Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-Q

| x | QUARTERLY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the quarterly period ended February 28, 2009

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number 001-08399

WORTHINGTON INDUSTRIES, INC.

(Exact name of registrant as specified in its charter)

| Ohio | 31-1189815 | |||

| (State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) | |||

| 200 Old Wilson Bridge Road, Columbus, Ohio | 43085 | |||

| (Address of principal executive offices) | (Zip Code) | |||

(614) 438-3210

(Registrant’s telephone number, including area code)

Not applicable

(Former name, former address and former fiscal year, if changed since last report)

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

YES x NO ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer x |

Accelerated filer ¨ | |||

| Non-accelerated filer ¨ (Do not check if a smaller reporting company) |

Smaller reporting company ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

YES ¨ NO x

APPLICABLE ONLY TO CORPORATE ISSUERS:

Indicate the number of shares outstanding of each of the Issuer’s classes of common stock, as of the latest practicable date.

As of March 31, 2009, 78,945,237 of the registrant’s common shares, without par value, were outstanding.

Table of Contents

| ii | ||||

| Part I. Financial Information |

||||

| Item 1. |

Financial Statements (Unaudited) |

|||

| Consolidated Balance Sheets – |

1 | |||

| 2 | ||||

| 3 | ||||

| 4 | ||||

| Item 2. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

14 | ||

| Item 3. |

28 | |||

| Item 4. |

28 | |||

| Part II. Other Information |

||||

| Item 1. |

30 | |||

| Item 1A. |

30 | |||

| Item 2. |

31 | |||

| Item 3. |

31 | |||

| Item 4. |

Submission of Matters to a Vote of Security Holders (Not applicable) |

31 | ||

| Item 5. |

31 | |||

| Item 6. |

32 | |||

| 33 | ||||

| 34 | ||||

i

Table of Contents

Selected statements contained in this Quarterly Report on Form 10-Q, including, without limitation, in “PART I – Item 2. –Management’s Discussion and Analysis of Financial Condition and Results of Operations,” constitute “forward-looking statements” as that term is used in the Private Securities Litigation Reform Act of 1995 (the “Act”). These forward-looking statements include, without limitation, statements relating to:

| — | business plans or to future or expected performance, sales, operating results and earnings per share; |

| — | projected capacity and working capital needs; |

| — | demand trends; |

| — | pricing trends for raw materials and finished goods; |

| — | anticipated capital expenditures and asset sales; |

| — | anticipated improvements and efficiencies in operations, sales and sourcing and the results thereof; |

| — | anticipated impacts of transformation efforts; |

| — | projected timing, results, costs, charges and expenditures related to headcount reductions and facility dispositions, shutdowns and consolidations; |

| — | the alignment of operations with demand; |

| — | the ability to take advantage of future opportunities, new products and markets; |

| — | expectations for Company and customer inventories, jobs and orders; |

| — | expectations for the economy and markets; |

| — | expected benefits from turnaround plans, cost reduction efforts and other new initiatives; |

| — | expectations for improving margins and increasing shareholder value; and |

| — | effects of judicial rulings; and |

| — | other non-historical matters. |

Because they are based on beliefs, estimates and assumptions, forward-looking statements are inherently subject to risks and uncertainties that could cause actual results to differ materially from those projected. Any number of factors could affect actual results, including, without limitation, those that follow:

| — | the effect of regional, national, and worldwide economic conditions generally and within major product markets, including a prolonged or substantial economic downturn; |

| — | the effect of conditions in national and worldwide financial markets; |

| — | product demand and pricing; |

| — | changes in product mix, product substitution and market acceptance of the Company’s products; |

| — | fluctuations in pricing, quality or availability of raw materials (particularly steel), supplies, transportation, utilities and other items required by operations; |

| — | effects of facility closures and the consolidation of operations; |

| — | the effect of financial difficulties, consolidation and other changes within the steel, automotive, construction and related industries; |

| — | failure to maintain appropriate levels of inventories; |

| — | financial difficulties (including bankruptcy filings) of original equipment manufacturers, end-users and customers, suppliers, joint venture partners and others with whom the Company does business; |

| — | the ability to realize targeted expense reductions from head count reductions, facility closures and other cost reduction efforts; |

| — | the ability to realize other cost savings and operational, sales and sourcing improvement and efficiencies on a timely basis; |

| — | the overall success of, and the ability to integrate, newly-acquired businesses and achieve synergies therefrom; |

| — | capacity levels and efficiencies within facilities and within the industry as a whole; |

| — | the effect of disruption in the business of suppliers, customers, facilities and shipping operations due to adverse weather, casualty events, equipment breakdowns, acts of war or terrorist activities or other causes; |

| — | changes in customer demand, inventories, spending patterns, product choices, and supplier choices; |

| — | risks associated with doing business internationally, including economic, political and social instability, and foreign currency exposure; |

| — | the ability to improve and maintain processes and business practices to keep pace with the economic, competitive and technological environment; |

| — | adverse claims experience with respect to workers’ compensation, product recalls or liability, casualty events or other matters; |

| — | deviation of actual results from estimates and/or assumptions used by the Company in the application of its significant accounting policies; |

| — | level of imports and import prices in the Company’s markets; |

| — | the impact of judicial rulings and governmental regulations, both in the United States and abroad; and |

| — | other risks described from time to time in the Company’s filings with the Securities and Exchange Commission, including those described in “PART I – Item 1A. — Risk Factors” of the Company’s Annual Report on Form 10-K for the fiscal year ended May 31, 2008. |

ii

Table of Contents

We note these factors for investors as contemplated by the Act. It is impossible to predict or identify all potential risk factors. Consequently, you should not consider the foregoing list to be a complete set of all potential risks and uncertainties. Any forward-looking statements in this Quarterly Report on Form 10-Q are based on current information as of the date of this Form 10-Q, and we assume no obligation to correct or update any such statements in the future, except as required by applicable law.

iii

Table of Contents

PART I. FINANCIAL INFORMATION

Item 1. - Financial Statements

WORTHINGTON INDUSTRIES, INC.

CONSOLIDATED BALANCE SHEETS

(Unaudited, in thousands)

| February 28, 2009 |

May 31, 2008 | |||||

| Assets |

||||||

| Current assets: |

||||||

| Cash and cash equivalents |

$ | 31,943 | $ | 73,772 | ||

| Receivables, less allowances of $14,480 and $4,849 at February 28, 2009 and May 31, 2008 |

215,050 | 384,354 | ||||

| Inventories: |

||||||

| Raw materials |

186,866 | 350,256 | ||||

| Work in process |

59,884 | 123,106 | ||||

| Finished products |

118,772 | 119,599 | ||||

| Total inventories |

365,522 | 592,961 | ||||

| Income taxes receivable |

25,410 | — | ||||

| Assets held for sale |

2,025 | 1,132 | ||||

| Deferred income taxes |

54,659 | 17,966 | ||||

| Prepaid expenses and other current assets |

35,271 | 34,785 | ||||

| Total current assets |

729,880 | 1,104,970 | ||||

| Investments in unconsolidated affiliates |

102,440 | 119,808 | ||||

| Goodwill |

98,293 | 183,523 | ||||

| Other assets |

38,634 | 29,786 | ||||

| Property, plant & equipment, net |

519,697 | 549,944 | ||||

| Total assets |

$ | 1,488,944 | $ | 1,988,031 | ||

| Liabilities and shareholders’ equity |

||||||

| Current liabilities: |

||||||

| Accounts payable |

$ | 212,189 | $ | 356,129 | ||

| Notes payable |

7,840 | 135,450 | ||||

| Accrued compensation, contributions to employee benefit plans and related taxes |

29,711 | 59,619 | ||||

| Dividends payable |

13,452 | 13,487 | ||||

| Distributions in excess of investment in unconsolidated affiliates |

18,723 | — | ||||

| Other accrued items |

53,751 | 68,545 | ||||

| Income taxes payable |

7,465 | 31,665 | ||||

| Total current liabilities |

343,131 | 664,895 | ||||

| Other liabilities |

37,826 | 49,785 | ||||

| Long-term debt |

245,400 | 245,000 | ||||

| Deferred income taxes |

109,405 | 100,811 | ||||

| Total liabilities |

735,762 | 1,060,491 | ||||

| Minority interest |

40,044 | 42,163 | ||||

| Shareholders’ equity |

713,138 | 885,377 | ||||

| Total liabilities and shareholders’ equity |

$ | 1,488,944 | $ | 1,988,031 | ||

See notes to consolidated financial statements.

1

Table of Contents

CONSOLIDATED STATEMENTS OF EARNINGS

(Unaudited)

(In thousands, except per share)

| Three Months Ended | Nine Months Ended | |||||||||||||||

| February 28, 2009 |

February 29, 2008 |

February 28, 2009 |

February 29, 2008 |

|||||||||||||

| Net sales |

$ | 501,125 | $ | 725,667 | $ | 2,159,697 | $ | 2,198,286 | ||||||||

| Cost of goods sold |

461,204 | 649,940 | 2,022,293 | 1,973,764 | ||||||||||||

| Gross margin |

39,921 | 75,727 | 137,404 | 224,522 | ||||||||||||

| Selling, general and administrative expense |

47,778 | 53,494 | 159,520 | 161,766 | ||||||||||||

| Goodwill impairment |

— | — | 96,943 | — | ||||||||||||

| Restructuring charges |

16,309 | 4,179 | 36,997 | 13,217 | ||||||||||||

| Operating income (loss) |

(24,166 | ) | 18,054 | (156,056 | ) | 49,539 | ||||||||||

| Other income (expense): |

||||||||||||||||

| Miscellaneous expense |

(3,327 | ) | (818 | ) | (5,079 | ) | (4,157 | ) | ||||||||

| Gain on sale of investment in Aegis |

8,331 | — | 8,331 | — | ||||||||||||

| Interest expense |

(4,289 | ) | (5,702 | ) | (16,408 | ) | (15,710 | ) | ||||||||

| Equity in net income of unconsolidated affiliates |

3,814 | 15,665 | 39,857 | 45,577 | ||||||||||||

| Earnings (loss) before income taxes |

(19,637 | ) | 27,199 | (129,355 | ) | 75,249 | ||||||||||

| Income tax expense (benefit) |

(21,191 | ) | 8,897 | (34,879 | ) | 22,039 | ||||||||||

| Net earnings (loss) |

$ | 1,554 | $ | 18,302 | $ | (94,476 | ) | $ | 53,210 | |||||||

| Average common shares outstanding—basic |

78,856 | 80,184 | 78,892 | 81,879 | ||||||||||||

| Earnings (loss) per share—basic |

$ | 0.02 | $ | 0.23 | $ | (1.20 | ) | $ | 0.65 | |||||||

| Average common shares outstanding—diluted |

78,856 | 80,214 | 78,892 | 82,480 | ||||||||||||

| Earnings (loss) per share—diluted |

$ | 0.02 | $ | 0.23 | $ | (1.20 | ) | $ | 0.65 | |||||||

| Common shares outstanding at end of period |

78,892 | 79,304 | 78,892 | 79,304 | ||||||||||||

| Cash dividends declared per share |

$ | 0.17 | $ | 0.17 | $ | 0.51 | $ | 0.51 | ||||||||

See notes to consolidated financial statements.

2

Table of Contents

CONSOLIDATED STATEMENTS OF CASH FLOWS

(Unaudited, in thousands)

| Three Months Ended | Nine Months Ended | |||||||||||||||

| February 28, 2009 |

February 29, 2008 |

February 28, 2009 |

February 29, 2008 |

|||||||||||||

| Operating activities |

||||||||||||||||

| Net earnings (loss) |

$ | 1,554 | $ | 18,302 | $ | (94,476 | ) | $ | 53,210 | |||||||

| Adjustments to reconcile net earnings (loss) to net cash provided by operating activities: |

||||||||||||||||

| Depreciation and amortization |

15,848 | 15,768 | 48,227 | 46,990 | ||||||||||||

| Goodwill impairment |

- | - | 96,943 | - | ||||||||||||

| Restructuring charges, non-cash |

4,665 | 1,378 | 7,611 | 4,108 | ||||||||||||

| Provision for deferred income taxes |

26,876 | (10,169 | ) | (23,296 | ) | (3,693 | ) | |||||||||

| Gain on sale of investment in Aegis |

(8,331 | ) | - | (8,331 | ) | - | ||||||||||

| Equity in net income of unconsolidated affiliates, net of distributions |

29,085 | (2,665 | ) | 21,543 | (3,177 | ) | ||||||||||

| Minority interest in net income of consolidated subsidiaries |

2,181 | 1,212 | 3,743 | 5,199 | ||||||||||||

| Net loss (gain) on assets |

502 | (115 | ) | 512 | 2,827 | |||||||||||

| Stock-based compensation |

1,448 | 1,203 | 4,051 | 2,965 | ||||||||||||

| Excess tax benefits - stock-based compensation |

- | (44 | ) | (355 | ) | (2,292 | ) | |||||||||

| Changes in assets and liabilities: |

||||||||||||||||

| Receivables |

122,679 | (38,576 | ) | 202,125 | (13,012 | ) | ||||||||||

| Inventories |

94,334 | (42,852 | ) | 234,620 | (42,215 | ) | ||||||||||

| Prepaid expenses and other current assets |

(22,821 | ) | 3,165 | (28,558 | ) | 3,037 | ||||||||||

| Other assets |

244 | 221 | 899 | (131 | ) | |||||||||||

| Accounts payable and accrued expenses |

(132,011 | ) | 66,591 | (245,202 | ) | 56,846 | ||||||||||

| Other liabilities |

(11,567 | ) | (1,988 | ) | (16,375 | ) | (2,482 | ) | ||||||||

| Net cash provided by operating activities |

124,686 | 11,431 | 203,681 | 108,180 | ||||||||||||

| Investing activities |

||||||||||||||||

| Investment in property, plant and equipment, net |

(19,256 | ) | (10,612 | ) | (49,495 | ) | (37,233 | ) | ||||||||

| Acquisitions, net of cash acquired |

(150 | ) | 16 | (40,375 | ) | (2,225 | ) | |||||||||

| Distributions from (investments in) unconsolidated affiliates, net |

6,680 | (526 | ) | 3,542 | (47,569 | ) | ||||||||||

| Proceeds from sale of assets |

2,101 | 510 | 5,559 | 802 | ||||||||||||

| Proceeds from sale of investments in unconsolidated affiliates |

22,195 | - | 24,045 | - | ||||||||||||

| Sales of short-term investments |

- | - | - | 25,562 | ||||||||||||

| Net cash provided (used) by investing activities |

11,570 | (10,612 | ) | (56,724 | ) | (60,663 | ) | |||||||||

| Financing activities |

||||||||||||||||

| Net proceeds from (payments on) short-term borrowings |

(118,139 | ) | 70,100 | (135,525 | ) | 131,650 | ||||||||||

| Principal payments on long-term debt |

(4 | ) | - | (252 | ) | - | ||||||||||

| Proceeds from issuance of common shares |

785 | 98 | 2,528 | 13,146 | ||||||||||||

| Excess tax benefits - stock-based compensation |

- | 44 | 355 | 2,292 | ||||||||||||

| Payments to minority interest |

- | (3,840 | ) | (3,216 | ) | (10,560 | ) | |||||||||

| Repurchase of common shares |

- | (38,475 | ) | (12,402 | ) | (125,785 | ) | |||||||||

| Dividends paid |

(13,398 | ) | (13,868 | ) | (40,274 | ) | (42,105 | ) | ||||||||

| Net cash provided (used) by financing activities |

(130,756 | ) | 14,059 | (188,786 | ) | (31,362 | ) | |||||||||

| Increase (decrease) in cash and cash equivalents |

5,500 | 14,878 | (41,829 | ) | 16,155 | |||||||||||

| Cash and cash equivalents at beginning of period |

26,443 | 39,554 | 73,772 | 38,277 | ||||||||||||

| Cash and cash equivalents at end of period |

$ | 31,943 | $ | 54,432 | $ | 31,943 | $ | 54,432 | ||||||||

See notes to consolidated financial statements.

3

Table of Contents

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS

Three and Nine Month Periods Ended February 28, 2009 and February 29, 2008

(Unaudited)

NOTE A – Basis of Presentation

The accompanying unaudited consolidated financial statements include the accounts of Worthington Industries, Inc. and consolidated subsidiaries (collectively, “we”, “our”, “Worthington” or the “Company”). Spartan Steel Coating, LLC (owned 52%) is fully consolidated with the equity owned by the other joint venture member shown as minority interest on the consolidated balance sheets, and its portion of net earnings (loss) included in miscellaneous expense. Investments in unconsolidated affiliates are accounted for using the equity method. Significant intercompany accounts and transactions are eliminated. These financial statements have been prepared in accordance with accounting principles generally accepted in the United States of America (the “United States”) for interim financial information and with the instructions to Form 10-Q and Article 10 of Regulation S-X of the Securities and Exchange Commission (“SEC”). Accordingly, they do not include all of the information and notes required by accounting principles generally accepted in the United States for complete financial statements. In the opinion of management, all adjustments (consisting of normal recurring accruals) considered necessary for a fair presentation have been included. Operating results for the nine months ended February 28, 2009, are not necessarily indicative of the results that may be expected for the fiscal year ending May 31, 2009 (“fiscal 2009”). For further information, refer to the consolidated financial statements and notes thereto included in the Annual Report on Form 10-K for the fiscal year ended May 31, 2008 (“fiscal 2008”) of Worthington Industries, Inc. (the “2008 Form 10-K”).

Recently Issued Accounting Standards: In September 2006, the Financial Accounting Standards Board (“FASB”) issued Statement of Financial Accounting Standards (“SFAS”) No. 158, Employers’ Accounting for Defined Benefit Pension and Other Postretirement Plans—an amendment of FASB Statements No. 87, 88, 106, and 132(R) (“SFAS No. 158”), to improve financial reporting regarding defined benefit pension and other postretirement plans. We adopted the recognition provisions of SFAS No. 158 at May 31, 2007. The measurement date provision of SFAS No. 158 is effective at May 31, 2009, and is not expected to materially impact our consolidated financial statements.

In December 2007, the FASB issued SFAS No. 141 (revised 2007), Business Combinations (“SFAS No. 141(R)”), to improve the relevance, representational faithfulness and comparability of the information that a reporting entity provides in its financial reports about a business combination and its effects. SFAS No. 141(R) applies prospectively to business combinations after May 31, 2009, and is not expected to materially impact our consolidated financial statements.

In December 2007, the FASB issued SFAS No. 160, Noncontrolling Interests In Consolidated Financial Statements - an amendment of ARB No. 51 (“SFAS No. 160”), to improve the relevance, comparability and transparency of the financial information that a reporting entity provides in its consolidated financial statements by establishing accounting and reporting standards for the noncontrolling interest (minority interest) in a subsidiary and for the deconsolidation of a subsidiary. SFAS No. 160 is effective June 1, 2009, and will require a change in the presentation of the minority interest in the consolidated financial statements.

4

Table of Contents

NOTE B – Segment Operations

Summarized financial information for our reportable segments is shown in the following table:

| Three Months Ended | Nine Months Ended | |||||||||||||||

| (in thousands) | February 28, 2009 |

February 29, 2008 |

February 28, 2009 |

February 29, 2008 |

||||||||||||

| Net sales |

||||||||||||||||

| Steel Processing |

$ | 192,471 | $ | 350,402 | $ | 1,003,950 | $ | 1,050,486 | ||||||||

| Metal Framing |

137,210 | 182,789 | 550,495 | 563,275 | ||||||||||||

| Pressure Cylinders |

117,531 | 138,287 | 408,330 | 408,099 | ||||||||||||

| Other |

53,913 | 54,189 | 196,922 | 176,426 | ||||||||||||

| Consolidated |

$ | 501,125 | $ | 725,667 | $ | 2,159,697 | $ | 2,198,286 | ||||||||

| Operating income (loss) |

||||||||||||||||

| Steel Processing |

$ | (18,643 | ) | $ | 10,030 | $ | (46,097 | ) | $ | 30,276 | ||||||

| Metal Framing |

(6,049 | ) | (7,562 | ) | (139,071 | ) | (31,610 | ) | ||||||||

| Pressure Cylinders |

13,136 | 13,889 | 51,958 | 49,285 | ||||||||||||

| Other |

(12,610 | ) | 1,697 | (22,846 | ) | 1,588 | ||||||||||

| Consolidated |

$ | (24,166 | ) | $ | 18,054 | $ | (156,056 | ) | $ | 49,539 | ||||||

| Pre-tax restructuring charges |

||||||||||||||||

| Steel Processing |

$ | 2,606 | $ | - | $ | 3,079 | $ | 1,096 | ||||||||

| Metal Framing |

5,854 | 2,466 | 11,504 | 6,905 | ||||||||||||

| Pressure Cylinders |

- | 103 | 7 | 103 | ||||||||||||

| Other |

7,849 | 1,610 | 22,407 | 5,113 | ||||||||||||

| Consolidated |

$ | 16,309 | $ | 4,179 | $ | 36,997 | $ | 13,217 | ||||||||

| (in thousands) | February 28, 2009 |

May 31, 2008 |

||||||||||||||

| Total assets |

||||||||||||||||

| Steel Processing |

$ | 542,023 | $ | 942,885 | ||||||||||||

| Metal Framing |

263,809 | 527,446 | ||||||||||||||

| Pressure Cylinders |

353,481 | 437,159 | ||||||||||||||

| Other |

329,631 | 80,541 | ||||||||||||||

| Consolidated |

$ | 1,488,944 | $ | 1,988,031 | ||||||||||||

5

Table of Contents

NOTE C – Comprehensive Income

The components of total comprehensive income (loss), net of tax, were as follows:

| Three Months Ended | Nine Months Ended | |||||||||||||||

| (in thousands) | February 28, 2009 |

February 29, 2008 |

February 28, 2009 |

February 29, 2008 |

||||||||||||

| Net earnings (loss) |

$ | 1,554 | $ | 18,302 | $ | (94,476 | ) | $ | 53,210 | |||||||

| Foreign currency translation |

(2,281 | ) | 2,575 | (25,424 | ) | 11,400 | ||||||||||

| Cash flow hedges |

593 | (3,341 | ) | (5,450 | ) | (12,068 | ) | |||||||||

| Other |

(1,109 | ) | 415 | (1,109 | ) | 126 | ||||||||||

| Total comprehensive income (loss) |

$ | (1,243 | ) | $ | 17,951 | $ | (126,459 | ) | $ | 52,668 | ||||||

NOTE D – Stock-Based Compensation

We granted non-qualified stock options during the nine months ended February 28, 2009, covering 574,450 common shares under our stock-based compensation plans. The weighted average option price of $19.24 per share was equal to the weighted average of the market prices of the underlying common shares at the grant dates. The fair value of these stock options, based on the Black-Scholes option-pricing model, calculated at the grant dates, was $5.57 per share. The calculated pre-tax stock-based compensation expense for these stock options, after an estimate for forfeitures, is $2,666,000, which will be recognized on a straight-line basis over the vesting period of the stock options. The following assumptions were used to value the stock options:

| Dividend yield |

3.4 | % | |

| Expected term (years) |

6.0 | ||

| Expected volatility |

35.1 | % | |

| Risk-free interest rate |

3.5 | % |

The expected volatility is based on the historical volatility of the common shares

of Worthington Industries, Inc., and the

risk-free interest rate is based on the United States Treasury strip rate for the expected term of the stock options. The expected term was developed using the historical exercise experience.

We granted 22,850 restricted common shares during the nine months ended February 28, 2009, under our stock-based compensation plans. The weighted average fair value of these restricted common shares was $15.95 per share, the market price of the underlying common shares at the grant date. The calculated pre-tax stock-based compensation expense for these restricted common shares is $364,000, which will be recognized on a straight-line basis over the vesting period.

NOTE E – Employee Pension Plans

The following table summarizes the components of net periodic pension cost for our defined benefit plans for the periods indicated:

6

Table of Contents

| Three Months Ended | Nine Months Ended | |||||||||||||||

| (in thousands) | February 28, 2009 |

February 29, 2008 |

February 28, 2009 |

February 29, 2008 |

||||||||||||

| Defined benefit plans: |

||||||||||||||||

| Service cost |

$ | 218 | $ | 253 | $ | 669 | $ | 751 | ||||||||

| Interest cost |

326 | 301 | 991 | 895 | ||||||||||||

| Expected return on plan assets |

(306 | ) | (321 | ) | (917 | ) | (963 | ) | ||||||||

| Net amortization and deferral |

55 | 60 | 165 | 180 | ||||||||||||

| Net pension cost of defined benefit plans |

$ | 293 | $ | 293 | $ | 908 | $ | 863 | ||||||||

Pension plan assets experienced a significant loss in fair value from the recent market downturn. This is not expected to have a material affect on our future annual pension expense as gains or losses are deferred over our average future service life of 12 years. No contributions, which are calculated at the beginning of the year, will be required to fund our defined benefit pension plans in fiscal 2009; however, we anticipate contributions of approximately $1,400,000 in fiscal 2010.

NOTE F – Income Taxes

Income tax expense (benefit) for the first nine months of fiscal 2009 and fiscal 2008 reflects an estimated annual effective income tax rate of 27.0% and 29.3%, respectively. Management is required to estimate the annual effective tax rate based upon its forecast of annual pre-tax income for domestic and foreign operations. The reduction in the estimated rate is primarily due to goodwill that is non-deductible for tax purposes, partially offset by the losses in domestic operations and reduced forecasted income from foreign operations. To the extent that actual pre-tax results for the year differ from the forecast estimates applied at the end of the most recent interim period, the actual tax rate recognized in fiscal 2009 could be materially different from the forecasted rate as of the end of the third quarter of fiscal 2009.

Income tax benefit for the first nine months of fiscal 2009 was calculated using the estimated annual effective income tax rate for fiscal 2009 and included a $2,006,000 net adjustment to reduce other estimated tax liabilities and a deferred tax benefit of $13,588,000 for the portion of the goodwill impairment (see “Note M – Goodwill Impairment”) that is deductible for tax purposes. Income tax expense for the first nine months of fiscal 2008 was calculated using the estimated annual effective income tax rate for fiscal 2008, and included a $430,000 net adjustment to reduce other estimated tax liabilities and deferred tax valuation allowances, which was partially offset by an increase to deferred tax liabilities for state and foreign tax law changes.

NOTE G – Investments in Unconsolidated Affiliates

Our investments in affiliated companies that are not controlled through majority ownership or otherwise are accounted for using the equity method. At February 28, 2009, these equity investments, and the percentage interest owned, consisted of: Worthington Armstrong Venture (“WAVE”) (50%), TWB Company, L.L.C. (45%), Worthington Specialty Processing (“WSP”) (51%), Serviacero Planos, S.A. de C.V. (50%), and LEFCO Worthington, LLC (49%). WSP is considered to be jointly controlled and not consolidated due to substantive participating rights of the minority partner.

We received distributions from unconsolidated affiliated companies totaling $68,080,000 during the nine months ended February 28, 2009. During the three months ended February 28, 2009, we received distributions from WAVE in excess of our investment balance, which created a negative balance in our investment account of $18,723,000 at February 28, 2009. The accounting treatment of excess distributions for a general partnership is to reclassify the negative balance to the liability section of the balance sheet, which was done during the current quarter. We will continue to record equity in net income from WAVE as a debit to the investment account, and when it becomes positive, it will again be shown as an asset on the balance sheet. If it becomes obvious that any excess distribution may not be returned (upon joint venture liquidation, etc.), we will record any balance in the liability as immediate income or gain.

7

Table of Contents

Combined financial information for these affiliated companies is summarized in the following table:

| (in thousands) | February 28, 2009 |

May 31, 2008 | |||||||||||

| Cash |

$ | 83,610 | $ | 79,538 | |||||||||

| Other current assets |

180,433 | 225,469 | |||||||||||

| Noncurrent assets |

169,201 | 194,169 | |||||||||||

| Total assets |

$ | 433,244 | $ | 499,176 | |||||||||

| Current liabilities |

$ | 80,878 | $ | 124,258 | |||||||||

| Long-term debt |

150,604 | 101,411 | |||||||||||

| Other noncurrent liabilities |

25,826 | 34,394 | |||||||||||

| Equity |

175,936 | 239,113 | |||||||||||

| Total liabilities and equity |

$ | 433,244 | $ | 499,176 | |||||||||

| Three Months Ended | Nine Months Ended | ||||||||||||

| (in thousands) | February 28, 2009 |

February 29, 2008 |

February 28, 2009 |

February 29, 2008 | |||||||||

| Net sales |

$ | 134,315 | $ | 181,368 | $ | 574,960 | $ | 531,006 | |||||

| Gross margin |

23,052 | 47,900 | 143,169 | 142,876 | |||||||||

| Depreciation and amortization |

2,976 | 2,976 | 11,056 | 9,301 | |||||||||

| Interest expense |

955 | 1,946 | 2,957 | 6,338 | |||||||||

| Income tax expense |

(2,885 | ) | 2,021 | 7,330 | 6,037 | ||||||||

| Net earnings |

5,533 | 30,798 | 85,252 | 90,861 | |||||||||

On June 2, 2008, we made an additional capital contribution of $392,000 to Viking & Worthington Steel Enterprise, LLC (“VWSE”). The other member in the joint venture did not make its contribution as required by the operating agreement. As a result, we now own 100% of VWSE, which has been fully consolidated in our financial statements since the beginning of fiscal 2009. VWSE has closed its manufacturing operations and its business is being handled by the consolidated operations of the Steel Processing segment.

On October 1, 2008, we expanded and modified WSP, our joint venture with United States Steel Corporation (“U.S. Steel”). U.S. Steel contributed ProCoil Company, LLC, its steel processing facility in Canton, Michigan, and we contributed Worthington Steel Taylor, our steel processing subsidiary in Taylor, Michigan, with a book value of $13,851,000 and $2,500,000 of cash.

During October 2008, we sold our 49% equity interest in Canessa Worthington Slovakia s.r.o. for approximately $3,700,000 to the Magnetto Group, the other member of the joint venture. The gain on the transaction was immaterial.

During January 2009, we sold our 60% equity interest in Aegis Metal Framing, LLC for approximately $24,000,000 to MiTek Industries, Inc., the other member of the joint venture. This resulted in a gain of $8,331,000.

During April 2009, we sold our 50% equity interest in Accelerated Building Technologies, LLC to NOVA Chemicals Corporation, the other member of the joint venture. The sales price and loss on the transaction were immaterial.

NOTE H – Restructuring

In the first quarter of fiscal 2008, we announced the initiation of a Transformation Plan (the “Plan”) with the overall goal to increase the Company’s sustainable earnings potential. The Plan is being implemented over a three-

8

Table of Contents

year period and focuses on cost reduction, margin expansion and organizational capability improvements, and in the process drives excellence in three core competencies: sales, operations and supply chain management. The Plan is comprehensive in scope and includes aggressive diagnostic and implementation phases in the Steel Processing and Metal Framing business segments.

To assist in the development and implementation of the Plan, a consulting firm has been retained. The services provided by this firm include diagnostic tools, performance improvement technologies, project management techniques, benchmarking information, and insights that directly relate to the Plan and, accordingly, their fees have been included in restructuring charges. To date, the following actions have been taken:

| — | On September 25, 2007, we announced the closure or downsizing of five locations in our Metal Framing segment. These actions were completed as of May 31, 2008. |

| — | During the first quarter of fiscal 2009, the Metal Framing corporate offices were moved from Pittsburgh and Blairsville, Pennsylvania to Columbus, Ohio. |

| — | Headcount was reduced through a combination of voluntary retirement and severance packages. |

| — | On October 23, 2008, we announced the closure of two facilities, one Steel Processing (Louisville, Kentucky) and one Metal Framing (Renton, Washington), and headcount reductions of 282. The Louisville facility was closed at February 28, 2009, and the Renton facility closed on December 31, 2008. |

| — | On December 5, 2008, we announced the closure and suspension of operations at three Metal Framing facilities and headcount reductions in Steel Processing of 186 and in Metal Framing of 125. The Lunenburg, Massachusetts facility closed on February 28, 2009, and operations suspended in Miami, Florida and Phoenix, Arizona on February 28, 2009. |

In connection with the Plan, a total of $55,108,000 has been recorded to date as restructuring charges in the consolidated statements of earnings: $18,111,000 was incurred in fiscal 2008, and $36,997,000 was incurred during the first nine months of fiscal 2009. Restructuring charges for the first nine months of fiscal 2009 are summarized as follows:

| In thousands | 5/31/2008 Liability |

Expense | Payments | Adjustments | 2/28/2009 Liability | |||||||||||

| Early retirement and severance |

$ | 1,143 | $ | 6,511 | $ | (3,350 | ) | $ | - | $ | 4,304 | |||||

| Other costs |

1,710 | 22,875 | (17,939 | ) | - | 6,646 | ||||||||||

| $ | 2,853 | 29,386 | $ | (21,289 | ) | $ | - | $ | 10,950 | |||||||

| Non-cash charges |

7,611 | |||||||||||||||

| Total |

$ | 36,997 | ||||||||||||||

Cash expenditures of $21,289,000, associated with implementing the Plan, were paid during the first nine months of fiscal 2009, with the remainder to be paid during the last quarter of fiscal 2009 and the first quarter of fiscal 2010. Certain cash payments associated with lease terminations may be paid over the remaining lease terms.

NOTE I – Business Interruption

On January 5, 2008, Severstal North America, Inc. (“Severstal”) experienced a furnace outage. Severstal is a primary steel supplier to, and a minority partner in, our Spartan Steel Coating, LLC joint venture (“Spartan”). Severstal is also a steel supplier to some of our other Steel Processing locations and to our Pressure Cylinders segment. Business interruption losses were incurred through February 28, 2009 in the form of lost sales and added costs for material, freight, scrap, and other items. As of February 28, 2009, the additional expenses incurred for material costs, freight and scrap in excess of our deductible, have been offset by proceeds from our insurance company. Net proceeds of $5,749,000 from final settlement of the insurance claim were recorded in cost of goods sold during the three months ended February 28, 2009, to offset the reduced profit from lost sales at Spartan. Miscellaneous expense was increased $2,760,000, as our partner’s portion of the net proceeds was eliminated from our consolidated earnings.

9

Table of Contents

NOTE J – Acquisitions

On June 2, 2008, Worthington purchased substantially all of the assets of The Sharon Companies Ltd. (“Sharon Stairs”) for $37,150,000. Sharon Stairs designs and manufactures steel egress stair systems for the commercial construction market, and operates one manufacturing facility in Akron, Ohio. It operates as part of Worthington Integrated Building Systems, LLC (“WIBS”). The purchase price was allocated to the acquired assets and assumed liabilities based on their estimated fair values at the date of acquisition, with goodwill representing the excess of the purchase price over the fair value allocated to the net assets. The purchase price allocated to intangibles will be amortized over a weighted average life of 13 years.

The allocation was as follows:

| In thousands | |||

| Current assets |

$ | 8,520 | |

| Intangibles |

12,440 | ||

| Property, plant and equipment, net |

2,500 | ||

| Total assets |

23,460 | ||

| Current liabilities |

3,841 | ||

| Other liabilities |

19 | ||

| Long-term debt |

400 | ||

| Identifiable net assets |

19,200 | ||

| Goodwill |

17,950 | ||

| Total purchase price |

$ | 37,150 | |

Cash flows used to determine the purchase price included strategic and synergistic benefits (investment value) specific to us, which resulted in a purchase price in excess of the fair value of identifiable assets. Since the fair values assigned to the acquired assets could only assume strategies and synergies of market participants, that additional investment value specific to us was included in goodwill. The purchase price included fair values of other assets that were not identifiable, not separately recognizable per accounting rules (e.g. assembled workforce), or of immaterial value. The purchase price also included a going-concern element that represents our ability to earn a higher rate of return on a group of assets than would be expected on the separate assets as determined during the valuation process.

On July 31, 2008, our Worthington Steelpac Systems, LLC subsidiary purchased the assets of Laser Products (“Laser”) for $3,425,000. Laser is a steel rack fabricator primarily serving the auto industry with locations in North Lewisburg, Ohio, and Greensburg, Indiana. The purchase price was allocated to working capital, fixed assets and customer list. The purchase price allocated to the customer list will be amortized over ten years.

Pro forma results, including the acquired businesses described above since the beginning of fiscal 2009, would not be materially different than actual results.

NOTE K – Fair Value

Effective June 1, 2008, we adopted SFAS No. 157, Fair Value Measurements (“SFAS No. 157”). SFAS No. 157 establishes a framework for measuring fair value and expands disclosures about fair value measurements. SFAS No. 157 was effective for our financial assets and liabilities after May 31, 2008, and will be effective for our non-financial assets and liabilities after May 31, 2009. Adoption of SFAS No. 157 for our financial assets and liabilities did not have a material impact on our consolidated financial statements. Adopting SFAS No. 157 for our non-financial assets and liabilities is not expected to materially impact our consolidated financial statements.

SFAS No. 157 clarifies that fair value is an exit price, representing the amount that would be received to sell an asset or paid to transfer a liability in an orderly transaction between market participants. Fair value should be determined based on assumptions that market participants would use in pricing an asset or liability. SFAS No. 157 uses a three-tier hierarchy that classifies assets and liabilities based on the inputs used in the valuation methodologies. In accordance with SFAS No. 157, we measured our derivative contracts at fair value. We

10

Table of Contents

classified these as level 2 assets and liabilities for purposes of SFAS No. 157 as they are based upon models utilizing market observable inputs and credit risk.

At February 28, 2009, our financial assets and liabilities measured at fair value on a recurring basis were as follows:

| In thousands | Quoted Prices in Active Markets (Level 1) |

Significant Other Observable Inputs (Level 2) |

Significant Unobservable Inputs (Level 3) |

Totals | ||||||||

| Assets |

||||||||||||

| Foreign currency derivative contracts |

$ | - | $ | 349 | $ | - | $ | 349 | ||||

| Liabilities |

||||||||||||

| Foreign currency derivative contracts |

$ | - | $ | 782 | $ | - | $ | 782 | ||||

| Interest rate derivative contracts |

- | 7,824 | - | 7,824 | ||||||||

| Total liabilities |

$ | - | $ | 8,606 | $ | - | $ | 8,606 | ||||

NOTE L – Inventory

During the second quarter ended November 30, 2009, we recorded an inventory write-down adjustment totaling $98,021,000. Of this amount, $94,853,000 related to the consolidated operations of the Steel Processing and Metal Framing segments and is recorded in cost of goods sold, while $3,168,000 related to our portion of the loss recorded by our Mexican steel processing joint venture, and is recorded in equity in net income of unconsolidated affiliates. These adjustments were necessitated by the speed and severity of the recent decline in demand and steel pricing. During the third quarter ended February 28, 2009, an additional write-down of $716,000 was recorded.

NOTE M – Goodwill Impairment

Due to industry changes, weakness in the construction market, and the depressed results in the Metal Framing segment over the last year, we have tested this business segment for impairment on a quarterly basis. Given the significant decline in the economy during the second quarter of fiscal 2009 and its impact on the construction market, we revised the forecasted cash flows and discount rate assumptions used in our previous valuations of this business segment. The forecasted cash flows were revised downward due to the significant decline in, and the future uncertainty of, the economy. The discount rate, based on our current cost of debt and equity capital, was changed due to the increased risk in our forecast. After reviewing the revised valuation and the fair value estimates of the remaining assets, it was determined that the value of the business no longer supported its $96,943,000 goodwill balance. As a result, the full amount was written-off in the second quarter ended November 30, 2008. During the third quarter ended February 28, 2009, a final determination of the fair values of the remaining assets required no adjustment to the write-down.

NOTE N – Debt

We have $145,000,000 of 6.7% senior notes (the “senior notes”) due December 1, 2009. At February 28, 2009, we had a $435,000,000 multi-year revolving credit facility (the “facility”) with a group of lenders. The facility matures in May 2013, except for a $35,000,000 commitment by one lender, which expires in September 2010. The outstanding balance under the facility at February 28, 2009 was $7,840,000 ($427,160,000 available). We have the intent and ability to refinance the senior notes (due December 2009) on a long-term basis by using the facility; therefore, the senior notes continue to be classified as long-term.

11

Table of Contents

NOTE O – Derivative Instruments and Hedging Activities

SFAS No. 161, Disclosures about Derivative Instruments and Hedging Activities – an amendment of FASB Statement No. 133 (“SFAS No. 161”), was effective December 1, 2008 and requires certain disclosures on our derivatives and hedging activities. These disclosures follow.

We do not engage in currency or commodity speculation and generally enter into derivatives only to hedge specific interest, foreign currency or commodity transactions. All derivatives are accounted for using mark-to-market accounting. Gains or losses from these transactions offset gains or losses of the assets, liabilities or transactions being hedged. No credit loss is anticipated as the counterparties to these agreements are major financial institutions that are highly rated. Counterparty hedging agreements include master netting arrangements.

Interest Rate Risk

We entered into an interest rate swap in October 2004, which was amended December 17, 2004. The swap had a notional amount of $100,000,000 to hedge changes in cash flows attributable to changes in the LIBOR rate associated with the December 17, 2004, issuance of the unsecured Floating Rate Senior Notes due December 17, 2014. We pay a fixed rate of 4.46% and receive a variable rate based on six-month LIBOR.

Foreign Currency Risk

The translation of foreign currencies into United States dollars subjects the Company to exposure related to fluctuating exchange rates. Derivative instruments are not used to manage this risk; however, the Company does make use of forward contracts to manage exposure to certain inter-company loans with our foreign affiliates. Such contracts limit exposure to both favorable and unfavorable currency fluctuations.

Commodity Price Risk

We are exposed to market risk for price fluctuations on purchases of steel, natural gas, zinc and other raw materials and utility requirements. The Company attempts to negotiate the best prices for commodities and to competitively price products and services to reflect the fluctuations in market prices. Derivative financial instruments are used to manage a portion of our exposure to fluctuations in the cost of natural gas and zinc. No derivatives are held for trading purposes.

The fair value of derivatives at February 28, 2009 is summarized in the following table:

| Asset Derivatives | Liability Derivatives | |||||||||

| (in thousands) | Balance Sheet Location |

Fair Value |

Balance Sheet Location |

Fair Value | ||||||

| Derivatives designated as hedging instruments under SFAS 133: |

||||||||||

| Interest rate contracts |

Receivables |

$ | - | Accounts payable |

$ | 1,134 | ||||

| Other assets |

- | Other liabilities |

6,690 | |||||||

| Totals |

- | 7,824 | ||||||||

| Derivatives not designated as hedging instruments under SFAS 133: |

||||||||||

| Foreign exchange contracts |

Receivables |

349 | Accounts payable |

636 | ||||||

| Other assets |

- | Other accrued items |

146 | |||||||

| Totals |

349 | 782 | ||||||||

| Total Derivatives |

$ | 349 | $ | 8,606 | ||||||

The effect of derivative instruments on the consolidated statement of earnings is summarized in the following tables:

12

Table of Contents

Derivatives designated as cash flow hedging instruments under SFAS 133:

| (in thousands) | Gain (Loss) Recognized in OCI (Effective Portion) |

Location of Gain |

Gain (Loss) Reclassified from Accumulated OCI (Effective Portion) |

Location of

Gain |

Gain (Loss) (Ineffective Portion) and Excluded from Effectiveness Testing | ||||||||||

| For the three months ended February 28, 2009: |

|||||||||||||||

| Interest rate contracts |

$ | 456 | Interest expense | $ | (515 | ) | Interest expense | $ | - | ||||||

| Commodity contracts |

59 | Cost of goods sold | 174 | Cost of goods sold | - | ||||||||||

| Totals |

$ | 515 | $ | (341 | ) | $ | - | ||||||||

| For the nine months ended February 28, 2009: |

|||||||||||||||

| Interest rate contracts |

$ | (7,921 | ) | Interest expense | $ | (1,057 | ) | Interest expense | $ | - | |||||

| Commodity contracts |

(847 | ) | Cost of goods sold | 2,306 | Cost of goods sold | - | |||||||||

| Totals |

$ | (8,768 | ) | $ | 1,249 | $ | - | ||||||||

Derivatives not designated as hedging instruments under SFAS 133:

| Gain (Loss) Recognized in Earnings |

||||||||||

| (in thousands) | Location of Gain (Loss) Recognized in Earnings |

Three Months Ended |

Nine Months Ended |

|||||||

| February 28, 2009 | ||||||||||

| Commodity contracts |

Cost of goods sold | $ | (47 | ) | $ | (1,433 | ) | |||

| Foreign exchange contracts |

Miscellaneous expense | 192 | 8,707 | |||||||

| Totals |

$ | 145 | $ | 7,274 | ||||||

The gain (loss) on these derivatives significantly offset the gain (loss) on the hedged items.

13

Table of Contents

Item 2. - Management’s Discussion and Analysis of Financial Condition and Results of Operations

Selected statements contained in this “Item 2. – Management’s Discussion and Analysis of Financial Condition and Results of Operations” constitute “forward-looking statements” as that term is used in the Private Securities Litigation Reform Act of 1995. Such forward-looking statements are based, in whole or in part, on management’s beliefs, estimates, assumptions and currently available information. For a more detailed discussion of what constitutes a forward-looking statement and of some of the factors that could cause actual results to differ materially from such forward-looking statements, please refer to the “Safe Harbor Statement” in the beginning of this Quarterly Report on Form 10-Q and “Part I – Item 1A. – Risk Factors” of our Annual Report on Form 10-K for the fiscal year ended May 31, 2008.

Introduction

The following discussion and analysis of market and industry trends, business strategy, and the results of operations and financial position of Worthington Industries, Inc., together with its subsidiaries (collectively, “we,” “our,” “Worthington,” or our “Company”), should be read in conjunction with our consolidated financial statements included in “Item 1. – Financial Statements.” Our Annual Report on Form 10-K for the fiscal year ended May 31, 2008 (“fiscal 2008”) includes additional information about our Company, our operations and our financial position and should be read in conjunction with this Quarterly Report on Form 10-Q.

We are primarily a diversified metal processing company focused on value-added steel processing and manufactured metal products. As of February 28, 2009, excluding our joint ventures, we operated 41 manufacturing facilities worldwide, principally in three reportable business segments: Steel Processing, Metal Framing and Pressure Cylinders. Other business segments, which are immaterial for purposes of separate disclosure, include Automotive Body Panels, Construction Services and Steel Packaging. We also held equity positions in 6 joint ventures, which operated 20 manufacturing facilities worldwide.

Overview

While there were many factors that affected our results, the third quarter of fiscal 2009 was most affected by the ongoing financial crisis and the recession. Demand throughout most sectors of the economy decreased significantly in the third quarter, and construction and automotive, our two largest markets, were hit particularly hard. Normal seasonal shutdowns were greatly extended by many customers, while others put off placing orders as they worked to correct their own inventory levels.

Market & Industry Overview

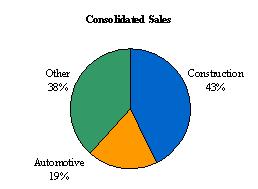

| For the three months ended February 28, 2009, our sales breakdown by end user market is illustrated by the chart below. | ||

|

Substantially all of the sales of our Metal Framing and Construction Services segments, as well as approximately 25% of the sales of our Steel Processing segment, are to the construction market, both residential and non-residential. We estimate that approximately 10% of our consolidated sales, or one-fourth of our construction market sales, are to the residential market. While the market price of steel significantly impacts this business, there are other key indicators that are meaningful in analyzing construction market demand including U.S. gross domestic product (“GDP”), the Dodge Index of construction contracts, and trends in the relative price of framing lumber and steel. Construction is also the predominant end market for our joint venture WAVE. The sales of WAVE are not consolidated in our results; however, adding our ownership percentage of WAVE’s construction market sales to our reported sales would not materially change the breakdown in the chart. | |

The automotive industry is the largest consumer of flat-rolled steel and thus the largest end market for our Steel Processing segment. Just less than half of the sales of our Steel Processing segment, and substantially all of the sales of our Automotive Body Panels segment, are to the automotive market. North American vehicle production,

14

Table of Contents

primarily by Chrysler, Ford and General Motors (the “Big Three automakers”), has a considerable impact on the customers within these two segments. These segments are also impacted by the market price of steel and, to a lesser extent, the market price of commodities used in their operations, such as zinc, natural gas and diesel fuel. The majority of the sales from two of our unconsolidated joint ventures also go to the automotive end market. These sales are not consolidated in our results; however, adding our ownership percentage of joint venture automotive market sales to our reported sales would not materially change the sales breakdown in the previous chart.

The sales of our Pressure Cylinders and Steel Packaging segments, and approximately 30% of the sales of our Steel Processing segment, are to other markets such as agriculture, appliance, leisure and recreation, distribution and transportation, HVAC, lawn and garden, and consumer specialty products. Given the many different product lines that make up these sales and the wide variety of end markets, it is very difficult to detail the key market indicators that drive this portion of our business. However, we believe that the trend in U.S. GDP growth is a good economic indicator for analyzing these segments.

We use the following information to monitor our cost and major end markets:

| Three Months Ended, | Nine Months Ended, | ||||||||||||||||||||||

| Feb. 28, 2009 |

Feb. 29 2008 |

Inc / (Dec) |

Feb. 28, 2009 |

Feb. 29 2008 |

Inc / (Dec) |

||||||||||||||||||

| U.S. GDP (% growth year-over-year) |

-1.0 | % | 2.5 | % | -3.5 | % | 0.0 | % | 2.4 | % | -2.4 | % | |||||||||||

| Hot-Rolled Steel ($ per ton) 1 |

$ | 527 | $ | 623 | ($96 | ) | $ | 822 | $ | 556 | $ | 266 | |||||||||||

| Big Three Auto Build (000’s vehicles) 2 |

993 | 2,000 | (1,007 | ) | 4,544 | 6,703 | (2,159 | ) | |||||||||||||||

| No. America Auto Build (000’s vehicles) 2 |

1,758 | 3,378 | (1,620 | ) | 7,995 | 11,115 | (3,120 | ) | |||||||||||||||

| Dodge Index |

88 | 115 | (27 | ) | 103 | 122 | (20 | ) | |||||||||||||||

| Framing Lumber ($ per 1,000 board ft) 3 |

$ | 203 | $ | 253 | ($50 | ) | $ | 239 | $ | 273 | ($34 | ) | |||||||||||

| Zinc ($ per pound) 4 |

$ | 0.51 | $ | 1.08 | ($0.57 | ) | $ | 0.66 | $ | 1.31 | ($0.65 | ) | |||||||||||

| Natural Gas ($ per mcf) 5 |

$ | 5.44 | $ | 7.46 | ($2.02 | ) | $ | 8.10 | $ | 6.90 | $ | 1.20 | |||||||||||

| Retail Diesel Prices, All Types ($ per gallon) 6 |

$ | 2.80 | $ | 3.44 | ($0.64 | ) | $ | 3.57 | $ | 3.15 | $ | 0.42 | |||||||||||

| 1 |

CRU Index; period average 2 CSM Autobase 3 Random Lengths; period average 4 LME Zinc; period average |

| 5 |

NYMEX Henry Hub Natural Gas; period average 6 Energy Information Administration; period average |

U.S. GDP growth rate trends are generally indicative of the strength in demand and, in many cases, pricing for our products. Historically, we have seen that decreasing U.S. GDP growth rates year-over-year can have a negative effect on our results, as a weaker economy generally hurts demand and pricing for our products. Conversely, the opposite is also generally true. Changes in U.S. GDP growth rates can also signal changes in conversion costs related to production and selling, general and administrative (“SG&A”) expenses.

In recent quarters, the market price of hot-rolled steel has been one of the most significant factors impacting selling prices and has materially impacted earnings. In a rising price environment, our results are generally favorably impacted as lower-priced material, purchased in previous periods, flows through cost of goods sold, while our selling prices increase at a faster pace to cover current replacement costs. On the other hand, when steel prices fall, we typically have higher-priced material flowing through cost of goods sold while selling prices compress to what the market will bear, negatively impacting our results.

No single customer contributed more than 4% of our consolidated net sales for the quarter. While our automotive business is largely driven by the production schedules of the Big Three automakers, our customer base is much broader and includes many of their suppliers as well. Production has declined for domestic automakers in recent quarters and is currently severely depressed due to the uncertain financial markets, declining demand and the recessionary economic climate. Because of lower production and higher inventories of unsold cars, automakers and their suppliers have significantly reduced production schedules. We continue to pursue customer diversification beyond the Big Three automakers and their suppliers, and, in recent quarters, we have increased our business in other markets such as energy and agriculture.

The Dodge Index represents the value of total construction contracts, including residential and non-residential building construction. This overall index serves as a broad indicator of the construction markets in which we participate, as it tracks actual construction starts. The relative price of framing lumber, an alternative construction

15

Table of Contents

material against which we compete, can also affect our Metal Framing segment, as certain applications may permit the use of this alternative building material.

The market trends of certain other commodities such as zinc, natural gas and diesel fuel can be important to us as they represent a significant portion of our cost of goods sold, both directly through our plant operations and indirectly through transportation and freight expense. Although these costs decreased in the third quarter of fiscal 2009, the impact was dwarfed by the negative impacts of lower demand and the dramatic decline in steel prices.

Transformation Plan

Cost reduction efforts, announced in the first quarter of fiscal 2008, grew into a broader program called the Transformation Plan by the fourth quarter of fiscal 2008. The Transformation Plan includes a focus on cost reduction, margin expansion and organizational capability improvements, as well as an effort to develop excellence in three core competencies: sales, operations and supply chain management. The Transformation Plan is comprehensive in scope and includes aggressive diagnostic and implementation phases in our Steel Processing and Metal Framing business segments. The goal of the Transformation Plan is to increase our Company’s sustainable earnings potential.

The initial cost reduction effort identified opportunities for $39.0 million in annual savings in overhead expense reductions, early retirements, and plant closures, exclusive of the expenses related to achieving these savings. To date, $31.3 million of the $39.0 million in annual saving initiatives has been realized, of which $12.8 million in savings was realized in the first nine months of fiscal 2009. Since the plan was expanded into Steel Processing and Metal Framing operations, we have identified an additional $70.0 million in increased annual earnings opportunities, of which over $30.0 million have been executed. Restructuring charges associated with the Transformation Plan totaled $37.0 million in the first nine months of fiscal 2009. Additional charges are expected during the life of the Transformation Plan including charges related to professional fees, facility closures, and employee severance and relocation.

State of our Business & Outlook

Our results reflect the rapid decline in demand and steel pricing associated with the global economic recession and its impact on end markets that first took hold in our second quarter. Steel pricing continued to fall during the third quarter, but the weakened demand was the main factor driving down our results.

We have continued to focus on reducing costs, increasing asset utilization and driving improvements in our operations, from which we have seen positive results. However, given the current market and economic conditions, particularly those related to our Steel Processing and Metal Framing segments, we face difficulties in the next quarter despite the fourth quarter being a historically strong seasonal quarter. In response to the challenging environment, we have taken, or announced, the following actions this fiscal year:

| — | Reduced workforce of approximately 600 in our Steel Processing and Metal Framing segments through a combination of plant closings and layoffs. |

| — | Closed three facilities, one Steel Processing (Louisville, Kentucky) and two Metal Framing (Renton, Washington and Lunenburg, Massachusetts). In addition, two Metal Framing facilities have suspended operations indefinitely (Miami, Florida and Phoenix, Arizona). See “Note [H] – Restructuring” for more information on headcount reductions and facility closures. |

| — | Sold our interests in three joint ventures: our 49% equity interest in Canessa Worthington Slovokia (“Slovakia”); our 60% equity interest in Aegis Metal Framing, LLC (“Aegis”); and our 50% equity interest in Accelerated Building Technologies, LLC (“ABT”). See “Note [G] – Investments in Unconsolidated Affiliates” for more information on these actions. |

| — | Expanded our Worthington Steel Processing joint venture with United States Steel Corporation (“U.S. Steel”), which consolidated steel processing operations in eastern Michigan. U.S. Steel contributed Procoil Company, LLC, its steel processing facility in Canton, Michigan, and we contributed Worthington Steel |

16

Table of Contents

| Taylor, our steel processing subsidiary in Taylor, Michigan, plus $2.5 million of cash, increasing our ownership interest from 50% to 51%. |

We will continue to pursue opportunities for enhancing margin, developing new customers, improving our supply chain, and where necessary, restructuring our business to match demand.

Results of Operations

Third Quarter – Fiscal 2009 Compared to Fiscal 2008

Consolidated Operations

The following table presents consolidated operating results:

| Three Months Ended, | ||||||||||||||||

| Dollars in millions | Feb. 28, 2009 |

% of Net sales |

Feb. 29, 2008 |

% of Net sales |

Increase/ (Decrease) |

|||||||||||

| Net sales |

$ | 501.1 | 100.0% | $ | 725.7 | 100.0% | $ | (224.6 | ) | |||||||

| Cost of goods sold |

461.2 | 92.0% | 649.9 | 89.6% | (188.7 | ) | ||||||||||

| Gross margin |

39.9 | 8.0% | 75.8 | 10.4% | (35.9 | ) | ||||||||||

| Selling, general and administrative expense |

47.8 | 9.5% | 53.5 | 7.4% | (5.7 | ) | ||||||||||

| Restructuring charges |

16.3 | 3.3% | 4.2 | 0.6% | 12.1 | |||||||||||

| Operating income (loss) |

(24.2 | ) | -4.8% | 18.1 | 2.5% | (42.3 | ) | |||||||||

| Other expense, net |

(3.3 | ) | -0.7% | (0.8 | ) | -0.1% | 2.5 | |||||||||

| Gain on sale of Aegis |

8.3 | 1.7% | - | 0.0% | (8.3 | ) | ||||||||||

| Interest expense |

(4.3 | ) | -0.9% | (5.7 | ) | -0.8% | (1.4 | ) | ||||||||

| Equity in net income of unconsolidated affiliates |

3.8 | 0.8% | 15.7 | 2.2% | (11.9 | ) | ||||||||||

| Income tax (expense) benefit |

21.2 | 4.2% | (8.9 | ) | -1.2% | (30.1 | ) | |||||||||

| Net earnings |

$ | 1.5 | 0.3% | $ | 18.4 | 2.5% | $ | (16.8 | ) | |||||||

Net earnings for the third quarter of fiscal 2009 decreased $16.8 million from the prior year quarter to $1.5 million. We traditionally experience seasonal declines in demand during our third quarter; however, the global recession has adversely impacted all of our end-markets, including our two largest customer end markets, construction and automotive.

| — | Net sales decreased $224.6 million from the prior year to $501.1 million. Lower volumes decreased sales by $279.1 million, most notably in our Metal Framing and Steel Processing segments where demand declined dramatically, particularly in the construction and automotive sectors. Average selling prices increased over the prior year due to the higher cost of steel. These higher average selling prices increased sales $54.6 million year-over-year. |

| — | Gross margin decreased $35.9 million from the prior year as a result of the lower volumes in our Steel Processing and Metal Framing segments. |

| — | Selling, general, and administrative (“SG&A”) expense decreased $5.7 million from the prior year, primarily due to reduced compensation expense, as profit sharing was down significantly due to the lower earnings. Offsetting the decrease was a $6.0 million increase in bad debt reserves for specific automotive-related accounts. |

| — | Restructuring charges totaled $16.3 million compared to $4.2 million in the prior year. All of these charges related to the Transformation Plan, which includes charges related to previously announced layoffs and facility closures. |

| — | We realized a gain of $8.3 million on the sale of our interest in Aegis to our partner, MiTek Industries, Inc. in January 2009. |

17

Table of Contents

| — | Interest expense decreased $1.4 million over the prior year as short-term interest rates declined and average short-term borrowings declined significantly due to lower working capital needs. |

| — | Equity in net income of unconsolidated affiliates of $3.8 million declined $11.9 million from the third quarter of fiscal 2008. WAVE contributed the only positive equity earnings, although its earnings declined 45% from last year’s third quarter. See “Note [G] – Investments in Unconsolidated Affiliates” for more financial information on our unconsolidated affiliates. |

| — | Due to the quarterly loss and a change in the annual effective tax rate, an income tax benefit of $21.2 million was recorded, representing 108.0% of the pre-tax loss. This compares to the $8.9 million tax expense, or 32.7% of pre-tax income, recorded in the prior year quarter. The change from tax expense to a tax benefit is due to the current quarter loss while the change in the effective tax rate is primarily due to the change in the mix of income among the jurisdictions in which we do business. |

Segment Operations

Steel Processing

The following table presents a summary of operating results for our Steel Processing segment for the periods indicated:

| Three Months Ended, | |||||||||||||||

| Dollars in millions | Feb. 28, 2009 |

% of Net sales |

Feb. 29, 2008 |

% of Net sales |

Increase/ (Decrease) |

||||||||||

| Net sales |

$ | 192.5 | 100.0% | $ | 350.4 | 100.0% | $ | (157.9 | ) | ||||||

| Cost of goods sold |

191.7 | 99.6% | 318.2 | 90.8% | (126.5 | ) | |||||||||

| Gross margin |

0.8 | 0.4% | 32.2 | 9.2% | (31.4 | ) | |||||||||

| Selling, general and administrative expense |

16.9 | 8.8% | 22.2 | 6.3% | (5.3 | ) | |||||||||

| Restructuring charges |

2.6 | 1.4% | - | 0.0% | 2.6 | ||||||||||

| Operating income (loss) |

$ | (18.7 | ) | -9.7% | $ | 10.0 | 2.9% | $ | (28.7 | ) | |||||

| Material cost |

$ | 161.1 | $ | 266.8 | $ | (105.7 | ) | ||||||||

| Tons shipped (in thousands) |

344 | 809 | (465 | ) | |||||||||||

Net sales and operating income (loss) highlights were as follows:

| — | Net sales decreased $157.9 million from the prior year to $192.5 million. The decrease in net sales was primarily due to sharply lower volume (down 57%). Economic conditions have weakened demand in all customer groups, especially automotive and construction. While average selling prices were higher than in the prior year, selling prices continued to fall throughout the quarter. |

| — | There was an operating loss of $18.7 million for the quarter compared to operating income of $10.0 million last year, primarily due to reduced volumes ($19.8 million) resulting from lower demand and a lower spread between average selling prices and material costs ($8.3 million). SG&A expense declined $5.3 million, due to lower compensation expense, partially offset by a $3.0 million increase in bad debt expense. |

Metal Framing

The following table presents a summary of operating results for our Metal Framing segment for the periods indicated:

18

Table of Contents

| Three Months Ended, | ||||||||||||||||

| Dollars in millions | Feb. 28, 2009 |

% of Net sales |

Feb. 29, 2008 |

% of Net sales |

Increase/ (Decrease) |

|||||||||||

| Net sales |

$ | 137.2 | 100.0% | $ | 182.8 | 100.0% | $ | (45.6 | ) | |||||||

| Cost of goods sold |

125.5 | 91.5% | 172.0 | 94.1% | (46.5 | ) | ||||||||||

| Gross margin |

11.7 | 8.5% | 10.8 | 5.9% | 0.9 | |||||||||||

| Selling, general and administrative expense |

11.9 | 8.7% | 15.9 | 8.7% | (4.0 | ) | ||||||||||

| Restructuring charges |

5.9 | 4.3% | 2.5 | 1.4% | 3.4 | |||||||||||

| Operating loss |

$ | (6.1 | ) | -4.4% | $ | (7.6 | ) | -4.2% | $ | 1.5 | ||||||

| Material cost |

$ | 94.3 | $ | 130.0 | $ | (35.7 | ) | |||||||||

| Tons shipped (in thousands) |

97 | 157 | (60 | ) | ||||||||||||

Net sales and operating loss highlights were as follows:

| — | Net sales decreased $45.6 million from the prior year to $137.2 million, as higher average pricing, up 21%, was more than offset by a 38% decline in volume. |

| — | Operating loss decreased from $7.6 million last year to $6.1 million. The affect of lower sales volumes was largely offset by an improved spread between average selling prices and material costs. In addition, manufacturing expenses were lower as a result of savings related to previously announced plant closures, headcount reductions, and variable expenses related to volume. SG&A expense declined due to lower compensation expense, but was mostly offset by higher restructuring charges. |

Pressure Cylinders

The following table presents a summary of operating results for our Pressure Cylinders segment for the periods indicated:

| Three Months Ended, | ||||||||||||||

| Dollars in millions | Feb. 28, 2009 |

% of Net sales |

Feb. 29, 2008 |

% of Net sales |

Increase/ (Decrease) |

|||||||||

| Net sales |

$ | 117.5 | 100.0% | $ | 138.3 | 100.0% | $ | (20.8 | ) | |||||

| Cost of goods sold |

94.5 | 80.4% | 111.9 | 80.9% | (17.4 | ) | ||||||||

| Gross margin |

23.0 | 19.6% | 26.4 | 19.1% | (3.4 | ) | ||||||||

| Selling, general and administrative expense |

9.8 | 8.3% | 12.4 | 9.0% | (2.6 | ) | ||||||||

| Restructuring charges |

— | 0.0% | 0.1 | 0.1% | (0.1 | ) | ||||||||

| Operating income |

$ | 13.2 | 11.2% | $ | 13.9 | 10.1% | $ | (0.7 | ) | |||||

| Material cost |

$ | 55.6 | $ | 66.3 | $ | (10.7 | ) | |||||||

| Units shipped (in thousands) |

10,968 | 11,460 | (492 | ) | ||||||||||

Net sales and operating income highlights were as follows:

| — | Net sales of $117.5 million decreased $20.8 million from the year ago quarter. This decline was due to lower units shipped across most product lines and weaker foreign currencies relative to the U.S. dollar. |

| — | Operating income decreased $0.7 million from last year to $13.2 million. Gross margin improved to 19.6% of sales from 19.1% due to a modest increase in the spread between average selling prices and material costs. SG&A expense declined due to lower compensation expense. |

Other

The “Other” category includes our Automotive Body Panels, Construction Services and Steel Packaging segments, which are immaterial for purposes of separate disclosure, along with income and expense items not

19

Table of Contents

allocated to the business segments. The following table presents a summary of operating results for the periods indicated:

| Three Months Ended, | |||||||||||||||

| Dollars in millions | Feb. 28, 2009 |

% of Net sales |

Feb. 29, 2008 |

% of Net sales |

Increase/ (Decrease) |

||||||||||

| Net sales |

$ | 53.9 | 100.0% | $ | 54.2 | 100.0% | $ | (0.3 | ) | ||||||

| Cost of goods sold |

49.4 | 91.7% | 47.8 | 88.2% | 1.6 | ||||||||||

| Gross margin |

4.5 | 8.3% | 6.4 | 11.8% | (1.9 | ) | |||||||||

| Selling, general and administrative expense |

9.2 | 17.1% | 3.1 | 5.7% | 6.1 | ||||||||||

| Restructuring charges |

7.8 | 14.5% | 1.6 | 3.0% | 6.2 | ||||||||||

| Operating income (loss) |

$ | (12.5 | ) | -23.2% | $ | 1.7 | 3.1% | $ | (14.2 | ) | |||||

Net sales and operating income (loss) highlights were as follows:

| — | Net sales fell $0.3 million to $53.9 million for the third quarter. The decrease was attributable to weaker volumes and lower average selling prices in our Automotive Body Panels segment, nearly offset by improved sales in our Construction Services segment, primarily due to military construction and the acquisition of the Sharon Stairs and increased activity. |

| — | The operating loss for the quarter of $12.5 million compared to last year’s income of $1.7 million. SG&A expenses increased primarily due to a $2.9 million increase in bad debt. Restructuring charges, related to the Transformation Plan, increased $6.2 million compared to the fiscal 2008 quarter. |

Year to Date - Fiscal 2009 Compared to Fiscal 2008

Consolidated Operations

The following table presents consolidated operating results:

| Nine Months Ended, | ||||||||||||||||

| Dollars in millions | Feb. 28, 2009 |

% of Net sales |

Feb. 29, 2008 |

% of Net sales |

Increase/ (Decrease) |

|||||||||||

| Net sales |

$ | 2,159.7 | 100.0% | $ | 2,198.3 | 100.0% | $ | (38.6 | ) | |||||||

| Cost of goods sold |

2,022.3 | 93.6% | 1,973.8 | 89.8% | 48.5 | |||||||||||

| Gross margin |

137.4 | 6.4% | 224.5 | 10.2% | (87.1 | ) | ||||||||||

| Selling, general and administrative expense |

159.5 | 7.4% | 161.8 | 7.4% | (2.3 | ) | ||||||||||

| Goodwill impairment & restructuring charges |

133.9 | 6.2% | 13.2 | 0.6% | 120.7 | |||||||||||

| Operating income (loss) |

(156.1 | ) | -7.2% | 49.5 | 2.3% | (205.6 | ) | |||||||||

| Miscellaneous expense |

(5.0 | ) | -0.2% | (4.2 | ) | -0.2% | 0.8 | |||||||||

| Gain on sale of Aegis |

8.3 | 0.4% | - | 0.0% | (8.3 | ) | ||||||||||

| Interest expense |

(16.4 | ) | -0.8% | (15.7 | ) | -0.7% | 0.7 | |||||||||

| Equity in net income of unconsolidated affiliates |

39.9 | 1.8% | 45.6 | 2.1% | (5.7 | ) | ||||||||||

| Income tax (expense) benefit |

34.9 | 1.6% | (22.0 | ) | -1.0% | (56.9 | ) | |||||||||

| Net earnings (loss) |

$ | (94.4 | ) | -4.4% | $ | 53.2 | 2.4% | $ | (147.6 | ) | ||||||

Our year-to-date net loss of $94.4 million for fiscal 2009 reflected a reduction of $147.6 million in earnings from the fiscal 2008 net earnings of $53.2 million as a result of a $98.0 million inventory write-down and a $96.9 million goodwill impairment charge recorded in the second quarter.