FORM 6 - K

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Report of Foreign Private Issuer

Pursuant to Rule 13a - 16 or 15d - 16 of

the Securities Exchange Act of 1934

As of 7/20/2020

Ternium S.A.

(Translation of Registrant's name into English)

Ternium S.A.

26, Boulevard Royal - 4th floor

26, Boulevard Royal - 4th floor

L-2449 Luxembourg

(352) 2668-3152

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover Form 20-F or 40-F.

Form 20-F a Form 40-F __

Indicate by check mark whether the registrant by furnishing the information contained in this Form is also thereby furnishing the information to the Commission pursuant to Rule 12G3-2(b) under the Securities Exchange Act of 1934.

Yes __ No a

If “Yes” is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b):

Not applicable

The attached material is being furnished to the Securities and Exchange Commission pursuant to Rule 13a-16 and Form 6-K under the Securities Exchange Act of 1934, as amended.

This report contains Ternium S.A.’s 2019 Sustainability Report.

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the Registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

TERNIUM S.A.

By: /s/ Pablo Brizzio By: /s/ Máximo Vedoya

Name: Pablo Brizzio Name: Máximo Vedoya

Title: Chief Financial Officer Title: Chief Executive Officer

Dated: July 20, 2020

|

|

2. Ternium |

Contents | |

4 | About Ternium's Reporting |

7 | The Company |

14 | Chairman's Letter |

19 | A Comprehensive Approach to Value Creation |

22 | Delivering Ternium's Business Strategy |

38 | Improving Our Safety Performance |

46 | Minimizing Ternium's Environmental Footprint |

56 | Realizing People's Full Potential |

66 | Strengthening of Ternium's Value Chain |

70 | Helping Our Communities Thrive |

79 | Commitment to Integrity |

89 | GRI and UN Global Compact Information |

Ternium S.A. (the “Company”) is a Luxembourg company and its American Depositary Shares, or ADSs, are listed on the New York Stock Exchange (NYSE: TX). We refer to Ternium S.A. and its consolidated subsidiaries as “we,” “our” or “Ternium.” | TX LISTED NYSE | The financial and operational information contained in this report is based on Ternium’s operational data and on the Company’s consolidated financial statements, which were prepared in accordance with IFRS and IFRIC interpretations as issued by the IASB and adopted by the European Union and presented in U.S. dollars ($) and metric tons. |

3. Sustainability Report 2019 |

'

About Ternium's Reporting | |

Ternium's 2019 Sustainability Report

This report intends to be an integral discussion of Ternium's progress towards achieving its objectives in a sustainable way. It has been prepared taking into account the guidelines established by worldsteel, the UN Global Compact and the Global Reporting Initiative.

Ternium's Sources of Corporate Information

|  |  |  | |||

Annual Report on Form 20-F | Consolidated Management Report | Sustainability Report | Ternium.com | |||

Global Reporting Initiative (GRI) Guidelines

Ternium's Sustainability Report for the year 2019 follows the GRI standard core option of the reporting levels.

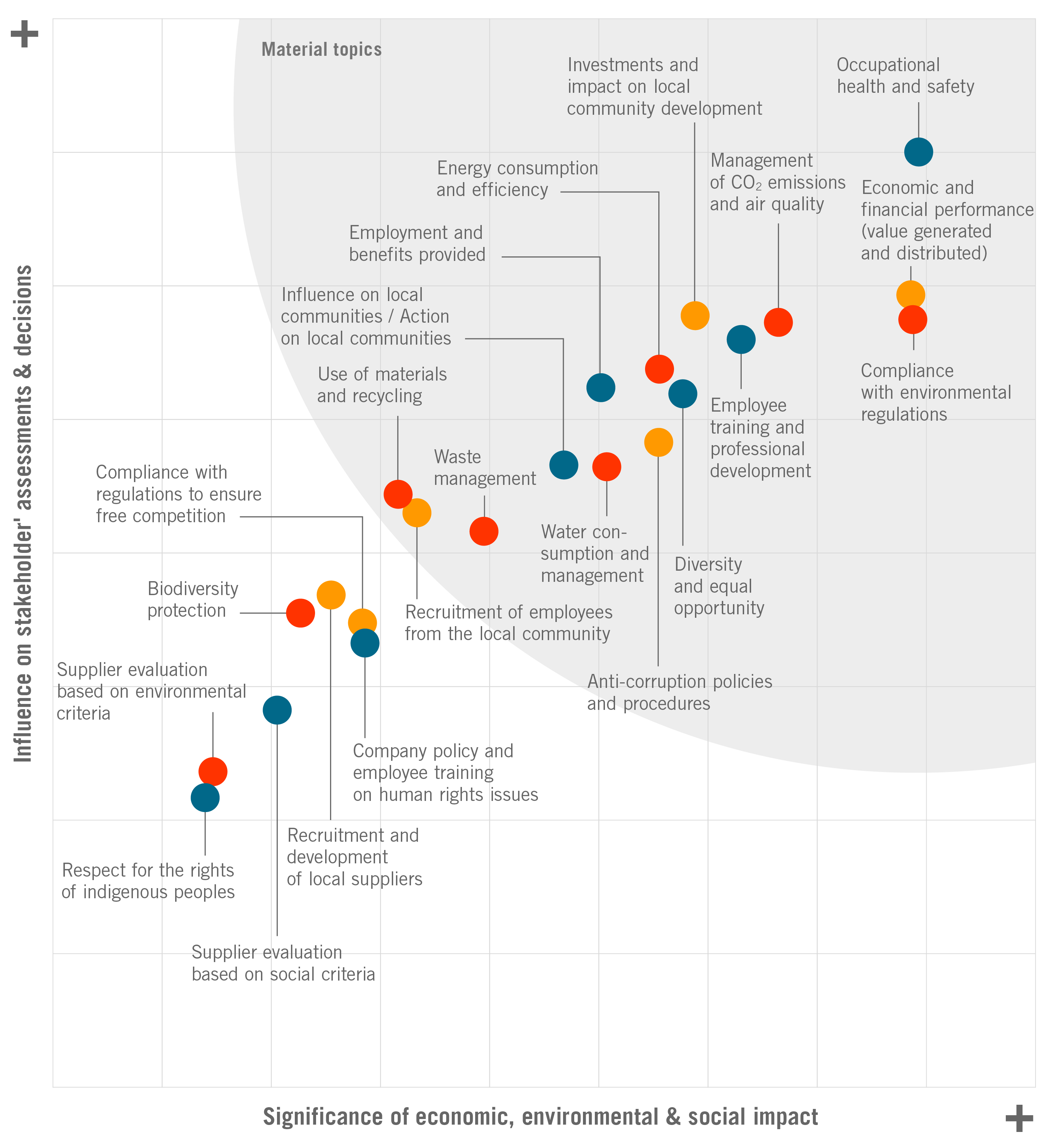

In order to comply with this standard, Ternium has assessed its sustainability report in light of the GRI principles of Stakeholder Inclusiveness, Sustainability Context, Materiality and Completeness. The company

has carried out a Materiality Analysis according to the GRI four-step process. The result of this analysis has been included on page 90, by means of a materiality matrix that ranks relevant economic, environmental and social topics according to their influence on stakeholders' assessments and decisions, and according to their significance to Ternium. The GRI standards that Ternium has selected to fulfill, in accordance with the reporting requirements of those topics, have been

4. Ternium |

included in the GRI Index on pages 92 to 94 of this sustainability report. The historical data related to these standards, as well as other historical data, has been included on pages 95 to 101 of this sustainability report.

UN Global Compact Initiative

In 2019, Ternium joined the UN Global Compact Initiative with a commitment to integrate its principles into the company's strategy, culture and day-to-day operations. Ternium has engaged in collaborative projects to advance the broader development goals of the United Nations, particularly the Sustainable Development Goals (SDGs). The company's contribution to the UN Global Compact SDGs is reported throughout the document and has been indexed on page 102 of this sustainability report.

New Ternium.com

In September 2019, Ternium launched a new corporate website with a new approach to interact with its stakeholders. The company has established different goals for this project:

Firstly, to increase the importance of the website as a go-to resource for current and potential customers, encouraging them to engage with Ternium’s wide range of products and solutions. As a company that operates in various countries, Ternium.com aims to link customers to its local commercial contacts while keeping a seamless brand vision, through new relevant and localized content supported by cutting-edge easy-to-use navigation tools.

Secondly, to improve the navigation experience of the investor relations section with the addition of new trends in design and functionality. The new features facilitate access to corporate messages and reports, and the new resources enhance interactions with the company.

Thirdly, as a leading steel manufacturer, Ternium.com has been conceived as a relevant means of communication to raise awareness on the role that steel plays today and will play in the future, as we build an increasingly sustainable society.

Forward looking Statements

This sustainability report contains “forward-looking statements”, including with respect to certain of our plans and current goals and expectations relating to Ternium’s future financial condition and performance, which are provided to allow potential investors the opportunity to understand management’s beliefs and opinions in respect of the future so that they may use such beliefs and opinions as one factor in evaluating an investment in Ternium’s securities. All forward-looking statements are based on management’s present expectations of future events and are subject to a number of factors and uncertainties that may cause actual results, performance or events to differ materially from those expressed or implied by those statements. By their nature, certain disclosures relating to these expectations are only estimates and could be materially different from what actually occurs in the future. As a result, actual future gains or losses that may affect Ternium’s financial condition and results of operations could differ materially from those that have been estimated. You should not place undue reliance on the forward-looking statements, which speak only as of the date of this sustainability report. Except as required by law, we are not under any obligation, and expressly disclaim any obligation, to update or alter any forward-looking statements, whether as a result of changes of circumstances or management’s estimates or opinions, new information, future events or otherwise.

Risk factors

For a detailed description of Ternium’s main risk factors, please see the section "Risk Factors" included in the Company's annual report on form 20-F for the year ended December 31, 2019.

These risks include but are not limited to risks relating to the steel industry and mining activities, risks relating to countries in which Ternium operates, risks relating to our business, including uncertainties as to gross domestic product, related market demand, global production capacity, tariffs, cyclicality in the industries that purchase steel products, risks relating to the Company’s structure and regulatory risks, as well as other factors beyond Ternium’s control.

5. Sustainability Report 2019 |

|

6. Ternium |

The Company | |

Ternium is Latin America’s leading flat steel producer. We operate manufacturing facilities, service centers and distribution centers in several countries in the region and the southern United States, serving customers from various industries. | ||

$10.2 BILLION ANNUAL NET SALES OF STEEL AND OTHER PRODUCTS. | 12.5 MILLION TONS OF FINISHED AND SEMI-FINISHED STEEL SHIPMENTS. | 20,000 EMPLOYEES OF 27 NATIONALITIES. |

7. Sustainability Report 2019 |

The Company | |

|

worldsteel Sustainable Champion. In 2019, Ternium was honored with this recognition for the second consecutive year for its contribution to sustainability initiatives and reporting. |

Profile

Ternium is Latin America’s leading flat steel producer with an annual crude steel production capacity of 12.4 million tons. It operates in Mexico, Brazil, Argentina, Colombia, the southern United States and Central America through regional manufacturing facilities, service centers and its own distribution network. In addition, Ternium participates in the control group of Usiminas, a leading flat steel company in the Brazilian market.

The company's customers range from small businesses to large global companies in the automotive, home appliances, heat, ventilation and air conditioning (HVAC), construction, capital goods, container, food and energy industries across the Americas. Ternium’s industrial system has various production technologies that provide a diversified cost structure, based on different types of raw material and energy sources, and a flexible production configuration. The industrial system includes proprietary iron ore mines and processing facilities, steelmaking facilities, finishing facilities, service centers and a broad distribution network to offer slabs, billets, hot-rolled products, cold-rolled products, galvanized and electro-galvanized sheets, pre-painted sheets, tinplate, welded pipes, rebars and wire rods as well as slit and cut-to-length products.

Ternium's innovative culture, industrial expertise and long-term view enable the company to continuously achieve new breakthroughs in industrial excellence, competitiveness and customer service. Ternium is the leading supplier of flat steel products in Mexico and Argentina, has a significant position as supplier of steel products in Colombia and in other Latin American coumtries, and is a competitive player in the international steel market for steel products.

Through its network of commercial offices in several countries in Latin America, the United States and Europe, Ternium maintains an international presence that allows it to reach customers outside its local markets, achieves improved effectiveness in the supply of products and in the procurement of semi-finished steel, and maintains a fluent commercial relationship with its customers by providing continuous services and assistance.

We operate with a broad and long-term perspective, and we work towards improving the quality of life of our employees, their families and the company's local communities.

8. Ternium |

A Comprehensive Approach to Value Creation • Quest for excellence in industrial management and technology • Focus on differentiation through sophisticated products and services • Proactive approach to environment, health and safety • Recruitment, training, and retention of talent • Fostering of steel value chain • Deep ties with our communities • Commitment to integrity | ||||

Environment, Health and Safety

We devote significant resources to environment, and occupational health and safety (EHS), as we believe they are key to our long-term sustainability. We have standardized EHS management systems. Our employees are well trained in EHS and our management is accountable for EHS performance. Ternium's occupational health and safety system is certified under OHSAS 18001, and its environment and energy system is certified under ISO 14001 and ISO 50001. The company regularly invests in state-of-the-art technologies to reduce its environmental footprint and minimize safety risks.

Integrity

We believe integrity is key to Ternium's long term sustainability. The Company’s Board has an Audit Committee solely composed of independent directors and an Internal Audit Department, which reports to the Chairman of the Board and, with respect to internal control over financial reporting, to the Audit Committee and meets organizational independence and objectivity standards. Ternium has a Business Conduct Compliance Officer reporting to the CEO and a compliance department that oversees SOX certifications and related party transactions. The company's employees are trained and accountable for ensuring a transparent behavior. Ternium has established different policies, codes and procedures for this purpose. In addition, it has

confidential channels to report all types of alleged breaches of the Code of Conduct and its principles.

Communities

We believe that having deep ties with Ternium's communities is also fundamental to the company's long- term sustainability. We are having a significant positive impact on Ternium's communities, both from a human perspective as well as in terms of economic development. We work together with local institutions to enhance the communities' education and welfare. We provide scholarships, internships, teachers' training and infrastructure funding. We also organize and fund volunteering programs and health prevention campaigns, and sponsor sports, social and arts events.

Steel Industry Value Chain

We support approximately 1,800 small and medium-sized enterprises (SMEs), customers and suppliers through our ProPymes program to strengthen the steel value chain in our markets. ProPymes provides training, industrial and business consultancy, institutional assistance, commercial support and financial aid. The program plays an active role at universities, business schools, government agencies and industrial associations. ProPymes has helped create an industrial network that encourages the professionalization and quest for excellence of SMEs.

9. Sustainability Report 2019 |

|

10. Ternium |

Ternium's manufacturing facilities, service centers and distribution centers are located in Mexico, Brazil, Argentina, Colombia, the southern United States, Guatemala and other Central American countries. The company's mining operations are located in Mexico. | |||||

01. 02. 03. 04. 05. 06. 07. 08. 09. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. | Shreveport Monclova Baja California Chihuahua Culiacán Guerrero* Pesquería Universidad Churubusco* Apodaca Juventud* Edificios Metálicos Apodaca Industrial Apodaca Comercial Norte San Luis Guadalajara Las Encimas Peña Colorada León México | 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. | Puebla Veracruz Tuxtla Villahermosa Mérida Petén Villa Nueva* Cobán Huehuetenango Teculután Quetzaltenango Occidente Norte Juitapa San Salvador Managua San José Barranquilla Montería Medellín Itagüí | 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. 55. | Bucaramanga Bogotá Manizales Cali Río de Janeiro Rosario San Nicolás Serviacero III Sidercrom Haedo* Canning* Florencio Varela* Ensenada |

(*) Includes service or distribution centers | |||||

FACILITIES • Steel production and processing • Service or distribution centers • Iron ore mining and processing | |||||

11. Sustainability Report 2019 |

The Company | |

|

Sophisticated steel products and services. The Mexican automotive sector is the largest in Latin America and the seventh largest worldwide. |

TERNIUM'S STEEL MARKETS

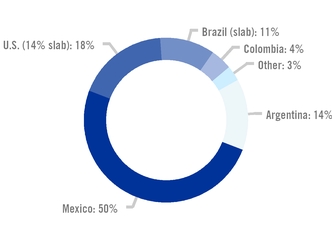

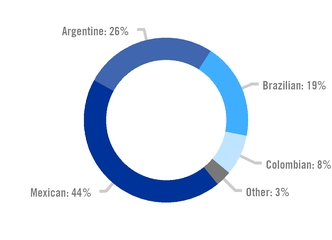

Ternium's customers range from small businesses to large global companies in the construction and industrial sectors. We report steel shipments under three geographical regions: Mexico, the Southern Region and Other Markets.

Mexico

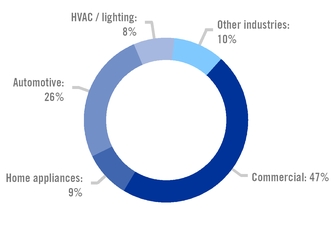

The Mexican steel market is the largest in Latin America. The industrial sector, which in 2019 accounted for 53% of Ternium’s total shipments in the country, is the main driver behind an attractive high-end steel market segment.

Ternium's largest industrial customer in Mexico is the automotive industry. With 3.8 million vehicles produced in 2019, the local industrial hub is the largest in Latin America and ranks seventh in the world behind China, the US, Japan, Germany, India and South Korea.

The Mexican manufacturing industry is a fundamental part of a complex supply chain within the USMCA, and is prepared to supply highly sophisticated products for demanding end-user markets. In addition to the

automotive industry, the Mexican home appliance, HVAC and lighting manufacturers have also reached a high level of sophistication, requiring innovative and high-end steel products.

Southern Region

The Southern Region encompasses the steel markets of

Argentina, Bolivia, Chile, Paraguay and Uruguay. The Argentine steel market, the third largest in Latin America, accounts for most of Ternium's shipments in this region.

Ternium's industrial customer base in Argentina represented approximately 47% of Ternium’s total shipments in the country in 2019. The Argentine automotive industry, the third largest in Latin America, is part of the value chain within the Mercosur, a customs union encompassing Argentina, Brazil, Uruguay and Paraguay that has eliminated or significantly reduced import duties, tariffs and other trade barriers among member states.

Other relevant industrial sectors in Argentina include the agro machinery, cans and home appliance manufactures, and the oil & gas sector.

12. Ternium |

|

High-end steel. An attractive market segment. |

Other Markets

Ternium’s finished steel customers in the Other Markets segment are mainly in the construction and energy-related industries in Colombia, the United States and Central America. Following the acquisition of Ternium Brasil in September 2017, Ternium started shipping steel slabs to third party steel companies mainly in the United States and Brazil.

A small share of Ternium’s shipments is destined for steel markets outside the Americas. Sales to Europe, Asia and Africa are carried out mainly through Ternium’s commercial office in Spain.

TERNIUM'S STEEL SHIPMENTS BY COUNTRY 2019 |

ATTRACTIVE HIGH-END STEEL MARKET SEGMENTS |

53% PARTICIPATION OF SHIPMENTS TO INDUSTRIAL CUSTOMERS IN MEXICO. |

47% PARTICIPATION OF SHIPMENTS TO INDUSTRIAL CUSTOMERS IN ARGENTINA. |

67 MILLION TONS OF STEEL CONSUMED IN LATIN AMERICA IN 2019, MAINLY IN MEXICO, BRAZIL, ARGENTINA AND COLOMBIA. |

13. Sustainability Report 2019 |

|

14. Ternium |

Chairman’s Letter | |

Over the past months, the global economy has been deeply affected by the COVID-19 pandemic. The measures taken around the world to contain the spread of the virus have resulted in a global crisis, whose speed and severity is unprecedented in recent history. Though, in many parts of the world, businesses are reopening, people are gradually returning to work, and developed country governments have implemented massive economic stimulus programs, the pandemic continues to spread and the recovery from the crisis will take time and hasten change in many fields.

Latin America is particularly affected, as its economies were already under stress and the number of affected persons continues to rise. We took prompt action to adjust the company for the crisis and a high level of ongoing uncertainty.

To protect our people and assure a safe working environment, we introduced new work protocols including mandatory use of face masks, temperature checks, strict social distancing rules and disinfection policies for company transportation, site entry and common working areas as well as applying work-from-home policies and testing every person showing compatible symptoms and their close contacts.

To secure the financial stability of the company, we are making full use of the opportunities we have for industrial integration to optimize production and overhead costs, reducing inventories and working capital and quickly adjusting our operations to the reduction in sales. We are delaying some of our investment projects, pushing out the startups of our new hot rolling mill in Pesqueria, Mexico, and our new rebar mill in Colombia, and thereby reducing our capital expenditure commitments for this year to $600 million from the $850 we had originally planned. We also elected to suspend our annual dividend payment for the 2019 fiscal year.

To support our communities, we established and deployed a $5.5 million fund to strengthen local medical response capabilities, using our global procurement network to provide ventilators, intensive care equipment and protective gear as well as constructing and operating a field hospital with 100 beds for the community of Monterrey in Mexico and providing infrastructure and equipment for intensive care units to other hospitals in Ensenada in Argentina and in Rio de Janeiro in Brazil. Our employees have responded with solidarity and purpose in joining these initiatives.

At a time like this, the support we provide to our smaller customers and suppliers through the ProPymes program is particularly relevant and we are reinforcing the financial help we provide to members of the program with $8.0 million applied among 125 companies, together with assistance in raising financing from local financial institutions. Our training programs have been reinforced with more webinars and online workshops reaching over 1,200 persons. Equally, as the gradual recovery advances, our Webservice digital integration portal, which is used by our commercial customers to place 80% of their orders, will facilitate safe working practices.

As we reflect on our achievements during the past year, this crisis is a reminder of the importance of a long-term management focus that addresses all aspects of the company’s performance and its relations with customers, suppliers, employees and the communities that sustain us. To better report on the actions we carry out on this respect, this year we completely

15. Sustainability Report 2019 |

Chairman's Letter | |

redesigned our Sustainability Report and strengthened it by using the guidelines established by the Global Reporting Initiative (GRI), including consultations with our stakeholders to determine material topics to cover.

Our operational and financial results in 2019, though down from the outstanding results of the previous year, were solid, with an EBITDA of $1.5 billion on sales of $10.2 billion. Even after investments of $1.1 billion in our expansion program, our free cash flow amounted to $595 million and we ended the year with net debt of $1.5 billion, which has declined further in the year to date.

We continue to consolidate our position as a leading Latin American steel producer with a strong focus on serving the industrial and construction sectors. In Mexico, we started up new galvanizing and painting lines expanding our product range for industrial markets, which account for over 50% of our sales in the country. With the recent enactment of the new USMCA agreement confirming a free trade area across North America, the Mexican automotive and industrial sector is well positioned for a post-pandemic recovery. Although we have delayed the planned start-up of our new hot rolling mill in Pesquería until 2021, this new mill will strengthen our competitiveness through further broadening our range of high-end industrial products and allowing further integration of our industrial system by using high quality steel slabs from our mill in Brazil. In times when regional supply chains are being strengthened, the new line will also reinforce our import substitution strategy.

At the center of the growing community in Pesquería, Mexico, lies the Roberto Rocca Technical School. Last year, the first cohort of students graduated following three years of study focused on technical education, including industrial apprenticeships. During the annual worldsteel assembly held in Monterrey in October 2019, Ternium received the Steelie Award for “Excellence in Education and Training” based on the achievements of the school and its pupils. Aside from our response to the pandemic, education at all levels remains the focus of our community programs, not only in terms of money spent but also in terms of the design and organization of programs that can contribute to improving the level of education, particularly technical education, and open educational opportunities at all levels in the communities where we operate.

Last year marked the 50th anniversary of the origins of the company in the inauguration of a cold rolling mill at Ensenada in Argentina. The construction and start-up of this greenfield plant, carried out by a highly motivated team of young professionals, has shaped the culture and management ethos of the company to this day. Providing a stimulating working environment and effective opportunities for employee training, education and development is a constant focus in our management efforts and critical to maintaining high levels of employee motivation. In August 2019, we inaugurated an in-house corporate university with responsibility for organizing knowledge and training across the company and developing a curriculum with participation from outside universities that provide employees the tools for their own education and development. In 2019, Ternium’s employees had an average of 62 hours of training and 662 employees participated in management development programs. In our most recent pulse survey on employee satisfaction, with an 87% participation rate, 83% of the respondents expressed their satisfaction with Ternium as a place to work.

16. Ternium |

Safety and minimizing the environmental impact of our operations are paramount in our management focus and routines. In total, we invested $120 million during 2019 in projects aimed at improving our environmental, energy and safety performance by modernizing our facilities. Major investments include those aimed at reducing particulate emissions at our steel shops, significantly improving air quality and working conditions, and reducing water consumption rates in our facilities in Mexico which are located in a region of high water stress. We also advanced with the certification of our energy intensive operations under the new ISO 50001 standard. Now most of our steelmaking, hot rolling and finishing facilities in Brazil, Argentina and Mexico are either certified or under certification.

During the year, we revised our health and safety strategy, developing specific practices to prevent situations where our employees or contractors are exposed to severe injury, and establishing safety committees to strengthen the consultation and participation of workers and their representatives on health and safety issues.

We are active participants in worldsteel’s climate action initiatives, joining the recent Step Up Program to reduce carbon emissions through benchmarking, and have committed ourselves to the UN Global Compact and to advance its Sustainable Development Goals. In the past five years, we have implemented a number of energy savings initiatives which have yielded an annual reduction of 298,000 tons of carbon emissions. We are also working with industrial gases companies serving the soft drink bottling industry to recycle carbon emissions captured in our production system which should yield further annual savings of 60,000 tons. The challenge of reducing emissions to meet the Paris Agreement commitments is, however, of a different order of magnitude and will require a coordinated response from our industry alongside governments, customers and suppliers. Our ambition is to be at the forefront of our industry’s response to this challenge.

As we prepare for the future, we are confident that the company is well positioned to continue a path of sustainable growth as a leading supplier of steel products to the industrial sector in the Americas. Our ongoing investment program, the transformation of our industrial system using Industry 4.0 technologies, and the long-term focus developed since the origins of the company 50 years ago will enhance our competitive position and the sustainability of our operations over the coming years.

During these difficult times, I would like to give special thanks to our employees, who are showing exemplary solidarity and resilience. I would also like to thanks our customers, suppliers and investors for their ongoing support.

July 20, 2020

|

Paolo Rocca

Chairman

17. Sustainability Report 2019 |

|

18. Ternium |

A Comprehensive Approach to Value Creation |

Ternium's value proposition aims to achieve profitable operations on a sustainable basis, through a management approach that comprehends the interests of shareholders, employees, customers and suppliers, as well as of the community. | |||

$10.3 BILLION ECONOMIC VALUE GENERATED IN 2019 | |||

$827 MILLION EMPLOYEES | $1.1 BILLION CAPEX | $357 MILLION TAXES | |

$7.7 BILLION SUPPLIERS | $352 MILLION CAPITAL PROVIDERS | ||

$10 MILLION RESEARCH AND DEVELOPMENT | $7 MILLION COMMUNITY INVESTMENTS | ||

19. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

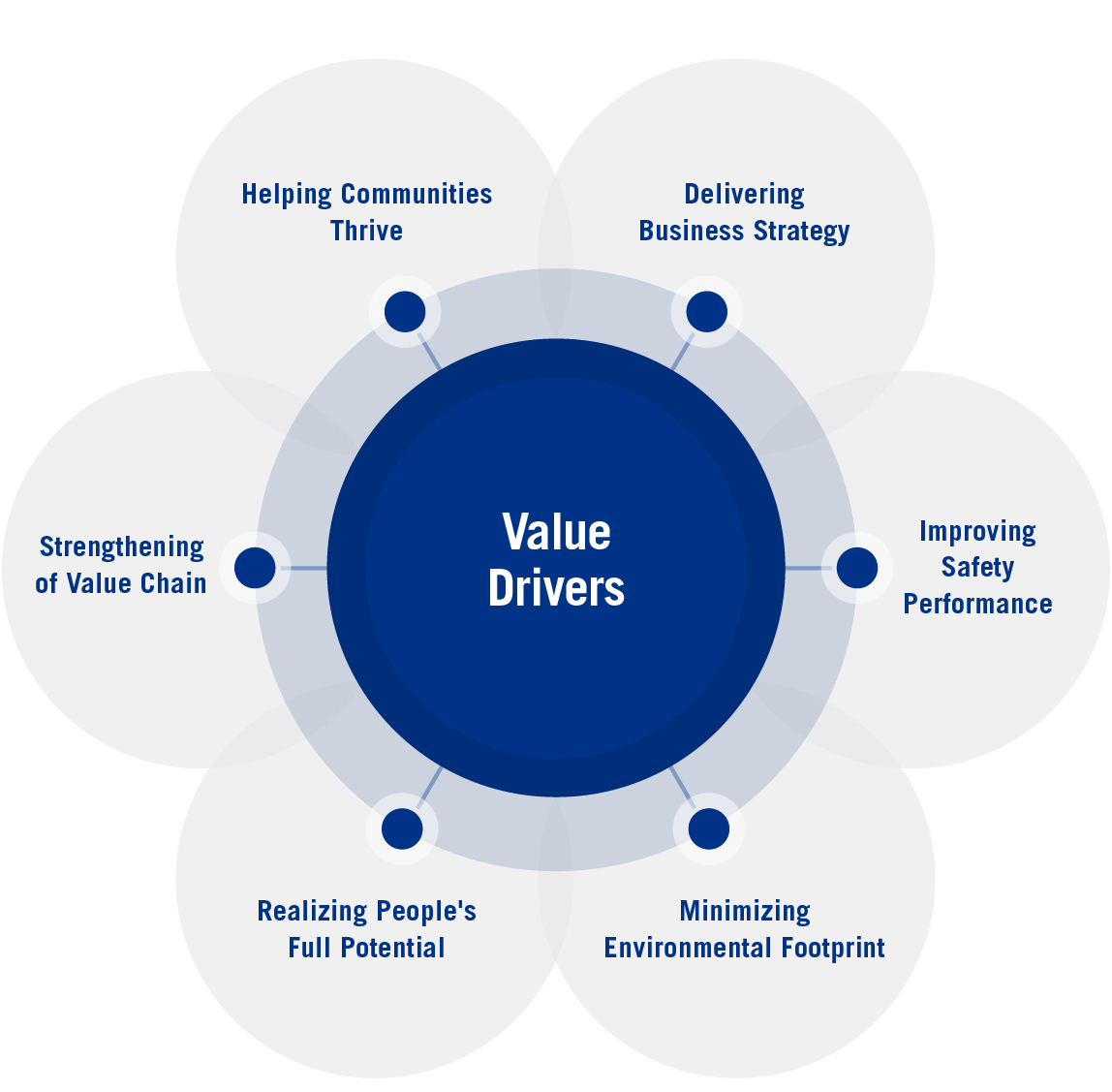

Value Drivers

|

20. Ternium |

Delivering Ternium's Business Strategy • Focus on higher margin value-added products. • Pursue strategic growth opportunities. • Implement Ternium's best practices. • Maximize the benefits arising from Ternium's distribution network. • Enhance Ternium's position as a competitive steel producer. SEE PAGE 22 | |

Improving Our Safety Performance • Prevent all work-related injuries and illnesses, and achieve zero accidents • Promote healthy and safe operations in the steel industry value chain. SEE PAGE 38 | |

Minimizing Ternium's Environmental Footprint • Use natural resources responsibly. • Pursue excellence in environmental performance. • Protect biodiversity. SEE PAGE 46 | |

Realizing People's Full Potential • Attract and retain talented employees. • Promote a culture of excellence throughout the company. SEE PAGE 56 | |

Strengthening Ternium's Value Chain • Promote a collaborative network to foster performance excellence. • Help small and medium-sized customers and suppliers grow. SEE PAGE 66 | |

Helping Our Communities Thrive • Foster education. • Support initiatives that strengthen our communities. SEE PAGE 70 | |

21. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

Delivering Ternium's Business Strategy | |

SUSTAINABLE DEVELOPMENT GOALS | |

| |

4.4 MILLION TON ANNUAL CAPACITY OF NEW HOT-ROLLING MILL IN MEXICO, WITH EXPECTED START UP IN 2021. | |

Elements of strategy | Actions | |

Focus on high-margin value-added products | New laboratory, project launch for new research center | |

Research and development of products and processes | ||

Pursue strategic growth opportunities | New galvanizing and painting lines (start-up in 2019) | |

Progress in the construction of the new hot-rolling mill | ||

Progress in the construction of the new steel bar & coil mill | ||

Implement Ternium's best practices | Integration and optimization on newly-acquired Rio de Janeiro unit | |

Maximize the benefits arising from Ternium's distribution network | Full range of products and services | |

On-line purchasing platform (Webservice) | ||

Just-in-time and short notice supply agreements | ||

Enhance Ternium's position as a competitive steel producer | Continuous improvement program | |

Industry 4.0 initiatives | ||

22. Ternium |

|

Implementation of best practices. Ternium’s managerial, commercial and production experience generates benefits and savings in acquired new businesses. |

Ternium's Business Strategy

Ternium's main strategic objective is to enhance stakeholder value by further consolidating the company’s position as a leading steel producer in Latin America and a strong player in the Americas, while strengthening its competitiveness. The main elements of this strategy are:

FOCUS ON HIGHER MARGIN VALUE-ADDED PRODUCTS

We intend to continue to shift Ternium’s sales mix toward higher margin value-added products, such as cold-rolled sheets and coated and tailor-made products, and services, such as just-in-time delivery and inventory management. For example, during 2019 Ternium inaugurated a new hot-dip galvanizing line and a new painting line, and made progress on the construction of a new state-of-the-art hot-rolling mill at its facility in Pesquería, Mexico.

PURSUE STRATEGIC GROWTH OPPORTUNITIES

We have a history of strategically growing our businesses through acquisitions and joint ventures. In addition to pursuing organic growth, we intend to continue to identify and actively pursue growth-enhancing strategic opportunities to consolidate Ternium’s presence in its main markets and expand it to the rest of the Americas, increase its integration,

Delivering Ternium's Business Strategy • New state-of-the-art hot-dipped galvanizing and painting lines in Mexico. • New cutting-edge hot-rolling mill in Mexico (2021). • Integration of the Rio de Janeiro high-end steel mill. • Strengthened product research and development capabilities. • Digital transformation agenda. • Continuous improvement plan. • Solid financial performance. |

23. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

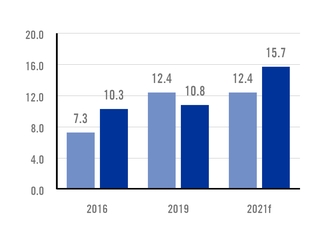

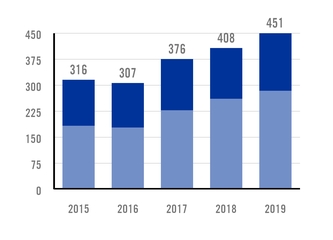

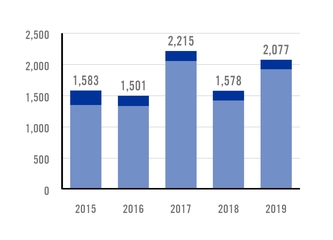

TOTAL CRUDE1 AND HOT-ROLLED2 STEEL PRODUCTION CAPACITY MILLION TONS PER YEAR. |

n 1 Crude steel: flat steel slabs and long steel billets n 2 Hot-rolled steel: flat steel coils and long steel rods |

expand its offerings of value-added products, and enhance its production and distribution capabilities.

IMPLEMENT TERNIUM’S BEST PRACTICES

We believe that the implementation of Ternium’s managerial, commercial and production best practices in acquired and new facilities and businesses should generate benefits and savings.

MAXIMIZE THE BENEFITS ARISING FROM TERNIUM’S BROAD DISTRIBUTION NETWORK

We intend to maximize the benefits from Ternium’s broad distribution, sales and marketing network to reach customers in major steel markets with a comprehensive range of value-added products and services and to continue to expand its customer base and improve the value of its product mix.

ENHANCE TERNIUM’S POSITION AS A COMPETITIVE STEEL PRODUCER

We are focused on improving utilization levels of our plants, increasing efficiency and further reducing production costs from levels that we already consider to be among the most competitive in the steel industry through, among other measures, capital investments and further integration of our facilities. In addition, we aim at obtaining better purchase conditions and prices

68% SLAB CAPACITY INCREASE ON 2017 ACQUISITION. 47% HOT-ROLLED COILS CAPACITY EXPANSION IN 2021. | |

by combining the demand of products and services by both Ternium and our affiliate Tenaris. We pursue this goal through Exiros, a purchase and sale agency which we own 50/50 with Tenaris. Exiros has offices in various countries and is in charge of the procurement of a majority of our raw materials and other products and services.

A Significant Expansion of Ternium’s Industrial Capabilities

In September 2017, the company acquired a state-of-the-art slab facility in Rio de Janeiro, Brazil, with an annual production capacity of 5 million tons of high-end steel slabs, a deep-water harbor and a 490 MW combined cycle power plant.

With the addition of this mill, total crude steel production capacity of Ternium's industrial system increased 5.0 million tons to 12.4 million tons.

The Rio de Janeiro unit has provided Ternium with new business opportunities, particularly in Mexico. Following its acquisition, the company started the construction of new hot-rolling, hot-dipped galvanizing and painting lines in its Pesquería Industrial Center, Mexico, and strengthened its product research and

24. Ternium |

|

Steel production and processing. A relentless quest for excellence in operating performance. |

development capabilities. In addition, Ternium started the construction of a greenfield reinforcing bars facility in Palmar de Varela, Colombia.

The results of this transformation process started in 2018 with the inauguration of a new laboratory in Pesquería, which increased Ternium's product research capabilities for high-end industrial requirements. During 2019, the company started-up its new hot-dip galvanizing and painting lines in Pesquería, adding 350,000 and 120,000 tons of annual production capacity to Ternium's industrial system, respectively. These new facilities incorporated the most advanced painting technology to the Mexican steel industry, providing high-end value-added products for the HVAC and automotive industries.

Ternium's new hot-rolling mill in Mexico will have an annual production capacity of 4.4 million tons, with an option to increase capacity in the future by an additional 300,000 tons. With the addition of this new mill, Ternium's industrial system will increase total flat steel hot-rolling production capacity by 47% to 13.8 million tons. In addition, expected synergies between Ternium's new hot-rolling mill and its cold-rolling mill in Pesquería will result in an annual production capacity increase of

CONTINUOUS IMPROVEMENT PROGRAM TO MAXIMIZE EFFICIENCY |

44 PRODUCTION LINES ACHIEVED NEW RECORD OUTPUT IN 2019. |

68 TEAMS WORKING TO MAXIMIZE EFFICIENCY, MINIMIZE COSTS AND IMPROVE ENVIRONMENTAL, SAFETY AND QUALITY PERFORMANCE. |

300,000-tons of cold-rolled coils. Ternium's state-of-the-art hot-rolling mill in Pesquería will represent a significant technological leap forward in the country's steel production capacity. The company’s product range will encompass a broader dimensional offering with the most advanced steel grades. In addition, customer service will be enhanced and the value chain lead-times reduced.

This, combined with the company's service center and distribution capabilities in the country, will enable Ternium to expand its footprint in Mexico with cutting-edge new products and substitute high-value-added steel imports targeting the demanding and innovative automotive industry, as well as the home appliance, machinery, energy and construction sectors. The new hot-rolling mill will source high-end slabs from our facility in Rio de Janeiro, Brazil, and from third parties.

Ternium's new reinforcing bar facility will enable the expansion of its market share in Colombia's construction sector by substituting imports. In addition, the company's new facility will enable the upstream integration of its operations by replacing current purchases of reinforcing bars from third parties.

25. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

2019 Award in "Innovation". Granted by the Nuevo Leon Automotive Industry Cluster in Mexico for the design of a new heavy-duty trailer model. Ternium and one of its customers developed the new model, which enables a more efficient transportation of extra-heavy steel coils. | ||||

RESCHEDULED INVESTMENT PLAN FOLLOWING COVID-19 OUTBREAK

In order to mitigate the impact of expected lower sales resulting from the COVID-19 pandemic induced recession, Ternium has recently reduced its planned capital expenditures for the year 2020 by an estimated $250 million, to $600 million. Consequently, the inauguration of Ternium's new hot-rolling mill in the Pesquería Industrial Center has been postponed from 2020 to 2021, and the commissioning of the new reinforced bar facility in Palmar de Varela has been postponed from March 2020 until the second half of 2020. The final reduction in Ternium's capital expenditures in 2020 will depend on the pace of recovery of economic activity and steel market demand.

Strengthened Product Research and Development Capabilities

Steel is a highly versatile metal, offering a wide space for product innovation. For example, over 70% of the structural steel parts used to build a car today involve solutions that did not exist 20 years ago.

The properties of the steel products required by Ternium's customers are usually the result of a combination of their metal composition and the way metal gets processed into finished steel products. Ternium’s business strategy

is based on offering a complete range of value-added,

high-end products, with an emphasis on creating and manufacturing increasingly sophisticated steel products for new applications and industries.

A COLLABORATIVE APPROACH TO PRODUCT RESEARCH AND DEVELOMENT

At Ternium, we carry out applied research efforts in different ways. We develop steel products through in-house programs, joint projects with leading industrial customers, joint efforts with recognized universities or research centers, and through our participation in international consortia.

Ternium has identified synergies in collaborating with its customers in the early stages of their projects. Anticipating our customers' upcoming steel product requirements through our participation in joint development projects is key not only to build customer relationships but also to plan and develop new processes, which may sometimes require the addition of new equipment and technology.

Ternium’s research programs are open to a broad-based international network of industry consortia. Over 50 universities and research laboratories from both the public and private sectors collaborate with Ternium. The goal is to find and develop the best solutions to

26. Ternium |

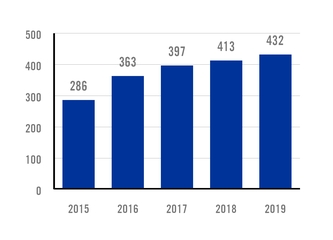

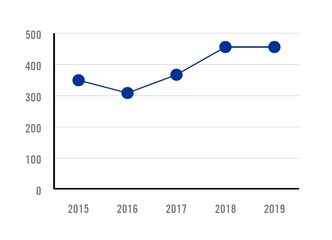

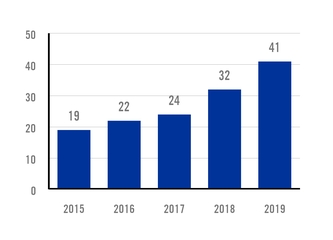

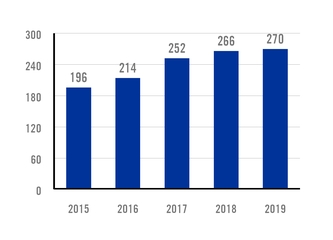

AUTOMOBILE INDUSTRY CERTIFICATIONS NUMBER OF CERTIFICATIONS APPROVED |

support an agenda aimed at achieving better and more sustainable steel. Research spans the entire production cycle, from primary steel making and metallurgy, to rolling and galvanizing.

Ternium is a member of WorldAutoSteel, an organization comprising some of the world’s major steel producers. Under the auspices of worldsteel, the group regularly updates the automotive industry on upcoming new steel capabilities available to meet their design and manufacturing requirements.

The company is engaged in over 120 ongoing product development projects in partnership with industrial customers, and over 50 ongoing research projects including in-house developments and others involving university researchers and students from some of the world’s most prestigious institutions. We have been increasingly engaging universities in our research efforts in order to expand and further diversify Ternium’s research network and capabilities. This initiative fosters the development of fundamental knowledge and know-how at participating universities while enabling the optimization of Ternium’s in-house research resources. In 2019, approximately thirty undergraduate and postgraduate students pursuing degrees in engineering, materials science and metallurgy took part in the program.

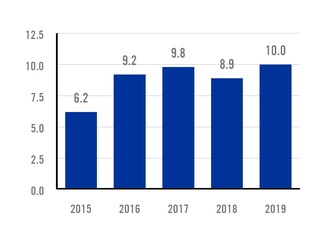

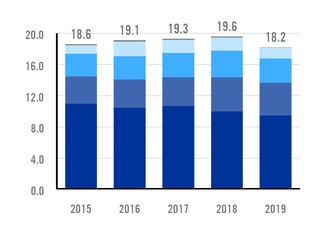

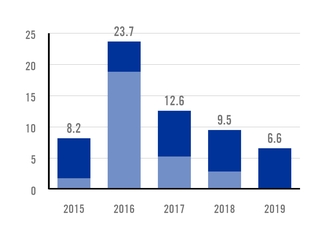

INVESTMENT IN PRODUCT RESEARCH AND DEVELOPMENT $ MILLION |

INVESTING IN NEW EQUIPMENT AND TECHNOLOGIES FOR HIGH-END STEEL

The inauguration of the Ternium Industrial Center in Pesquería, Mexico, in 2013, gave way to an intensive product development period. We broadened our product range offering to include sophisticated high-end steel products required by the manufacturing industry, particularly automotive manufacturers. These developments were made possible with the addition of new production technologies to our industrial system at the Pesquería unit, such as cold-rolled steel and galvanized products that provide corrosion resistance to external vehicle parts.

Furthermore, the installation in 2015 of state-of-the-art cooling technology in the hot strip mill of our Churubusco unit in Mexico, has allowed developing and processing new advanced high-strength steel grades, including dual phase, ferrite-bainite, martensitic and complex phase grades. Based on these new capabilities, we have further widened our high-end product portfolio for customers in the automotive, metalmechanic, home appliance, oil & gas and electric motors industries.

Advancing Ternium's Digital Transformation

Since Ternium's origins in 1969 with the inauguration of

the Ensenada manufacturing unit in Argentina, the

27. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

"Steel to Make", a media campaign in Argentina aimed at consolidating a seamless brand recognition to support Ternium's regional leadership. The campaign highlighted the use of steel in everyday life and its importance for our future. | ||||

company has acquired various steelmaking and steel

processing facilities in Mexico, Brazil, Argentina, Colombia, the United States and Central America, that resulted in a myriad of legacy industrial information technology (IT) systems. Ternium's business model required a unified industrial system able to offer an ample range of products and services to its customer base. The implementation of this unified model implied a significant effort of digital transformation. For example, after the acquisition of Hylsamex in 2005 and Grupo Imsa in 2007, there were 28 different information technology systems that had to be consolidated into a single one.

With that target in mind, by 2009 we were able to bring Ternium on-line in real time with a single, unified information technology system, spanning all of its facilities. Once this process was completed, the company extended its digital tools to its customers and suppliers, enabling the integration of its processes with theirs.

This integration was implemented through the development of a digital marketplace called "WebService". Nowadays, approximately 80% of Ternium’s commercial orders are placed through this tool, enabling an efficient business to business interaction.

CERTIFICATION OF TERNIUM'S INFORMATION TECHNOLOGY SYSTEMS

In May 2017, after a two-year preparation process, Ternium certified its information technology system under the ISO 20000 standard. This standard describes the best practices in the management of an organization's IT processes and services.

This certification process has helped the company to optimize costs, resources and processes, enhance customer satisfaction, strengthen the performance assessment of its IT system, increase compliance with multiple regulations, and increase overall business competitiveness.

SMART FACTORY

Ternium is making progress in the construction of a SMART factory, the acronym for Social, Mobile, Analytics, Robotics and (internet of) Things. This concept, supported by the company’s unified information technology platform, ensures a constant stream of knowledge and information (data and events) that will lead its facilities to a more productive and efficient evolutionary stage.

Users achieve a more efficient performance by interacting from any location (offices, facilities or elsewhere) through different kinds of devices.

28. Ternium |

|

2,100 cameras to oversee a safe operating environment. The assessment of worker distance from suspended loads is one of the functionalities comprising an early alarm system. |

Employees working in Ternium's industrial, commercial and maintenance areas are equipped with mobile devices that enable them to perform all their tasks from any location with a remarkable increase in productivity.

Analytics and data correlation detect patterns for various applications to increase safety and efficiency, and to reduce costs. Through video-feed analysis (machine learning), new applications include real-time detection and reporting of unsafe situations or behavior within the facilities to prevent accidents and, using drone technology, the identification of potential damages in either tall structures or confined spaces, whether internal or external, as well as the assessment of bulk material stockpiles. Drones substitute human inspection at height and minimize the risks inherent to this type of tasks. In 2019, the system autonomously issued 440 maintenance tickets, removing human inspection at 55 roofs.

We installed 2,100 cameras for tracking operations in our Mexican, Argentine and Brazilian facilities, enabling the implementation of an early alarm system.

Through video analytics, 500 of those cameras are able to assess distances from suspended loads, moving vehicles and entrapment

|

Implementation of mobile monitoring capabilities. Efficient, real-time analysis of equipment parameters during maintenance inspections. |

areas, verify the observance of marked pathways and social distancing, and monitor the use of safety helmets, vests and face masks. Deviations from protocols are automatically reported to the relevant manager with the ultimate purpose of preventing accidents based on early detection.

In addition, radio frequency identification (RFID) technology enables the automated handling of steel products in the yards, speeding up logistics and increasing safety. Ternium’s RFID project is intended to identify and track each coil from the moment it reaches the yards until shipment, facilitating inspections procedures, improving inspectors' safety and reducing operations lead times. The tracking system has already been implemented in 27 stockpile yards in Mexico and Argentina.

In the maintenance area, analytics and data correlation technology has proved its potential with the prediction of failures two to three weeks in advance. During 2019, we applied this technology to the continuous casters at the company's Mexican and Argentine facilities.

We plan to apply this technology in the company's most critical production lines to shield strategic equipment and significantly reduce non-operational interruptions and,

29. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

|

Inspection at height. During 2019, the system autonomously issued 440 maintenance tickets, removing human inspection at 55 roofs. |

therefore, the impact on the production process. In order to support Ternium's analytics needs across all business functions, we have implemented a single technological platform, known as Data Lake, that meets all our big data and analytics requirements.

Other projects aimed at improving safety and productivity are the use of virtual reality software for training purposes, the use of augmented reality for experts providing remote assistance to operators, 3D printing and the use of 3D scanning for several applications. We have also developed virtual reality software to train employees on risk perception. This software simulates risky situations in 3D, depicting potential sequences that could end up in fatal accidents.

In addition, we have successfully finished the proof-of-concept stage for replacing on-site crane training exercises with virtual reality training facilities, simulating the cabins of the three types of cranes used by Ternium: magnetic crane, hook crane and dump. We have also developed a virtual reality software to train our personnel on specific operating procedures performed in the secondary metallurgy area of our steel shop in Argentina. In Mexico, we are developing

projects to train employees in water leakage protocols and in productivity enhancement using digital twin technology. This technology generates a digital replica of physical assets, processes, people, sites, systems and devices that can be used for various purposes.

Ternium has seven administrative robots in operation, running automated processes and tasks in the areas of accounts payable, accounts receivable, sales back office and industrial engineering administration. We are advancing projects to gain productivity in accounts payable tasks in Mexico and Argentina, where more than 50% of all suppliers' invoices are expected to be loaded in our systems using robots.

CONCERTED RESEARCH EFFORTS IN THE QUEST FOR INNOVATIVE IT SOLUTIONS

Through cooperation agreements with two universities, Ternium has engaged 110 students in twenty Industry 4.0 projects. The objective of this new initiative is to develop innovative IT solutions aimed at improving the company's operations in the areas of health & safety, maintenance, automation, management, commercial, quality and raw materials.

30. Ternium |

Virtual reality training. During 2019, the company incorporated new VR training modules for the operation of cranes as well as steel making equipment. |

|

31. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

Ternium has recently reinforced its financial profile, which has been traditionally robust, through a quick deployment of economic and financial measures to better face the recession induced by the COVID-19 outbreak. |

2019 Economic and Financial Performance

GOOD RESULTS IN A CHALLENGING YEAR

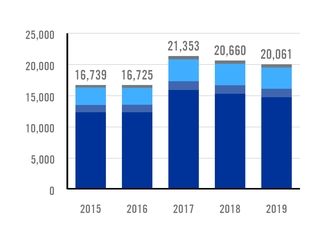

During 2019, shipments in the Mexican market were 6.3 million tons, representing 50% of Ternium’s total steel shipments. Apparent flat steel use decreased in the year reflecting a softer commercial market in 2019 and a strong level of shipments in the first half of 2018 in anticipation of rising steel prices.

Shipments in the Southern Region reached 1.9 million tons in 2019, or 15% of Ternium’s consolidated shipments in the steel segment. Most of Ternium’s shipments in the region are destined for the Argentine market. Apparent steel use decreased significantly in Argentina in 2019, as the country's macroeconomic situation deteriorated.

Shipments in the Other Markets region reached 4.3 million tons in 2019, or 34% of Ternium’s consolidated shipments in the steel segment. Our major shipment destinations in the Other Markets region were the United States, Brazil, Colombia and Central America.

Net sales in 2019 were $10.2 billion, including net sales of steel products for $9.9 billion on steel shipments of 12.5 million tons, net sales of other products for $296.1 million and net sales of iron ore products for $364 million on iron ore shipments of 3.6 million tons.

Most of the iron ore production was consumed in our own steel operations. Steel revenue per ton was $790

in 2019. Steel prices declined in North America during the year, following a strong pricing environment in 2018.

EBITDA reached $1.5 billion in 2019 with EBITDA margin of 15%, remaining at an industry-leading level of profitability.

Net income attributable to Ternium's equity owners was $564.3 million, or $2.87 per ADS. Free cash flow was $595.4 million, with a high level of capital expenditures being partially offset by a $572.7 million reduction in working capital.

SOUND FINANCIAL POSITION

In 2019, the company’s capital expenditures were $1.1 billion, $532.0 million higher than in 2018, as Ternium's investment program progressed as planned.

The main investments during the year included those made for new hot-rolling, hot-dipped galvanizing and painting production capacity in the company’s Pesquería industrial center, a new steel bar and coil mill in Colombia, the improvement of environmental and safety conditions at certain facilities, the expansion of connectivity, integration and automation of our operations, and those made in the iron ore mining operations.

Ternium's net debt position reached $1.5 billion at the end of December 2019, with a net debt to last twelve months EBITDA ratio of 1.0.

32. Ternium |

Economic and Financial Performance | |

2019 | 2018 | 2017 | 2016 | 2015 | ||||||||||

STEEL SALES VOLUME (THOUSAND TONS) | ||||||||||||||

Mexico | 6,305.0 | 6,544.8 | 6,622.8 | 6,405.2 | 5,933.4 | |||||||||

Southern Region | 1,938.3 | 2,301.1 | 2,456.0 | 2,220.8 | 2,552.2 | |||||||||

Other Markets | 4,268.0 | 4,105.2 | 2,517.7 | 1,138.1 | 1,114.6 | |||||||||

Total | 12,511.3 | 12,951.1 | 11,596.5 | 9,764.1 | 9,600.2 | |||||||||

IRON ORE SALES VOLUME (THOUSAND TONS) | 3,575.9 | 3,616.3 | 3,551.1 | 3,309.6 | 3,635.6 | |||||||||

FINANCIAL INDICATORS ($ MILLION) | ||||||||||||||

Net sales | 10,192.8 | 11,453.4 | 9,700.3 | 7,224.0 | 7,877.4 | |||||||||

Operating income | 864.6 | 2,108.4 | 1,456.8 | 1,141.7 | 639.3 | |||||||||

EBITDA(1) | 1,525.7 | 2,697.7 | 1,931.1 | 1,548.6 | 1,073.1 | |||||||||

EBITDA MARGIN (% OF NET SALES) | ||||||||||||||

EBITDA PER TON ($)(2) | ||||||||||||||

Equity in earnings (losses) of non-consolidated companies | 61.0 | 102.8 | 68.1 | 14.6 | (272.8 | ) | ||||||||

Profit before income tax expense | 826.6 | 2,031.6 | 1,359.8 | 1,118.5 | 267.1 | |||||||||

Profit for the year attributable to: | ||||||||||||||

Owners of the Parent | 564.3 | 1,506.6 | 886.2 | 595.6 | 8.1 | |||||||||

Non-controlling interest | 65.8 | 155.5 | 136.7 | 111.3 | 51.7 | |||||||||

Profit for the year | 630.0 | 1,662.1 | 1,022.9 | 706.9 | 59.8 | |||||||||

Capital expenditures | 1,052.3 | 520.3 | 409.4 | 435.5 | 466.6 | |||||||||

Free cash flow(3) | 595.4 | 1,219.0 | (25.5 | ) | 664.1 | 856.8 | ||||||||

BALANCE SHEET ($ MILLION) | ||||||||||||||

Total assets | 12,935.5 | 12,547.9 | 12,122.6 | 8,322.9 | 8,062.6 | |||||||||

Financial debt | 2,188.7 | 2,037.0 | 3,221.9 | 1,218.6 | 1,521.0 | |||||||||

Net financial debt(4) | 1,453.4 | 1,734.9 | 2,748.3 | 884.3 | 1,132.3 | |||||||||

Total liabilities | 5,220.6 | 5,063.3 | 6,269.8 | 3,156.3 | 3,259.6 | |||||||||

Capital and reserves attributable to the owners of the parent | 6,611.7 | 6,393.3 | 5,010.4 | 4,391.3 | 4,033.1 | |||||||||

Non-controlling interest | 1,103.2 | 1,091.3 | 842.3 | 775.3 | 769.8 | |||||||||

STOCK DATA ($ PER SHARE/ADS(5)) | ||||||||||||||

Basic earnings per share | 0.29 | 0.77 | 0.45 | 0.30 | 0.00 | |||||||||

Basic earnings per ADS | 2.87 | 7.67 | 4.51 | 3.03 | 0.04 | |||||||||

Dividend per ADS paid in the year | 1.20 | 1.10 | 1.00 | 0.90 | 0.90 | |||||||||

Weighted average number of shares outstanding(6) (million shares) | 1,963.1 | 1,963.1 | 1,963.1 | 1,963.1 | 1,963.1 | |||||||||

(1) EBITDA is operating income adjusted to exclude depreciation and amortization.

(2) Consolidated EBITDA divided by steel shipments

(3) Free cash flow equals net cash provided by operating activities less capital expenditures.

(4) Net financial debt equals total financial debt less cash and cash equivalents plus other investments.

(5) Each ADS represents 10 shares.

(6) Ternium S.A. has an authorized share capital of a single class of 3.5 billion shares having a nominal value of $1.00 per share. As of December 31, 2019, there were 2,004,743,442 shares issued. All issued shares are fully paid. In addition, as of December 31, 2019 Ternium S.A. held 41,666,666 shares as treasury shares, representing 3% of the subscribed capital.

33. Sustainability Report 2019 |

Why to Invest in Mexico |

Why to invest in Mexico |

The Mexican steel market is the largest in Latin America. Steel consumption growth in Mexico over the last decades has been mainly driven by a dynamic manufacturing industry. The result has been an attractive steel market with a significant demand for high-end steel products. |

TERNIUM HAS A LEADING POSITION IN THE MEXICAN MARKET | |

8 PRODUCTION FACILITIES INTEGRATED AND/OR DOWNSTREAM | 7 SERVICE CENTERS DELIVERING CUSTOMIZED PRODUCTS JUST-IN-TIME OR ON SHORT NOTICE |

12 DISTRIBUTION CENTERS TOGETHER WITH A BROAD NETWORK OF REGIONAL DISTRIBUTORS | |

The Largest Steel Market in Latin America

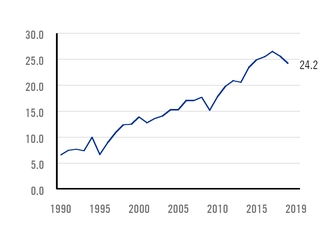

SOLID GROWTH FOR A LONG PERIOD

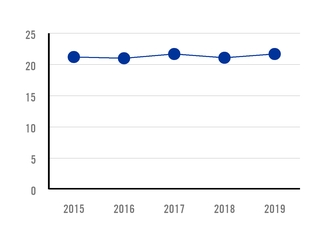

Compound annual growth rate of Mexican steel consumption during the last 30 years reached 4.6%, leading to an average of 192 kilograms of steel consumed per person by 2019.

The rate of steel consumption achieved by the Mexican economy was approximately two times higher than that of other Latin American nations with a developed industrial sector. With 24.2 million tons of steel consumed in 2019, Mexico is the largest steel consumer in the region.

TERNIUM'S LARGEST STEEL MARKET

Ternium's net sales in Mexico accounted for 54% of the company’s total net sales of steel products in 2019. The majority of Ternium's flat steel products are sold to industrial customers, which usually require more sophisticated services and high-value-added steel products, with the balance being sold to construction companies and distributors.

Mexican Competitive Advantages

Mexico's privileged conditions to home a competitive and innovative manufacturing sector have been behind its success story.

LOGISTICS

The country's geographic location provides a competitive logistics base to reach every major market.

TRADE AGREEMENTS

The Mexican industrial sector has access to the US and Canadian markets through the US, Mexico and Canada Agreement (USMCA), and to other major economic regions and trade blocks through other trade agreements in place, including a free trade agreement with the European Union (FTA EU-MX) and Japan (a.k.a. Agreement Between Japan and the United Mexican States for the Strengthening of the Economic Partnership).

34. Ternium |

Why to Invest in Mexico |

|

Ternium's Pesquería unit. Inaugurated in 2013, the new industrial center has incorporated cold-rolling, galvanizing and painting facilities, and will incorporate a new hot-rolling mill in 2021. |

In addition, Mexico has trade agreements in place with Argentina, Australia, Bolivia, Brunei, Colombia, Chile, Costa Rica, Iceland, Liechtenstein, Malaysia, New Zealand, Nicaragua, Norway, Peru, Singapore, Switzerland, Uruguay and Vietnam.

Growth Opportunities

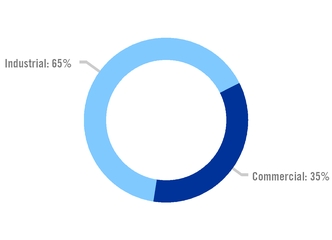

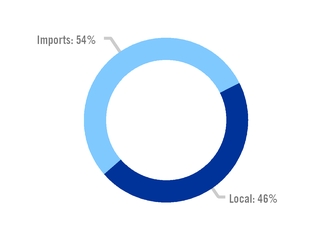

We compete in the Mexican steel market with other domestic steel producers, and with US and other foreign steel producers. Local steel producers, including Ternium, represent a little over half of total apparent flat steel use in Mexico, with the balance of the country's flat steel consumption being supplied from abroad.

According to Canacero, the Mexican chamber of the iron and steel industry, imports of finished flat steel products into Mexico accounted for approximately 8.2 million tons in 2019.

Ternium believes that it is very well positioned to compete with foreign producers and substitute imports in Mexico. The company believes it has built

APPARENT STEEL USE - MEXICO MILLION TONS |

35. Sustainability Report 2019 |

Why to Invest in Mexico |

| |

" | |

The new state-of-the-art hot-rolling mill at Pesquería Industrial Center will enable us to consolidate our leadership in the Mexican flat steel market”. Máximo Vedoya CEO | |

TERNIUM'S STEEL SHIPMENTS IN MEXICO BY INDUSTRY 2019 |

a solid differentiation strategy leaning on its unique industrial presence in the country, as well as on its cost competitiveness.

TERNIUM'S COMPETITIVE ADVANTAGES AS A LOCAL STEEL PRODUCER

Ternium's industrial presence together with its own network of distribution centers and commercial offices enable the company to provide logistics and stock management services. In addition, Ternium offers its customers an integrated connectivity platform that has 75 functions covering the entire customer relationship process. For more information on Ternium's Webservice Platform, see page 22 "Delivering Ternium's Business Strategy".

Ternium's ProPymes program has been focusing its efforts on the development of small and medium-sized customers and suppliers in Mexico. The prosperity of small and medium-sized companies, and the development of a collaborative industrial network have strengthened the country's steel industry value chain.

The consequent improved competitiveness has led to a virtuous cycle of increased exports as well as imports substituted by locally manufactured new products. For more information on the ProPymes program, see page 66 "Strengthening Ternium's Value Chain".

In addition, Ternium has further enhanced its differentiation strategy by investing in state-of-the-art technologies. This strategy included the inauguration of its Pesquería Industrial Center in 2013, with new cold-rolling and galvanizing mills, an expansion of this industrial center in 2019, with the inauguration of new galvanizing and painting lines, and a further expansion expected by 2021, with a new state-of-the-art hot-rolling mill.

Together with the technological upgrade of its facilities, Ternium has increased its product research and development capabilities in the country in order to broaden its range of product offerings, particularly in the high-end steel segment, with the aim of fulfilling all industry requirements.

36. Ternium |

Why to Invest in Mexico |

Furthermore, Ternium's product research and development area has provided technical assistance to its customers, maximizing the performance of the company's steel products and the manufacturing processes downstream in the Mexican steel industry value chain.

APPARENT FLAT STEEL USE IN MEXICO BY SEGMENT 2019 |

APPARENT FLAT STEEL USE IN MEXICO BY ORIGIN 2019 |

Source: Canacero |

The US, Mexico and Canada

free trade agreement, or USMCA, came into effect on July 1, 2020. The new agreement, which resulted from the renegotiation of NAFTA between the three member states, encourages the production of cars and trucks within the trade block.

|

Strengthened research capabilities in Mexico through the inauguration of a new laboratory and the construction of a new research center, launched during 2019. |

37. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

Improving Our Safety Performance | |

SUSTAINABLE DEVELOPMENT GOALS | |

| |

DEC 2019 NEW CORPORATE STRATEGY ON OCCUPATIONAL HEALTH AND SAFETY MANAGEMENT TO ADVANCE OUR SUSTAINABLE DEVELOPMENT AGENDA. | |

Goals | Measures | |

Prevent all work-related injuries and illnesses, and achieve zero accidents | Occupational health and safety policy | |

-Identify and eliminate operational hazards | Occupational health and safety management system | |

-Operate in compliance with established protocols | Safety-focused capital expenditure plan | |

-Raise people's awareness of non-compliance risks | Integral program for critical steel production processes and iron ore tailings dams | |

-Identify and rectify unsafe acts or situations | Periodical management tours at the facilities, training activities, workshops and conferences to raise awareness | |

Extensive communication to engage and commit Ternium's and contractor's employees | ||

Promote healthy and safe operations in the steel industry value chain | Code of conduct for suppliers | |

-Evaluate suppliers' occupational health and safety policies and performance | Safe supplier program | |

-Raise people's awareness of non-compliance risks | Safety training of third-party employees | |

Participation of suppliers in deviations reporting | ||

38. Ternium |

|

Fast implementation of COVID-19 mitigation measures. New protocols for on-site working and work-from-home policy whenever possible. |

Ternium ranks occupational health and safety (OH&S) performance as its top priority, with the conviction that all injuries and work-related illnesses can and must be prevented. Each of the company's and third-party employees' OH&S is our top concern.

COVID-19 Outbreak

Ternium is focused on safeguarding the OH&S of its employees, customers and suppliers based on best practices that comply with and, in some cases, exceed local governmental directives. Beyond implementing work-from-home policies wherever possible, the company has looked to protect the safety of those employees working on-site by adopting stringent social distancing, temperature check and disinfection policies at all transportation, site admission, working post and cafeteria locations, among other initiatives. In addition, Ternium has developed a protocol to track suspect or positive contagion cases and the successful reintegration of returning workers.

New Occupational Health and Safety Corporate Strategy

According to Ternium's OH&S policy, the assessment of risks and management of our people's OH&S must be integrated into all our business processes. Management is responsible and accountable for

achieving excellence in OH&S performance as part of a comprehensive set of goals. In December 2019, Ternium launched a new corporate strategy on OH&S. We are committed to taking every possible step to protect the safety and health of our employees and the people of the communities in which we operate. This vision has acted as a framework to adjust our strategies and to adopt new ones, including the alignment of our safety culture to our vision, the prevention of severe accidents or fatalities, the achievement of excellence in process safety management, the engagement of employees through effective communication and the engagement of customers' and suppliers' managers and employees to embrace our vision and goals. In 2019, Ternium invested $50 million under its safety-focused capital expenditures plan.

Occupational Health and Safety Management System

Ternium has an OH&S management system to oversee its production units, which abides by the company's OH&S policy, and local and national laws and regulations. The company periodically audits its processes and procedures, which helps us find new opportunities to improve our safety management systems and ensure their compliance with our policy. Ternium’s steelmaking and steel processing facilities in Mexico, Argentina, Colombia and

39. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

Improving Health and Safety Performance • Proactive approach to occupational health and safety management • Standardized OH&S management system • Extensive employee training • Management accountable for OH&S performance • Certified OH&S management system • Capital expenditures program to reduce H&S risks | ||||

Guatemala have their OH&S management system certified under international standards by third party certification bodies. The company’s facilities in Mexico have completed the migration process of their OH&S management system to ISO 45001:2018, and have

obtained the certification in this new standard. Ternium’s Rio de Janeiro unit in Brazil and its mining facilities in Mexico are undergoing a migration and certification process, which is expected to be completed within the next two years.

Aligning Our Safety Culture to Our Vision

Ternium’s continuous quest for a virtuous safety culture leans on its top management’s effective leadership. The company’s senior management has identified measurable, repeatable, proactive and leading safety attitudes to deploy along the organization, as part of a strategy to align people’s safety culture with the company’s vision.

SAFETY FIRST PROGRAM

The Safety First program fosters a pro-active approach to safety issues to prevent incidents and accidents. One of the program's main tool is the Safety Hour initiative, in which middle and senior managers tour operating areas for an hour, three times a week, to identify safe behaviors to be consolidated or unsafe acts or situations to be

addressed through an open dialogue with employees. This exchange helps identify potential risks and enables a fluid and constructive feedback to implement effective preventive measures. In 2019, the company held a total of 147,100 Safety Hour sessions, with the regular participation of 1,600 employees and contractors, that helped to detect, record and correct 177,500 deviations. In addition, these sessions helped to recognize 106,800 full-compliance cases. Furthermore, management performed safety verification audits (SVAs) at the facilities to evaluate compliance with policies, procedures and practices in relation to relevant OH&S topics. In 2019, a new record 200,000 SVAs were performed.

TEN LIFE-SAVING RULES

Ternium has established Ten Life-Saving Rules, which lists the actions that all employees must follow in order to protect their lives and that of their colleagues. The rules are the result of a process that included worldsteel's guidance, and the contribution of focus groups and studies performed to detect the main causes of risks in our operations. The rules are backed by practices and routines to follow and reflect the scope of safety regulations in the countries where Ternium operates. The rules have been extensively communicated throughout Ternium’s operations to foster employees',

40. Ternium |

|

Safety hour (hora segura) at the Villa Nueva unit, Guatemala. An articulated on-site exchange to implement effective preventive measures. |

customers' and suppliers' awareness, and have been audited to ensure their observance. In 2019, we held 42,800 compliance audits.

TERNIUM’S ANNUAL SAFETY DAY

Since 2014, every July 22nd we have been holding Ternium's Annual Safety Day, an occasion to prompt a renewed commitment to improving safety and increasing risk awareness, in the belief that every accident can and must be prevented. During this event, we hold safety management meetings and discussions to review our performance in the past year and agree on concrete actions to improve safety in every facility.

TRAINING PROGRAMS

Management is committed to training Ternium's employees, customers and suppliers on the appropriate application of the company’s OH&S management systems in performing their tasks, and to raising awareness of risks. In 2019, Ternium delivered 487,600 safety training hours to 15,700 employees, customers and suppliers.

TASK REJECTION TOOL

This tool aims at strengthening people’s determination not to start or, if started, to suspend a task under certain conditions. The Task Rejection tool helps people prevent

injuries risks stemming from the lack of effective control over identified safety risks.

Prevention of Severe Injuries or Fatalities

A steel industry-wide analysis found out that, over time, the downward trend in fatal accidents has been slower than the trend for non-fatal accidents, mainly due to causality differences. Accordingly, the company has increased its efforts to identify severe injury or fatality precursors. In order to do so, we identify non-controlled repetitive precursors through interviews with employees, based on critical control and verification methodologies.

Process Safety Management

Iron ore processing, and steel production and processing include potentially hazardous processes. Ternium has identified critical processes in some of its facilities, and developed specific tools to manage them. In addition, during 2019 Ternium launched a new program focused on the identification of risk factors in critical processes and the development of specific strategies aimed at eliminating the exposure to severe personal injury.

Engaging Through Effective Communication

Over the years, Ternium has increased the visibility of safety issues through its communications platforms.

41. Sustainability Report 2019 |

A Comprehensive Approach to Value Creation | |

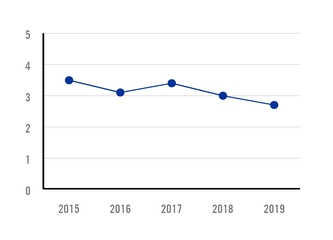

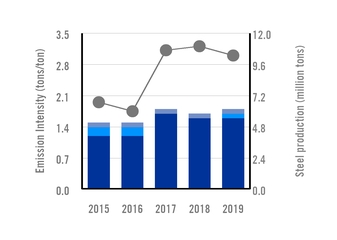

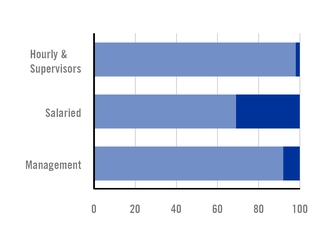

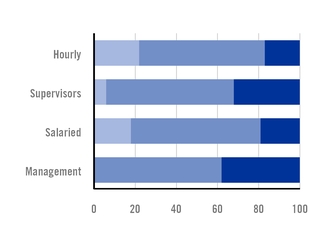

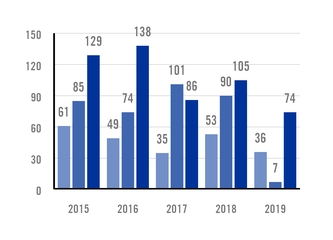

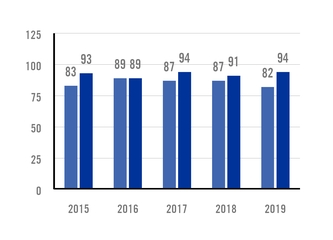

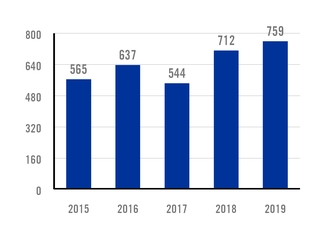

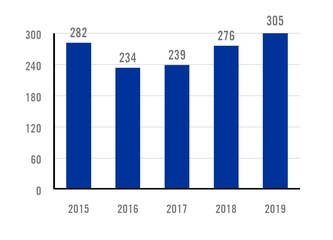

INJURY FREQUENCY RATE (IFR) TOTAL QUANTITY OF INJURIES PER MILLION HOURS WORKED |

Our agenda includes videos, articles and the coverage of selected events. To engage the company’s employees and raise awareness on safety issues, we have developed a new communications system aimed at sharing key messages with employees operating at every location, including posts at the company’s communications platforms and other distribution channels. We have also implemented the Five-Minutes Safety Talks, an open-dialogue instance for blue-collar supervisors and their teams to analyze OH&S issues selected every week by senior management.

Engaging Customers' and Suppliers' Managers and Employees

We aim at having all contractors' employees embrace our vision and goals. With this purpose, we have launched several initiatives including working meetings with contractor’s top managers and the participation of their employees in Ternium's OH&S workshops. We have recently launched an OH&S improvement plan for contractors. This plan has been developed based on contractors' best practices, which were identified through a benchmark of contractors' operations at the company's facilities in different locations and countries.

Accidents and incidents

In 2019, Ternium recorded an injury frequency rate (IFR) of 2.7 injuries per million of hours worked, compared to

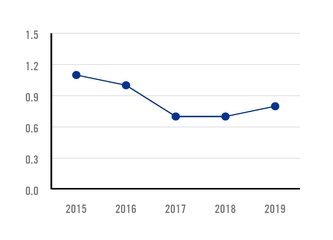

LOST TIME INJURY FREQUENCY RATE (LTIFR) 1 QUANTITY OF DAY-LOSS INJURIES PER MILLION HOURS WORKED |

an IFR of 3.0 in 2018. The lost time injury frequency rate (LTIFR) was 0.8 day-loss injuries per million hours worked in 2019, compared to an LTIFR of 0.7 in 2018. The year-over-year increase in LTIFR in 2019 reflected mainly the effect of construction works carried out for the new facilities in Pesquería, Mexico, and Palmar de Varela, Colombia.

Analysis of Accidents and Incidents

Ternium's management follows specific protocols when a workplace accident or incident occurs, regardless of the damage or injury, or lack of, cause by an event. The research and analysis of an event is conducted by multidisciplinary teams that include the participation of the manager with direct responsibilities in the area involved.

An event is analyzed through a causal factor tree methodology that has been homologated at Ternium. Management uses all available resources that could contribute to the understanding of an event, including the evidence collected by nearby cameras. Once causes are fully understood, the company implements a new preventive action plan structured in hierarchy of controls. This methodology was incorporated in the company’s occupational health and safety management system in 2019.

42. Ternium |

|

Las Encinas, Mexico. Ternium has a proactive approach to safe mining operations. |

Health and Well-being