NI 43-101

Compliant

TECHNICAL

REPORT

on

the

LOOKOUT

HILL PROJECT

Ömnögovi

Aimag, Southern Mongolia

Prepared

for:

Entrée

Gold Inc.

1201

- 1166 Alberni Street

Vancouver,

BC

Canada

|

June

10, 2009

|

Prepared

by: John

Vann, F.AusIMM, M.AIG

Scott

Jackson, M.AusIMM

Owen

Cullingham, P.Geol.

Dean

David, M.AusIMM

Robert

M Cann, P. Geo.

James

R. Foster, P.Geo.

|

CERTIFICATES AND

CONSENT LETTER

Quantitative Group

Our

Skills On Your

Team TM

|

Geostatistics

Resources

& Reserves

Reconciliation

& Grade Control

Audit

& Due Diligence

Strategic

Mine Planning

Geometallurgical

Modelling

Mine

Geology

Training

|

John

Vann

Suite 10/18 Parry

St, Fremantle,

WA, 6160,

Australia

Tel.:

+61 8 9433 3511

Fax:

+61 8 9433 3611

Email:

jv@qgroup.net.au

CONSENT

|

To:

|

Toronto

Stock Exchange

|

British

Columbia Securities Commission

Alberta

Securities Commission

Saskatchewan

Securities Commission

Manitoba

Securities Commission

Ontario

Securities Commission

New

Brunswick Securities Commission

Nova

Scotia Securities Commission

Prince

Edward Island Securities Commission

Newfoundland

and Labrador Securities Commission

|

And

To:

|

Entrée

Gold Inc.

|

I, John Vann, do

hereby consent to the public filing of the technical report prepared for Entrée

Gold Inc. titled ‘NI 43-101 Compliant Technical Report on the Lookout Hill

Project, Omnogovi Aimag, Southern Mongolia’, with an effective date of June 10,

2009 (the “Technical Report”) with the securities regulatory authorities

referred to above.

I further consent

(a) to the public filing of the Technical Report with any stock exchange and

other regulatory authority and any publication of the Technical Report by them

for regulatory purposes, including electronic publication in the public company

files on their websites accessible by the public, and (b) to the publication of

the Technical Report by Entrée Gold Inc. on its company website or

otherwise.

Dated this 26th day

of June, 2009.

“Signed

and sealed”

__________________________

John Vann,

M.AusIMM

Quantitative Geoscience Pty Ltd (ABN 30 095 494 947)

and Quantitative Group Pty Ltd (ABN 61 120 267 192). trading as QG

address: Suite 12, 18 Parry St Fremantle WA.

Australia 6160 (PO Box 1304 Fremantle WA. Australia 6959)

phone: +61 (0) 8 9433 3511 | fax: +61 (0) 8 9433 3611 | email: info@qgroup.net.au | web:

www.qgroup.net.au

Quantitative Group

Our

Skills On Your

Team TM

|

Geostatistics

Resources

& Reserves

Reconciliation

& Grade Control

Audit

& Due Diligence

Strategic

Mine Planning

Geometallurgical

Modelling

Mine

Geology

Training

|

CERTIFICATE

of AUTHOR

John

Vann

Suite 10/18 Parry

St, Fremantle,

WA, 6160,

Australia

Tel.:

+61 8 9433 3511

Fax:

+61 8 9433 3611

Email:

jv@qgroup.net.au

I,

John Edward Vann, do hereby certify that:

|

1.

|

I am

currently employed as Principal Consultant and Director

by:

|

Quantitative Group

Pty Ltd.

Suite 10/18 Parry

St, Fremantle,

WA, 6160,

Australia

|

2.

|

I graduated

from the Royal Melbourne Institute of Technology, Victoria, Australia with

a Bachelor of Applied Science (with Distinction) in Applied Geology in

1984. I also graduated from the University of New England, NSW, Australia

with a Bachelor of Science (with Honours) in Geology in 1985. I further

graduated from the University of Leeds, United Kingdom, with the degree

Master of Science in Mining Geostatistics (with Distinction) in

1993.

|

|

3.

|

I am a Fellow

of the Australasian Institute of Mining and Metallurgy (no. 103352) and

also a Member of the Australian Institute of Geoscientists and a Member of

the Society for Economic Geology.

|

|

4.

|

I have

practised my profession continuously since 1985 and have experience in

mining operations, consulting and professional development teaching at and

for mines in various countries including Australia, Canada, The United

States of America, The United Kingdom, Indonesia, Laos, Mongolia, New

Caledonia, New Zealand, Papua New Guinea, Zimbabwe and South Africa. I

have specific experience in large porphyry Cu-Au deposits such as Ok Tedi

and Cadia Hill. As a result of my qualifications and experience, I am a

Qualified Person as defined in National Instrument

43-101.

|

|

5.

|

I have read

the definition of “qualified person” set out in National Instrument 43-

101 (“NI 43-101”) and certify that by reason of my education, affiliation

with a professional association (as defined in NI 43-101) and past

relevant work experience, I fulfil the requirements to be a “qualified

person” for the purposes of NI

43-101.

|

|

6.

|

I am

responsible for the preparation of sections pertaining to the Javhlant

MEL, the Heruga deposit (Sections 1.4, 7.2.3, 9.2, 11.3, 12.2.2, 14.2,

17.2, 20.1.3, and 21.1.3) and the Hugo North Extension Resource (Sections

1.3, 7.2.1, 9.1, 11.2.2, 11.2.3, 12.2.1, 13.3.3, 14.1, 17.1, 20.1.1, and

21.1.1) of the technical report titled “NI 43-101 Compliant Technical

Report on the Lookout Hill Project, Omnogovi Aimag, Southern Mongolia,”

with an effective date of 10 June 2009 (the “Technical Report”) relating

to the Lookout Hill Property. I am the QP with overall responsibility for

report preparation and preparation of any report sections not specifically

assigned to other QPs in Section 2 of the Technical Report. I visited the

Lookout Hill Project February 19-26, 2008 and September 2-9, 2008. I have

personally visited Heruga, and Hugo North Extension, Southern Oyu, Zone I

and Zone III mentioned in this

report.

|

Quantitative Geoscience Pty Ltd (ABN 30 095 494 947)

and Quantitative Group Pty Ltd (ABN 61 120 267 192). trading as QG

address: Suite 12, 18 Parry St Fremantle WA.

Australia 6160 (PO Box 1304 Fremantle WA. Australia 6959)

phone: +61 (0) 8 9433 3511 | fax: +61 (0) 8 9433 3611 | email: info@qgroup.net.au | web:

www.qgroup.net.au

Quantitative Group

Our

Skills On Your

Team TM

|

Geostatistics

Resources

& Reserves

Reconciliation

& Grade Control

Audit

& Due Diligence

Strategic

Mine Planning

Geometallurgical

Modelling

Mine

Geology

Training

|

|

7.

|

I have not

had prior involvement with the properties that are the subject of the

Technical Report.

|

|

8.

|

As of the

date of the certificate, to the best of my knowledge, information and

belief, the Technical Report contains all scientific and technical

information that is required to be disclosed to make the Technical Report

not misleading.

|

|

9.

|

I am

independent of the issuer applying all of the tests in Section 1.4 of

National Instrument 43-101. I do not own any shares of Entrée

Gold Inc.

|

|

10.

|

I have read

National Instrument 43-101 and Form 43-101F1, and the Technical Report has

been prepared in compliance with that instrument and

form.

|

|

11.

|

I consent to

the filing of the Technical Report with any stock exchange and other

regulatory authority and any publication by them, including electronic

publication in the public company files on their websites accessible by

the public.

|

Dated this 10th day

of June, 2009.

“Signed

and sealed”

__________________________

John Edward Vann,

F.AusIMM, M.AIG

Quantitative Geoscience Pty Ltd (ABN 30 095 494 947)

and Quantitative Group Pty Ltd (ABN 61 120 267 192). trading as QG

address: Suite 12, 18 Parry St Fremantle WA.

Australia 6160 (PO Box 1304 Fremantle WA. Australia 6959)

phone: +61 (0) 8 9433 3511 | fax: +61 (0) 8 9433 3611 | email: info@qgroup.net.au | web:

www.qgroup.net.au

Quantitative Group

Our

Skills On Your

Team TM

|

Geostatistics

Resources

& Reserves

Reconciliation

& Grade Control

Audit

& Due Diligence

Strategic

Mine Planning

Geometallurgical

Modelling

Mine

Geology

Training

|

Scott Jackson,

M.AusIMM

Suite 10/18 Parry

St, Fremantle,

WA, 6160,

Australia

Tel.:

+61 8 9433 3511

Fax:

+61 8 9433 3611

Email:

sj@qgroup.net.au

CONSENT

|

To:

|

Toronto

Stock Exchange

|

British

Columbia Securities Commission

Alberta

Securities Commission

Saskatchewan

Securities Commission

Manitoba

Securities Commission

Ontario

Securities Commission

New

Brunswick Securities Commission

Nova

Scotia Securities Commission

Prince

Edward Island Securities Commission

Newfoundland

and Labrador Securities Commission

|

And

To:

|

Entrée

Gold Inc.

|

I, Scott Jackson,

do hereby consent to the public filing of the technical report prepared for

Entrée Gold Inc. titled ‘NI 43-101 Compliant Technical Report on the Lookout

Hill Project, Omnogovi Aimag, Southern Mongolia’, with an effective date of June

10, 2009 (the “Technical Report”) with the securities regulatory authorities

referred to above.

I further consent

(a) to the public filing of the Technical Report with any stock exchange and

other regulatory authority and any publication of the Technical Report by them

for regulatory purposes, including electronic publication in the public company

files on their websites accessible by the public, and (b) to the publication of

the Technical Report by Entrée Gold Inc. on its company website or

otherwise.

Dated this 26th day

of June, 2009.

“Signed

and sealed”

__________________________

Scott Jackson,

M.AusIMM

Quantitative Geoscience Pty Ltd (ABN 30 095 494 947)

and Quantitative Group Pty Ltd (ABN 61 120 267 192). trading as QG

address: Suite 12, 18 Parry St Fremantle WA.

Australia 6160 (PO Box 1304 Fremantle WA. Australia 6959)

phone: +61 (0) 8 9433 3511 | fax: +61 (0) 8 9433 3611 | email: info@qgroup.net.au | web:

www.qgroup.net.au

Quantitative Group

Our

Skills On Your

Team TM

|

Geostatistics

Resources

& Reserves

Reconciliation

& Grade Control

Audit

& Due Diligence

Strategic

Mine Planning

Geometallurgical

Modelling

Mine

Geology

Training

|

CERTIFICATE

of AUTHOR

Scott

Jackson

Suite 10/18 Parry

St, Fremantle,

WA, 6160,

Australia

Tel.:

+61 8 9433 3511

Fax:

+61 8 9433 3611

Email:

sj@qgroup.net.au

I,

Scott Jackson, do hereby certify that:

|

1.

|

I am

currently employed as Principal Consultant and Director

by:

|

Quantitative Group

Pty Ltd.

Suite 10/18 Parry

St, Fremantle,

WA, 6160,

Australia

|

2.

|

I graduated

with a B.Sc. degree in Honours Geology from The University of Western

Australia in 1990. In addition, I obtained a CFSG (Mining Geostatistics

degree) from the Paris School of Mines in

1998.

|

|

3.

|

I am a

registered member of the Australasian Institute of Mining and Metallurgy.

I am also a member of the Australian Institute of

Geoscientists.

|

|

4.

|

I have worked

as a geologist for more than 18 years since my graduation from university.

I have worked on porphyry and epithermal systems in Australia, Indonesia,

New Zealand and Papua New Guinea.

|

|

5.

|

I have read

the definition of “qualified person” set out in National Instrument 43-

101 (“NI 43-101”) and certify that by reason of my education, affiliation

with a professional association (as defined in NI 43-101) and past

relevant work experience, I fulfil the requirements to be a “qualified

person” for the purposes of NI

43-101.

|

|

6.

|

I am

responsible for the preparation of sections pertaining to the Javhlant

MEL, the Heruga deposit (Sections 1.4, 7.2.3, 9.2, 11.3, 12.2.2, 14.2,

17.2, 20.1.3, and 21.1.3) and the Hugo North Extension Resource (Sections

1.3, 7.2.1, 9.1, 11.2.2, 11.2.3, 12.2.1, 13.3.3, 14.1, 17.1, 20.1.1, and

21.1.1) of the technical report titled “NI 43-101 Compliant Technical

Report on the Lookout Hill Project, Omnogovi Aimag, Southern Mongolia,”

with an effective date of 10 June 2009 (the “Technical Report”)

relating to the Lookout Hill Property. I am the QP with overall

responsibility for report preparation and preparation of any report

sections not specifically assigned to other QPs in Section 2 of the

Technical Report. I visited the Lookout Hill Project February 19-22, 2008

and September 2-9, 2008. . I have personally visited Heruga, and Hugo

North Extension, Southern Oyu, Zone I and Zone III mentioned in this

report.

|

|

7.

|

I have not

had prior involvement with the properties that are the subject of the

Technical Report.

|

Quantitative Geoscience Pty Ltd (ABN 30 095 494 947)

and Quantitative Group Pty Ltd (ABN 61 120 267 192). trading as QG

address: Suite 12, 18 Parry St Fremantle WA.

Australia 6160 (PO Box 1304 Fremantle WA. Australia 6959)

phone: +61 (0) 8 9433 3511 | fax: +61 (0) 8 9433 3611 | email: info@qgroup.net.au | web:

www.qgroup.net.au

Quantitative Group

Our

Skills On Your

Team TM

|

Geostatistics

Resources

& Reserves

Reconciliation

& Grade Control

Audit

& Due Diligence

Strategic

Mine Planning

Geometallurgical

Modelling

Mine

Geology

Training

|

|

8.

|

As of the

date of the certificate, to the best of my knowledge, information and

belief, the Technical Report contains all scientific and technical

information that is required to be disclosed to make the Technical Report

not misleading.

|

|

9.

|

I am

independent of the issuer applying all of the tests in Section 1.4 of

National Instrument 43-101. I do not own any shares of Entrée

Gold Inc.

|

|

10.

|

I have read

National Instrument 43-101 and Form 43-101F1, and the Technical Report has

been prepared in compliance with that instrument and

form.

|

|

11.

|

I consent to

the filing of the Technical Report with any stock exchange and other

regulatory authority and any publication by them, including electronic

publication in the public company files on their websites accessible by

the public.

|

Dated this 10th day

of June, 2009.

“Signed

and sealed”

__________________________

Scott Jackson,

M.AusIMM

Quantitative Geoscience Pty Ltd (ABN 30 095 494 947)

and Quantitative Group Pty Ltd (ABN 61 120 267 192). trading as QG

address: Suite 12, 18 Parry St Fremantle WA.

Australia 6160 (PO Box 1304 Fremantle WA. Australia 6959)

phone: +61 (0) 8 9433 3511 | fax: +61 (0) 8 9433 3611 | email: info@qgroup.net.au | web:

www.qgroup.net.au

Owen

R. Cullingham, P. Geol., P.Geo.

128

Oakcliffe Place S.W.

Calgary,

Alberta T2V 0J8

Tel.:

(403) 281-5755

Fax:

(403) 281-5761

Email:

ocullingham@shaw.ca

CONSENT

|

To:

|

Toronto

Stock Exchange

|

British Columbia Securities

Commission

Alberta Securities

Commission

Saskatchewan Securities

Commission

Manitoba Securities

Commission

Ontario Securities

Commission

New Brunswick Securities

Commission

Nova Scotia Securities

Commission

Prince Edward Island Securities

Commission

Newfoundland and Labrador Securities

Commission

|

And

To:

|

Entrée

Gold Inc.

|

I, Owen R.

Cullingham, do hereby consent to the public filing of the technical report

prepared for Entrée Gold Inc. titled ‘NI 43-101 Compliant Technical Report on

the Lookout Hill Project, Omnogovi Aimag, Southern Mongolia’, with an effective

date of June 10, 2009 (the “Technical Report”) with the securities regulatory

authorities referred to above.

I further consent

(a) to the public filing of the Technical Report with any stock exchange and

other regulatory authority and any publication of the Technical Report by them

for regulatory purposes, including electronic publication in the public company

files on their websites accessible by the public, and (b) to the publication of

the Technical Report by Entrée Gold Inc. on its company website or

otherwise.

Dated this 26th day

of June, 2009.

“signed

and sealed”

__________________________

Owen R. Cullingham,

P.Geol., P.Geo.

CERTIFICATE

of AUTHOR

Owen R. Cullingham,

P. Geol., P. Geo.

128 Oakcliffe Place

S.W.

Calgary,

Alberta T2V 0J8

Tel.:

(403) 281-5755

Fax:

(403) 281-5761

Email:

ocullingham@shaw.ca

I, Owen R.

Cullingham, P. Geol., P. Geo., do hereby certify that:

|

1.

|

I am an

independent coal consultant based in Calgary, Alberta, Canada and was

contracted by:

|

Entrée Gold

Inc.

1201-1166 Alberni

Street

Vancouver,

BC

V6E

3Z3

|

2.

|

I graduated

with a B.Sc. degree in Geology from the University of Calgary in

1971.

|

|

3.

|

I am a

registered member of the Association of Professional Engineers and

Geoscientists of British Columbia, licence number # 20409. I am also a

member of the Association of Professional Engineers, Geologists and

Geophysicists of Alberta, member #

M33886.

|

|

4.

|

I have worked

as a geologist for more than 35 years since my graduation from

university.

|

|

5.

|

I have read

the definition of “qualified person” set out in National Instrument 43-

101 (“NI 43-101”) and certify that by reason of my education, affiliation

with a professional association (as defined in NI 43-101) and past

relevant work experience, I fulfill the requirements to be a “qualified

person” for the purposes of NI

43-101.

|

|

6.

|

I am the QP

responsible (together with James R. Foster) for the preparation of

Sections 8.4, 9.3.3, 10.2.5, 12.3.2, 13.4.5, 20.2.2, 21.2 related to coal

exploration on the Western MEL’s (100% Entrée) of the NI 43-101 Compliant

technical report titled “Technical Report on the Lookout Hill Project,

Omnogovi Aimag, Southern Mongolia,” with an effective date of June 10,

2009 (the “Technical Report”) relating to the Lookout Hill Property. I

visited the Nomkhon Bohr coal project from October 4-14,

2008.

|

|

7.

|

I have not

had prior involvement with the properties that are the subject of the

Technical Report.

|

|

8.

|

As of the

date of the certificate, to the best of my knowledge, information and

belief, I am not aware of any material fact or material change with

respect to the subject matter of the technical report, the omission to

disclose which makes the technical report

misleading.

|

|

10.

|

I am

independent of the issuer applying all of the tests in Section 1.5 of

National Instrument 43-101 and do not own any shares of Entrée Gold

Inc.

|

|

11.

|

I have read

National Instrument 43-101 and Form 43-101F1, and the Technical Report has

been prepared in compliance with that instrument and

form.

|

|

12.

|

I consent to

the filing of the Technical Report with any stock exchange and other

regulatory authority and any publication by them, including electronic

publication in the public company files on their websites accessible by

the public.

|

Dated this 10th day

of June, 2009.

“Signed

and sealed”

__________________________

Owen Cullingham,

B.Sc., P.Geol., P.Geo.

|

Level

14 / 140 St Georges Terrace

Perth

Western Australia 6000

GPO Box

Z5266

Perth

Western Australia 6831

|

Telephone:

61 8 9347 4777

Facsimile:

61 8 9347 4747

www.minproc.com.au

ABN

52

DOB 992 694

|

|

Dean David,

M.AusIMM

14/140 St Georges

Tce,

Perth, WA

6000 Australia

Tel.:

+61 8 9347 4734

Fax:

+61 8 9347 4747

Email:

dean.david@minproc.com.au

CONSENT

|

To:

|

Toronto

Stock Exchange

|

British

Columbia Securities Commission

Alberta

Securities Commission

Saskatchewan

Securities Commission

Manitoba

Securities Commission

Ontario

Securities Commission

New

Brunswick Securities Commission

Nova

Scotia Securities Commission

Prince

Edward Island Securities Commission

Newfoundland

and Labrador Securities Commission

|

And

To:

|

Entrée

Gold Inc.

|

I, Dean David, do

hereby consent to the public filing of the technical report prepared for Entrée

Gold Inc. titled ‘NI 43-101 Compliant Technical Report on the Lookout Hill

Project, Omnogovi Aimag, Southern Mongolia’, with an effective date of June 10,

2009 (the “Technical Report”) with the securities regulatory authorities

referred to above.

I further consent

(a) to the public filing of the Technical Report with any stock exchange and

other regulatory authority and any publication of the Technical Report by them

for regulatory purposes, including electronic publication in the public company

files on their websites accessible by the public, and (b) to the publication of

the Technical Report by Entrée Gold Inc. on its company website or

otherwise.

Dated this 26th day

of June, 2009.

“Signed

and sealed”

__________________________

Dean David,

M.AusIMM

|

Level

14 / 140 St Georges Terrace

Perth

Western Australia 6000

GPO Box

Z5266

Perth

Western Australia 6831

|

Telephone:

61 8 9347 4777

Facsimile:

61 8 9347 4747

www.minproc.com.au

ABN

52

DOB 992 694

|

|

CERTIFICATE

of AUTHOR

Dean

David

14/140 St Georges

Tce,

Perth, WA

6000 Australia

Tel.:

+61 8 9347 4734

Fax:

+FAX

Email:

dean.david@minproc.com.au

I,

Dean David, do hereby certify that:

|

1.

|

I am

currently employed as Process Consultant

by:

|

|

|

GRD

Minproc

|

|

|

14/140 St

Georges Tce,

|

|

|

Perth, WA

6000 Australia

|

|

2.

|

I graduated

from the South Australian Institute of Technology (Now University of South

Australia) in 1982 with a Bachelor of Applied Science in

Metallurgy.

|

|

3.

|

I am a member

of the Australasian Institute of Mining and Metallurgy

(no.102351).

|

|

4.

|

I have

practised my profession as a metallurgist for a total of 23 years and with

GRD Minproc since October 2003. As a result of my experience and

qualifications, I am a Qualified Person as defined in National Instrument

43-101.

|

|

5.

|

I have read

the definition of “qualified person” set out in National Instrument 43-

101 (“NI 43-101”) and certify that by reason of my education, affiliation

with a professional association (as defined in NI 43-101) and past

relevant work experience, I fulfil the requirements to be a “qualified

person” for the purposes of NI

43-101.

|

|

6.

|

I am

responsible for the preparation of Section 16 and 21.1.1 of the technical

report titled “NI 43-101 Compliant Technical Report on the Lookout Hill

Project, Omnogovi Aimag, Southern Mongolia,” with an effective date of

June 10th,

2009 (the “Technical Report”) relating to the Lookout Hill

Property. I have not visited the property and have relied on

the visit in December 2005 by a Principal Process Engineer and visits to

site and Mongolia for the Lookout Hill Project by others employed by GRD

Minproc Limited in 2007.

|

|

7.

|

I have not

had prior involvement with the properties that are the subject of the

Technical Report.

|

|

8.

|

As of the

date of the certificate, to the best of my knowledge, information and

belief, the Technical Report contains all scientific and technical

information that is required to be disclosed to make the Technical Report

not misleading..

|

|

Level

14 / 140 St Georges Terrace

Perth

Western Australia 6000

GPO Box

Z5266

Perth

Western Australia 6831

|

Telephone:

61 8 9347 4777

Facsimile:

61 8 9347 4747

www.minproc.com.au

ABN

52

DOB 992 694

|

|

|

9.

|

I am

independent of the issuer applying all of the tests in Section 1.4 of

National Instrument 43-101. I do not own any shares of Entrée

Gold Inc.

|

|

10.

|

I have read

National Instrument 43-101 and Form 43-101F1, and the Technical Report has

been prepared in compliance with that instrument and

form.

|

|

11.

|

I consent to

the filing of the Technical Report with any stock exchange and other

regulatory authority and any publication by them, including electronic

publication in the public company files on their websites accessible by

the public.

|

Dated this 10th day

of June, 2009.

“Signed

and sealed”

__________________________

Dean David, M.

AusIMM

|

Robert

M. Cann, P.Geo.

|

||

|

1201-1166

Alberni Street

|

||

|

Vancouver,

BC V6E 3Z3

|

Tel.:

(604) 687-4777

Fax:

(604) 687-4770

Email:

rcann@entreegold.com

CONSENT

|

To:

|

Toronto

Stock Exchange

|

British

Columbia Securities Commission

Alberta

Securities Commission

Saskatchewan

Securities Commission

Manitoba

Securities Commission

Ontario

Securities Commission

New

Brunswick Securities Commission

Nova

Scotia Securities Commission

Prince

Edward Island Securities Commission

Newfoundland

and Labrador Securities Commission

|

And

To:

|

Entrée

Gold Inc.

|

I, Robert Cann, do

hereby consent to the public filing of the technical report prepared for Entrée

Gold Inc. titled ‘NI 43-101

Compliant Technical Report on the Lookout Hill Project, Omnogovi Aimag, Southern

Mongolia’, with an effective date of June 10, 2009 (the “Technical

Report”) with the securities regulatory authorities referred to

above.

I further consent

(a) to the public filing of the Technical Report with any stock exchange and

other regulatory authority and any publication of the Technical Report by them

for regulatory purposes, including electronic publication in the public company

files on their websites accessible by the public, and (b) to the publication of

the Technical Report by Entrée Gold Inc. on its company website or

otherwise.

Dated this 26th day

of June 2009.

“Signed

and sealed”

__________________________

Robert M. Cann,

M.Sc., P.Geo

CERTIFICATE

of AUTHOR

Robert M. Cann,

P.Geo.

1201-1166 Alberni

Street

Vancouver,

BC V6E 3Z3

Tel.:

(604) 687-4777

Fax:

(604) 687-4770

Email:

rcann@entreegold.com

I,

Robert M. Cann, P.Geo., do hereby certify that:

|

|

1.

|

I am

currently employed as Vice-President, Exploration

by:

|

Entrée Gold

Inc.

1201-1166 Alberni

Street

Vancouver,

BC

V6E

3Z3

|

|

2.

|

I graduated

with a B.Sc. degree in Honours Geology from The University of British

Columbia in 1976. In addition, I obtained a M.Sc. degree in Economic

Geology from The University of British Columbia in

1979.

|

|

|

3.

|

I am a

registered member of the Association of Professional Engineers and

Geoscientists of British Columbia. I am also a member of the Canadian

Institute of Mining and Metallurgy (CIMM) and the Society of Economic

Geologists (SEG).

|

|

|

4.

|

I have worked

as a geologist for more than 25 years since my graduation from university.

I have worked on porphyry and epithermal systems in Canada, USA, Mexico,

Central America, and South America.

|

|

|

5.

|

I have read

the definition of “qualified person” set out in National Instrument 43-

101 (“NI 43-101”) and certify that by reason of my education, affiliation

with a professional association (as defined in NI 43-101) and past

relevant work experience, I fulfill the requirements to be a “qualified

person” for the purposes of NI

43-101.

|

|

|

6.

|

I assisted,

under the direct supervision of Quantitative Group, in preparation of

Sections 1.5, 4.2.2, 6.3, 7.3, 9.3, 10.2, 11.4, 12.3, 13.4, 14.3, 20.2 and

21.2 related to the Western MEL’s (100% Entrée) of the NI 43-101 Compliant

technical report titled “Technical Report on the Lookout Hill Project,

Omnogovi Aimag, Southern Mongolia,” with an effective date of June 10,

2009 (the “Technical Report”) relating to the Lookout Hill

Property.

|

|

Entrée

Gold Inc.

|

Entrée

LLC

|

www.entreegold.com

|

|

Suite 1201

|

Jamyan Gun

Street-5

|

TSX:

ETG

|

||

|

1166 Alberni

St.

|

Ar Mongol

Travel Building

|

AMEX:

EGI

|

||

|

Vancouver, BC

V6E 3Z3

|

Suite #201,

#202

|

Frankfurt:

EKA

|

||

|

Tel:

604.687.4777 Fax: 604.687.4770

|

Sukhbaatar

District, 1st County

|

|||

|

Ulaanbaatar,

Mongolia

|

||||

|

Tel:

976.11.330953 Fax: 976.11.319426

|

|

|

7.

|

I am the Vice

President, Exploration responsible for overall project management on the

100% Entrée ground (Western MEL’s). I have made four site

visits (in February, June, August and November) to the Oyu Tolgoi project

and Lookout Hill project in 2008.

|

|

|

8.

|

I have not

had prior involvement with the properties that are the subject of the

Technical Report.

|

|

|

9.

|

As of the

date of the certificate, to the best of my knowledge, information and

belief, I am not aware of any material fact or material change with

respect to the subject matter of the technical report, the omission to

disclose which makes the technical report

misleading.

|

|

|

10.

|

I am not

independent of the issuer applying all of the tests in Section 1.5 of

National Instrument 43-101 because I have been a full-time employee of

Entrée Gold Inc. since July 2002. I currently own 31,000 shares

of Entrée Gold Inc.; and, I hold stock options granted by Entrée Gold Inc.

to acquire up to 725,000 shares.

|

|

|

11.

|

I have read

National Instrument 43-101 and Form 43-101F1, and the Technical Report has

been prepared in compliance with that instrument and

form.

|

|

|

12.

|

I consent to

the filing of the Technical Report with any stock exchange and other

regulatory authority and any publication by them, including electronic

publication in the public company files on their websites accessible by

the public.

|

Dated this 10th day

of June, 2009.

“Signed

and sealed”

__________________________

Robert M. Cann,

M.Sc., P.Geo.

|

James

R. Foster, H.B.Sc., P.Geo.

|

||

|

1201-1166

Alberni Street

|

||

|

Vancouver,

BC V6E 3Z3

|

Tel.:

(604) 687-4777

Fax:

(604) 687-4770

Email:

jfoster@entreegold.com

CONSENT

|

To:

|

Toronto

Stock Exchange

|

British

Columbia Securities Commission

Alberta

Securities Commission

Saskatchewan

Securities Commission

Manitoba

Securities Commission

Ontario

Securities Commission

New

Brunswick Securities Commission

Nova

Scotia Securities Commission

Prince

Edward Island Securities Commission

Newfoundland

and Labrador Securities Commission

|

And

To:

|

Entrée

Gold Inc.

|

I, James R. Foster,

do hereby consent to the public filing of the technical report prepared for

Entrée Gold Inc. titled ‘NI 43-101 Compliant Technical Report on the Lookout

Hill Project, Omnogovi Aimag, Southern Mongolia’, with an effective date of June

10, 2009 (the “Technical Report”) with the securities regulatory authorities

referred to above.

I further consent

(a) to the public filing of the Technical Report with any stock exchange and

other regulatory authority and any publication of the Technical Report by them

for regulatory purposes, including electronic publication in the public company

files on their websites accessible by the public, and (b) to the publication of

the Technical Report by Entrée Gold Inc. on its company website or

otherwise.

Dated this 26th day

of June, 2009.

“Signed

and sealed”

__________________________

James R. Foster,

H.B.Sc., P.Geo

CERTIFICATE

of AUTHOR

James R. Foster,

H.B.Sc., P.Geo.

1201-1166 Alberni

Street

Vancouver,

BC V6E 3Z3

Tel.:

(604) 687-4777

Fax:

(604) 687-4770

Email:

jfoster@entreegold.com

I,

James R. Foster, H.B.Sc., P.Geo., do hereby certify that:

|

1.

|

I am

currently employed as Project Manager

by:

|

Entrée Gold

Inc.

1201-1166 Alberni

Street

Vancouver,

BC

V6E

3Z3

|

2.

|

I graduated

with an Honours B.Sc. degree in Earth Science and Geography from The

University of Waterloo in 1979.

|

|

3.

|

I am a

registered member of the Association of Professional Engineers and

Geoscientists of British Columbia. I am also a member of the Society of

Economic Geologists (SEG).

|

|

4.

|

I have worked

as a geologist for more than 25 years since my graduation from university.

I have worked on porphyry and epithermal systems in Canada, USA, Mexico,

Central America, and South America.

|

|

5.

|

I have read

the definition of “qualified person” set out in National Instrument 43-

101 (“NI 43-101”) and certify that by reason of my education, affiliation

with a professional association (as defined in NI 43-101) and past

relevant work experience, I fulfill the requirements to be a “qualified

person” for the purposes of NI

43-101.

|

|

6.

|

I assisted in

preparation of Sections 1.5, 4.2.2, 6.3, 7.3, 9.3, 10.2, 11.4, 12.3, 13.4,

14.3, 20.2 and 21.2 related to the Western MELs (100% Entrée) of the NI

43-101 Compliant technical report titled “Technical Report on the Lookout

Hill Project, Omnogovi Aimag, Southern Mongolia,” with an effective date

of 10 June 2009 (the “Technical Report”) relating to the Lookout Hill

Property. I was the Project Manager responsible for day to day project

management on the 100% Entrée ground and was almost continuously on site

from April 2008 to December 2008. During this period, I also

made numerous site visits to Ivanhoe Mines project site to review

exploration progress and results from the Heruga drilling

project.

|

|

Entrée

Gold Inc.

|

Entrée

LLC

|

www.entreegold.com

|

|

Suite 1201

|

Jamyan Gun

Street-5

|

TSX:

ETG

|

||

|

1166 Alberni

St.

|

Ar Mongol

Travel Building

|

AMEX:

EGI

|

||

|

Vancouver, BC

V6E 3Z3

|

Suite #201,

#202

|

Frankfurt:

EKA

|

||

|

Tel:

604.687.4777 Fax: 604.687.4770

|

Sukhbaatar

District, 1st County

|

|||

|

Ulaanbaatar,

Mongolia

|

||||

|

Tel:

976.11.330953 Fax: 976.11.319426

|

|

7.

|

I have not

had prior involvement with the properties that are the subject of the

Technical Report.

|

|

8.

|

As of the

date of the certificate, to the best of my knowledge, information and

belief, I am not aware of any material fact or material change with

respect to the subject matter of the technical report, the omission to

disclose which makes the technical report

misleading.

|

|

9.

|

I am not

independent of the issuer applying all of the tests in Section 1.5 of

National Instrument 43-101 because I have been under contract or have been

an employee of Entrée Gold Inc. since July 2006. I currently

own Nil shares of Entrée Gold Inc.; and I do hold stock options granted by

Entrée Gold Inc. to acquire up to 240,000

shares.

|

|

10.

|

I have read

National Instrument 43-101 and Form 43-101F1, and the Technical Report has

been prepared in compliance with that instrument and

form.

|

|

11.

|

I consent to

the filing of the Technical Report with any stock exchange and other

regulatory authority and any publication by them, including electronic

publication in the public company files on their websites accessible by

the public.

|

Dated this 10th day

of June, 2009.

“Signed

and sealed”

__________________________

James R. Foster,

H.B.Sc., P.Geo.

ENTRÉE GOLD INC.

LOOKOUT HILL PROJECT, MONGOLIA

NI 43-101 TECHNICAL REPORT, JUNE 2009

|

CONTENTS

|

||||||

|

1.0

|

SUMMARY

|

1

|

||||

|

1.1

|

Project

Overview

|

1

|

||||

|

1.2

|

Project

Description

|

1

|

||||

|

1.3

|

Hugo

North Extension

|

2

|

||||

|

1.4

|

Heruga

|

5

|

||||

|

1.5

|

Western

Mineral Exploration Licences

|

7

|

||||

|

2.0

|

INTRODUCTION

|

10

|

||||

|

2.1

|

General

|

10

|

||||

|

2.2

|

Responsibility

|

11

|

||||

|

2.3

|

Site

Visits

|

11

|

||||

|

2.4

|

Terms

of Reference

|

12

|

||||

|

3.0

|

RELIANCE

ON OTHER EXPERTS

|

14

|

||||

|

3.1

|

Introduction

|

14

|

||||

|

3.2

|

Mineral

Tenure

|

14

|

||||

|

4.0

|

PROPERTY

DESCRIPTION AND LOCATION

|

15

|

||||

|

4.1

|

Location

|

15

|

||||

|

4.2

|

Property

Description

|

15

|

||||

|

4.2.1

|

Shivee

Tolgoi JV Property

|

16

|

||||

|

4.2.2

|

Western

Mineral Exploration Licences (100% Entrée)

|

19

|

||||

|

4.2.3

|

Exploration

and Mining Title in Mongolia

|

20

|

||||

|

4.2.4

|

Surface

Rights and Permits

|

21

|

||||

|

4.2.5

|

Surveying

|

21

|

||||

|

4.2.6

|

Environmental

and Socio-Economic Issues

|

21

|

||||

|

5.0

|

ACCESSIBILITY,

CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY

|

23

|

||||

|

5.1

|

Accessibility

|

23

|

||||

|

5.2

|

Climate

|

23

|

||||

|

5.3

|

Local

Resources and Infrastructure

|

23

|

||||

|

5.4

|

Physiography

|

26

|

||||

|

5.5

|

Seismicity

|

26

|

||||

|

6.0

|

HISTORY

|

28

|

||||

|

6.1

|

Introduction

|

28

|

||||

|

6.2

|

Shivee

Tolgoi JV Property

|

28

|

||||

|

6.3

|

Western

MELs (100% Entrée)

|

30

|

||||

|

7.0

|

GEOLOGICAL

SETTING

|

32

|

||||

|

7.1

|

Regional

Geology

|

32

|

||||

|

7.2

|

Shivee

Tolgoi JV Property

|

34

|

||||

|

7.2.1

|

Hugo

North Extension

|

34

|

||||

|

7.2.2

|

Ulaan

Khud Prospect

|

39

|

||||

|

7.2.3

|

Heruga

Deposit

|

39

|

||||

|

7.3

|

Western

MELs (100% Entrée) Geology

|

44

|

||||

|

7.3.1

|

Shivee

Tolgoi Licence

|

44

|

||||

|

7.3.2

|

Togoot

Licence

|

44

|

||||

|

8.0

|

DEPOSIT

TYPES

|

54

|

||||

|

8.1

|

Porphyry

Copper ± Gold Deposits

|

54

|

||||

TOC i

ENTRÉE GOLD INC.

LOOKOUT HILL PROJECT, MONGOLIA

NI 43-101 TECHNICAL REPORT, JUNE 2009

|

8.2

|

High-sulphidation

Epithermal Deposits

|

55

|

||||

|

8.3

|

Low-sulphidation

Epithermal Deposits

|

56

|

||||

|

8.4

|

Coal

Deposits

|

57

|

||||

|

9.0

|

MINERALIZATION

|

59

|

||||

|

9.1

|

Shivee

Tolgoi JV Property

|

59

|

||||

|

9.1.1

|

Hugo

North Extension

|

59

|

||||

|

9.1.2

|

Ulaan

Khud

|

63

|

||||

|

9.2

|

Heruga

Deposit

|

63

|

||||

|

9.3

|

Western

MELs

|

69

|

||||

|

9.3.1

|

Altan

Khulan Target - Shivee Tolgoi Licence

|

69

|

||||

|

9.3.2

|

Tom

Bogd Target - Shivee Tolgoi Licence

|

69

|

||||

|

9.3.3

|

Coal

Targets - Togoot Licence

|

69

|

||||

|

9.3.4

|

Ring

Dyke Prospect - Togoot Licence

|

70

|

||||

|

9.3.5

|

Baruun

Khatnii Guya - Togoot Licence

|

70

|

||||

|

10.0

|

EXPLORATION

|

71

|

||||

|

10.1

|

Shivee

Tolgoi JV Property

|

73

|

||||

|

10.1.1

|

Introduction

|

73

|

||||

|

10.1.2

|

Hugo

North Extension - Shivee Tolgoi MEL

|

73

|

||||

|

10.1.3

|

Ulaan

Khud - Shivee Tolgoi MEL

|

73

|

||||

|

10.1.4

|

Heruga

- Javhlant MEL

|

73

|

||||

|

10.2

|

Western

MELs

|

73

|

||||

|

10.2.1

|

Introduction

|

73

|

||||

|

10.2.2

|

Altan

Khulan Target - Shivee Tolgoi MEL

|

79

|

||||

|

10.2.3

|

Tom

Bogd Target - Shivee Tolgoi MEL

|

79

|

||||

|

10.2.4

|

Nomkhon

Bohr and Coking Flats Coal Targets - Togoot MEL

|

80

|

||||

|

10.2.5

|

Ukhaa

Tolgod Target - Togoot MEL

|

85

|

||||

|

10.2.6

|

Baruun

Khatnii Guya Target - Togoot MEL

|

89

|

||||

|

10.2.7

|

Ring

Dyke Target - Togoot MEL

|

89

|

||||

|

10.2.8

|

Toogie

East Target - Togoot MEL

|

91

|

||||

|

11.0

|

DRILLING

|

93

|

||||

|

11.1

|

General

|

93

|

||||

|

11.2

|

Shivee

Tolgoi JV Property - Shivee Tolgoi MEL

|

93

|

||||

|

11.2.1

|

Introduction

|

93

|

||||

|

11.2.2

|

Hugo

North Extension Exploration Diamond Drilling

|

95

|

||||

|

11.2.3

|

Hugo

North Extension Drill Results

|

95

|

||||

|

11.2.4

|

Ulaan

Khud (Airport North) Diamond Drilling

|

95

|

||||

|

11.2.5

|

Geotechnical

Drilling

|

97

|

||||

|

11.3

|

Shivee

Tolgoi JV Property - Javhlant MEL

|

97

|

||||

|

11.3.1

|

Introduction

|

97

|

||||

|

11.3.2

|

Exploration

Diamond Drilling at Heruga

|

99

|

||||

|

11.3.3

|

Heruga

Drill Results

|

101

|

||||

|

11.4

|

Western

MELs (100% Entrée)

|

105

|

||||

|

11.4.1

|

Introduction

|

105

|

||||

|

11.4.2

|

Exploration

Diamond Drilling - Shivee Licence

|

106

|

||||

|

11.4.3

|

Drill

Results - Shivee Tolgoi Licence

|

108

|

||||

|

Altan

Khulan Target

|

108

|

|||||

|

Tom

Bogd Target

|

108

|

|||||

|

11.4.4

|

Exploration

Drilling - Togoot Licence

|

108

|

||||

|

Core

Drilling

|

108

|

|||||

|

RC

Drilling

|

111

|

|||||

|

11.4.5

|

Downhole

Geophysical Surveys

|

113

|

||||

|

11.4.6

|

Drill

Results - Togoot MEL

|

114

|

||||

TOC ii

ENTRÉE GOLD INC.

LOOKOUT HILL PROJECT, MONGOLIA

NI 43-101 TECHNICAL REPORT, JUNE 2009

|

12.0

|

SAMPLING

METHOD AND APPROACH

|

118

|

||||

|

12.1

|

Introduction

|

118

|

||||

|

12.2

|

Shivee

Tolgoi JV Property

|

118

|

||||

|

12.2.1

|

Diamond

Drill Core Sampling - Hugo North Extension

|

118

|

||||

|

12.2.2

|

Diamond

Drill Core Sampling - Heruga

|

119

|

||||

|

12.3

|

Western

MELs (100% Entrée)

|

119

|

||||

|

12.3.1

|

Introduction

|

119

|

||||

|

12.3.2

|

Core

Sampling Procedures

|

119

|

||||

|

Coal

Sampling

|

119

|

|||||

|

Base

and Precious Metal Sampling

|

120

|

|||||

|

12.3.3

|

Soil

Sampling - “MMI-M”

|

121

|

||||

|

12.3.4

|

Rock

Sampling

|

121

|

||||

|

13.0

|

SAMPLE

PREPARATION, ANALYSES, AND SECURITY

|

122

|

||||

|

13.1

|

Introduction

|

122

|

||||

|

13.2

|

Shivee

Tolgoi JV Property

|

122

|

||||

|

13.3

|

Sample

Preparation and Shipment

|

123

|

||||

|

13.3.1

|

Analyses

|

124

|

||||

|

13.3.2

|

QA/QC

Program

|

125

|

||||

|

13.3.3

|

QG

2008 Review and Comments on Ivanhoe Sampling and QA/QC

|

129

|

||||

|

13.4

|

Western

MELs

|

144

|

||||

|

13.4.1

|

Rock

Chip Sampling

|

144

|

||||

|

13.4.2

|

Soil

Sampling

|

144

|

||||

|

13.4.3

|

Trench

sampling

|

144

|

||||

|

13.4.4

|

Core

Sampling - Base and Precious Metals

|

144

|

||||

|

13.4.5

|

Core

Sampling - Coal

|

145

|

||||

|

14.0

|

DATA

VERIFICATION

|

148

|

||||

|

14.1

|

Shivee

Tolgoi JV 2008 Property Visits and Sampling by QG

|

148

|

||||

|

14.1.1

|

QG

Core Review

|

149

|

||||

|

14.2

|

Javhlant

JV Property - 2008 Visit by Quantitative Group

|

150

|

||||

|

14.2.1

|

QG

Heruga Core Review

|

151

|

||||

|

14.2.2

|

QG

Drill Site Visit

|

153

|

||||

|

14.2.3

|

QG

Database Review

|

153

|

||||

|

14.2.4

|

QG

Comments on Sample Security Measures at Heruga

|

153

|

||||

|

14.3

|

Western

MELs

|

154

|

||||

|

14.3.1

|

General

|

154

|

||||

|

15.0

|

ADJACENT

PROPERTIES

|

156

|

||||

|

16.0

|

MINERAL

PROCESSING AND METALLURGICAL TESTING

|

159

|

||||

|

16.1

|

Summary

|

159

|

||||

|

16.2

|

Test

Programs

|

160

|

||||

|

16.2.1

|

AMMTEC

Bench-Scale Flotation Test Program

|

162

|

||||

|

16.2.2

|

MinnovEX

Comminution Testing

|

162

|

||||

|

16.2.3

|

MinnovEX

FLEET Test Program

|

162

|

||||

|

16.2.4

|

AMMTEC

Comminution Testing

|

162

|

||||

|

16.2.5

|

SAG

Pilot Plant

|

162

|

||||

|

16.2.6

|

Hugo

North Extension

|

163

|

||||

|

16.2.7

|

Bulk

Flotation Test

|

163

|

||||

|

16.2.8

|

Concentrate

Upgrading Program, SGS

|

163

|

||||

|

16.3

|

Hugo

North Extension Flotation Testwork

|

163

|

||||

|

16.3.1

|

Introduction

|

163

|

||||

|

16.3.2

|

Flotation

Tests

|

165

|

||||

|

16.3.3

|

Results

|

165

|

||||

|

16.4

|

Conclusions |

167

|

||||

TOC iii

ENTRÉE GOLD INC.

LOOKOUT HILL PROJECT, MONGOLIA

NI 43-101 TECHNICAL REPORT, JUNE 2009

|

17.0

|

Mineral

Resource and MINERAL RESERVE Estimates

|

168

|

||||

|

17.1

|

Hugo

North Extension Deposit

|

168

|

||||

|

17.1.1

|

Introduction

|

168

|

||||

|

17.1.2

|

QG

Checks on 2007 Estimate

|

168

|

||||

|

17.1.3

|

Geological

Models

|

171

|

||||

|

17.1.4

|

Composites

|

172

|

||||

|

17.1.5

|

Data

Analysis

|

175

|

||||

|

17.1.6

|

Variography

|

178

|

||||

|

17.1.7

|

Model

Setup

|

182

|

||||

|

17.1.8

|

Estimation

|

182

|

||||

|

17.1.9

|

Validation

|

185

|

||||

|

17.1.10

|

Mineral

Resource Summary - Hugo North Extension

|

189

|

||||

|

17.2

|

Heruga Deposit |

191

|

||||

|

17.2.1

|

Introduction

|

191

|

||||

|

17.2.2

|

Geologic

Models

|

191

|

||||

|

17.2.1

|

Composites

|

197

|

||||

|

17.2.2

|

Data

Analysis

|

197

|

||||

|

17.2.3

|

Variography

|

202

|

||||

|

17.2.4

|

Model

Setup

|

203

|

||||

|

17.2.5

|

Estimation

|

203

|

||||

|

17.2.6

|

Validation

|

205

|

||||

|

17.2.7

|

Mineral

Resource Classification

|

210

|

||||

|

17.2.8

|

Mineral

Resource Summary

|

211

|

||||

|

18.0

|

OTHER

RELEVANT DATA AND INFORMATION

|

212

|

||||

|

19.0

|

ADDITIONAL

REQUIREMENTS FOR TECHNICAL REPORTS ON DEVELOPMENT PROPERTIES AND

PRODUCTION PROPERTIES

|

213

|

||||

|

20.0

|

INTERPRETATIONS

AND CONCLUSIONS

|

214

|

||||

|

20.1

|

Shivee

Tolgoi JV Property

|

214

|

||||

|

20.1.1

|

Hugo

North Extension

|

214

|

||||

|

20.1.2

|

Ulaan

Khud (Airport North)

|

216

|

||||

|

20.1.3

|

Heruga

Deposit - Javhlant MEL

|

216

|

||||

|

20.2

|

Western

MELs (100% Entrée)

|

219

|

||||

|

20.2.1

|

Shivee

Tolgoi MEL

|

219

|

||||

|

20.2.2

|

Togoot

MEL

|

219

|

||||

|

21.0

|

RECOMMENDATIONS

|

221

|

||||

|

21.1

|

Shivee

Tolgoi JV Property

|

221

|

||||

|

21.1.1

|

Hugo

North Extension

|

221

|

||||

|

21.1.2

|

Ulaan

Khud

|

221

|

||||

|

21.1.3

|

Heruga

Deposit - Javhlant MEL

|

221

|

||||

|

21.2

|

Western

MELs

|

221

|

||||

|

22.0

|

REFERENCES

|

223

|

||||

|

23.0

|

DATE

AND SIGNATURE PAGE

|

227

|

||||

TOC iv

ENTRÉE GOLD INC.

LOOKOUT HILL PROJECT, MONGOLIA

NI 43-101 TECHNICAL REPORT, JUNE 2009

|

Tables

|

||||

|

Table

1-1:

|

Hugo North

Extension Mineral Resources, Based on Drilling Completed to 01 November

2006 (0.6% CuEq Cut-off); Effective Date 20 February,

2007

|

4

|

||

|

Table

1-2:

|

Heruga

Inferred Mineral Resources, Based on Drilling Completed to

13 February, 2008; Effective Date 12 March, 2008

|

7

|

||

|

Table

4-1:

|

Lookout Hill

Project - Licence Details

|

16

|

||

|

Table

4-2:

|

Shivee Tolgoi

JV Property Boundary Coordinates

|

19

|

||

|

Table

4-3:

|

Western MELs

(100% Entrée) Boundary Coordinates

|

20

|

||

|

Table

4-4:

|

Exploration

and Mining Licence Annual Fees

|

20

|

||

|

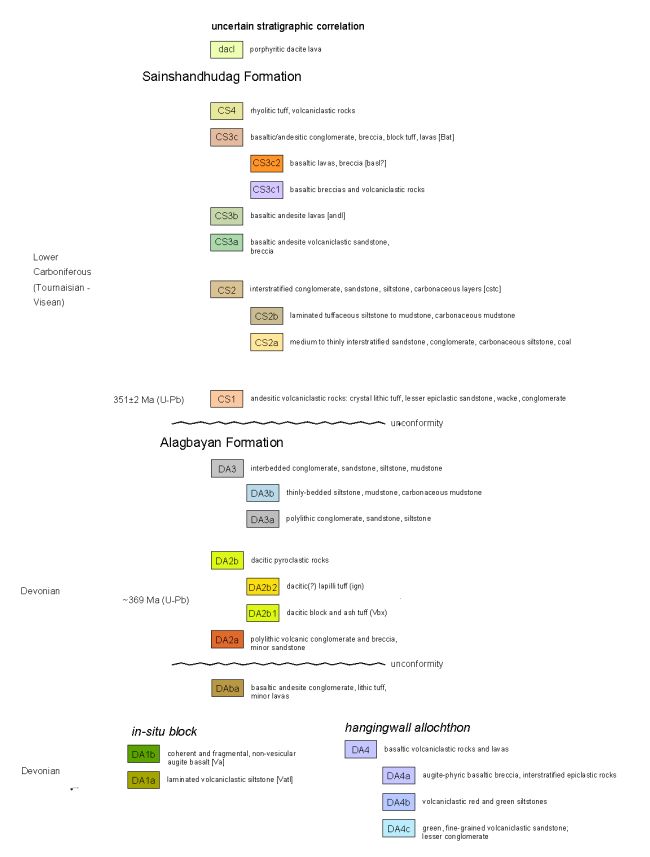

Table

7-1:

|

Stratigraphy

of the Oyu Tolgoi - Lookout Hill Area

|

45

|

||

|

Table

8-1:

|

Modified

Classification of Coal

|

57

|

||

|

Table

10-1:

|

Exploration

Summary JV property and Western MELs, 2002-2008

|

71

|

||

|

Table

10-2:

|

Summary of

2008 IP Surveys, Togoot Licence

|

82

|

||

|

Table

10-3:

|

Summary of

Ukhaa Tolgod Trench Assays, Togoot Licence

|

85

|

||

|

Table

11-1:

|

Lookout Hill

Project - Drilling Summary

|

94

|

||

|

Table

11-2:

|

Ulaan Khud

2008 Drilling Summary

|

97

|

||

|

Table

11-3:

|

Javhlant MEL

Drilling Summary to March 03, 2009

|

98

|

||

|

Table

11-4:

|

Selected

Mineralized Intervals from the Heruga Deposit, 2008

Drilling

|

104

|

||

|

Table

11-5:

|

2008 Core

Hole Drilling Summary - Shivee Tolgoi Licence

|

106

|

||

|

Table

11-6:

|

2008 Core

Hole Drilling Summary - Togoot Licence

|

109

|

||

|

Table

11-7:

|

Reverse

Circulation Drilling - Togoot Licence

|

111

|

||

|

Table

11-8:

|

Reverse-Circulation

Drilling Results - Togoot Licence

|

117

|

||

|

Table

13-1:

|

Duplicate

Percent Difference at the 90th Population Percentile

|

129

|

||

|

Table

14-1:

|

Check

Assaying on Selected Oyu Tolgoi Drill Cores

|

149

|

||

|

Table

14-2:

|

Summary of

Oyu Tolgoi Core Reviewed by QG

|

150

|

||

|

Table

14-3:

|

Summary of

Heruga Core Reviewed by QG

|

152

|

||

|

Table

14-4:

|

Entrée Check

Sampling (Feb. 2008) - Core Chip Samples

|

155

|

||

|

Table

16-1:

|

Oyu Tolgoi

Project Flotation Testwork

|

161

|

||

|

Table

16-2:

|

Summary of

Comminution Samples Dispatched to Testwork Facilities

|

161

|

||

|

Table

16-3:

|

Samples

Submitted for PRA Flotation Testwork

|

164

|

||

|

Table

16-4:

|

Summary of

Composite Head Grades

|

164

|

||

|

Table

16-5:

|

Rougher

Flotation Recoveries After 8 Minutes - Entrée Composites

|

165

|

||

|

Table

16-6:

|

Cleaner

Grades and Recoveries at 6 Minutes - Entrée Composites

|

165

|

||

|

Table

16-7:

|

Cleaner

Concentrate (6 minutes) Impurity Levels

|

166

|

||

|

Table

17-1:

|

Lithology and

Structural Solids and Surfaces, Hugo North Deposit

|

172

|

||

|

Table

17-2:

|

Hugo North

Statistics for 5 m Composites - Cu % Data

|

176

|

||

|

Table

17-3:

|

Hugo North

Statistics for 5 m Composites - Au g/t Data

|

177

|

||

|

Table

17-4:

|

Hugo North

Copper Intra-domain Boundary Contacts

|

179

|

||

|

Table

17-5:

|

Hugo North

Gold Intra-domain Boundary Contacts

|

179

|

||

|

Table

17-6:

|

Copper

Variogram Parameters

|

180

|

||

|

Table

17-7:

|

Azimuth and

Dip Angles of Rotated Variogram Axes for Copper

|

180

|

||

|

Table

17-8:

|

Gold

Variogram Parameters

|

181

|

||

|

Table

17-9:

|

Azimuth and

Dip Angles of Rotated Variogram Axes for Gold

|

181

|

||

|

Table

17-10:

|

Copper Search

Ellipsoids for Hugo North

|

183

|

||

|

Table

17-11:

|

Gold Search

Ellipsoids for Hugo North

|

184

|

||

|

Table

17-12:

|

Outlier

Thresholds Applied to Cu Grade Domains

|

184

|

||

|

Table

17-13:

|

Outlier

Thresholds Applied to Au Grade Domains

|

184

|

||

|

Table

17-14:

|

Bulk Density

Search Ellipsoids for Hugo North

|

185

|

||

|

Table

17-15:

|

Average Bulk

Density

|

185

|

||

|

Table

17-16:

|

Global Model

Mean Grade Values by Domain in Each Zone

|

186

|

||

TOC v

ENTRÉE GOLD INC.

LOOKOUT HILL PROJECT, MONGOLIA

NI 43-101 TECHNICAL REPORT, JUNE 2009

|

Table

17-17:

|

Mineral

Resource Inventory, Hugo North Extension, Based on Drilling Completed to

01 November 2006, and Reported by Ivanhoe (Effective Date 20

February 2007)

|

190

|

||

|

Table

17-18:

|

Project Area

Limits and Block Size

|

191

|

||

|

Table

17-19:

|

Lithology and

Structural Solids and Surfaces, Heruga Deposit

|

192

|

||

|

Table

17-20:

|

Heruga

Statistics for 5 m Composites - Cu % Data

|

198

|

||

|

Table

17-21:

|

Heruga

Statistics for 5 m Composites - Au g/t Data

|

198

|

||

|

Table

17-22:

|

Heruga

Statistics for 5 m Composites - Mo ppm Data

|

198

|

||

|

Table

17-23:

|

Gold

Estimation Domains - Mineralised Lithologies Only

|

201

|

||

|

Table

17-24:

|

Copper

Estimation Domains - Mineralised Lithologies Only

|

201

|

||

|

Table

17-25:

|

Molybdenum

Estimation Domains - Mineralised Lithologies Only

|

201

|

||

|

Table

17-26:

|

Summary of

Capping Parameters

|

202

|

||

|

Table

17-27:

|

Variogram

Parameters

|

203

|

||

|

Table

17-28:

|

Search

Ellipsoids for Heruga

|

204

|

||

|

Table

17-29:

|

Bulk Density

Search Ellipsoids for Heruga

|

205

|

||

|

Table

17-30:

|

Average Bulk

Density

|

205

|

||

|

Table

17-31:

|

Global Model

Mean Grade Values by Domain in Each Zone

|

206

|

||

|

Table

17-32:

|

Copper

Equivalent Assumptions

|

211

|

||

|

Table

17-33:

|

Mineral

Resource Inventory, Heruga Deposit, Based on Drilling Completed as of Feb.

13, 2008 and Reported by Ivanhoe Mar. 12, 2008

|

211

|

||

|

Table

21-1:

|

Western MELs

- 2009 Exploration Budget, Phase 1

|

222

|

TOC vi

ENTRÉE GOLD INC.

LOOKOUT HILL PROJECT, MONGOLIA

NI 43-101 TECHNICAL REPORT, JUNE 2009

|

Figures

|

||||

|

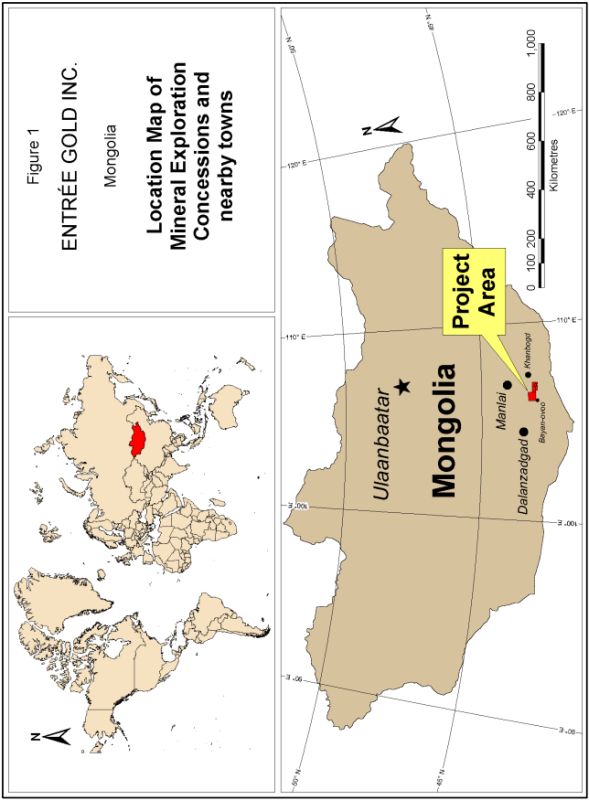

Figure

4-1:

|

Location

Map

|

17

|

||

|

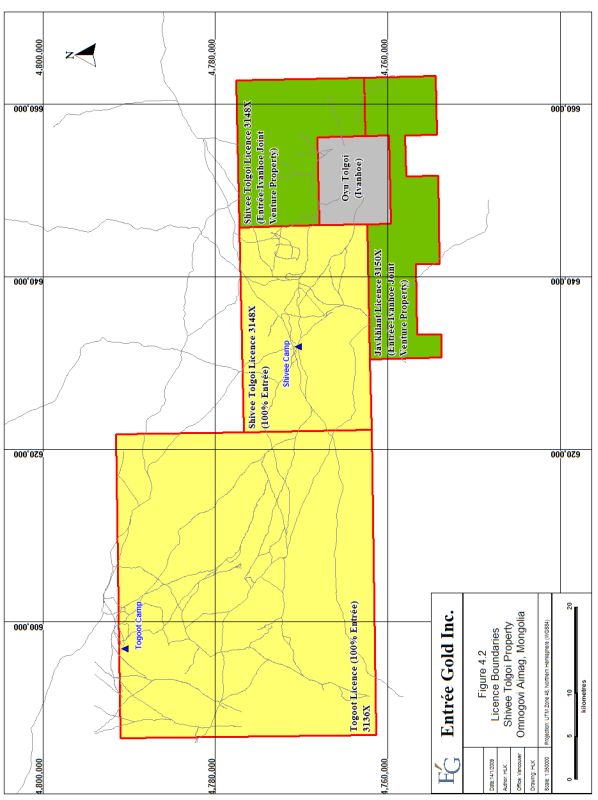

Figure

4-2:

|

Lookout Hill

Project - Land Tenure

|

18

|

||

|

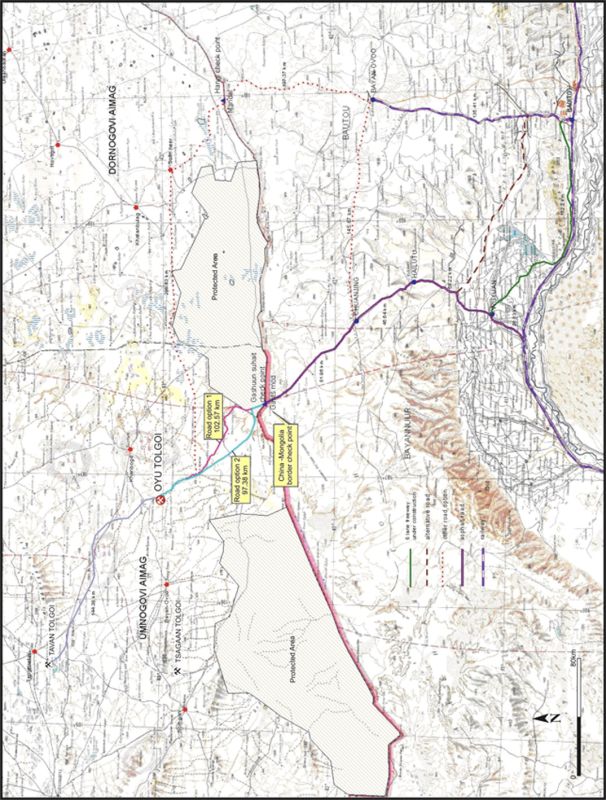

Figure

5-1:

|

Transportation

Infrastructure

|

25

|

||

|

Figure

6-1:

|

2002 - 2008

Exploration Areas, Shivee Tolgoi Property

|

29

|

||

|

Figure

7-1:

|

General

Geology of Mongolia (after Badarch et al.,

2002)

|

33

|

||

|

Figure

7-2:

|

Stratigraphic

Column, Oyu Tolgoi Exploration Area

|

36

|

||

|

Figure

7-3:

|

Surface

Geology Map Shivee Tolgoi JV Property Showing Hugo North Extension and

Ulaan Khud

|

37

|

||

|

Figure

7-4:

|

Geological

Plan of Heruga Deposit Area (Legend as in Fig. 7-2)

|

42

|

||

|

Figure

7-5:

|

Geology of

Northwest Togoot MEL (Legend on following page; Panteleyev,

2008)

|

50

|

||

|

Figure

7-6:

|

Detailed

Geology - Nomkhon Bohr

|

52

|

||

|

Figure

7-7:

|

Detailed

Geology - Coking Flats

|

53

|

||

|

Figure

9-1:

|

Geological

Interpretation Showing Assay Histograms, Section N4768300, Looking

North

|

60

|

||

|

Figure

9-2:

|

Geology and

Mineralization Section N4768300, Looking North

|

61

|

||

|

Figure

9-3:

|

Heruga

Deposit Area Section N4759300

|

66

|

||

|

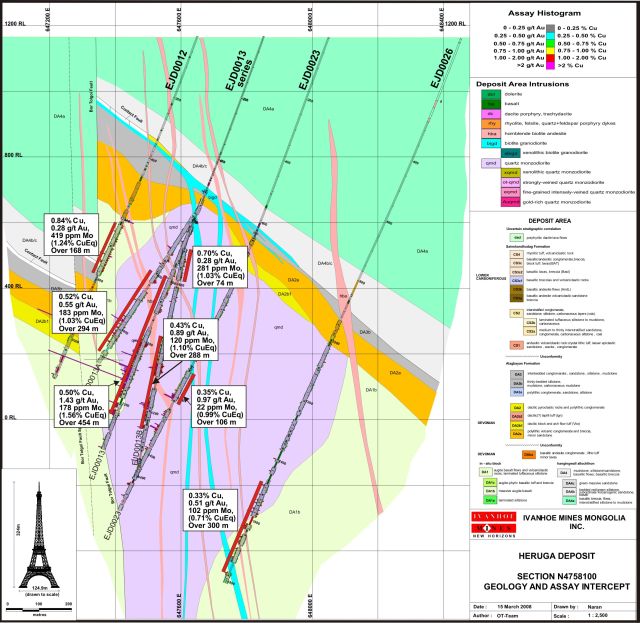

Figure

9-4:

|

Heruga

Deposit Area Section N4758100

|

67

|

||

|

Figure

9-5:

|

Generalized

Mo Shell on Heruga Drill Sections (North to South)

|

68

|

||

|

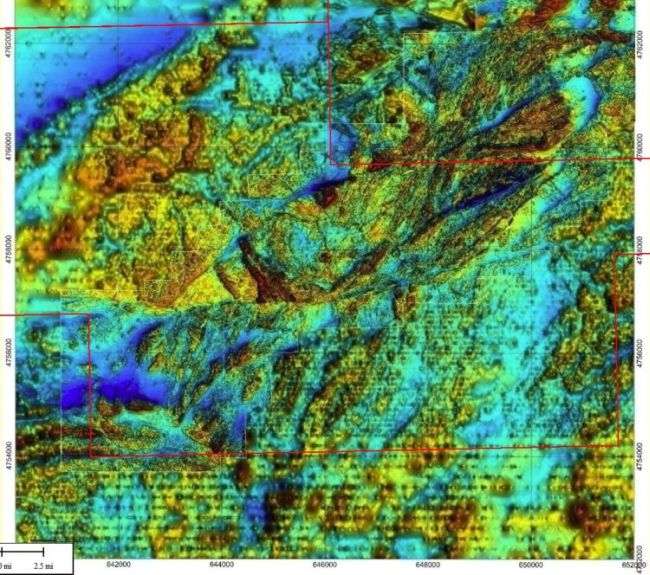

Figure

10-1:

|

Detailed

magnetic over Heruga Deposit - Javhlant MEL

|

74

|

||

|

Figure

10-2:

|

2008 Targets

on Western MELs

|

76

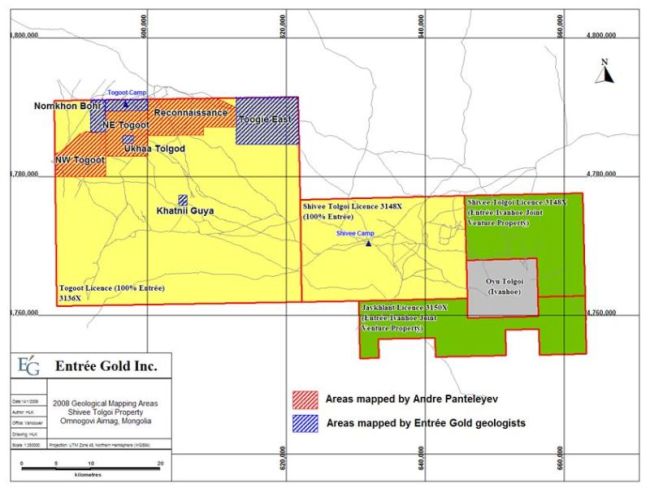

|

||

|

Figure

10-3:

|

2008 Mapping

areas on Western MELs

|

77

|

||

|

Figure

10-4:

|

2008 MMI

sampling areas on Western MELs

|

78

|

||

|

Figure

10-5:

|

Tom Bogd

Target - 2008 Geology and MMI-Mo Anomaly

|

79

|

||

|

Figure

10-6:

|

Nomkhon Bohr

Excavator Trenching

|

81

|

||

|

Figure

10-7:

|

Nomkhon Bohr

Resistivity

|

83

|

||

|

Figure

10-8:

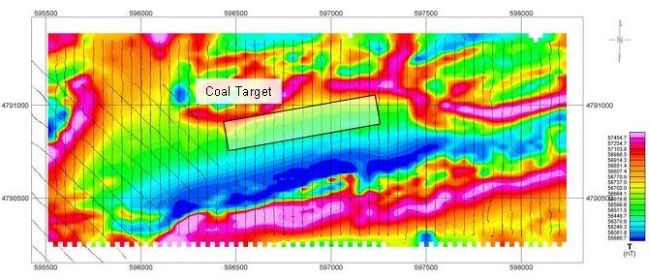

|

TMI Nomkhon

Bohr Magnetics

|

83

|

||

|

Figure

10-9:

|

TMI Coking

Flats Magnetics

|

84

|

||

|

Figure

10-10:

|

Coking Flats

Chargeability

|

84

|

||

|

Figure

10-11:

|

Geology of

the Ukhaa Tolgod Area

|

86

|

||

|

Figure

10-12:

|

MMI-Au -

Ukhaa Tolgod Grid, Togoot Licence

|

87

|

||

|

Figure

10-13:

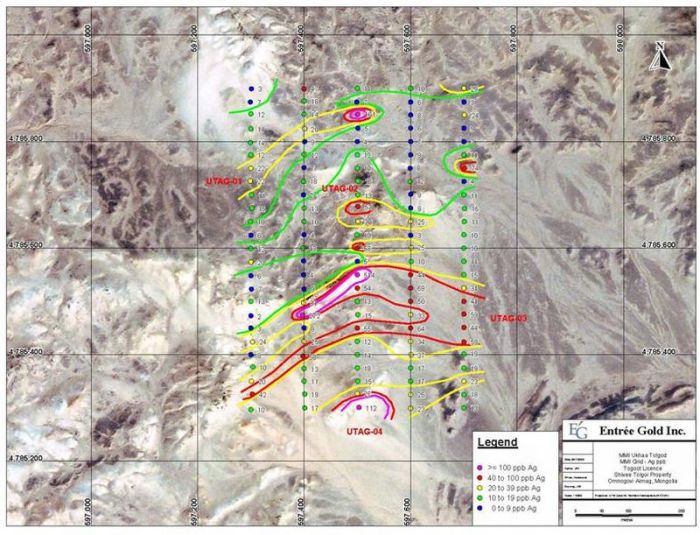

|

MMI-Ag -

Ukhaa Tolgod Grid, Togoot Licence

|

88

|

||

|

Figure

10-14:

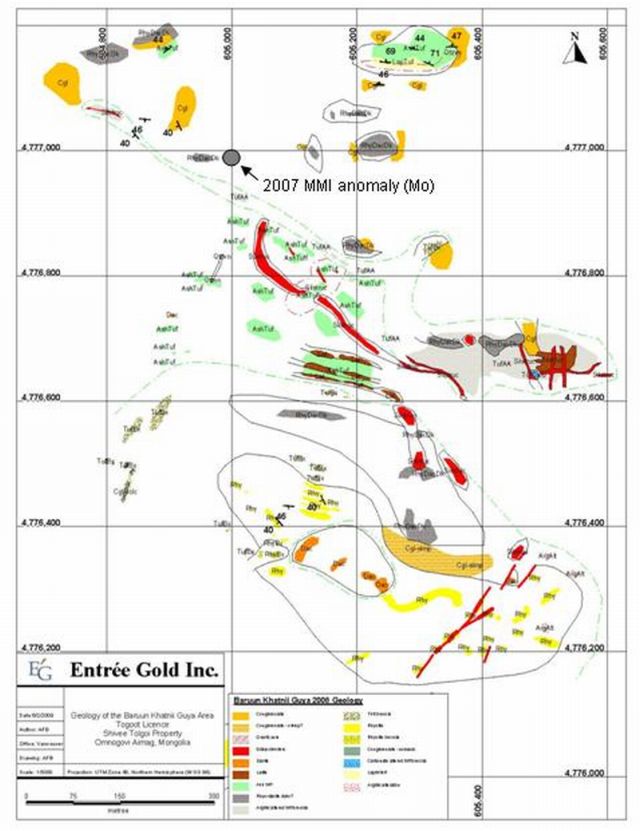

|

Geology of

the Baruun Khatnii Guya Area

|

90

|

||

|

Figure

10-15:

|

Toogie East

Geology

|

92

|

||

|

Figure

11-1:

|

Ulaan Khud

Drillhole Locations

|

96

|

||

|

Figure

11-2:

|

Drillhole

Location on IP, Heruga Deposit

|

100

|

||

|

Figure

11-3:

|

Geology and

Mineralization Section N4758100, Looking North

|

102

|

||

|

Figure

11-4:

|

Geology and

Mineralization Section N4757900, Looking North

|

103

|

||

|

Figure

11-5:

|

2008 Drill

collar locations on Shivee Tolgoi Licence

|

107

|

||

|

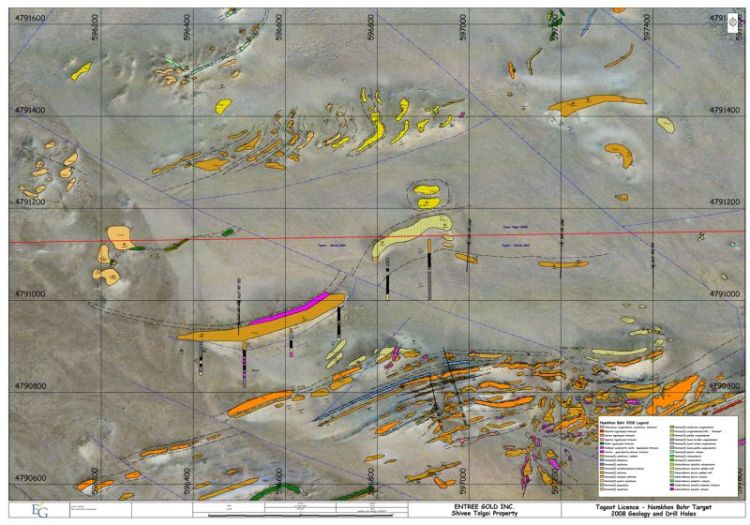

Figure

11-6:

|

2008 Diamond

drillhole collar locations on Togoot Licence

|

110

|

||

|

Figure

11-7:

|

2008 RC

Drillhole Collar Locations on Togoot Licence

|

112

|

||

|

Figure

11-8:

|

Representative

Core and RC Section Through Nomkhon Bohr

|

115

|

||

|

Figure

11-9:

|

RC Drill

Section - Coking Flats

|

116

|

||

|

Figure

13-1:

|

Field Blank

Performance - Gold

|

127

|

||

|

Figure

13-2:

|

Field Blank

Performance - Copper

|

127

|

||

|

Figure

13-3:

|

Gold

Duplicate Samples

|

128

|

||

|

Figure

13-4:

|

Copper

Duplicate Samples

|

128

|

||

|

Figure

13-7:

|

Average SGS

SRM Molybdenum Bias, 2002-2008

|

133

|

||