Exhibit 96.1

|

Submitted by: WWC Engineering 1849 Terra Avenue Sheridan, WY 82801 |

|

|

|

Contents |

||

|

1.0 |

EXECUTIVE SUMMARY |

1-1 |

|

1.1 |

Property Description |

1-1 |

|

1.2 |

Ownership |

1-2 |

|

1.3 |

Geology and Mineralization |

1-2 |

|

1.4 |

Exploration Status |

1-2 |

|

1.5 |

Development and Operations |

1-3 |

|

1.6 |

Mineral Resource Estimates |

1-3 |

|

1.7 |

Permitting Requirements |

1-3 |

|

1.8 |

QP Conclusion and Recommendations |

1-3 |

|

2.0 |

INTRODUCTION |

2-1 |

|

2.1 |

Registrant/Issuer of Report |

2-1 |

|

2.2 |

Terms of Reference |

2-1 |

|

2.3 |

Data Sources, Units of Measurement and Abbreviations |

2-1 |

|

2.4 |

Personal Inspection |

2-1 |

|

2.4.1 |

QP Qualifications |

2-1 |

|

2.5 |

Previous Technical Report Summaries |

2-2 |

|

3.0 |

PROPERTY DESCRIPTION |

3-1 |

|

3.1 |

Location, Description, Leases and Mineral Rights |

3-1 |

|

3.1.1 |

Allemand-Ross |

3-7 |

|

3.1.2 |

Barge |

3-7 |

|

3.1.3 |

Charlie |

3-8 |

|

3.1.4 |

Christensen Ranch |

3-8 |

|

3.1.5 |

Clarkson Hill |

3-8 |

|

3.1.6 |

Irigaray |

3-9 |

|

3.1.7 |

Jab/West Jab |

3-9 |

|

3.1.8 |

Ludeman |

3-9 |

|

3.1.9 |

Moore Ranch |

3-10 |

|

3.1.10 |

Nine Mile |

3-10 |

|

3.1.11 |

Red Rim |

3-11 |

|

3.1.12 |

Reno Creek |

3-11 |

|

3.2 |

Encumbrances |

3-12 |

|

3.3 |

Property Risk Factors |

3-13 |

|

3.4 |

Royalties (Confidential) |

3-15 |

|

4.0 |

ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

4-1 |

|

4.1 |

Physical Setting |

4-1 |

|

4.1.1 |

Powder River Basin |

4-1 |

|

4.1.2 |

Greater Green River Basin |

4-1 |

|

4.1.3 |

Wind River Basin |

4-2 |

|

4.2 |

Accessibility and Local Resources |

4-3 |

|

4.3 |

Availability of Infrastructure |

4-4 |

|

5.0 |

HISTORY |

5-1 |

|

6.0 |

GEOLOGICAL SETTING, MINERALIZATION AND DEPOSIT |

6-1 |

|

6.1 |

Regional Geology |

6-1 |

|

6.1.1 |

Powder River Basin |

6-1 |

|

6.1.2 |

Greater Green River Basin |

6-8 |

|

|

|

6.1.3 |

Wind River Basin |

6-9 |

|

6.2 |

Local Geology |

6-18 |

|

6.2.1 |

Powder River Basin |

6-18 |

|

6.2.2 |

Greater Green River Basin |

6-20 |

|

6.2.3 |

Wind River Basin |

6-21 |

|

6.3 |

Mineralization and Deposit Type |

6-21 |

|

7.0 |

EXPLORATION |

7-1 |

|

7.1 |

Drilling Programs |

7-1 |

|

7.2 |

Hydrogeologic Information |

7-8 |

|

7.3 |

Geotechnical Information |

7-11 |

|

8.0 |

SAMPLE PREPARATION, ANALYSES AND SECURITY |

8-1 |

|

8.1 |

Typical and Standard Industry Methods |

8-1 |

|

8.2 |

QP Opinion on Sample Preparation, Security and Analytical Procedures |

8-3 |

|

9.0 |

DATA VERIFICATION |

9-1 |

|

9.1 |

Summary |

9-1 |

|

9.2 |

Exploration Potential |

9-5 |

|

9.2.1 |

Charlie Project Area |

9-5 |

|

9.2.2 |

Jab/West Jab |

9-6 |

|

9.3 |

Limitations |

9-7 |

|

9.4 |

QP Opinion on Data Adequacy |

9-7 |

|

10.0 |

MINERAL PROCESSING AND METALLURGICAL TESTING |

10-1 |

|

10.1 |

Summary of Properties |

10-1 |

|

10.2 |

QP Opinion on Data Adequacy |

10-3 |

|

11.0 |

MINERAL RESOURCE ESTIMATES |

11-1 |

|

11.1 |

Mineral Resource Assumptions and Parameters Applied to Each Project Area |

11-1 |

|

11.1.1 |

Reasonable Prospects of Economic Extraction |

11-1 |

|

11.1.2 |

Confidence Classification of Mineral Resource Estimates |

11-3 |

|

11.2 |

Site-by-Site Summaries |

11-4 |

|

11.3 |

Uncertainties (Factors) That May Affect the Mineral Resource Estimate |

11-9 |

|

11.4 |

QP Opinion on the Mineral Resource Estimate |

11-10 |

|

12.0 |

MINERAL RESERVE ESTIMATES |

12-1 |

|

13.0 |

MINING METHODS |

13-1 |

|

14.0 |

PROCESSING AND RECOVERY METHODS |

14-1 |

|

15.0 |

INFRASTRUCTURE |

15-1 |

|

16.0 |

MARKET STUDIES |

16-1 |

|

17.0 |

ENVIRONMENTAL STUDIES, PERMITTING, PLANS, NEGOTIATIONS OR AGREEMENTS WITH LOCAL INDIVIDUALS OR GROUPS |

17-1 |

|

18.0 |

CAPITAL AND OPERATING COSTS |

18-1 |

|

19.0 |

ECONOMIC ANALYSIS |

19-1 |

|

20.0 |

ADJACENT PROPERTIES |

20-1 |

|

21.0 |

OTHER RELEVANT DATA AND INFORMATION |

21-1 |

|

22.0 |

INTERPRETATION AND CONCLUSIONS |

22-1 |

|

|

|

22.1 |

Conclusions |

22-1 |

|

22.2 |

Risks and Opportunities |

22-1 |

|

23.0 |

RECOMMENDATIONS |

23-1 |

|

24.0 |

REFERENCES |

24-1 |

|

25.0 |

RELIANCE ON INFORMATION PROVIDED BY THE REGISTRANT |

25-1 |

|

26.0 |

DATE AND SIGNATURE PAGE |

26-1 |

|

Tables |

||

|

Table 1-1: |

Wyoming ISR Hub and Spoke Project Areas |

1-1 |

|

Table 3-1: |

Property Description Summary |

3-5 |

|

Table 3-2: |

Project Area Permitting Status |

3-12 |

|

Table 5-1: |

Past Operations Summary |

5-2 |

|

Table 7-1: |

Project Area Drilling Programs Summary |

7-2 |

|

Table 7-2: |

Extent of Project Area Hydrogeologic Investigations |

7-9 |

|

Table 9‑1: |

Project Exploration Potential |

9-6 |

|

Table 10-1. |

Project Area Mineral Processing and Metallurgical Testing Summary |

10-1 |

|

Table 11‑1: |

Methods, Parameters and Cutoffs by Project Area |

11-2 |

|

Table 11-2: |

UxC Q4 2021 Uranium Price Forecast ($/lb U3O8) |

11-3 |

|

Table 11-3: |

Resource Classification Criteria by Project Area |

11-4 |

|

Table 11‑4: |

Project Area Measured and Indicated Resources Summary |

11-6 |

|

Table 11‑5: |

Project Area Inferred Resources Summary |

11-8 |

|

Table 20-1: |

Significant Uranium Projects in the Powder River, Wind River and Greater Green River Basins |

20-1 |

|

Figures |

||

|

Figure 3‑1: |

General Location Map |

3-2 |

|

Figure 3‑2: |

Powder River Basin and Wind River Basin Projects Location Map |

3-3 |

|

Figure 3‑3: |

Greater Green River Basin Projects Location Map |

3-4 |

|

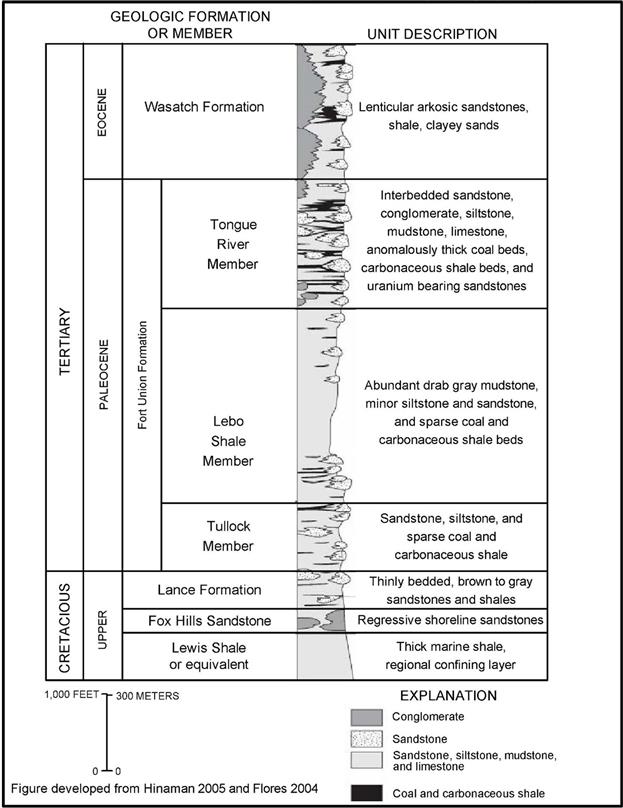

Figure 6‑1: |

Upper PRB Stratigraphic Column |

6-3 |

|

Figure 6-2: |

Nine Mile Project Area Stratigraphic Column and Cross Section A-A’ |

6-4 |

|

Figure 6‑3: |

PRB Projects Cross-Section Location Map |

6-5 |

|

Figure 6‑3a: |

PRB Projects Cross-Sections B-B’ and C-C’ |

6-6 |

|

Figure 6‑3b: |

PRB Projects Cross-Sections C-C’ and D-D’ |

6-7 |

|

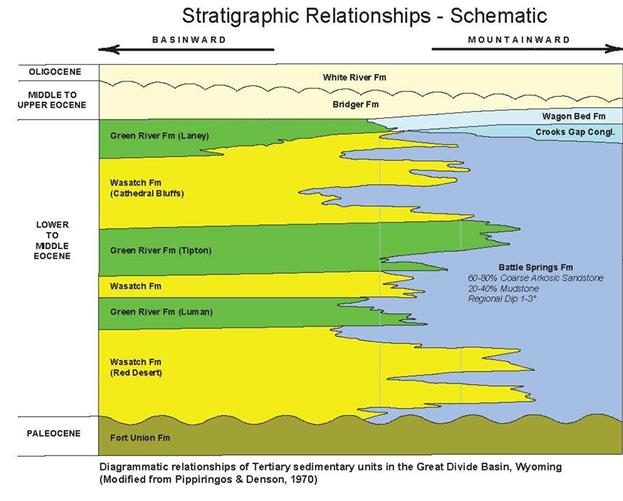

Figure 6‑4: |

GGRB Stratigraphy and Sedimentary Relationships |

6-10 |

|

Figure 6‑5: |

Jab/West Jab Project Area Cross-Section Location Map |

6-11 |

|

Figure 6‑5a: |

Jab/West Jab Project Area Cross-Section |

6-12 |

|

Figure 6‑6: |

Red Rim Project Area Cross-Section Location Map |

6-13 |

|

Figure 6‑6a: |

Red Rim Project Area Cross-Section |

6-14 |

|

Figure 6‑7: |

Wind River Basin Stratigraphic Column |

6-15 |

|

Figure 6‑8: |

Clarkson Hill Project Area Cross-Section Location Map |

6-16 |

|

Figure 6‑8a: |

Clarkson Hill Project Area Cross-Section |

6-17 |

|

|

|

Figure 7-1: |

Drill Hole Map for the Charlie, Christensen Ranch, Irigaray, Moore Ranch and Reno Creek Project Areas |

7-3 |

|

Figure 7‑2: |

Drill Hole Map for the Allemand-Ross, Barge and Ludeman Project Areas |

7-4 |

|

Figure 7‑3: |

Drill Hole Map for the Clarkson Hill and Nine Mile Project Areas |

7-5 |

|

Figure 7‑4: |

Drill Hole Map for the Jab/West Jab Project Area |

7-6 |

|

Figure 7-5: |

Drill Hole Map for the Red Rim Project Area |

7-7 |

[The remainder of this page is intentionally left blank.]

|

|

|

1.0 |

EXECUTIVE SUMMARY |

This independent Technical Report Summary (TRS) for the Wyoming In-Situ Recovery (ISR) Hub and Spoke Project (the Project) has been prepared for Uranium Energy Corporation (UEC) under the supervision of Western Water Consultants, Inc., d/b/a WWC Engineering (WWC), pursuant to Regulation S-K Subpart 1300, “Modernization of Property Disclosures for Mining Registrants” (S‑K 1300). This TRS identifies and summarizes the scientific and technical information and conclusions reached concerning the Initial Assessment (IA) to support disclosure of mineral resources on the Project. The objective of this TRS is to disclose the mineral resources on the Project.

|

1.1 |

Property Description |

The Project consists of 12 project areas as shown in Table 1-1.

|

Table 1-1: |

Wyoming ISR Hub and Spoke Project Areas |

|

Project Area |

County |

Structural Basin |

Site Visit Date |

|

Allemand-Ross |

Converse |

Powder River |

3/27/2019 |

|

Barge |

Converse |

Powder River |

Inaccessible |

|

Charlie |

Johnson |

Powder River |

6/28/2022 |

|

Christensen Ranch |

Johnson/Campbell |

Powder River |

2/16/2022 |

|

Clarkson Hill |

Natrona |

Wind River |

7/15/2022 |

|

Irigaray |

Johnson |

Powder River |

2/16/2022 |

|

Jab/West Jab |

Sweetwater/Fremont |

Greater Green River |

1/28/2022 |

|

Ludeman |

Converse |

Powder River |

10/18/2018 |

|

Moore Ranch |

Campbell |

Powder River |

12/27/2021 |

|

Nine Mile |

Natrona |

Powder River |

5/23/2022 |

|

Red Rim |

Carbon |

Greater Green River |

6/29/2022 |

|

Reno Creek |

Campbell |

Powder River |

12/27/2021 |

Mineral rights for the Project are a combination of federally administered minerals (unpatented lode claims), State of Wyoming mineral leases and private (fee) mineral leases. Federal mining claims were staked and recorded consistent with federal and state law, state mineral leases were obtained by submitting a lease application and appropriate fee to the State Board of Land Commissioners and fee mineral leases were obtained through negotiation with individual mineral owners. Chapter 3 summarizes the different mineral leases and claims for each project area, and the annual maintenance cost.

|

|

|

1.2 |

Ownership |

This Project is owned and operated by UEC. UEC has executed fee mineral leases with landowners who hold mineral ownership within and outside the various project boundaries. UEC also holds unpatented Bureau of Land Management (BLM) lode claims and leases on Wyoming state land on the various project areas.

|

1.3 |

Geology and Mineralization |

The Allemand-Ross, Barge, Charlie, Christensen Ranch, Irigaray, Ludeman, Moore Ranch, Nine Mile and Reno Creek project areas reside in the Powder River Basin (PRB). The PRB is a structural basin that extends over much of northeastern Wyoming and southeastern Montana and consists of a large north-northwest trending asymmetric syncline. The basin is bounded by the Big Horn Mountains on the west and Casper Arch to the southwest, the Black Hills to the east and the Hartville Uplift and Laramie Mountains to the south. The PRB is filled with marine, non-marine and continental sediments ranging in age from early Paleozoic through Cenozoic.

The Jab/West Jab and Red Rim project areas are located within the northeastern portion of the Greater Green River Basin (GGRB). The GGRB is a structural basin that extends over southwestern Wyoming and northwestern Colorado and is divided by the Rock Springs Uplift, a north-south trending anticline. The basin is bounded by the Wyoming thrust belt to the west, the Rawlins Uplift and the Sierra Madre Mountains to the east, the Wind River Mountains to the north and the Uinta Mountains to the south. The GGRB contains up to 25,000 ft of Cretaceous to recent sedimentary rocks.

The Clarkson Hill project area is located in the eastern portion of the Wind River Basin (WRB). The WRB is a structural basin in west-central Wyoming. The basin is bounded by the Wind River Range to the west, the Casper Arch to the east, the Owl Creek Mountains to the north and the Granite Mountains to the south. The WRB is filled with marine, lacustrine and fluvial sediments ranging in age from Paleozoic to Cenozoic.

Uranium mineralization at the Project is typical of Wyoming roll-front sandstone deposits. The formation of roll-front deposits is largely a groundwater process that occurs when uranium-rich, oxygenated groundwater interacts with a reducing environment in the subsurface and precipitates uranium. The most favorable host rocks for roll-fronts are permeable sandstones with large aquifer systems. Interbedded mudstone, claystone and siltstone are often present and aid in the formation process by focusing groundwater flow.

|

1.4 |

Exploration Status |

To date, UEC holds data from approximately 51,780 drill holes and core holes that have been drilled by previous uranium exploration companies on and nearby the 12 project areas held by UEC. Data from the drilling, including survey coordinates, collar elevations, depths and grade of uranium intercepts, have been incorporated into UEC’s database.

|

|

|

1.5 |

Development and Operations |

Summary capital and operating cost estimates are not included with this TRS, because UEC is reporting the results of an IA without economic analysis. No construction has taken place on the Project during UEC’s ownership.

|

1.6 |

Mineral Resource Estimates |

Cautionary Statement:

This TRS is preliminary in nature and includes mineral resources. Mineral resources that are not mineral reserves do not have demonstrated economic viability. There is increased risk and uncertainty to commencing and conducting production without established mineral reserves, which may result in economic and technical failure and may adversely impact future profitability.

The in-place resources were estimated separately for each area in the Project. The Project contains a measured resource of 23.90 million lbs and an indicated resource of 42.30 million lbs of U3O8 in-place. The Project contains 15.05 million lbs of inferred mineral resources in-place.

|

1.7 |

Permitting Requirements |

The Irigaray Central Processing Plant (CPP) is fully permitted. The Christensen Ranch, Ludeman and Moore Ranch project areas are fully permitted for ISR operations through both the Wyoming Department of Environmental Quality/Land Quality Division (WDEQ/LQD) and BLM as appropriate. Portions of the Irigaray and Reno Creek project areas are also permitted for ISR operations.

The Allemand-Ross, Barge, Charlie, Clarkson Hill, Jab/West Jab, Nine Mile and Red Rim project areas are not permitted. Portions of the Reno Creek project area and the majority of the Irigaray project area are also not permitted for ISR operations.

|

1.8 |

QP Conclusion and Recommendations |

Key conclusions and recommendations from WWC, a third-party firm, which employs professionals meeting the definition of “qualified person” (QP) set out in S-K 1300, are as follows:

|

• |

The QP considers the scale and quality of the mineral resources at the Project to indicate favorable conditions for future extraction. |

|

• |

UEC should develop a Preliminary Feasibility Study for the Project; obtain required regulatory authorizations required to mine at the Bing, Moore and Pine Tree resource areas and the Allemand-Ross, Barge, Clarkson Hill, Charlie, Jab/West Jab, Nine Mile and Red Rim project areas; and continue to maintain mining claims and mineral leases along with surface use agreements to accommodate future oil and gas drilling and Project development. |

|

|

|

• |

UEC should advance the baseline studies necessary to obtain regulatory authorizations required to mine at the Allemand-Ross, Barge, Clarkson Hill, Charlie, Jab/West Jab, Nine Mile, Red Rim and portions of the Reno Creek project areas as the resources become necessary to provide material to the Irigaray CPP. |

[The remainder of this page is intentionally left blank.]

|

|

|

2.0 |

INTRODUCTION |

|

2.1 |

Registrant/Issuer of Report |

This TRS was prepared for UEC to report the results of an IA and describe the Project. The Project includes the 12 project areas shown in Table 1-1.

The Irigaray CPP, located at the Irigaray project area, will serve as the “hub” of the Project, with the other project areas serving as satellite ISR mining facilities, or the “spokes.” For the purposes of this TRS, the satellite facilities are considered material to the Irigaray CPP.

UEC is incorporated in the State of Nevada, with principal offices located at 500 North Shoreline Boulevard, Suite 800N, Corpus Christi, Texas 78401, and at 1030 West Georgia Street, Suite 1830, Vancouver, British Columbia, Canada V6E 2Y3.

|

2.2 |

Terms of Reference |

The Project includes the 12 project areas shown in Table 1-1. The Project is owned and operated by UEC. This TRS has been prepared for UEC to report mineral resources for the Project.

|

2.3 |

Data Sources, Units of Measurement and Abbreviations |

The information and data presented in this TRS were gathered from various sources listed in Chapters 24 and 25 of this TRS.

Data sources for the estimation of uranium mineral resources for the Project include 51,780 drill holes and core holes, including survey coordinates, collar elevations, depths and grade of uranium intercepts.

Units of measurement unless otherwise indicated are feet (ft), miles, acres, pounds (lbs), short tons (2,000 lbs), grams (g), milligrams (mg), liters (L), parts per million (ppm) and gallons per minute (gpm). Uranium production is expressed as pounds U3O8, the standard market unit. ISR refers to in-situ recovery, sometimes also termed in-situ leach (ISL). Unless otherwise indicated, all references to dollars ($) refer to United States currency.

|

2.4 |

Personal Inspection |

WWC professionals most recently visited the project areas on the dates shown in Table 1-1. Additionally, a professional employed by WWC worked at the facilities for over four years in the late 1990s when Christensen Ranch was operated by COGEMA Resources, Inc. (COGEMA). WWC professionals were unable to inspect the Barge project area due to surface access limitations.

|

2.4.1 |

QP Qualifications |

Completion of this TRS was under the direction and supervision of WWC. WWC is a third-party QP as defined by Regulation S-K 1300. Additionally, WWC has approved the technical disclosure contained in this TRS.

|

|

|

2.5 |

Previous Technical Report Summaries |

UEC previously filed a TRS for the Reno Creek Project titled “S-K 1300 Initial Assessment Mineral Resource Report Reno Creek Project, Campbell County, WY USA,” which was current on December 31, 2021.

On March 31, 2022, UEC filed a TRS for the Wyoming Assets ISR Hub and Spoke Project titled “S-K 1300 Mineral Resource Report Wyoming Assets ISR Hub and Spoke Project, WY USA,” which was current on December 31, 2021. This report represents an update to the March 31, 2022 TRS, adding the Charlie, Clarkson Hill, Nine Mile and Red Rim project areas to the Project.

[The remainder of this page is intentionally left blank.]

|

|

|

3.0 |

PROPERTY DESCRIPTION |

|

3.1 |

Location, Description, Leases and Mineral Rights |

The Project is located in Wyoming, USA, and includes the 12 project areas shown in Table 1-1. The Irigaray CPP will serve as the “hub” of the Project, with the other project areas serving as satellite ISR mining facilities, or the “spokes.” The project area locations are shown in Figures 3-1 through 3-3. Each project area is described in detail in Chapters 3.1.1 through 3.1.12.

Mineral rights for the Project are a combination of federally administered minerals (unpatented lode claims), State of Wyoming mineral leases and private (fee) mineral leases. Federal mining claims were staked and recorded consistent with federal and state law, state mineral leases were obtained by submitting a lease application and appropriate fee to the State Board of Land Commissioners and fee mineral leases were obtained through negotiation with individual mineral owners. State surface and mineral leases can be extended in perpetuity, provided that annual payments and/or production royalty payments are current. If the terms of the lease are not fulfilled and/or the lease is not renewed, the State of Wyoming may revoke or terminate the lease. Table 3-1 summarizes the different mineral leases or claims for each project area, expiration dates, if applicable, and the annual maintenance costs.

State mineral leases have a 5% gross royalty attached. No royalties are due to the federal government from mining on lode claims. The claims will remain under UEC’s ownership and control, provided that UEC adheres to required BLM annual filing and payment requirements. Legal surveys of unpatented claims are not required and to the QP’s knowledge have not been completed. Fee minerals have varying royalty rates and calculations, depending on the agreements negotiated with individual mineral owners. In addition, surface use and access agreements may include a production royalty, depending on agreements negotiated with individual surface owners at various levels. UEC’s average combined mineral plus surface production royalty applicable to the Project is variable, based upon the selling price of U3O8.

Surface ownership at the Project consists of predominantly agricultural fee lands, lands owned by the State of Wyoming and federally owned lands administered by the BLM. As part of the Wyoming mine permitting process, the company must have obtained surface access to conduct baseline data acquisition and must demonstrate surface owner consent to the mine and reclamation plans. On the project areas that are currently permitted, UEC has surface use agreements in place with the private landowners and, as necessary, the state and federal authorities have approved of the mine and reclamation plans. UEC has or will obtain surface use agreements with landowners and, as necessary, will obtain state and federal approval of the mine and reclamation plans before a mine permit is issued. Obtaining surface access rights is a standard process in mine permitting, and the QP does not anticipate that obtaining these rights presents a significant risk to UEC’s ability to perform work on the Project as a whole. Chapters 3.2 and 3.3 discuss specific project areas in detail.

The QP has not verified the claims within the various project areas or how the claims are mapped or plotted. The QP has relied on information provided by UEC with regard to royalty rates and has not independently verified royalty agreements, rates or surface use and access agreements.

|

|

|

Figure 3‑1: |

General Location Map |

|

|

|

Figure 3‑2: |

Powder River Basin and Wind River Basin Projects Location Map |

|

|

|

Figure 3‑3: |

Greater Green River Basin Projects Location Map |

|

|

|

Table 3-1: |

Property Description Summary |

|

Project Area |

State of Wyoming Leases |

Expiration Date |

Fee Mineral Leases |

Expiration |

Federal Lode Mining Claims |

Expiration Date |

Total |

|

Allemand-Ross |

|||||||

|

Acreage |

318 |

Annual |

2,773.9 |

March 2025 through Jan. 2029 (Variable) |

8,518.2 |

Annual |

11,610.1 |

|

Leases/Claims |

2 |

7 |

452 |

461 |

|||

|

Total Annual Cost |

$683 |

Confidential |

$74,580 |

$75,263 |

|||

|

Barge |

|||||||

|

Acreage |

640 |

Annual |

0 |

N/A |

6,374.2 |

Annual |

7,014.2 |

|

Leases/Claims |

1 |

0 |

342 |

343 |

|||

|

Total Annual Cost |

$1,920 |

$0 |

$56,430 |

$58,350 |

|||

|

Charlie |

|||||||

|

Acreage |

720 |

6/1/2026 |

0 |

N/A |

0 |

N/A |

720 |

|

Leases/Claims |

1 |

0 |

0 |

1 |

|||

|

Total Annual Cost |

$2,880 |

$0 |

$0 |

$2,880 |

|||

|

Christensen Ranch |

|||||||

|

Acreage |

1,280 |

Annual |

720 |

Annual |

5,140 |

Annual |

7,140 |

|

Leases/Claims |

1 |

1 |

257 |

259 |

|||

|

Total Annual Cost |

$5,120 |

Confidential |

$42,405 |

$47,525 |

|||

|

Clarkson Hill |

|||||||

|

Acreage |

0 |

N/A |

0 |

N/A |

500 |

Annual |

500 |

|

Leases/Claims |

0 |

0 |

25 |

25 |

|||

|

Total Annual Cost |

$0 |

$0 |

$4,125 |

$4,125 |

|||

|

Irigaray |

|||||||

|

Acreage |

480 |

Annual |

0 |

N/A |

1,640 |

Annual |

2,120 |

|

Leases/Claims |

2 |

0 |

82 |

84 |

|||

|

Total Annual Cost |

$1,600 |

$0 |

$13,530 |

$15,130 |

|||

|

Jab/West Jab |

|||||||

|

Acreage |

960 |

Annual |

0 |

N/A |

4,483.4 |

Annual |

5,443.4 |

|

Leases/Claims |

3 |

0 |

217 |

220 |

|||

|

Total Annual Cost |

$2,880 |

$0 |

$35,805 |

$38,685 |

|||

|

Ludeman |

|||||||

|

Acreage |

1,440 |

Annual |

1,741.9 |

Sept. 2026 and |

17,586.1 |

Annual |

20,768 |

|

Leases/Claims |

4 |

Annual |

2 |

746 |

Annual |

752 |

|

|

Total Annual Cost |

$4,320 |

Confidential |

$123,090 |

$127,410 |

|||

|

|

|

Table 3-1: |

Property Description Summary (Continued) |

|

Project Area |

State of Wyoming Leases |

Expiration Date |

Fee Mineral Leases |

Expiration |

Federal Lode Mining Claims |

Expiration Date |

Total |

|

Moore Ranch |

|||||||

|

Acreage |

1,200 |

Annual |

1,740 |

Aug. 2025 through Feb. 2029 (Variable) |

1,754.1 |

Annual |

4,694.1 |

|

Leases/Claims |

2 |

5 |

86 |

93 |

|||

|

Total Annual Cost |

$3,600 |

Confidential |

$14,190 |

$17,790 |

|||

|

Nine Mile |

|||||||

|

Acreage |

1,280 |

2024 & 2025 |

1,258.6 |

Oct. 2025 and Aug. 2026 |

3,800 |

Annual |

6,339 |

|

Leases/Claims |

2 |

2 |

190 |

194 |

|||

|

Total Annual Cost |

$2,560 |

Confidential |

$31,350 |

$33,910 |

|||

|

Red Rim |

|||||||

|

Acreage |

0 |

N/A |

0 |

N/A |

1,000 |

Annual |

1,000 |

|

Leases/Claims |

0 |

0 |

49 |

49 |

|||

|

Total Annual Cost |

$0 |

$0 |

$8,085 |

$8,085 |

|||

|

Reno Creek |

|||||||

|

Acreage |

3,200 |

Annual |

4,583 |

Annual |

10,980 |

Annual |

18,763 |

|

Leases/Claims |

4 |

36 |

549 |

589 |

|||

|

Total Annual Cost |

$9,600 |

Confidential |

$90,585 |

$100,185 |

|||

|

Project Totals |

State of Wyoming Leases |

Fee Mineral Leases |

Federal Lode Mining Claims |

Total |

|||

|

Acreage |

11,518 |

12,817 |

61,776 |

86,111 |

|||

|

Leases/Claims |

22 |

53 |

2,995 |

3,070 |

|||

|

Annual Cost |

35,163 |

Confidential |

494,175 |

529,338 |

|||

[The remainder of this page is intentionally left blank.]

|

|

|

3.1.1 |

Allemand-Ross |

The Allemand-Ross project area was previously divided into north and south areas, with North Allemand-Ross historically called the Sand Draw Property and South Allemand-Ross called the North Bear Creek Property. This designation is not utilized by UEC as both areas are now within UEC’s Allemand-Ross project area.

The Allemand-Ross project area is in the PRB in Converse County (Figure 3-2). The Allemand-Ross project area covers all or portions of 21 sections in four townships with legal descriptions as follows:

|

● |

T39N R75W – All of Section 24 and portions of Sections 12, 13 and 25 |

|

● |

T39N R74W – All of Sections 7, 18, 19, 29, 30, 31 and 32 and portions of Sections 17, 20 and 33 |

|

● |

T38N R75W – Portions of Section 12 |

|

● |

T38N R74W – All of Sections 4, 5, 8 and 9 and portions of Sections 6 and 7 |

The Allemand-Ross project area is located approximately 40 air miles northeast of Casper, Wyoming, and is primarily on private surface land with some areas of federal (BLM) or state managed land.

UEC’s mineral holdings in the Allemand-Ross project area include two State of Wyoming uranium leases (318 acres), 452 unpatented lode claims on federally administered minerals (8,518.2 acres) and seven fee (private) mineral leases (2,773.9 acres). These mineral holdings comprise 11,610.1 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

3.1.2 |

Barge |

The Barge project area is in the PRB in Converse County (Figure 3-2). The Barge project area covers all or portions of 18 sections in three townships with legal descriptions as follows:

|

● |

T38N R72W – All of Sections 16, 17 and 18 and portions of Sections 7 and 19 |

|

● |

T38N R73W – All of Sections 2, 3, 10, 11, 12, 13, 14 and 15 and portions of Sections 22, 23 and 24 |

|

● |

T39N R73W – All of Sections 35 and 36 |

The Barge project area is located approximately 50 air miles northeast of Casper, Wyoming, and is primarily on private surface land with some areas of federal (BLM) or state managed land.

UEC’s mineral holdings in the Barge project area include one State of Wyoming uranium lease (640 acres) and 342 unpatented lode claims on federally administered minerals (6,374.2 acres). These mineral holdings comprise 7,014.2 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for the lease and all claims are up to date as of the effective date of this TRS.

|

|

|

3.1.3 |

Charlie |

The Charlie project area is in the PRB in Johnson County (Figure 3-2). It is surrounded by the Christensen Ranch project area. The Charlie project area covers all or portions of two sections in one township with legal description as follows:

|

● |

T45N R77W – All of Section 36 and portions of Section 25 |

The Charlie project area is located approximately 70 air miles north of Casper, Wyoming, and is on private surface land.

UEC’s mineral holdings in the Charlie project area include one State of Wyoming uranium lease (720 acres). Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for the lease are up to date as of the effective date of this TRS.

|

3.1.4 |

Christensen Ranch |

The Christensen Ranch project area is in the PRB in Johnson and Campbell counties (Figure 3‑2). The Christensen Ranch project area is adjacent to the Irigaray project area and surrounds the Charlie project area. The Christensen Ranch project area covers all or portions of 30 sections in 4 townships with legal descriptions as follows:

|

● |

T45N R77W – Portions of Sections 24, 25, 24, 35 and 36 |

|

● |

T45N R76W – All of Sections 30 and 31 and portions of Sections 19, 32 and 33 |

|

● |

T44N R77W – All of Sections 1, 2 and 3 and portions of Sections 10, 11 and 12 |

|

● |

T44N R76W – All of Sections 4, 5, 6, 7, 8, 9, 16, 17, 18, 19, 20 and 21 and portions of Sections 3 and 10 |

The Christensen Ranch project area is approximately 70 air miles north of Casper, Wyoming, and is primarily on private surface land with some areas of federal (BLM) managed land.

UEC’s mineral holdings in the Christensen Ranch project area include one State of Wyoming uranium lease (1,280 acres), 257 unpatented lode claims on federally administered minerals (5,140 acres) and one fee (private) mineral lease (720 acres). These mineral holdings comprise 7,140 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

3.1.5 |

Clarkson Hill |

The Clarkson Hill project area is in the WRB in Natrona County (Figure 3-2). The Clarkson Hill project area covers portions of three sections in one township with legal description as follows:

|

● |

T31N R82W – Portions of Sections 7, 17 and 18 |

The Clarkson Hill project area is located approximately 20 air miles southwest of Casper, Wyoming, and is on private surface land and federal (BLM) managed land.

UEC’s mineral holdings in the Clarkson Hill project area include 25 unpatented lode claims on federally administered minerals (500 acres). Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all claims are up to date as of the effective date of this TRS.

|

|

|

3.1.6 |

Irigaray |

The Irigaray project area is in the PRB in Johnson County (Figure 3-2). The Irigaray CPP, located at the Irigaray project area, will serve as the Project hub. The Irigaray project area covers portions of 12 sections in two townships with legal descriptions as follows:

|

● |

T46N R77W – Portions of Section 29 and 32 |

|

● |

T45N R77W – Portions of Sections 4, 5, 8, 9, 16, 21, 27, 28, 33 and 34 |

The Irigaray project area is located approximately 70 air miles north of Casper, Wyoming, and is primarily on private surface land and federal (BLM) managed land, with a portion located on one section of state managed land.

UEC’s mineral holdings in the Irigaray project area include two State of Wyoming uranium leases (480 acres) and 82 unpatented lode claims on federally administered minerals (1,640 acres). These mineral holdings comprise 2,120 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

3.1.7 |

Jab/West Jab |

The Jab/West Jab project area is in the GGRB in Sweetwater and Fremont counties (Figure 3‑3). The Jab/West Jab project area consists of two separate areas separated by less than two miles. Jab is located entirely in Sweetwater County and covers all or portions of 11 sections in one township as follows:

|

● |

T26N R94W – All of Sections 16 and 21 and portions of Sections 8, 9, 10, 13, 14, 15, 17, 20 and 22 |

West Jab is located in both Sweetwater and Fremont counties and covers all or portions of 11 sections in four townships with legal descriptions as follows:

|

● |

T27N R95W – All of Section 36 and portions of Sections 25, 26 and 35 |

|

● |

T27N R94W – Portions of Sections 30 and 31 |

|

● |

T26N R95W – Portions of Sections 1, 2, 11 and 12 |

|

● |

T26N R94W – Portions of Section 6 |

The Jab/West Jab project area is located approximately 55 air miles northwest of Rawlins, Wyoming, and is on federal (BLM) and state managed land.

UEC’s mineral holdings in the Jab/West Jab project area include three State of Wyoming uranium leases (960 acres) and 217 unpatented lode claims on federally administered minerals (4,483.4 acres). These mineral holdings comprise 5,443.4 acres. Annual holding costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

|

|

3.1.8 |

Ludeman |

The Ludeman project area is in the PRB in Converse County (Figure 3-2). The Ludeman project area covers all or portions of 39 sections in four townships with legal descriptions as follows:

|

● |

T34N R74W – All of Sections 12, 13, 14, 23 and 24 and portions of Section 22 |

|

● |

T34N R73W – All of Sections 3, 4, 5, 7, 8, 9, 10, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 26, 27, 34 and 35 and portions of Sections 2, 6, 11, 24, 25, 28 and 36 |

|

● |

T34N R72W – Portions of Sections 19 and 30 |

|

● |

T33N R73W – Portions of Sections 1, 2 and 3 |

The Ludeman project area is located approximately 30 air miles east of Casper, Wyoming, and is primarily on private surface land with some areas of federal (BLM) or state managed land.

UEC’s mineral holdings in the Ludeman project area include four State of Wyoming uranium leases (1,440 acres), 746 unpatented lode claims on federally administered minerals (17,586.1 acres) and two fee (private) mineral leases (1,741.9 acres). These mineral holdings comprise 20,768 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

3.1.9 |

Moore Ranch |

The Moore Ranch project area is in the PRB in Campbell County (Figure 3-2). The Moore Ranch project area covers all or portions of 16 sections in three townships with legal descriptions as follows:

|

● |

T42N R75W – All of Sections 26, 27, 33, 34, 35 and 36 and portions of Sections 25 and 28 |

|

● |

T42N R74W – Portions of Sections 30 and 31 |

|

● |

T41N R75W – All of Sections 2, 3 and 4 and portions of Sections 1, 9 and 10 |

The Moore Ranch project area is located approximately 55 air miles northeast of Casper, Wyoming, and is primarily on private surface land with some areas of state managed land.

UEC’s mineral holdings within the Moore Ranch project area include two State of Wyoming uranium leases (1,200 acres), 86 unpatented lode claims on federally administered minerals (1,754.1 acres) and five fee (private) mineral leases (1,740 acres). These mineral holdings comprise 4,694.1 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

3.1.10 |

Nine Mile |

The Nine Mile project area is in the PRB in Natrona County (Figure 3-2). The Nine Mile project area covers all or portions of 22 sections in three townships with legal descriptions as follows:

|

● |

T36N R80W – All of Section 36 |

|

● |

T35N R79W – Portions of Sections 6, 7, 8, 9, 10, 14, 16, 17, 20, 21, 22, 26, 27, 28, 29, 32, 33 and 34 |

|

● |

T34N R79W – All of Section 3 and portions of Sections 4 and 10 |

The Nine Mile project area is located approximately 1.5 miles north of Casper, Wyoming, and is on private surface land and state managed land.

UEC’s mineral holdings in the Nine Mile project area include two State of Wyoming uranium leases (1,280 acres), 190 unpatented lode claims on federally administered minerals (3,800 acres) and two fee (private) mineral leases (1,258.6 acres). These mineral holdings comprise 6,339 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

|

|

3.1.11 |

Red Rim |

The Red Rim project area is in the GGRB in Carbon County (Figure 3-3). The Red Rim project area covers all or portions of four sections in two townships with legal descriptions as follows:

|

● |

T19N R90W – Portions of Sections 6, 8 and 18 |

|

● |

T19N R91W - Portions of Section 12 |

The Red Rim project area is located approximately 20 air miles southwest of Rawlins, Wyoming, and is on federal (BLM) managed land.

UEC’s mineral holdings in the Red Rim project area include 49 unpatented federal mining lode claims (1,000 acres). Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all claims are up to date as of the effective date of this TRS.

|

3.1.12 |

Reno Creek |

The Reno Creek project area includes the Bing, Moore, North Reno Creek, Pine Tree and Southwest Reno Creek resource areas. The North Reno Creek and Southwest Reno Creek resource areas are contiguous, consolidated and fully permitted for mining by ISR methods. The Bing, Moore and Pine Tree resource areas are within about five miles of the permitted areas and have not been permitted.

The Reno Creek project area is in the PRB in Campbell County (Figure 3-2). The Reno Creek project area covers all or portions of 45 sections in six townships with legal descriptions as follows:

|

● |

T44N R75W – All of Section 36 |

|

● |

T44N R74W – Portions of Sections 26, 34 and 35 |

|

● |

T43N R74W – All of Sections 3, 9, 16, 17 and 36 and portions of Sections 2, 4, 7, 10, 18, 20, 26, 30, 31, 32, 34 and 35 |

|

● |

T43N R73W – All of Sections 27, 28, 31 and 34 and portions of Sections 21, 22, 29, 30, 32, 33 and 35 |

|

● |

T42N R74W – All of Sections 1, 12 and 16 and portions of Sections 2, 3, 6, 7, 17 and 20 |

|

● |

T42N R73W – All of Sections 6 and 16 and portions of Sections 7 and 10 |

The Reno Creek project area is located approximately 10 air miles southwest of the town of Wright and is primarily on private surface land and state managed land. UEC owns approximately 40 acres of surface land in the Reno Creek project area for a future satellite facility.

UEC’s mineral holdings in the Reno Creek project area include four State of Wyoming uranium leases (3,200 acres), 549 unpatented lode claims on federally administered minerals (10,980 acres) and 36 fee (private) mineral leases (4,583 acres). These mineral holdings comprise 18,763 acres. Annual costs are shown in Table 3-1. UEC has indicated to the QP that payments for all leases and claims are up to date as of the effective date of this TRS.

|

|

|

3.2 |

Encumbrances |

To the QP’s knowledge, there are no unusual encumbrances to the project areas. However, there are general regulatory and permitting requirements, depending on the specific project area. The permitting status of each project area is shown in Table 3-2.

|

Table 3-2: |

Project Area Permitting Status |

|

Project Area |

Permitted |

Not Permitted |

Notes |

|

Allemand-Ross |

✔ |

||

|

Barge |

✔ |

||

|

Charlie |

✔ |

May be able to be incorporated into Christensen Ranch with a permit modification. Active surface mining permit (acquired by Cotter Corporation (Cotter) in 1979). Cotter sought conversion to ISR in 2014, but the process has not been completed. |

|

|

Christensen Ranch |

✔ |

||

|

Clarkson Hill |

✔ |

||

|

Irigaray |

Irigaray CPP |

✔ |

Permitting for the majority of the ISR areas is still required. |

|

Jab/West Jab |

✔ |

Permit application submitted in 2008 but withdrawn. |

|

|

Ludeman |

✔ |

||

|

Moore Ranch |

✔ |

||

|

Nine Mile |

✔ |

Near existing residential development. Land surface includes residential subdivision and is a risk factor for project permitting. |

|

|

Red Rim |

✔ |

||

|

Reno Creek |

North Reno Creek and Southwest Reno Creek resource areas |

Bing, Moore and Pine Tree resource areas |

|

|

The environmental liability for the Project falls under jurisdiction of the WDEQ/LQD, which regulates the Permit to Mine and the Source and Byproduct Materials License. Portions of the Project that are located on federal surfaces would require an approved Plan of Operations from the BLM; this would include wildlife considerations such as greater sage-grouse, which could limit development of resources in some areas.

Other potential permitting requirements, depending on the status of each project area, may include:

|

● |

Source and Byproduct Materials License (WDEQ/Uranium Recovery Program [under LQD]); |

|

● |

Wetland delineation and mitigation as required by the U.S. Army Corps of Engineers, in applicable locations; |

|

● |

Aquifer exemption (40 CFR 144, 146) for Class III Underground Injection Control (UIC) to be issued by the U.S. Environmental Protection Agency (EPA); |

|

● |

Air quality permits from WDEQ/Air Quality Division (WDEQ/AQD) for applicable facility construction activities; |

|

● |

Groundwater reclassification, if necessary, would be approved by WDEQ/Water Quality Division (WDEQ/WQD) (Wyoming Statutes Title 35-11) as part of the aquifer exemption process; |

|

● |

EPA Subpart W pond construction permits would be required to construct holding ponds; |

|

● |

If water management will utilize deep disposal, a Class I UIC Permit (deep disposal well) must be approved by WDEQ/WQD (Wyoming Statutes Title 35-11); |

|

● |

A Class III UIC Permit to Mine and Class III UIC Permit would be approved by WDEQ/WQD as the primary Permit to Mine to allow injection, recovery and processing of fluids (Wyoming Statutes Title 35-11); |

|

● |

Class V UIC permits may be required for any site septic systems (Wyoming Statutes Title 35-11); |

|

● |

Construction stormwater NPDES permits must be obtained annually for projected construction activities (Wyoming Statutes Title 35-11); |

|

● |

Industrial stormwater NPDES permits would be required in CPP and satellite areas (Wyoming Statutes Title 35-11); and |

|

● |

Groundwater appropriations would be obtained from the Wyoming State Engineer’s Office prior to the installation of water supply wells and ISR wellfields. |

|

|

|

3.3 |

Property Risk Factors |

A variety of property risk factors exist but are not unique to the specific project areas. Many uranium deposits occur in relatively compact special areas. Large horizontal well pads or wind turbine pads sited on top of mineralization could limit the ability to access resources. Oil and gas development or wind turbines are common in Wyoming. Examples of property risk factors are included in the following list, with descriptions of each risk:

|

● |

Commercial oilfield waste disposal facilities (COWDFs) and/or lined ponds |

|

o |

COWDFs or other lined ponds may limit surface access and could impact optimal placement of wellfields. It is the opinion of the QP that COWDFs and other lined ponds present a low risk of impacting development of the resources. |

|

● |

Commercial wind power |

|

o |

Commercial wind power could limit surface accessibility and impact optimal placement of wellfields. There are project areas where the average annual wind speed at 80 meters is suitable for commercial wind development. It is the opinion of the QP that there is a low to moderate risk that commercial wind power could limit development of resources. |

|

● |

Industrial wells impacting aquifers |

|

o |

Industrial wells could impact available water in target aquifers but will not impact the resources. It is the opinion of the QP that industrial wells present a low risk of impacting development of the resources. |

|

● |

Oil and gas horizontal pads and development |

|

o |

Aquifer dewatering due to shallow water supply wells to produce water used in oil and gas operations could impact target aquifers. Large horizontal wellpads could limit surface accessibility and placement of wellfields. A site-specific discussion is provided below: |

|

■ |

Allemand–Ross – This project area is spaced for horizontal development with some historical production. It is the opinion of the QP that there is moderate to high risk of impact to resource access. |

|

■ |

Barge – This project area is spaced for horizontal development with some active drilling and minor horizontal production. It is the opinion of the QP that there is moderate to high risk of impact to resource access. The QP was unable to complete a site visit due to surface access limitations. Since the QP was unable to observe the project area and confirm unobstructed access to mineral trends, additional risk to resource access could be present due to oil and gas development. |

|

■ |

Charlie – The project area is not spaced for horizontal development, although minor historical conventional production from the Shannon and Parkman formations has occurred. It is the opinion of the QP that there is low to moderate risk of impact to resource access. |

|

■ |

Christensen Ranch – The project area is not spaced for horizontal development, although minor historical conventional production from the Shannon Formation has occurred. It is the opinion of the QP that there is low to moderate risk of impact to resource access. |

|

|

|

■ |

Clarkson Hill – This project area is not spaced for horizontal development and no historical production or exploration has occurred. It is the opinion of the QP that there is low risk of impact to resource access. |

|

■ |

Irigaray – A portion of the project area is spaced for horizontal development and some historical development has occurred. It is the opinion of the QP that there is low to moderate risk of impact to the resource access due to the federally controlled surface land in the southern portion of the mineralized resource area. |

|

■ |

Jab/West Jab – This project area is not spaced for horizontal pads. There has been little exploration and no production. Hydrocarbons are likely present in the Lewis, Mesaverde and Ericson formations. It is the opinion of the QP that there is a low risk of impacts to resource access. |

|

■ |

Ludeman – The project area is spaced for horizontal development; however, little production has occurred. It is the opinion of the QP that there is moderate to high risk of impact to resource access. |

|

■ |

Moore Ranch – This project area is spaced for horizontal development with some historical production. It is the opinion of the QP that there is moderate to high risk of impact to resource access. |

|

■ |

Nine Mile – This project area is not spaced for horizontal development and no historical production or exploration has occurred. It is the opinion of the QP that there is low risk of impact to resource access. |

|

■ |

Red Rim - This project area is not spaced for horizontal development and no historical production or exploration has occurred. It is the opinion of the QP that there is low risk of impact to resource access. |

|

■ |

Reno Creek – This project area has historical production as well as additional oil and gas wells that are permitted or waiting on permits. It is the opinion of the QP that there is moderate to high risk of impact to resource access. |

|

● |

Surface Development |

|

o |

Where surface ownership of a project area is held by a large number of private entities, there may be challenges to obtaining sufficient surface use agreements (SUAs) for a project, or there may be opposition to a project where it could impact surface use such as residential use. |

|

■ |

Nine Mile – There are currently multiple landowners, including agricultural operators, land development companies and residential property owners. Surface ownership has been subdivided for residential development in T35N R79W Sections 9, 10, 14, 22, 26, 27 and 34. The multiple property owners and residential land use creates potential risk of not being able to obtain sufficient SUAs for the project and for opposition to a Wyoming Permit to Mine. |

|

3.4 |

Royalties (Confidential) |

Due to the confidentiality of royalties in private agreements, these data are not included in the TRS. Royalties will be provided upon request.

|

|

|

4.0 |

ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

|

4.1 |

Physical Setting |

|

4.1.1 |

Powder River Basin |

The Allemand-Ross, Barge, Charlie, Christensen Ranch, Irigaray, Ludeman, Moore Ranch, Nine Mile and Reno Creek project areas are located in the PRB in the counties shown in Table 1‑1. These project areas are in the southern portion of the PRB and generally lie near the synclinal axis of the basin. The exception is the Nine Mile project area, which is near the Casper Arch. The Casper Arch marks the southwestern boundary of the PRB.

The PRB is a part of the Northwestern Great Plains ecoregion (U.S. EPA, 2013), a semiarid rolling plain of shale and sandstone punctuated by occasional buttes. The project areas are characterized as rolling prairie and dissected river breaks. Regional structural features include the Big Horn Mountains to the west, Casper Arch to the south and the Black Hills to the east. At the northernmost project areas in the PRB, the landscape is dominated by the Pumpkin Buttes.

Topography in the area ranges from generally flat to gently rolling hills with numerous drainages containing ephemeral streams that dissect the area. Elevations range from approximately 4,500 to 5,400 ft above mean sea level.

Vegetation within the project areas consists primarily of grassland with areas of sagebrush. Some of the project areas lie within the mixed grass ecoregion of the Northwestern Great Plains. Interspersed among these major vegetation communities, within and along the ephemeral drainages, are grasslands and meadow grasslands and less abundant types of seeded grasslands (improved pastures).

The project areas in the PRB are located in a semi-arid or steppe climate. The region is characterized by cold, harsh winters and hot, dry summers. The spring season is relatively warm and moist, and autumns are cool. Temperature extremes range from roughly -25 °F in the winter to 100 °F in the summer. Typically, the “last freeze” occurs during late May, and the “first freeze” occurs in mid- to late September (Curtis and Grimes, 2004).

Yearly precipitation averages about 13 inches. The region is prone to severe thunderstorm events throughout the spring and early summer months, and much of the precipitation is attributed to these events. Snow falls throughout the winter months (approximately 40 to 50 inches per year) but provides much less moisture than rain events (Curtis and Grimes, 2004).

|

4.1.2 |

Greater Green River Basin |

The Jab/West Jab and Red Rim project areas are located in the GGRB in the counties shown in Table 1-1. The project areas are in the northeast portion of the GGRB. The GGRB is a structural basin that encompasses nearly 21,000 square miles in southwest Wyoming and northwest Colorado. Regional structural features include the Wyoming thrust belt to the west, the Rawlins Uplift and the Sierra Madre Mountains to the east, the Wind River Mountains to the north and the Uinta Mountains to the south.

|

|

The topography at the Jab/West Jab project area ranges from flat plains to gentle slopes that are dissected by southerly-flowing ephemeral washes. Elevations in the area range from approximately 6,900 to 7,400 ft above mean sea level. Topography at the Red Rim project area includes the Red Rim, a prominent low-lying ridge with a southwest/northeast orientation, and Separation Creek, which generally forms the southern boundary of the project area. Elevations range from approximately 6,000 to slightly over 7,000 ft above mean sea level.

The Jab/West Jab and Red Rim project areas are located in the Wyoming Basin Level III ecoregion (U.S. EPA, 2013) and are characterized as rolling sagebrush steppe. This ecoregion is a broad intermontane basin interrupted by hills and low mountains and dominated by arid grasslands and shrublands. Vegetation on the Jab/West Jab project area mostly consists of sagebrush, but includes some native perennial grasses, cushion plants, cacti, perennial forbs and lichens. The Red Rim project area is rangeland with vegetation consisting primarily of sagebrush and grasses.

Yearly precipitation in the area is approximately 8 to 12 inches (Curtis and Grimes, 2004). Precipitation is predominantly in the form of late autumnal to early spring snows. The summer months are usually hot with temperature occasionally exceeding 100 °F, dry and clear except for infrequent rains. Winter conditions can be severe and can include sub-zero temperatures and ground blizzards.

|

4.1.3 |

Wind River Basin |

The Clarkson Hill project area is in the WRB in Natrona County, Wyoming. Clarkson Hill is located near the southern and eastern margin of the WRB just west of the Casper Arch, which separates the PRB and WRB. The Clarkson Hill project area is located in a broad synclinal valley northeast of the North Granite Mountain Fault. The project area extends from the base to the top of a small mesa known as Clarkson Hill.

Clarkson Hill is located in the Wyoming Basin Level III ecoregion (U.S. EPA, 2013), which is characterized as rolling sagebrush steppe. This ecoregion is a broad intermontane basin interrupted by hills and low mountains and dominated by arid grasslands and shrublands.

The top of the mesa is relatively flat, with an elevation of approximately 6,200 ft above mean sea level. The mesa has approximately 200 ft of vertical relief with some relatively steep slopes, in excess of 3:1 (horizontal to vertical). The currently defined area of mineralization is at the base and along the slope of the mesa.

The most common native vegetation is sagebrush and prairie grasses and, to a lesser extent, rabbitbrush. No threatened or endangered plants are known in the area. Limited upland areas have juniper and limber pine trees on north-facing slopes. Most drainages in the area are ephemeral, flowing only during storm events or spring snow melt. The North Platte River, some four to five miles south of the project area, is perennial and is one of the major river systems in Wyoming.

The climate at the Clarkson Hill project area is continental semi-arid, with annual precipitation of 8-12 inches, mostly falling in the form of late autumnal to early spring snows. The summer months are usually hot with temperature occasionally exceeding 100 ºF, dry and clear except for infrequent rains. Winter conditions can be severe and can include sub-zero temperatures and ground blizzards.

|

|

|

4.2 |

Accessibility and Local Resources |

Since the Project includes multiple assets in seven Wyoming counties, there are multiple accessibility and resource options for the various project areas. All of the project areas are accessible and capable of operating year-round given appropriate maintenance of project roads.

Workforce personnel will commute daily from nearby small communities or the larger population centers noted for each property below. The communities included in the Project area have a long history of oil and gas development and uranium and coal mining. The major population centers have adequate workforce skilled in mining and mineral exploration to support the Project. The major population centers of Gillette, Casper, Rawlins, and Rock Springs have adequate oilfield and mining service companies, heavy equipment sales and rentals, drilling and pump contractors, construction contractors and industrial supply companies to serve the Project.

The PRB project areas in Johnson and Campbell counties include Charlie, Christensen Ranch, Irigaray, Moore Ranch and Reno Creek. The nearest community is Wright, which is approximately 9 to 32 miles from the project areas. Wright is a small, incorporated town with a population of 1,644 (U.S. Census Bureau, 2020) at the junction of Wyoming Highway 387 and Wyoming Highway 59. Gillette is a major local population center with a population of 33,403 and a regional airport. Gillette is located along Interstate 90, north and east of the project areas via both Wyoming Highway 59 (due north of Wright) and Wyoming Highway 50. The towns of Edgerton and Midwest are in Natrona County, approximately 20 to 30 miles southwest of the project areas on Wyoming Highway 387. A major north–south railroad, BNSF Railway (BNSF), used primarily for transporting coal, is located between 11 and 34 miles east of the project areas and parallel to Wyoming Highway 59.

The PRB project areas in Converse County include Allemand-Ross, Barge and Ludeman. These project areas are near the communities of Glenrock and Douglas. They can be accessed from Interstate 25 via Wyoming Highway 95 from Glenrock, Wyoming Highway 93 from Douglas, or Wyoming Highway 59 from Douglas. The Converse County project areas are approximately 8 to 30 miles from Glenrock. Glenrock is an incorporated town with a population of 2,420 (U.S. Census Bureau, 2020) adjacent to Interstate 25. Douglas is an incorporated town with a population of 6,386 also along Interstate 25. Casper is a major population center with a population of 59,038 (U.S. Census Bureau, 2020) and a regional airport. Casper is southwest or west of these project areas and can be accessed by state highways to Interstate 25. The same north-south BNSF rail line that runs parallel to Wyoming Highway 59 is eight miles east of the Barge project area and 20 miles east of the Allemand-Ross project area. An east-west railway owned by BNSF is in close proximity to the Ludeman project area, to the south near Interstate 25.

The PRB Nine Mile project area is located in Natrona County near Casper. The Nine Mile project area is bisected by Interstate 25 and is accessible from the Salt Creek Highway, which parallels Interstate 25, and from County Road 705. Casper is located 1.5 miles south of the Nine Mile project area. The east-west railway owned by BNSF is approximately five miles south of the project area.

|

|

The GGRB Jab/West Jab project area is located in Sweetwater and Fremont counties. The Jab/West Jab project area can be accessed from State Highway 287 via Bairoil Road (County Road 22) from Bairoil. The project area is approximately 22 miles west of Bairoil, a small, incorporated town with a population of 68 (U.S. Census Bureau, 2020). The project area is approximately 50 air miles northwest of Rawlins, an incorporated community with a population of 8,221 on Interstate 80. Casper can be accessed from state highways via Bairoil. A major east-west railway (the Union Pacific) lies approximately 40 air miles south of the Jab/West Jab project area in Wamsutter, near Interstate 80.

The GGRB Red Rim project area is located in Carbon County and can be accessed from Interstate 80 via Daley and Hadsell roads, or from Rawlins via Carbon County Road 605. The Red Rim project area is approximately 18 miles southwest of Rawlins. Rock Springs, an incorporated city with a population of 23,526 (U.S. Census Bureau 2020), is located on Interstate 80 approximately 100 miles from the project area. The Union Pacific railway lies approximately seven miles north of the project area, near Interstate 80.

The WRB Clarkson Hill project area is located in Natrona County, approximately 19 miles southwest of Casper. The project area is accessible from either Highway 220 or from the Oregon Trail Road, a Natrona County improved gravel road. From Highway 220, the site is approximately four miles northwest of the junction of the highway with Natrona County Road 318. From the Oregon Trail Road, the site is approximately three miles to the southeast. Site access from either route will require an arrangement with intervening private landowners for ingress/egress. The communities of Alcova and Bessemer Bend are located 10 and 13 miles away, respectively, and have limited services. The east-west BNSF railway in Casper is approximately 25 miles northeast of the project area.

|

4.3 |

Availability of Infrastructure |

Equipment and supplies needed for exploration and day-to-day operation are available from population centers such as Gillette, Casper, Rawlins, and Rock Springs. Specialized equipment for the wellfields or the Irigaray CPP will likely need to be acquired from outside the state.

The local economy is geared toward coal mining and oil and gas production as well as ranching operations, providing a well-trained and capable pool of workers for ISR production and processing operations. Workers will reside locally and commute to work daily.

As a result of energy development over the past 50 years, all of the project areas with the exception of Red Rim have existing or nearby (less than two miles) electrical power, gas and adequate telephone and internet connectivity.

At the Allemand-Ross project area, non-potable water will be supplied by wells developed on or near the project area. The Allemand-Ross project area is adjacent to all-weather roadways, which facilitate the transportation of equipment, supplies, personnel and product. Electrical power lines extend into and across the project area.

Near the Barge project area, historical uranium operations in the late 1970s and early 1980s brought access and electrical power to the area, which remain. Water supply needs to be reestablished in the Barge project area. The Barge project area is adjacent to all-weather roadways, which facilitate the transportation of equipment, supplies, personnel and product.

Development of the Charlie project area will require power and water supply. Infrastructure in the immediate vicinity includes an electrical substation and coal-bed methane gas plant. Water may be provided by wells. There is also a 14.4 kVa electrical supply operated by the Sheridan-Johnson Rural Electrical Association, approximately two miles from the project. Since the Charlie project area is surrounded by the Christensen Ranch project area, the two project areas may share infrastructure.

|

|

The Christensen Ranch project area is equipped with a satellite ion exchange (IX) plant with 6,500 gpm installed capacity, a groundwater restoration plant with 1,000 gpm capacity, two wastewater disposal wells and four lined evaporation ponds.

No infrastructure has been developed at the Clarkson Hill project area. ISR development will require power and water supply. A utility corridor exists along the Oregon Trail Road, including power and gas transmission lines. The principal access roads to the project area are maintained and year-round access is possible. Water supply could be obtained from locally permitted and constructed wells or from surface water sources including the Platte River, which is located approximately three miles east of the project area.

The Irigaray CPP is a fully operational and licensed ISR processing plant for resin elution, precipitation, filtration and drying and packaging of U3O8. The Irigaray CPP has a capacity of 1.3 million lbs U3O8 per year, which is expandable to 2.5 million lbs U3O8 per year. A second elution system is also at the Irigaray CPP for toll processing. The Irigaray CPP is equipped with a warehouse and office, power, telephone, water tank and domestic waste disposal. Loaded resin from each of the “spoke” project areas described in Chapter 3.1 would be transported to the Irigaray CPP “hub” for final concentrate production.

Limited infrastructure is available within the Jab/West Jab project area. A water supply well was permitted and installed during development drilling. The project area is within 6 to 10 miles of a county road, electrical power and natural gas transmission lines. Nearby infrastructure will be beneficial to future development. The county roads will facilitate the transportation of equipment, supplies, personnel and products.

The Ludeman project area has been used historically for livestock grazing. Nearby uranium operations have occurred historically. Non-potable water will be supplied by wells developed on or near the project area. The proximity of the Ludeman project area to paved roads will facilitate transportation of equipment, supplies, personnel and product. High voltage transmission lines from the Dave Johnston Power Plant pass within the project area.

At the Moore Ranch project area, non-potable water will be supplied by wells developed on or near the project area. The Moore Ranch project area is adjacent to paved, public roadways, which facilitate the transportation of equipment, supplies, personnel and product. Electrical power lines extend into and across the project area.

Infrastructure is present within and/or proximate to the Nine Mile project area. ISR development will require power and water supply. Infrastructure, including power lines and water wells, was established for past pilot ISR mining operations and currently exists for nearby residents in the Homa Hills area. Water supply may be provided by locally permitted and constructed wells.

Aside from existing access roads, no infrastructure has been developed at the Red Rim project area. ISR development will require better access roads, power and a water supply. The Red Rim project area previously had single phase line power and a water supply developed for exploration. Water may be developed from locally permitted and constructed wells.

|

|

UEC owns approximately 40 acres of surface land in the Reno Creek project area, near the intersection of Wyoming Highway 387 and Clarkelen County Road, for a future satellite facility. This land is equipped with a warehouse and office, power, telephone, water tank and domestic waste disposal. A well will be drilled to provide potable water for the Reno Creek project area.

[The remainder of this page is intentionally left blank.]

|

|

|

5.0 |

HISTORY |

Uranium was first discovered in the southern PRB during the early 1950s. By the mid- to late 1950s, small open-pit mine operations were established in the PRB. Early prospecting and exploration included geologic mapping and gamma surveys, which led to discoveries of uranium in the Wasatch and Fort Union formations. Extensive drill hole exploration has been utilized since the 1960s to locate deeper uranium mineralization and progress geologic models.

Uranium mineralization was discovered in the GGRB at the Lost Creek Schoekingerite deposits in the early 1950s. The Schoekingerite deposits were exposed at the surface along the Lost Creek drainage and were discovered using radiometric surveys. The U.S. Geological Survey (USGS) used shallow exploration to further evaluate the deposits. As in the PRB, drilling for deeper deposits began in the 1960s, and exploration since that time has consisted primarily of drilling.

Uranium exploration of the WRB began in 1953 with scintillation counter surveys of the Eocene Wind River Formation in the Gas Hills area (Gregory, 2019). In the mid-1950s, USGS, on behalf of the U.S. Atomic Energy Commission (AEC), studied uranium occurrence and potential in the Clarkson Hill area (Rich, 1962). Near surface uranium mineralization in the Wind River Formation was explored in the 1950s with shallow excavations. Later drilling defined deeper mineralization within the Fort Union Formation near the contact with the Lance Formation.

Ownership, control and operation of the project areas has varied greatly since the 1960s. Table 5-1 summarizes the operations and activities of various companies, the timeframe during which these activities were completed and the results of the work. Table 5-1 also summarizes historical drilling and the number of drill holes completed during each period.

[The remainder of this page is intentionally left blank.]

|

|

|

Table 5-1: |

Past Operations Summary |

|

Year |

Company |

Operations/Activity |

Amount (No. of Drill holes) |

Results of Work |

|

Allemand-Ross |

||||

|

1967-1970 |

Kerr-McGee Nuclear (Kerr-McGee), Homestake Mining Corp (Homestake), Teton Exploration (Teton) |

Early uranium exploration completed by the three companies in the Allemand-Ross project area. Exploration was typically for shallower mineralization (<1,000 ft). |

~100 |

Exploration of shallow mineralization (<1,000 ft) |

|

1971-1984 |

Conoco |

Conoco staked lode mining claims in 1969. In 1970, Conoco entered an agreement with National Resources Corporation (National Resources) to earn in on the Allemand-Ranch land holdings. National Resources’ interests were acquired by Pioneer Nuclear in 1972 and the joint venture partnership was maintained until 1975. In 1979, Conoco formed an association with Power Reactor & Nuclear Fuel Development Corporation (PNC). Conoco continued to operate the drilling program. Conoco closed its mineral department in 1984. |

~1,180 |

Delineation of a significant amount of the mineralization within the Allemand-Ross project area |

|

1984-1988 |

PNC |

PNC assumed control of the Allemand-Ross project area and continued exploration. |

~50 |

Additional exploration completed by PNC |

|

Early 1990s |

PNC |

Mineral rights were allowed to lapse due to further declining uranium market conditions. |

N/A |

Lost mineral rights |

|

Early 2000s-2005 |

High Plains Uranium (HPU) and Energy Metals Corporation (EMC) |

Claims and leases were acquired during the uranium market upswing. HPU held most claims and leases, with EMC holding the remainder of the Allemand-Ross project area. |

N/A |

Mineral rights acquired |

|

2007 |

EMC |

EMC acquired HPU. The properties were consolidated. |

N/A |

Properties consolidated |

|

Late 2007-2021 |

Uranium One Americas, Inc. (Uranium One) |

Uranium One acquired EMC. Uranium One proceeded to conduct verification and resource enhancement drilling. Most drilling was completed between 2008 and 2010. |

~300 |

Additional exploration completed within project areas with average depths ranging from 1,118 to 1,546 ft |

|

2021 |

UEC |

Allemand-Ross project area acquired by UEC from Uranium One. |

N/A |

Ownership transition |

|

|

|

Table 5-1: |

Past Operations Summary (Continued) |

|

Year |

Company |

Operations/Activity |

Amount (No. of Drill holes) |

Results of Work |

|

Barge |

||||

|

1969 |

Mono Power Company (Mono) and Rocky Mountain Energy Company (RME) |