples, the main zones and peripheral zones is shown in Table 16-3. These statistics are both length and density weighted.

Table 16-3. Samples' Statistical Summary

|

|

|

Log |

|||||||

|

|

|

Number of | Number | Standard | Geometric |

Estimate |

|||

|

ZONE |

FIELD |

Records | >0 | Maximum | Mean | Variance | Deviation | Mean |

of Mean |

|

|

AU |

4072 | 1847 | 44.6 | 0.4 | 2.1 | 1.4 | 0.1 |

0.5 |

|

|

AG |

4072 | 1867 | 1280 | 30.7 | 6676.3 | 81.7 | 5.9 |

36.3 |

|

ALL |

CU |

4072 | 2053 | 8.1 | 0.4 | 0.6 | 0.8 | 0.1 |

0.6 |

|

SAMPLES |

PB |

4072 | 1924 | 7.77 | 0.2 | 0.5 | 0.7 | 0.1 |

0.3 |

|

|

ZN |

4072 | 2074 | 41.9 | 1.9 | 24.4 | 4.9 | 0.1 |

1.8 |

|

|

DENSITY |

4072 | 1886 | 4.81 | 3.2 | 0.3 | 0.5 | 3.2 |

3.2 |

|

|

AU |

563 | 563 | 44.6 | 1.0 | 5.0 | 2.2 | 0.5 |

1.3 |

|

|

AG |

565 | 565 | 1280.0 | 71.5 | 15018.1 | 122.5 | 28.6 |

85.0 |

|

|

CU |

566 | 550 | 6.6 | 0.8 | 1.0 | 1.0 | 0.3 |

1.2 |

|

MAIN |

PB |

566 | 508 | 7.8 | 0.5 | 1.1 | 1.0 | 0.1 |

0.6 |

|

ZONES |

ZN |

566 | 566 | 41.7 | 5.4 | 59.2 | 7.7 | 1.0 |

15.0 |

|

|

DENSITY |

579 | 566 | 4.81 | 3.6 | 0.4 | 0.6 | 3.5 |

3.6 |

|

|

AU |

103 | 103 | 5.5 | 0.7 | 1.0 | 1.0 | 0.3 |

0.9 |

|

|

AG |

103 | 103 | 515.0 | 58.5 | 11798.1 | 108.6 | 14.0 |

73.2 |

|

PERIPHERAL |

CU |

103 | 102 | 8.1 | 0.7 | 1.1 | 1.0 | 0.3 |

1.0 |

|

ZONES |

PB |

103 | 66 | 6.7 | 0.5 | 0.9 | 0.9 | 0.1 |

1.6 |

|

|

ZN |

103 | 103 | 41.9 | 4.0 | 39.1 | 6.2 | 0.4 |

10.9 |

|

|

DENSITY |

106 | 103 | 4.64 | 3.3 | 0.3 | 0.5 | 3.3 |

3.3 |

Statistical plots were generated for each metal for the main zones' data set. These plots are all shown in Appendix A. Decile analyses of metal grades were also generated, and these results are shown in Appendix B. Marked kinks in the log-probability plots were used to help identify the levels of outlier anomalous grades. This is also shown in the decile analyses. For gold, more than 19% of the sampled metal is contained in just 1% of the samples, above a grade of 7g/t. For silver, more than 12% of the sample metal is contained in 1% of the samples, above a grade of 500g/t. For lead, copper, and zinc, upper outlier levels were also identified, in which more than 10% of the sampled metal was contained in only 1-2% of the analysed samples, indicating logical capping levels. For these reasons, it was decided to apply a top-cut to the metal grades, prior to compositing for grade interpolation purposes. The capping levels used are shown in Table 16-4, along with the number of affected samples.

The log-probability plots for zinc, in particular, two main populations are apparent. However when examining the grade distributions on sections, it was difficult to physically separate these two populations into logical zones. It was therefore decided to apply an indicator approach to zinc interpolation, which is discussed in more detail in Section 16.4.

| 32 |

May 2006 |

| Adam Wheeler |

Norrliden Resource Estimation |

| Table 16-4. Capping Levels | ||||||

| Zn | Pb | Cu | Au | Ag | ||

| % | % | % | g/t | g/t | ||

|

Capping Level |

|

30 | 4 | 3.5 | 7 | 700 |

|

|

|

|||||

|

No. of Samples |

Main Zone |

5 | 12 | 16 | 6 | 5 |

|

Affected |

Peripheral Zones |

2 | 4 | 10 | 1 | |

After these capping levels had been applied, 3m composites were created of the selected samples within each zone. This gave samples the same support, for consideration of variability. Composites were generated so as to give composite lengths of approximately 3m, with the same lengths within each intersection. This stopped the creation of small composites at the end of each intersection, if a rigid 3m had been applied. Three metres was selected as being reflective of a minimum mining width, and statistical analyses verified that compositing at this length did not drastically alter the statistical features of the captured sample groups.

A summary of the composites' grades statistics is shown in Table 16-5.

Table 16-5. Composites' Statistical Summary

|

ZONE |

FIELD | NUMBER | MAXIMUM | MEAN | VARIANCE | STANDDEV | GEOMEAN |

LOGESTMN |

|

|

AU | 182 | 5.0 | 0.9 | 0.7 | 0.8 | 0.6 |

1.0 |

|

MAIN |

AG | 182 | 640.2 | 69.6 | 8895.1 | 94.3 | 38.7 |

70.1 |

|

ZONE |

CU | 182 | 3.3 | 0.8 | 0.5 | 0.7 | 0.4 |

1.1 |

|

|

PB | 182 | 4.0 | 0.5 | 0.6 | 0.8 | 0.1 |

0.7 |

|

|

ZN | 182 | 25.8 | 5.4 | 40.2 | 6.3 | 1.6 |

12.2 |

|

|

AU | 91 | 2.8 | 0.6 | 0.4 | 0.6 | 0.4 |

0.6 |

|

PERIPHERAL |

AG | 91 | 308.5 | 52.5 | 5467.8 | 73.9 | 23.7 |

55.5 |

|

ZONES |

CU | 91 | 3.3 | 0.8 | 0.5 | 0.7 | 0.4 |

0.9 |

|

|

PB | 91 | 2.7 | 0.4 | 0.3 | 0.6 | 0.1 |

0.7 |

|

|

ZN | 91 | 18.2 | 3.2 | 16.4 | 4.1 | 0.8 |

7.2 |

Experimental variograms were generated for the composite metal grades in the main zones. The principal directions analysed were along-strike and down-dip (approximately 60 degrees). The zinc grades show a clear bi-model distribution, marked by a strong kink on the log-probability plot at 3% Zn. This was partly due to the metal zonation present. For this reason, a zinc-indicator variable was also introduced, with a value of 0 for all zinc grades<=3%, and a value of 1 for zinc grades greater than 3%. The experimental variogram generated from this zinc indicator variable showed a very clear overall range of influence of 80m, both down-dip and along-strike.

The copper experimental variograms indicated zonal anisotropy, with different sills in different directions. This is fairly common in stratiform-type deposits. The ranges of influence were approximately 60m along-strike and 30m down-dip.