Exhibit 99.1

HUDBAY MINERALS INC.

ANNUAL INFORMATION FORM

FOR THE

YEAR ENDED DECEMBER 31, 2013

March 28, 2014

TABLE OF CONTENTS

|

FORWARD-LOOKING INFORMATION |

1 |

|

INFORMATION CONCERNING AUGUSTA |

3 |

|

NOTE TO UNITED STATES INVESTORS |

3 |

|

CAUTIONARY NOTE IN RESPECT OF THE OFFER |

3 |

|

CURRENCY AND EXCHANGE RATES |

4 |

|

OTHER IMPORTANT INFORMATION |

4 |

|

CORPORATE STRUCTURE |

4 |

|

Incorporation and Registered Office |

4 |

|

Intercorporate Relationships |

5 |

|

DEVELOPMENT OF OUR BUSINESS |

5 |

|

Strategy |

5 |

|

Three Year History |

5 |

|

DESCRIPTION OF OUR BUSINESS |

8 |

|

General |

8 |

|

Material Mineral Projects |

9 |

|

Other Assets |

14 |

|

Other Information |

16 |

|

CORPORATE SOCIAL RESPONSIBILITY |

18 |

|

RISK FACTORS |

20 |

|

DESCRIPTION OF CAPITAL STRUCTURE |

31 |

|

Common Shares |

31 |

|

Preference Shares |

31 |

|

Senior Unsecured Notes |

32 |

|

Credit Ratings |

32 |

|

DIVIDENDS |

34 |

|

MARKET FOR SECURITIES |

34 |

|

Price Range and Trading Volume |

34 |

|

Prior Sales |

35 |

|

DIRECTORS AND OFFICERS |

35 |

|

Board of Directors |

35 |

|

Executive Officers |

36 |

|

Corporate Cease Trade Orders, Bankruptcies, Penalties and Sanctions |

38 |

|

Conflicts of Interest |

39 |

|

AUDIT COMMITTEE DISCLOSURE |

39 |

|

LEGAL PROCEEDINGS AND REGULATORY ACTIONS |

41 |

|

INTEREST OF MANAGEMENT AND OTHERS IN MATERIAL TRANSACTIONS |

43 |

|

TRANSFER AGENT AND REGISTRAR |

43 |

|

MATERIAL CONTRACTS |

43 |

|

QUALIFIED PERSONS |

43 |

|

INTERESTS OF EXPERTS |

43 |

|

ADDITIONAL INFORMATION |

44 |

|

SCHEDULE A GLOSSARY OF MINING TERMS |

1 |

|

SCHEDULE B MATERIAL MINERAL PROJECTS |

1 |

|

AUDIT COMMITTEE CHARTER |

1 |

FORWARD-LOOKING INFORMATION

This annual information form (“AIF”) contains “forward-looking statements” and “forward-looking information” (collectively, “forward-looking information”) within the meaning of applicable Canadian and United States securities legislation. All information contained in this AIF, other than statements of current and historical fact, is forward-looking information. Often, but not always, forward-looking information can be identified by the use of words such as “plans”, “expects”, “budget”, “guidance”, “scheduled”, “estimates”, “forecasts”, “strategy”, “target”, “intends”, “objective”, “goal”, “understands”, “anticipates” and “believes” (and variations of these or similar words) and statements that certain actions, events or results “may”, “could”, “would”, “should”, “might” “occur” or “be achieved” or “will be taken” (and variations of these or similar expressions). All of the forward-looking information in this AIF is qualified by this cautionary note.

Forward looking information includes, but is not limited to, statements with respect to the anticipated timing, mechanics, completion and settlement of the Offer (as defined below) to acquire all of the issued and outstanding shares of Augusta Resource Corporation (“Augusta”), the market for and listing of the common shares we may issue pursuant to the Offer, the value of our common shares that may be received as consideration under the Offer, our ability to complete the transactions contemplated by the Offer, the permitting, development and financing of Augusta’s Rosemont copper project (the “Rosemont Project”), the purpose of the Offer, the completion of any compulsory acquisition or subsequent acquisition transaction in connection with the Offer and any commitment to acquire outstanding shares of Augusta, our objectives, strategies, intentions, expectations and guidance and future financial and operating performance and prospects, our expectation as to the use of proceeds from the recently completed equity offering, production at our 777, Lalor and Reed mines and initial production from the Constancia project, continued processing at our Flin Flon concentrator, Snow Lake concentrator and Flin Flon zinc plant, our ability to complete the development of our Lalor, Constancia and Reed projects and the anticipated scope and cost of any development plans for these projects, anticipated timing of our projects and events that may affect our projects, including the anticipated issue of required licenses and permits, our expectation that we will receive the remaining deposit amount under our amended precious metals stream transaction with Silver Wheaton Corp. (“Silver Wheaton”) and additional funding under our equipment financing transaction with Caterpillar Financial Services Corporation (“CAT Financial”), expectations with respect to additional credit facilities, the anticipated effect of external factors on revenue, such as commodity prices, anticipated exploration and development expenditures and activities and the possible success of such activities, estimation of mineral reserves and resources, mine life projections, timing and amount of estimated future production, reclamation costs, economic outlook, government regulation of mining operations, and business and acquisition strategies.

Forward-looking information is not, and cannot be, a guarantee of future results or events. Forward-looking information is based on, among other things, opinions, assumptions, estimates and analyses that, while considered reasonable by us at the date the forward-looking information is provided, inherently are subject to significant risks, uncertainties, contingencies and other factors that may cause actual results and events to be materially different from those expressed or implied by the forward-looking information.

The material factors or assumptions that we identified and were applied by us in drawing conclusions or making forecasts or projections set out in the forward looking information include, but are not limited to:

· the success of mining, processing, exploration and development activities;

· the accuracy of geological, mining and metallurgical estimates;

· the costs of production;

· the supply and demand for metals we produce;

· no significant and continuing adverse changes in financial markets, including commodity prices and foreign exchange rates;

· the supply and availability of concentrate for our processing facilities;

· the supply and availability of reagents for our concentrators;

· the availability of third party processing facilities for our concentrate;

· the supply and availability of all forms of energy and fuels at reasonable prices;

· the availability of transportation services at reasonable prices;

· no significant unanticipated operational or technical difficulties;

· the execution of our business and growth strategies, including the success of our strategic investments and initiatives;

· the availability of financing for our exploration and development projects and activities;

· the ability to complete project targets on time and on budget and other events that may affect our ability to develop our projects;

· the timing and receipt of various regulatory and governmental approvals;

· the availability of personnel for our exploration, development and operational projects and ongoing employee relations;

· our ability to secure required land rights to complete our Constancia project;

· maintaining good relations with the communities in which we operate, including the communities surrounding our Constancia project and First Nations communities surrounding our Lalor and Reed projects;

· no significant unanticipated challenges with stakeholders at our various projects;

· no significant unanticipated events or changes relating to regulatory, environmental, health and safety matters;

· no contests over title to our properties, including as a result of rights or claimed rights of aboriginal peoples;

· the timing and possible outcome of pending litigation and no significant unanticipated litigation;

· certain tax matters, including, but not limited to current tax laws and regulations and the refund of certain value added taxes from the Canadian and Peruvian governments;

· no significant and continuing adverse changes in general economic conditions or conditions in the financial markets; and

· the accuracy of Augusta’s public disclosure.

The risks, uncertainties, contingencies and other factors that may cause actual results to differ materially from those expressed or implied by the forward-looking information may include, but are not limited to, the impact of the issuance of our common shares as consideration under the Offer on the market price of our common shares, the development of the Rosemont Project not occurring as planned, the exercising of dissent and appraisal rights by Augusta shareholders should a compulsory acquisition or subsequent acquisition transaction be undertaken in connection with the Offer, Augusta becoming a minority-owned or majority-owned subsidiary of Hudbay after consummation of the Offer, the possibility that Hudbay may remain a minority shareholder of Augusta after consummation of the Offer without the ability to control the management or direction of Augusta, the inaccuracy of Augusta’s public disclosure upon which the Offer is predicated, the triggering of change of control provisions in Augusta’s agreements leading to adverse consequences, the failure to obtain the required approvals or clearances from government authorities on a timely basis, risks generally associated with the mining industry, such as economic factors (including future commodity prices, currency fluctuations, energy prices and general cost escalation), uncertainties related to the development and operation of our projects (including the impact on project cost and schedule of construction delays and unforeseen risks and other factors beyond our control), depletion of our reserves, risks related to political or social unrest or change and those in respect of aboriginal and community relations, rights and title claims, operational risks and hazards, including unanticipated environmental, industrial and geological events and developments and the inability to insure against all risks, failure of plant, equipment, processes, transportation and other infrastructure to operate as anticipated, compliance with government and environmental regulations, including permitting requirements and anti-bribery legislation, dependence on key personnel and employee relations, volatile financial markets that may affect our ability to obtain financing on acceptable terms, uncertainties related to the geology, continuity, grade and estimates of mineral reserves and resources and the potential for variations in grade and recovery rates, uncertain costs of reclamation activities, our ability to comply with our pension and other post-retirement obligations, our ability to abide by the covenants in our debt instruments or other material contracts, tax refunds, hedging transactions, as well as the risks discussed under the heading “Risk Factors”.

Should one or more risk, uncertainty, contingency or other factor materialize or should any factor or assumption prove incorrect, actual results could vary materially from those expressed or implied in the forward-looking information. Accordingly, you should not place undue reliance on forward-looking information. We do not assume any obligation to update or revise any forward-looking information after the date of this AIF

or to explain any material difference between subsequent actual events and any forward-looking information, except as required by applicable law.

INFORMATION CONCERNING AUGUSTA

Except as otherwise expressly indicated herein, the information concerning Augusta contained in this AIF has been taken from and is based solely upon Augusta’s public disclosure on file with the relevant securities regulatory authorities. Augusta has not reviewed this document and has not confirmed the accuracy and completeness of the information in respect of Augusta contained in this AIF. Although we have no knowledge that would indicate that any information or statements contained in this AIF concerning Augusta taken from, or based upon, such public disclosure contain any untrue statement of a material fact or omit to state a material fact that is required to be stated or that is necessary to make a statement not misleading in light of the circumstances in which it was made, none of our directors or officers have verified the accuracy or completeness of such information or statements or are aware of any failure by Augusta to disclose events or facts which may have occurred or which may affect the significance or accuracy of any such information or statements. We have no means of verifying the accuracy or completeness of any of the information contained herein that is derived from Augusta’s publicly available documents or records or whether there has been any failure by Augusta to disclose events that may have occurred or may affect the significance or accuracy of any information. Except as otherwise indicated, information concerning Augusta is given based on information in Augusta’s public disclosure available as of the date of the Offer.

NOTE TO UNITED STATES INVESTORS

This AIF has been prepared in accordance with the requirements of the securities laws in effect in Canada, which may differ materially from the requirements of United States securities laws applicable to U.S. issuers.

Information concerning our mineral properties has been prepared in accordance with the requirements of Canadian securities laws, which differ in material respects from the requirements of the Securities and Exchange Commission (the “SEC”) set forth in Industry Guide 7. Under the SEC’s Industry Guide 7, mineralization may not be classified as a “reserve” unless the determination has been made that the mineralization could be economically and legally produced or extracted at the time of the reserve determination, and the SEC does not recognize the reporting of mineral deposits which do not meet the SEC Industry Guide 7 definition of “Reserve”. In accordance with National Instrument 43-101 — Standards of Disclosure for Mineral Projects (“NI 43-101”) of the Canadian Securities Administrators, the terms “mineral reserve”, “proven mineral reserve”, “probable mineral reserve”, “mineral resource”, “measured mineral resource”, “indicated mineral resource” and “inferred mineral resource” are defined in the Canadian Institute of Mining, Metallurgy and Petroleum (the “CIM”) Definition Standards for Mineral Resources and Mineral Reserves adopted by the CIM Council on December 11, 2005. While the terms “mineral resource”, “measured mineral resource”, “indicated mineral resource” and “inferred mineral resource” are recognized and required by NI 43-101, the SEC does not recognize them. You are cautioned that, except for that portion of mineral resources classified as mineral reserves, mineral resources do not have demonstrated economic value. Inferred mineral resources have a high degree of uncertainty as to their existence and as to whether they can be economically or legally mined. It cannot be assumed that all or any part of an inferred mineral resource will ever be upgraded to a higher category. Therefore, you are cautioned not to assume that all or any part of an inferred mineral resource exists, that it can be economically or legally mined, or that it will ever be upgraded to a higher category. Likewise, you are cautioned not to assume that all or any part of measured or indicated mineral resources will ever be upgraded into mineral reserves. You should consider closely the disclosure on the mining industry technical terms in Schedule A “Glossary of Mining Terms” of this AIF.

CAUTIONARY NOTE IN RESPECT OF THE OFFER

The full details of the Offer are set out in the takeover bid circular and accompanying offer documents (collectively, the “Offer Documents”), which we filed with the Canadian securities regulatory authorities. We also filed with the SEC a registration statement on Form F-10 (the “Registration Statement”), which contains a prospectus relating to the Offer (the “Prospectus”), and a tender offer statement on Schedule TO (the “Schedule TO”). The disclosure related to the Offer in this AIF is not a substitute for the Offer Documents, the

Prospectus, the Registration Statement or the Schedule TO. AUGUSTA SHAREHOLDERS AND OTHER INTERESTED PARTIES ARE URGED TO READ THESE DOCUMENTS, ALL DOCUMENTS INCORPORATED BY REFERENCE, ALL OTHER APPLICABLE DOCUMENTS AND ANY AMENDMENTS OR SUPPLEMENTS TO ANY SUCH DOCUMENTS WHEN THEY BECOME AVAILABLE, BECAUSE EACH WILL CONTAIN IMPORTANT INFORMATION ABOUT HUDBAY, AUGUSTA AND THE OFFER. Materials filed with the Canadian securities regulatory authorities are available electronically without charge at www.sedar.com. Materials filed with the SEC are available electronically without charge at the SEC’s website at www.sec.gov. All such materials may also be obtained without charge at Hudbay’s website, www.hudbayminerals.com or by directing a written or oral request to the information agent for the Offer, Kingsdale Shareholder Services at 1-866-229-8874 (North American Toll Free Number) or 1-416-867-2272 (outside North America), or by email at contactus@kingsdaleshareholder.com or to the Vice President, Legal and Corporate Secretary of Hudbay at 25 York Street, Suite 800, Toronto, Ontario, telephone (416) 362-8181.

This AIF does not constitute an offer to buy or the solicitation of an offer to sell any of the securities of Hudbay or Augusta, and the Offer does not constitute an offer to sell or a solicitation of an offer to buy any securities in any jurisdiction in which such offer or solicitation is unlawful.

CURRENCY AND EXCHANGE RATES

This AIF contains references to both United States dollars and Canadian dollars. All dollar amounts referenced, unless otherwise indicated, are expressed in Canadian dollars, and United States dollars are referred to as “United States dollars” or “US$”. For Canadian dollars to United States dollars, the average exchange rate for 2013 and the closing exchange rate at December 31, 2013, as reported by the Bank of Canada, were one Canadian dollar per 0.9402 and 1.0299 United States dollars, respectively. On March 25, 2014 the Bank of Canada noon rate of exchange was 0.8948.

OTHER IMPORTANT INFORMATION

Certain scientific and technical terms and abbreviations used in this AIF are defined in the “Glossary of Mining Terms” attached as Schedule A.

Unless the context suggests otherwise, references to “we”, “us”, “our” and similar terms, as well as references to “Hudbay” and “Company”, refer to HudBay Minerals Inc. and its direct and indirect subsidiaries.

CORPORATE STRUCTURE

Incorporation and Registered Office

We were formed by the amalgamation of Pan American Resources Inc. and Marvas Developments Ltd. on January 16, 1996, pursuant to the Business Corporations Act (Ontario) and changed our name to Pan American Resources Inc. On March 12, 2002, we acquired ONTZINC Corporation, a private Ontario corporation, through a reverse takeover and changed our name to ONTZINC Corporation. On December 21, 2004, we acquired Hudson Bay Mining and Smelting Co., Limited (“HBMS”) and changed our name to HudBay Minerals Inc. In connection with the acquisition of HBMS, on December 21, 2004, we amended our articles to consolidate our common shares on a 30 to 1 basis. On October 25, 2005, we were continued under the Canada Business Corporations Act (“CBCA”). On August 15, 2011, we completed a vertical short-form amalgamation under the CBCA with our subsidiary, HMI Nickel Inc.

Our registered office is located at 2200-201 Portage Avenue, Winnipeg, Manitoba R3B 3L3 and our principal executive office is located at 25 York Street, Suite 800, Toronto, Ontario M5J 2V5.

Our common shares are listed on the Toronto Stock Exchange (“TSX”), New York Stock Exchange (“NYSE”) and Bolsa de Valores de Lima under the symbol “HBM”.

Intercorporate Relationships

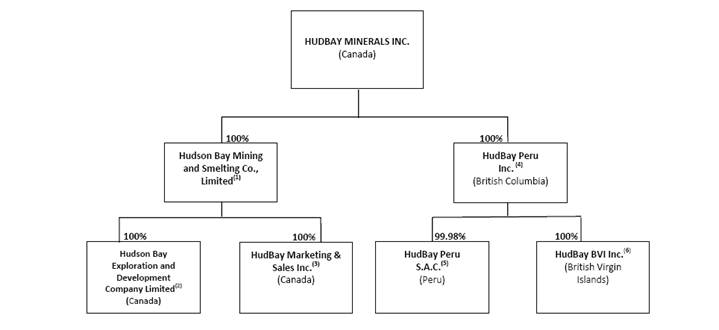

The following chart shows our principal subsidiaries, their jurisdiction of incorporation and the percentage of voting securities we beneficially own or over which we have control or direction.

Notes:

(1) HBMS owns our 777 and Lalor mines and our 70% owned Reed mine and is a guarantor of our 9.50% senior unsecured notes.

(2) Hudson Bay Exploration and Development Company Limited (“HBED”) holds our key exploration properties in Canada, acts as agent for HBMS and is a guarantor of our 9.50% senior unsecured notes.

(3) HudBay Marketing & Sales Inc. markets and sells our copper concentrate and zinc metal produced in Manitoba and is a guarantor of our 9.50% senior unsecured notes.

(4) HudBay Peru Inc. owns 99.98% of HudBay Peru S.A.C. (“Hudbay Peru”). The remaining 0.02% is owned by 6502873 Canada Inc., our wholly-owned subsidiary.

(5) Hudbay Peru S.A.C. owns the Constancia project.

(6) HudBay (BVI) Inc. (“Hudbay BVI”) was incorporated for the sole purpose of entering into and fulfilling our obligations under the precious metals stream agreement in respect of the Constancia project.

DEVELOPMENT OF OUR BUSINESS

Strategy

Our mission is to create sustainable value through increased commodity exposure on a per share basis, in high quality, long life deposits with exploration potential in mining friendly jurisdictions. Our growth strategy is focused on the exploration and development of properties we already control as well as other mineral assets we may acquire that fit our strategic criteria.

We intend to grow Hudbay through exploration and development of properties we already control, such as our Lalor and Reed projects in northern Manitoba and our Constancia project in Peru, as well as through the acquisition of exploration and development properties, as demonstrated by our Offer to acquire the issued and outstanding common shares of Augusta and its Rosemont Project. We also intend to optimize the value of our producing assets through efficient and safe operations.

Three Year History

Offer to Acquire Augusta

On February 9, 2014, we announced our intention to commence an offer to acquire all of the issued and outstanding common shares of Augusta not already owned by us (the “Offer”). Augusta owns the Rosemont Project near Tucson, Arizona.

Under the terms of the Offer, Augusta shareholders are entitled to receive 0.315 of a Hudbay common share for each Augusta common share held, representing approximately $2.96 per Augusta common share or an Augusta enterprise value of approximately $540 million (based on Hudbay’s closing share price on the TSX on February 7, 2014). The Offer represents a premium of approximately 62% based on the 20-day volume-weighted average share prices of Hudbay and Augusta on the TSX for the period ended February 7, 2014.

The Offer is currently open for acceptance until 5:00 p.m. (Toronto time) on April 2, 2014, unless further extended or withdrawn.

Equity Financing

On January 9, 2014, we announced that we had entered into an agreement with a syndicate of underwriters who agreed to purchase, on a bought deal basis, 18,200,000 of our common shares at a price of $8.25 per common share. The underwriters were also granted an over allotment option, which they exercised in full, for an additional 2,730,000 common shares. The transaction closed on January 30, 2014, and the aggregate gross proceeds from the offering were $172.7 million.

We intend to use the net proceeds of the offering for general corporate purposes, including providing us the flexibility to pursue opportunities to advance our growth strategy.

Issuance of 9.50% Senior Unsecured Notes

On September 13, 2012, we issued US$500 million aggregate principal amount of 9.50% senior unsecured notes due October 1, 2020 (the “Initial Notes”). The Initial Notes were priced at 100% of their face value, and yielded proceeds of US$484 million net of directly attributable transaction costs. On June 20, 2013 and December 9, 2013, we issued US$150 million and US$100 million aggregate principal amount, respectively, of our 9.50% senior unsecured notes due October 1, 2020 (the “Additional Notes” and together with the Initial Notes, the “Notes”). The Additional Notes issued in June 2013 were priced at 102% of the aggregate principal amount, resulting in gross proceeds of US$153 million and will yield 9.11% to maturity. The Additional Notes issued in December 2013 were priced at 100% of their face value and yielded gross proceeds of US$100 million. The Notes are fully and unconditionally guaranteed, jointly and severally, on a senior unsecured basis, by substantially all of our existing and future subsidiaries other than our subsidiaries associated with the Constancia project. For additional information, see “Description of Capital Structure — Senior Unsecured Notes”.

Amended and Restated Credit Facility

In connection with completing the issuance of the Additional Notes, in June 2013, we amended and restated our revolving credit facility. The amended and restated credit facility matures on September 12, 2016 and has a maximum availability equal to the lesser of US$100 million and a borrowing base related to the accounts receivable and inventory of our Manitoba business unit, which was US$73 million at December 31, 2013. The amendments also included the removal of debt to EBITDA and EBITDA to interest maintenance covenants, such that the only remaining financial maintenance covenant is the requirement to maintain a tangible net worth. The amended and restated credit facility contains other customary covenants for a facility of this type. As at December 31, 2013, we were in compliance with our covenants under the credit facility. Also as at December 31, 2013, we had $64.1 million in outstanding letters of credit collateralized by cash and cash equivalents that would have been classified as restricted cash in the absence of the credit facility.

Precious Metals Stream Transaction

On August 8, 2012, we entered into a precious metals stream transaction with Silver Wheaton pursuant to a precious metals purchase agreement (the “777 Stream Agreement”) among Silver Wheaton, Hudbay and HBMS and a silver purchase agreement (the “Constancia Stream Agreement” and, together with the 777 Stream Agreement, the “Stream Agreements”) among Silver Wheaton (Caymans) Ltd. (“SW Caymans”), Hudbay and Hudbay BVI.

Pursuant to the Stream Agreements, we agreed to receive aggregate upfront deposit payments of US$750 million against delivery of (i) 100% of payable gold and silver from our 777 mine until the later of December 31, 2016 and satisfaction of a completion test at Constancia, and thereafter 50% of payable gold and 100% of payable silver for the remainder of the 777 mine life, and (ii) 100% of payable silver from the Constancia project.

At closing, we received an upfront deposit payment of US$500 million and we have received two additional deposit payments of US$125 million each, upon incurrence of US$500 million and US$1 billion, respectively, in capital expenditures at our Constancia project.

On November 4, 2013, we amended and restated the Constancia Stream Agreement (the Constancia Stream Agreement, as amended, continues to be referred to herein as the “Constancia Stream Agreement”). The amendments provide that we will receive an additional US$135 million deposit against delivery of 50% of the payable gold from the Constancia project. Silver Wheaton has the option to make the deposit payment in cash or Silver Wheaton common shares, with the number of shares calculated at the time the payment is made. Gold recovery for purposes of calculating payable gold will be fixed at 55% for gold mined from Constancia and 70% for gold mined from Pampacancha. The US$135 million deposit will become payable following our incurrence of US$1.35 billion in capital expenditures at Constancia.

The stream transaction does not include precious metals production from our Lalor project or our land package in Peru outside of the Constancia and Pampacancha deposits or any other metals or minerals, including copper or zinc, from any of our properties.

In addition to the upfront payments, for gold and silver delivered in accordance with the Stream Agreements, we will receive cash payments equal to the lesser of (i) the market price and (ii) US$400 per ounce (for gold) and US$5.90 per ounce (for silver), subject to 1% annual escalation after three years. For additional information, refer to the complete copies of the Stream Agreements that have been filed on SEDAR and EDGAR and our Material Change Reports dated August 14, 2012 and November 13, 2013, also filed on SEDAR and EDGAR.

Constancia Project

On August 8, 2012, our board of directors approved a US$1.5 billion investment to fund the development and construction of our Constancia project in Peru. Following substantial completion of the detailed engineering in the third quarter of 2013, the board approved a revised capital cost estimate for the project of US$1.7 billion. As of the end of February 2014, the project was over 67% complete on a proportion spent basis; of the revised US$1.7 billion budget, we had incurred approximately US$1.15 billion in costs and had entered into an additional US$250 million in commitments as at that date. Construction activities remain on track for first production in late 2014 and commercial production in the second quarter of 2015.

We acquired the Constancia project through our acquisition of all of the outstanding shares of Norsemont Mining Inc. (“Norsemont”) pursuant to a support agreement dated January 9, 2011 and an offer dated January 24, 2011 (as extended by a notice of extension dated March 1, 2011, the “Norsemont Offer”). Pursuant to the Norsemont Offer, and subsequent compulsory acquisition, we issued 22,475,704 Hudbay common shares and paid an aggregate of $130 million in cash to former Norsemont shareholders. For additional information, see “Description of our Business — Material Mineral Projects — Constancia Project”.

Reed

On December 19, 2011, our board of directors approved the construction of the Reed mine. The capital construction budget for Reed is $72 million. Construction of the Reed mine is substantially completed and production commenced in the third quarter of 2013. Pursuant to our agreement with VMS Ventures Inc. (“VMS Ventures”), we have a 70% interest and VMS Ventures has a 30% interest in the project. For additional information, see “Description of Our Business — Other Assets — Joint Ventures — Reed”.

Closure of Trout Lake and Chisel North Mines

We closed our Trout Lake mine on June 29, 2012 after more than 30 years of operation, and our Chisel North mine closed on September 30, 2012.

Dispositions of Fenix Project and Zochem

On September 9, 2011, we completed the sale of our interest in the Fenix ferronickel project in Guatemala to the Solway Group (“Solway”) for cash consideration of US$140 million. In the fourth quarter of 2012, we received an additional $1 million from Solway to settle contingent consideration amounts that would have otherwise been receivable upon the satisfaction of certain conditions during the course of Solway’s development of the Fenix project and agreed with Solway to amend the terms of the indemnity to release us from all obligations except in respect of certain litigation matters. For additional information regarding these litigation matters, see “Legal Proceedings and Regulatory Actions”. We acquired the Fenix project in August 2008 through our acquisition of all of the issued and outstanding common shares of Skye Resources Inc.

On November 1, 2011, we sold our interest in Zochem Inc. to a third party for cash consideration of US$15 million. Zochem Inc. owns and operates a zinc oxide production facility in Brampton, Ontario.

DESCRIPTION OF OUR BUSINESS

General

We are an integrated mining company producing copper concentrate (containing copper, gold and silver) and zinc metal. With assets in North and South America, we are focused on the discovery, production and marketing of base and precious metals. Through our subsidiaries, we own copper/zinc/gold mines, ore concentrators and a zinc production facility in northern Manitoba and Saskatchewan and a copper project in Peru. We also have equity investments in a number of junior exploration companies. Our growth strategy is focused on the exploration and development of properties we already control, as well as other mineral assets we may acquire that fit our strategic criteria. Our mission is to create sustainable value through increased commodity exposure on a per share basis for our shareholders.

We have three material mineral projects, all of which are 100% owned:

1. 777, an underground mine in Flin Flon, Manitoba, which has been producing since 2004;

2. Lalor, a zinc, gold and copper project currently under construction near Snow Lake, Manitoba, which commenced initial ore production from the ventilation shaft in August 2012 and is expected to begin production from the main shaft in the second half of 2014; and

3. Constancia, a copper project in Peru, which is expected to commence initial production in late 2014 and begin full production in the second quarter of 2015.

We also own a 70% interest in the Reed mine near Snow Lake, Manitoba, which commenced production in the third quarter of 2013, exploration properties in North and South America and minority equity investments in several junior exploration companies as part of our strategy to build a pipeline of projects with the potential for development.

In addition, we own and operate a portfolio of processing facilities in northern Manitoba, including our primary Flin Flon ore concentrator, which produces zinc and copper concentrates, our Snow Lake concentrator, which produces zinc and copper concentrates and our Flin Flon zinc plant, which produces high-grade zinc metal.

The following map shows where our material mineral projects and certain of our other assets are located.

Material Mineral Projects

777 Mine

Our 100% owned 777 mine is an underground copper, zinc, gold and silver mine located within the Flin Flon Greenstone Belt, immediately adjacent to our principal concentrator and zinc pressure leach plant in Flin Flon, Manitoba. Development of the 777 mine commenced in 1999 and commercial production began in 2004. The anticipated mine life is until 2020.

In 2012, we completed the 777 North expansion, which involved driving a ramp from surface to the existing workings at the 440 metre level of 777 to enable access to ore zones and to additional underground exploration at 777. Full production from the 777 North expansion zones began in early 2013.

Ore produced at the 777 mine is transported to our Flin Flon concentrator for processing into copper and zinc concentrate. Copper concentrate is sold to third party purchasers and zinc concentrate is sent to our Flin Flon zinc plant where it is further processed into special high grade zinc before being sold to third party purchasers. For additional information, see “Description of our Business — Other Information — Processing Facilities” and “Description of our Business — Other Information — Products and Marketing”.

Pursuant to the 777 Stream Agreement, we received a US$455 million upfront deposit payment for a portion of the precious metals stream at our 777 mine (see “Development of our Business — Three Year History — Precious Metals Stream Transaction).

On November 6, 2012, we filed a NI 43-101 technical report titled “Technical Report, 777 mine, Flin Flon, Manitoba, Canada”, dated effective October 15, 2012 (the “777 Technical Report”), a copy of which is available under our profile on SEDAR at www.sedar.com and on EDGAR at www.sec.gov. For additional details on our 777 mine refer to Schedule B of this AIF.

Production

The following table sets forth our production from the 777 Mine for the years ended December 31, 2013, 2012 and 2011.

|

|

|

December 31 |

| ||||||

|

|

|

Units |

|

2013 |

|

2012 |

|

2011 |

|

|

Ore mined |

|

tonnes |

|

1,625,532 |

|

1,529,103 |

|

1,491,722 |

|

|

Copper grade in ore |

|

% |

|

1.85 |

|

2.32 |

|

3.18 |

|

|

Zinc grade in ore |

|

% |

|

3.81 |

|

4.16 |

|

3.71 |

|

|

Gold grade in ore |

|

grams/tonne |

|

2.02 |

|

2.18 |

|

2.37 |

|

|

Silver grade in ore |

|

grams/tonne |

|

23.01 |

|

25.77 |

|

26.78 |

|

Operating costs are expected to be similar to costs experienced in the past several years, as a result of ongoing productivity efforts. As in past years, costs in the first and fourth quarters are expected to be higher due to additional heating and other seasonal costs.

Mineral Reserves and Resources

The following tables set forth our estimates of the mineral reserves and resources at the 777 mine.

In-Mine Mineral Reserves — January 1, 2014(1)(2)(3)

|

|

|

Tonnes |

|

Cu (%) |

|

Zn (%) |

|

Au (g/t) |

|

Ag (g/t) |

|

|

777 Mine |

|

|

|

|

|

|

|

|

|

|

|

|

Proven |

|

4,893,000 |

|

2.27 |

|

4.01 |

|

1.84 |

|

24.71 |

|

|

Probable |

|

5,707,000 |

|

1.34 |

|

4.24 |

|

1.79 |

|

24.69 |

|

|

Total Mineral Reserve |

|

10,600,000 |

|

1.77 |

|

4.14 |

|

1.81 |

|

24.70 |

|

Notes:

(1) This table shows the estimated reserves at our 777 mine, including the 777 North expansion, in Manitoba.

(2) The zinc price used for mineral reserve estimation was US$1.06 per pound (includes premium), the copper price was US$3.00 per pound, the gold price was US$1,250.00 per ounce and the silver price was US$25.00 per ounce using an exchange of 1.05 C$/US$.

(3) For additional details relating to the estimates of mineral reserves and resources at our 777 mine, including data verification and quality assurance / quality control processes, refer to Schedule B and our technical report titled “Technical Report, 777 mine, Flin Flon, Manitoba, Canada” dated effective October 15, 2012, a copy of which is available on SEDAR at www.sedar.com and EDGAR at www.sec.gov.

In-Mine Inferred Mineral Resources — September 30, 2013(1)(2)(3)

|

|

|

Tonnes |

|

Cu (%) |

|

Zn (%) |

|

Au (g/t) |

|

Ag (g/t) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

777 Mine |

|

784,000 |

|

1.05 |

|

4.49 |

|

1.77 |

|

30.61 |

|

Notes:

(1) This table shows our estimated inferred mineral resources at our 777 mine, including the 777 North expansion, in Manitoba. Mineral resources that are not mineral reserves do not have demonstrated economic viability. The above mineral resources are exclusive of mineral reserves.

(2) The zinc price used for mineral resource estimation was US$1.06 per pound (includes premium), the copper price was US$3.00 per pound, the gold price was US$1,250.00 per ounce and the silver price was US$25.00 per ounce using an exchange of 1.05 C$/US$.

(3) For additional details relating to the estimates of mineral reserves and resources at our 777 mine, including data verification and quality assurance / quality control processes, refer to Schedule B and our technical report titled “Technical Report, 777 mine, Flin Flon, Manitoba, Canada” dated effective October 15, 2012, a copy of which is available on SEDAR at www.sedar.com and EDGAR at www.sec.gov.

Lalor Project

Our 100% owned Lalor project is a zinc, gold and copper project currently under construction near the town of Snow Lake in the province of Manitoba. Lalor is located approximately 210 kilometres by road east of Flin Flon, Manitoba.

In 2013, we hoisted 400,590 tonnes of ore from the ventilation shaft at our Lalor project at a copper grade of 0.84% and a zinc grade of 9.44%. Underground development is ongoing and it is expected that the main production shaft will be commissioned during the second half of 2014. In the first quarter of 2014, we received the Environment Act licence for Lalor, which will enable full production via the main shaft.

Of the total mine construction budget of $441 million, we have invested approximately $386 million to February 28, 2014 and have entered into an additional $36 million in commitments.

We are also investing US$9 million at our Snow Lake concentrator to refurbish existing equipment and facilities and to double production capacity to approximately 2,700 tonnes per day by mid-2014, when the production shaft at Lalor is being commissioned. This investment will allow for the deferral of the construction of the new Lalor concentrator until 2015. We have allocated $10.5 million of Lalor’s $75 million capital budget to continue with engineering and optimization work for the new concentrator during 2014.

In January and March of 2013, members of the Mathias Colomb Cree Nation (“MCCN”) staged two separate blockades that impeded access to our Lalor site for part of a business day. After the two blockades, we successfully applied to the Manitoba Court of Queen’s Bench for an interlocutory injunction to prevent any further blockades at our Manitoba operations. On January 20, 2014, the Court of Appeal of Manitoba upheld the injunction order. We felt we had a responsibility to seek this injunction as any actions that prohibit access to our sites and operations present an unsustainable safety risk to our employees, contractors and others. Notwithstanding the court process, we remain committed to continued consultation and cooperation with the MCCN.

On March 30, 2012, we filed a NI 43-101 technical report titled “Pre-Feasibility Study Technical Report, on the Lalor Deposit, Snow Lake, Manitoba, Canada”, dated March 29, 2012 (the “Lalor Technical Report”), a copy of which is available under our profile on SEDAR at www.sedar.com and on EDGAR at www.sec.gov. For additional details on our Lalor project, refer to Schedule B of this AIF.

Production

The following table sets forth actual production from the ventilation shaft for the years ended December 31, 2013 and 2012. Production from the 985 metre production shaft is anticipated to commence in the second half of 2014.

|

|

|

|

|

December 31 |

| ||

|

|

|

Units |

|

2013 |

|

2012 |

|

|

Ore mined |

|

Tonnes |

|

400,590 |

|

72,293 |

|

|

Copper grade in ore |

|

% |

|

0.84 |

|

0.63 |

|

|

Zinc grade in ore |

|

% |

|

9.44 |

|

11.83 |

|

|

Gold grade in ore |

|

grams/tonne |

|

1.21 |

|

1.67 |

|

|

Silver grade in ore |

|

grams/tonne |

|

19.39 |

|

19.29 |

|

Mineral Reserves and Resources

Lalor Mineral Reserves — January 1, 2014(1)(2)

|

|

|

Tonnes |

|

Cu (%) |

|

Zn (%) |

|

Au (g/t) |

|

Ag (g/t) |

|

|

Lalor — Base Metal |

|

|

|

|

|

|

|

|

|

|

|

|

Proven |

|

1,332,000 |

|

0.73 |

|

8.99 |

|

1.53 |

|

17.49 |

|

|

Probable |

|

11,334,000 |

|

0.68 |

|

7.81 |

|

1.56 |

|

23.77 |

|

|

Lalor — Gold Zone |

|

|

|

|

|

|

|

|

|

|

|

|

Proven |

|

— |

|

|

|

|

|

|

|

|

|

|

Probable |

|

2,530,000 |

|

0.37 |

|

0.42 |

|

4.28 |

|

24.45 |

|

|

Total Mineral Reserve |

|

15,196,000 |

|

0.63 |

|

6.69 |

|

2.01 |

|

23.34 |

|

Notes:

(1) The zinc price used for mineral reserve estimation was US$1.06 per pound (includes premium), the copper price was US$3.00 per pound, the gold price was US$1,250.00 per ounce and the silver price was US$25.00 per ounce using an exchange of 1.05 C$/US$.

(2) For additional details relating to the estimates of mineral reserves at our Lalor project, including data verification and quality assurance / quality control processes, refer to Schedule B and our technical report titled “Pre-Feasibility Study Technical Report, on the Lalor Deposit, Snow Lake, Manitoba, Canada” dated effective March 29, 2012, a copy of which is available on SEDAR at www.sedar.com and EDGAR at www.sec.gov.

Lalor Inferred Mineral Resources — September 30, 2013(1)(2)(3

|

|

|

Tonnes |

|

Cu (%) |

|

Zn (%) |

|

Au (g/t) |

|

Ag (g/t) |

|

|

Lalor — Base Metal(4) |

|

|

|

|

|

|

|

|

|

|

|

|

Inferred |

|

3,832,000 |

|

2.04 |

|

5.77 |

|

3.47 |

|

21.24 |

|

|

Lalor — Gold Zone |

|

|

|

|

|

|

|

|

|

|

|

|

Inferred |

|

6,281,000 |

|

0.42 |

|

0.49 |

|

4.70 |

|

31.48 |

|

|

Total Inferred Mineral Resource |

|

10,113,000 |

|

1.04 |

|

2.49 |

|

4.24 |

|

27.60 |

|

Notes:

(1) Mineral resources that are not mineral reserves do not have demonstrated economic viability. The above mineral resources are exclusive of mineral reserves.

(2) The zinc price used for mineral resource estimation was US$1.06 per pound (includes premium), the copper price was US$3.00 per pound, the gold price was US$1,250.00 per ounce and the silver price was US$25.00 per ounce using an exchange of 1.05 C$/US$.

(3) For additional details relating to the estimates of mineral reserves at our Lalor project, including data verification and quality assurance / quality control processes, refer to Schedule B and our technical report titled “Pre-Feasibility Study Technical Report, on the Lalor Deposit, Snow Lake, Manitoba, Canada” dated effective March 29, 2012, a copy of which is available on SEDAR at www.sedar.com and EDGAR at www.sec.gov.

(4) Includes the copper-gold zone.

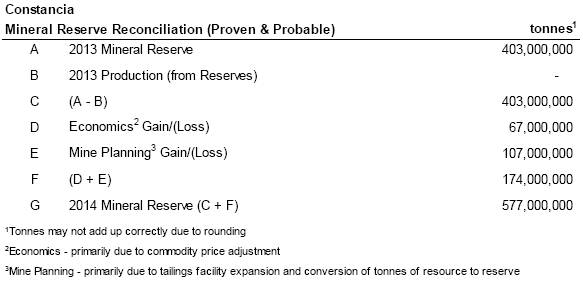

Constancia Project

Constancia is our 100% owned copper project in Peru, which we acquired through our acquisition of Norsemont in 2011. It is located in the Province of Chumbivilcas in southern Peru and consists of the Constancia and Pampacancha deposits.

On August 8, 2012, our board of directors approved a US$1.5 billion investment to fund the development and construction of our Constancia project. Following substantial completion of the detailed engineering in the third quarter of 2013, the board approved a revised capital cost estimate for the project of US$1.7 billion. As of the end of February 2014, the project was over 67% complete on a proportion spent basis; of the revised US$1.7 billion budget, we had incurred approximately US$1.15 billion in costs and had entered into an additional US$250 million in commitments as at that date. Construction activities remain on track for first production in late 2014 and commercial production in the second quarter of 2015.

We have received approval of all required construction permits. In the third quarter of 2013, we received approval of our Environmental and Social Impact Assessment (“ESIA”) Modification 1 and submitted an application for a second amendment to the ESIA in December 2013 in respect of the final project configuration and to permit the incorporation of Pampacancha into the mine plan. We have received the first round of observations from the Ministry on ESIA Modification 2 and are addressing them with no critical items noted. All permitting remains on schedule. We have also obtained approval for the early refund of value added tax on purchases with retroactive effect to December 2012 and have received refunds of US$55 million to date from the tax authorities. Also in December 2013, we entered into a 15-year tax and fiscal stability agreement with the government of Peru. Pursuant to the agreement, the increase in the applicable income tax rate from 30% to 32% is expected to be largely offset by the accelerated depreciation that the agreement provides.

Pursuant to the Constancia Stream Agreement, we have received US$295 million in upfront deposit payments against delivery of 100% of the payable silver at Constancia. We are entitled to receive an additional deposit amount of US$135 million against delivery of 50% of the payable gold at Constancia following our incurrence of US$1.35 billion in capital expenditures. Gold recovery for purposes of calculating payable gold will be fixed at 55% for gold mined from Constancia and 70% for gold mined from Pampacancha (see “Development of our Business — Three Year History — Precious Metals Stream Transaction).

On November 6, 2012, we filed a technical report titled “National Instrument 43-101, Technical Report, Constancia Project, Province of Chumbivilcas, Department of Cusco, Peru”, dated October 15, 2012 (the “Constancia Technical Report”), a copy of which is available under our profile on SEDAR at www.sedar.com and on EDGAR at www.sec.gov. For additional details on our Constancia project, refer to Schedule B of this AIF.

Mineral Reserves and Resources

The following table sets forth our estimates of the mineral reserves at the Constancia project as at January 1, 2014.

|

|

|

Tonnes |

|

Cu (%) |

|

Mo (g/t) |

|

Au (g/t) |

|

Ag (g/t) |

|

|

Constancia |

|

|

|

|

|

|

|

|

|

|

|

|

Proven |

|

483,000,000 |

|

0.32 |

|

93 |

|

0.040 |

|

3.04 |

|

|

Probable |

|

94,000,000 |

|

0.22 |

|

61 |

|

0.036 |

|

2.77 |

|

|

Pampacancha |

|

|

|

|

|

|

|

|

|

|

|

|

Proven |

|

23,000,000 |

|

0.52 |

|

142 |

|

0.298 |

|

4.28 |

|

|

Probable |

|

20,000,000 |

|

0.44 |

|

159 |

|

0.252 |

|

3.74 |

|

|

Total Mineral Reserve |

|

620,000,000 |

|

0.32 |

|

92 |

|

0.056 |

|

3.07 |

|

Notes:

(1) The above mineral reserves are based on a Peruvian Sole: US Dollar exchange rate of $2.85:1 and the following long term metals prices: Cu US$3.00/lb; Ag US$25.00/oz; Au US$1,250.00/oz; and Mo US$13.50/lb.

The following table sets forth our estimates of the mineral resources at the Constancia project as at September 30, 2013.(1)(2)

|

|

|

Tonnes |

|

Cu (%) |

|

Mo (g/t) |

|

Au (g/t) |

|

Ag (g/t) |

|

|

Constancia(3) |

|

|

|

|

|

|

|

|

|

|

|

|

Measured |

|

68,000,000 |

|

0.22 |

|

59 |

|

0.036 |

|

2.17 |

|

|

Indicated |

|

293,000,000 |

|

0.20 |

|

58 |

|

0.033 |

|

1.96 |

|

|

Inferred |

|

200,000,000 |

|

0.19 |

|

51 |

|

0.031 |

|

1.86 |

|

|

Pampacancha(4) |

|

|

|

|

|

|

|

|

|

|

|

|

Measured |

|

5,000,000 |

|

0.41 |

|

69 |

|

0.243 |

|

5.46 |

|

|

Indicated |

|

6,000,000 |

|

0.34 |

|

98 |

|

0.211 |

|

4.68 |

|

|

Total Measured & Indicated |

|

372,000,000 |

|

0.20 |

|

59 |

|

0.039 |

|

2.09 |

|

|

Total Inferred |

|

200,000,000 |

|

0.19 |

|

51 |

|

0.031 |

|

1.86 |

|

Notes:

(1) Mineral resources that are not mineral reserves do not have demonstrated economic viability. The above mineral resources are exclusive of mineral reserves.

(2) The resources shown in the table above correspond to a resources pit shell. In compliance with NI 43-101 requirements for the disclosure of mineral resources, a pit optimization to delimit the portion of the block model having reasonable prospects for economic extraction was performed.

(3) The Constancia resource pit consists of a non-operational pit of Measured, Indicated and Inferred resources diluted to a 10x10x15m full block size using a 0.12% copper cut-off based on a copper price of US$2.88 per pound and a molybdenum price of US$16.00 per pound, copper recovery of 89%, molybdenum recovery of 60%, processing costs of US$5.50 per tonne and mining costs of US$1.30 per tonne.

(4) The Pampacancha resource pit consists of a non-operational pit of Measured, Indicated and Inferred resources diluted to a 10x10x15m full block size using a 0.1% copper cut-off based on a copper price of US$3.00 per pound, a molybdenum price of US$13.50 per pound, silver price of US$25.00 per ounce, gold price of US$1,250 per ounce, copper recovery of 85%, molybdenum recovery of 40%, gold and silver recovery of 65%; processing costs of US$4.72 per tonne and mining costs of US$1.90 per tonne.

Other Assets

Reed

During the third quarter of 2013, our 70% owned Reed mine near Flin Flon, Manitoba, received its Environment Act licence from the Manitoba government and commenced initial production. The licence permits the operation of a 1,300 tonne per day underground copper mine and supporting infrastructure. Of our $72 million estimated capital construction budget for the project, we have invested approximately $64.9 million to February 28, 2014. As of that date, project development had advanced 2,927 metres with the mine producing 82,062 tonnes of ore from a combination of drift development in ore and longhole stope mining. The Reed mine is expected to reach commercial production by the second quarter of 2014.

Our estimates of mineral reserves and resources for Reed are set out below.

Reed — Probable Mineral Reserves — January 1, 2014 (1)(2)

|

Tonnes |

|

Cu |

|

Zn |

|

Au |

|

Ag |

|

|

2,121,000 |

|

3.80 |

|

0.50 |

|

0.42 |

|

5.28 |

|

Notes:

(1) The zinc price used for the mineral reserve estimations was US$1.06 per pound (includes premium), the copper price used for the mineral reserves estimation was US$3.00 per pound, the gold price was US$1,250.00 per ounce and the silver price was US$25.00 per ounce using an exchange rate of 1.05 C$/US$.

(2) For additional details relating to the estimates of mineral reserves and resources at the Reed mine, including data verification and quality assurance/quality control processes refer to the “Pre-Feasibility Study Technical Report on the Reed Copper Deposit, Central Manitoba, Canada” as filed on SEDAR by VMS Ventures Inc. on May 14, 2012.

Reed — Inferred Mineral Resources — September 30, 2013(1)

|

Tonnes |

|

Cu |

|

Zn |

|

Au |

|

Ag |

|

|

233,000 |

|

4.31 |

|

0.52 |

|

0.38 |

|

4.57 |

|

Notes:

(1) Mineral resources that are not mineral reserves do not have demonstrated economic viability. The above mineral resources are exclusive of reserves and were estimated using the same metals prices as were used for the estimate of mineral reserves at Reed.

Exploration Properties

Our exploration properties are key to our strategy of pursuing organic growth. Over the past 87 years, we and our predecessors have brought into production 26 ore bodies on our lands and continue to pursue brownfield opportunities near our existing deposits. A key component of this will be the development of the 955-1025 metre level exploration drifts at Lalor during the second half of 2014, which is expected to enable tighter-spaced drilling to upgrade known inferred resources and to test the down plunge exploration potential of the gold and copper gold zones. Underground exploration drilling at 777 will also continue with the objective of extending the mine life beyond 2020, and in Peru we plan to drill newly discovered geophysical anomalies on our large land position around Constancia. For 2014, our board of directors has approved total exploration expenditures of approximately $20 million.

We hold a land position of approximately 370,000 hectares in Manitoba and Saskatchewan, primarily in the highly prolific Flin Flon Greenstone Belt. Since much of this property is within 100 kilometres of our two ore concentrators in the region, and given that we have available capacity at our processing facilities from time to time, we are in a good position to economically exploit mineral deposits that a mining company without such proximate facilities may not be able to develop profitably due to higher costs of transportation and processing. This, along with our 22,000 hectare land package in Peru, aligns well with our focus in 2014 on brownfield opportunities.

In addition, we will continue to look for greenfield opportunities in North and South America.

Our other exploration properties include our wholly-owned Tom and Jason zinc-lead properties in the Yukon, which contain mineral resources. On January 17, 2014 we completed the sale of our 51% interest in the Back Forty project in Michigan’s Upper Peninsula to our former joint venture partner Aquila Resources Inc.

Processing Facilities

Concentrators

Our primary ore concentrator is located in Flin Flon, Manitoba. The concentrator, which is directly adjacent to our metallurgical zinc plant, produces zinc and copper concentrates from ore mined at our 777 mine. Its capacity is approximately 2.18 million tonnes of ore per year. The concentrator can handle ore from

more than one mine separately, and blending is done at the grinding stage. As a result, ore mined from our Lalor and Reed projects may be transported to the Flin Flon concentrator for processing. The Flin Flon concentrator facility includes a paste backfill plant and associated infrastructure such as maintenance shops and laboratories. Tailings from the concentrator are pumped to the Flin Flon tailings impoundment immediately adjacent to the concentrator.

Our concentrator in Snow Lake, Manitoba was re-started in late 2009 and a new copper recovery circuit was installed in the third quarter of 2012 to facilitate processing of early Lalor ore. The concentrator currently processes ore from Lalor and produces zinc and copper concentrates. The zinc concentrate is shipped by truck for further processing at our zinc plant in Flin Flon. The concentrator, which has crushing, grinding, flotation, thickening, filtering and drying capabilities, has a design capacity of approximately 1.1 million tonnes of ore per year. We are refurbishing equipment and facilities at the concentrator to double production capacity to approximately 2,700 tonnes per by day by mid-2014, at a capital cost of $9 million. Tailings generated by the Snow Lake concentrator are deposited in our Anderson Lake tailings facility, which we believe mitigates environmental impacts, as the tailings are deposited in a subaqueous manner, minimizing the potential for generation of acid rock drainage.

Zinc Plant

Our zinc plant located in Flin Flon, Manitoba produces special high-grade metal in three cast shapes from zinc concentrate. Our plant is one of four primary zinc producers in North America. We produced 96,305 tonnes of cast zinc in 2013. The capacity of the zinc plant is approximately 115,000 tonnes of cast zinc per year. Included in the zinc plant are an oxygen plant, concentrate handling, storage and regrinding facility, a zinc pressure leach plant, a solution purification plant, a modern electro-winning cellhouse, a casting plant and a zinc storage area with the ability to load trucks or rail cars. The zinc plant has a dedicated leach residue disposal facility. The bulk of the waste material is gypsum, iron and elemental sulphur. Wastewater is treated and recycled through the zinc plant.

Domestic concentrates produced from our mines and concentrate purchased from third parties are processed at the zinc plant. Purchased concentrate accounted for approximately 7% of zinc metal produced at our zinc plant in 2013, and is expected to account for 15-20% of zinc production in 2014. Domestic zinc concentrate production and purchased zinc concentrate are expected to support capacity utilization of approximately 95% in 2014. Upon full production from Lalor, domestic zinc concentrate production is expected to utilize fully the available capacity of the zinc plant.

Strategic Investments

As at December 31, 2013, we held minority equity positions in 15 junior exploration companies, representing investments with a fair market value of approximately $48 million, as part of our strategy to populate a pipeline of projects with the potential for development following the construction of Lalor and Constancia. Our early stage opportunity pipeline consists of projects in Canada, the United States, Chile, Peru and Colombia and includes our investment in, and proposed Offer for, Augusta. We are continuing to evaluate new projects and potential investments to add to our portfolio and will seek to dispose of investments when the underlying projects are no longer consistent with our strategy.

Cash and Cash Equivalents

Our cash and cash equivalents as of December 31, 2013 were $631 million, and are held in low risk liquid investments and deposit accounts pursuant to our investment policy.

Other Information

Products and Marketing

Our principal products are copper concentrate and zinc. In 2013, we produced 127,909 tonnes of copper concentrate and 96,305 tonnes of cast zinc. In 2013 copper concentrate sales represented

approximately 59% (2012 68%) and zinc metal sales represented approximately 40% (2012 31%) of our total gross consolidated revenue, respectively.

In 2013, we sold approximately 72% of our copper concentrate production to third party purchasers in North America and Europe on benchmark terms and in 2014 we expect to sell approximately the same percentage. We sell the remainder of our copper concentrate production pursuant to shorter-term contracts as opportunities arise.

We sell gold and silver produced from our 777 mine and contained in our copper concentrate to Silver Wheaton pursuant to the terms of the 777 Stream Agreement. For additional information, see “Three Year History”.

We ship cast zinc metal produced at our Flin Flon zinc plant to third party customers in North America by rail and truck. Following the sale of our Zochem Inc. subsidiary in November 2011, we have been selling approximately 20% of our zinc production to Zochem Inc. at market terms.

Commodity Markets

Over the course of 2013, prices for our key metals traded within a relatively narrow range when compared to the previous four years. However, average prices in 2013 generally were lower than average prices in 2012. For additional information refer to our market analysis of copper, zinc, gold and silver prices during this period on pages 21 and 22 of our management’s discussion and analysis for the year ended December 31, 2013, a copy of which has been filed on SEDAR at www.sedar.com and EDGAR at www.sec.gov.

Specialized Skill and Knowledge

The success of our operations depends in part on our ability to attract and retain geologists, engineers, metallurgists and other personnel in the geographic areas in which we operate with specialized skill and knowledge about the mining and mineral processing industries. For additional information, see “Risk Factors — Human Resources”.

Competitive Conditions

The mining industry is intensely competitive and we compete with many companies in the search for and the acquisition of attractive mineral properties. In addition, we also compete for the technical expertise to find, develop, and operate such properties, the labour to operate the properties, and the capital for the purpose of funding such properties. For additional information, see “Risk Factors — Competition”.

Economic Dependence

We do not have any contracts upon which our business is substantially dependent, as our principal products, copper concentrate and zinc, are widely traded commodities and we may enter into contracts for the sale of such products with a variety of potential purchasers.

Environmental Protection

Our activities are subject to environmental laws and regulations. Environmental laws and regulations are evolving in a manner that will require stricter standards and enforcement, increased fines and penalties for non-compliance, more stringent environmental assessments of proposed projects and a heightened degree of responsibility for companies and their officers, directors and employees. For additional information, see “Risk Factors — Governmental and Environmental Regulation”.

Our goal is to continually improve our environmental performance. We have established an environmental management program directed at environmental protection and compliance to achieve our goal and address these regulatory changes. For additional information, see “Corporate Social Responsibility”.

Employees

As at December 31, 2013, we had 52 employees at our Toronto head office, 1,365 employees in Flin Flon and Snow Lake, Manitoba and 157 employees in Peru. In addition, we had 20 employees elsewhere in North and South America.

Of our 1,365 employees in Flin Flon and Snow Lake, approximately 1,047 were unionized as at December 31, 2013. In 1998, we entered into a labour stability agreement in respect of our existing Flin Flon/Snow Lake collective bargaining agreements, whereby we agreed with the unions that any collective agreement expiring prior to July 1, 2012 would be settled by way of binding arbitration in the event that the parties could not otherwise agree to a negotiated contract settlement. Our current collective bargaining agreements at HBMS expire December on 31, 2014 and subsequent collective bargaining agreements will not be subject to the labour stability agreement.

HBMS maintains a profit sharing plan pursuant to which 10% of its after-tax profit (excluding provisions or recoveries for deferred income and mining tax) for any given year is distributed among eligible employees in the Flin Flon/Snow Lake operations, with the exception of executive officers and key management personnel.

Continuous Improvement

In early 2012, we began the process of formalizing our approach to continuous improvement in order to enhance our overall performance and contain costs. We refer to this approach as Continuous Improvement Process Optimization or CIPO. The key objectives of our CIPO program are to:

· establish a standard process to manage continuous improvement activities;

· establish targets and accountabilities related to continuous improvement projects;

· maintain our competitive edge, reduce our costs and enhance our growth potential; and

· enhance our company culture by incorporating continuous improvement into the normal course of business.

CIPO is not a project with a start and end date, but rather it is a structure that defines how projects are managed. Under the CIPO governance structure, Project Champions have been identified in each of the functional areas of our company. Their activities are overseen by a CIPO Steering Committee whose main focus is to ensure that CIPO projects are aligned with our overall strategy and objectives. The governance structure provides a formal means by which any employee can submit a continuous improvement idea and receive feedback as to its status. Typically, employees who suggest projects are involved in the implementation. As well, CIPO governance is structured to ensure that all ideas are captured, evaluated consistently, and prioritized — with the goal of maintaining a high value project pipeline and a sustainable program.

Since inception of the formal CIPO program, we have completed approximately 82 projects, which are expected, and in some cases have begun, to deliver financial as well as health and safety benefits. We currently have approximately 53 active CIPO projects underway as well as a robust pipeline of new ideas for the next generation of projects.

CORPORATE SOCIAL RESPONSIBILITY

At Hudbay, we view our responsible corporate behaviour as integral to the successful execution of our business strategy, particularly in maintaining a good reputation with our regulators and communities — and being able to bring that good reputation to new communities and jurisdictions when we embark on new projects. We therefore commit to our stakeholders to work to create benefits and opportunities that contribute to their economic and social sustainability, and to protect our natural environment. We also commit to our employees to maintain a safe and healthy work environment. As described below, we have adopted a number of voluntary codes and other external instruments that we consider particularly relevant to our business, including ISO 14001, Occupational Health and Safety Assessment Series (“OHSAS”) 18001 and our Human Rights Policy.

Health, Safety and Environmental Policies

Among our core values are protecting the health and welfare of our employees and contractors and reducing the impact of our operations on the environment. All of our producing operations have management systems certified to OHSAS 18001 and Environmental Management System Standard ISO 14001. In addition, the production and supply of our cast zinc products are registered to the ISO 9001 quality standard.

We believe that ongoing improvements in the safety of our workplace assists in maintaining healthy labour relations and that our ability to minimize lost-time injuries and environmental regulatory violations is a significant factor in maintaining and realizing opportunities to improve overall operational efficiency. Our safety management systems include the Positive Attitude Safety System (“PASS”), which is in use at our Manitoba operations. The PASS system is based on facilitated discussions at all levels of the organization to increase each person’s involvement in recognizing and managing workplace risks. In 2013, our lost time accident frequency per 200,000 hours worked was 0.4. This is higher than our frequency of 0.3 in 2012, in part due to a number of lost time accidents at our exploration sites in Colombia in 2013. While the severity of these injuries was low, we nevertheless take seriously our commitment to reducing such incidents and have taken steps to better oversee our exploration activities. We remain committed to continuously improving the safety of our workplace.

We have established an environmental management program directed at environmental protection and compliance. The program consists of an environmental policy, codes of practice, regular audits, the integration of environmental procedures with operating procedures, employee training and emergency prevention and response procedures. We have dedicated teams which are charged with managing our environmental activities and our compliance with all applicable environmental standards and regulations. We did not have any material environmental non-compliances in 2013.

Human Rights Policy

In May 2011, we adopted a formal Human Rights Policy. The policy is intended to capture and clearly state our commitments to human rights. Key aspects include our commitment to:

· Ethical business practices — further articulated in our Code of Business Conduct and Ethics;

· Labour practices and labour relations — including fair labour practices at our workplaces and a commitment to the health and safety of our employees;

· Community participation — including community consultation, contributing to long-term and sustainable opportunities for communities, respecting communities’ legal rights, and participating in a common effort to promote respect for human rights as they relate to our business; and

· Security measures that respect human rights — including our adoption of the Voluntary Principles on Security and Human Rights, and the United Nations Code of Conduct for Law Enforcement Officials.

Sustainability Reporting

We publish an annual corporate social responsibility report that further presents and discusses our environmental, social, health and safety performance. This report is prepared pursuant to the Global Reporting Initiative guidelines, which is the world’s most widely used sustainability framework. We also subscribe to the Mining Association of Canada’s “Toward Sustainable Mining” initiative, which was designed to help mining companies evaluate the quality, comprehensiveness and robustness of their management systems under key performance elements, including tailings management, energy use and emissions, external outreach and crisis management planning. Our 2012 Corporate Social Responsibility Report is available on our website at www.hudbayminerals.com and our 2013 report is expected to be released in the second quarter of 2014.

RISK FACTORS

An investment in our securities is speculative and involves significant risks that should be carefully considered by investors and prospective investors. In addition to the risk factors described elsewhere in this AIF, the risk factors that impact us and our business include, but are not limited to, those set out below. Any one or more of these risks could have a material adverse effect on our business, results of operations, financial condition and the value of our securities.

Metals Prices and Foreign Exchange

Our profit or loss and financial condition depend upon the market prices of metals, which are cyclical and which can fluctuate widely with demand for our metals. Demand is affected by numerous factors beyond our control, including the overall state of the economy, general level of industrial production, interest rates, rate of inflation, foreign exchange rates and investment demand for commodities. Such external economic factors are in turn influenced by changes in international investment patterns, monetary systems and political developments. Prices are also affected by the overall supply of the metals we produce, which can be affected by the start-up of major new mines, production disruptions and closures of existing mines.

Future price declines may, depending on hedging practices, materially reduce our profitability and could cause us to reduce output at our operations (including, possibly, closing one or more of our mines or plants), all of which could reduce our cash flow from operations. During August and September 2013, Hudbay entered into copper and zinc hedging transactions intended to manage the risk of adverse changes to operating cash flow as it approaches the expected completion of the Lalor and Constancia projects in the second half of 2014. For further details, see the risk factor, “Hedging Transactions” below.

In addition, since our core operations are located in Canada, our costs are incurred primarily in Canadian dollars. However, our revenue is tied to market prices for copper, zinc and other metals we produce, which are typically denominated in United States dollars. If the Canadian dollar appreciates in value against the United States dollar, our results of operations and financial condition could be materially adversely affected. Also, once our Constancia project reaches production, a substantial part of our operating costs will be incurred in Peruvian new soles, and future appreciation of the new sole relative to the United States dollar could adversely impact our future profitability. Although we may use hedging strategies to limit exposure to currency fluctuations, there can be no assurance that such hedging strategies will be successful or that they will mitigate the risk of such fluctuations.

Development of Key Projects