|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

ANALYSIS OF TECHNICAL CRITERIA

FOR THE

BELAHOURO GOLD MINE PROJECT

BURKINA FASO

FOR

GOLDBELT RESOURCES LIMITED

Prepared By

BS EN ISO 9001:2000

FS80050

PROJECT NUMBER: 0207

2ND DECEMBER 2005

| Page 1 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| TABLE OF CONTENTS | |||

| 1 | EXECUTIVE SUMMARY | 18 | |

| 1.1 | Property Description | 18 | |

| 1.2 | Exploration and Property History | 18 | |

| 1.2.1 Location and Access | 19 | ||

| 1.3 | Geology and Mineralization | 20 | |

| 1.4 | Metallurgical Testing | 22 | |

| 1.4.1 Metallurgical Test Work for Belahouro - CIL Process | 22 | ||

| 1.4.2 Metallurgical Test Work for Belahouro Project - Heap Leach | 24 | ||

| 1.5 | Mineral Resources | 25 | |

| 1.5.1 Pit Optimisation & Sensitivity | 26 | ||

| 1.6 | Mining Operations | 27 | |

| 1.7 | Mineral Processing Plant | 28 | |

| 1.8 | Mine Overhead | 28 | |

| 1.9 | Manpower | 28 | |

| 1.10 | Environmental Considerations | 28 | |

| 1.10.1 Water Supply | 29 | ||

| 1.11 | Capital and Operating Cost Estimates | 29 | |

| 1.12 | Markets and Contracts | 29 | |

| 1.13 | Conclusions and Recommendations | 29 | |

| 2 | INTRODUCTION AND TERMS OF REFERENCE | 32 | |

| Page 2 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 2.1 | Principal Sources of Information | 32 | |

| 3 | DISCLAIMER | 33 | |

| 4 | PROPERTY DESCRIPTION AND LOCATION | 34 | |

| 4.1 | Background Information on Burkina Faso | 34 | |

| 4.2 | Project Location | 35 | |

| 4.3 | Land Area | 35 | |

| 4.4 | Mining Claim Description | 36 | |

| 4.5 | Agreements and Encumbrances | 37 | |

| 4.6 | Environmental Liabilities | 37 | |

| 4.7 | Permits | 37 | |

| 5 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 38 | |

| 5.1 | Property Access and Freight Routing | 38 | |

| 5.2 | Physiography and Climate | 38 | |

| 5.3 | Geology | 39 | |

| 5.3.1 Regional Geology | 39 | ||

| 5.3.2 Local Geology | 39 | ||

| 5.4 | Hydrology and Hydrogeology | 40 | |

| 5.5 | Seismicity | 40 | |

| 5.6 | Local Resources and Infrastructure | 41 | |

| 6 | HISTORY OF PREVIOUS WORK RESULTS | 42 | |

| 6.1 | Owners | 42 | |

| 6.2 | Exploration History | 42 | |

| Page 3 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 6.3 | Historic Mineral Resource Estimates | 44 | |

| 6.4 | Historic Production | 46 | |

| 7 | GEOLOGICAL SETTING | 47 | |

| 7.1 | Regional Geology | 47 | |

| 7.2 | Project Geology | 48 | |

| 8 | DEPOSIT TYPES | 50 | |

| 9 | MINERALIZATION | 51 | |

| 10 | EXPLORATION | 52 | |

| 11 | DRILLING | 54 | |

| 11.1 | Reverse Circulation Drilling | 54 | |

| 11.2 | Diamond Core Drilling | 54 | |

| 11.3 | Drilling Quality | 55 | |

| 12 | SAMPLING METHODS AND APPROACH | 56 | |

| 12.1 | RC Sampling and Logging | 56 | |

| 12.2 | Diamond Core Sampling and Logging | 56 | |

| 12.3 | Sample Recovery | 57 | |

| 12.4 | Sample Quality | 57 | |

| 13 | SAMPLE PREPARATION, ANALYSIS AND SECURITY | 58 | |

| 13.1 | Sample Security | 58 | |

| 13.2 | Analytical Laboratories | 58 | |

| 13.3 | Sample Preparation and Analysis Methods | 59 | |

| 13.3.1 Intertek Testing Service (ITS) | 59 | ||

| Page 4 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 13.3.2 | Transworld - Tarkwa | 59 | ||

| 13.3.3 | SGS Tarkwa | 60 | ||

| 13.4 | Adequacy of Procedures | 60 | ||

| 14 | DATA VERIFICATION | 61 | ||

| 14.1 | Quality Control Procedures | 61 | ||

| 14.1.1 | Intertek Testing Services (ITS) | 61 | ||

| 14.1.2 | Transworld (Tarkwa) and SGS (Tarkwa) | 61 | ||

| 14.2 | Quality Control Analysis | 62 | ||

| 14.2.1 | Pre BHP | 63 | ||

| 14.2.2 | Resolute/BHP-Resolute (ITS) | 63 | ||

| 14.2.3 | Goldbelt (Transworld - Tarkwa) | 64 | ||

| 14.2.4 | Goldbelt (SGS - Tarkwa) | 65 | ||

| 14.2.5 | Analytical Data Quality Summary | 67 | ||

| 14.3 | Bulk Density Determinations | 67 | ||

| 14.4 | Survey Control | 68 | ||

| 14.4.1 | Topography | 68 | ||

| 14.4.2 | Collar Surveys | 68 | ||

| 14.4.3 | Down-hole Surveys | 68 | ||

| 14.5 | Data Quality Summary | 69 | ||

| 14.6 | Source Data | 70 | ||

| 14.7 | Drillhole Database | 70 | ||

| 15 | ADJACENT PROPERTIES | 73 | ||

| 16 | MINERAL PROCESSING AND METALLURGICAL TESTING | 74 | ||

| 17 | MINERAL RESOURCE AND MINERAL RESERVE ESTIMATES | 76 | ||

| Page 5 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 17.1 | Introduction | 76 | |

| 17.2 | Database | 76 | |

| 17.3 | Geological Modelling and Mineralized Zone Interpretation | 76 | |

| 17.4 | Statistical Analysis | 77 | |

| 17.5 | Variography | 80 | |

| 17.6 | Block Model Development | 82 | |

| 17.7 | Grade Estimation | 82 | |

| 17.8 | Resource Classification | 85 | |

| 17.9 | Resource Statement | 86 | |

| 18 | MINING OPERATIONS | 88 | |

| 18.1 | Mining Methods | 88 | |

| 18.2 | Open Pit Optimization and Parameters | 88 | |

| 18.2.1 Whittle Pit Optimization Model Construction | 88 | ||

| 18.2.2 Dilution and Mining Recovery Factors | 89 | ||

| 18.2.3 Whittle Four-X Input Parameters | 89 | ||

| 18.2.4 Commodity Price | 90 | ||

| 18.2.5 Mining Costs | 90 | ||

| 18.2.6 Pit Optimization for CIL and Heap Leach | 92 | ||

| 18.3 | Pit Optimization | 94 | |

| 18.3.1 Pit Optimization Setup | 94 | ||

| 18.4 | Pit Optimization Results | 96 | |

| 18.4.1 Scenarios | 96 | ||

| 18.4.2 HL Only | 98 | ||

| 18.4.3 CIL plus HL Combined Scenario | 101 | ||

| Page 6 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 18.5 | Whittle Four-X Sensitivity Analysis | 102 | ||

| 18.6 | Mine Production Schedule | 107 | ||

| 18.6.1 | Scheduling Results | 107 | ||

| 18.7 | Mine Design and Equipment | 108 | ||

| 18.8 | Mining Operation Facilities | 109 | ||

| 18.9 | Mine Capital Expenditures | 109 | ||

| 18.10 | Mine Manpower | 110 | ||

| 18.11 | Mine Operating Costs | 110 | ||

| 19 | METALLURGICAL PROCESSING PLANT | 111 | ||

| 19.1 | 19.1 Metallurgical Test Work Results | 111 | ||

| 19.1.1 | Results from A7029 | 114 | ||

| 19.2 | Ore Characterization | 114 | ||

| 19.3 | Plant Flowsheets | 114 | ||

| 19.3.1 | ROM Tip (CIL) | 115 | ||

| 19.3.2 | Milling (CIL) | 116 | ||

| 19.3.3 | Carbon in Leach (CIL) | 117 | ||

| 19.3.4 | Elution / Acid Wash Pressure "Zadra" System (2.5 tonne batch, CIL & Heap Leach) | 119 | ||

| 19.3.5 | Carbon Regeneration Area (CIL & Heap Leach) | 120 | ||

| 19.3.6 | Electrowinning and Smelting (CIL & Heap Leach) | 120 | ||

| 19.3.7 | Reagents and Consumables ( CIL) | 121 | ||

| 19.3.8 | ROM Tip, Crushing and Agglomeration (Heap Leach) | 122 | ||

| 19.3.9 | Conveying and Stacking (Heap Leach) | 123 | ||

| 19.3.10 | Leach Pads | 123 | ||

| 19.3.11 | Stacking Pattern | 124 | ||

| Page 7 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 19.3.12 | Heap Drainage Reticulation | 124 | ||

| 19.3.13 | Solution Corridor layout | 125 | ||

| 19.3.14 | Process Pond Layout | 125 | ||

| 19.3.15 | Solution Application System | 126 | ||

| 19.3.16 | Carbon Columns (Heap Leach) | 127 | ||

| 19.4 | Tailings Impoundment (CIL) | 127 | ||

| 19.4.1 | Introduction | 127 | ||

| 19.4.2 | Dry Tailings System (CIL) | 128 | ||

| 19.4.3 | Tailings Dam (Thickened Tailings) | 128 | ||

| 19.4.4 | Recommendations | 131 | ||

| 19.5 | Processing Water Supply | 131 | ||

| 19.5.1 | Sona Barrage | 131 | ||

| 19.5.2 | Bouro Barrage | 132 | ||

| 19.5.3 | Mormossal Barrage | 132 | ||

| 19.5.4 | Groundwater Aquifer | 133 | ||

| 19.5.5 | Recommendations | 133 | ||

| 19.6 | Processing Plant Support Facilities | 133 | ||

| 19.6.1 | Security Control Room | 133 | ||

| 19.6.2 | Change House | 134 | ||

| 19.6.3 | Plant Workshop and Stores | 134 | ||

| 19.6.4 | Laboratory | 134 | ||

| 19.7 | Gold Recovery | 134 | ||

| 19.8 | Capital Costs | 135 | ||

| 19.9 | Plant Personnel | 143 | ||

| 19.9.1 | Manpower &Training | 143 | ||

| Page 8 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 19.9.2 | Health & Safety | 144 | ||

| 19.9.3 | Plant Manpower Levels | 144 | ||

| 19.10 | Operating Costs | 147 | ||

| 20 | MINE INFRASTRUCTURE | 148 | ||

| 20.1 | Property Access | 148 | ||

| 20.2 | Primary Routes | 148 | ||

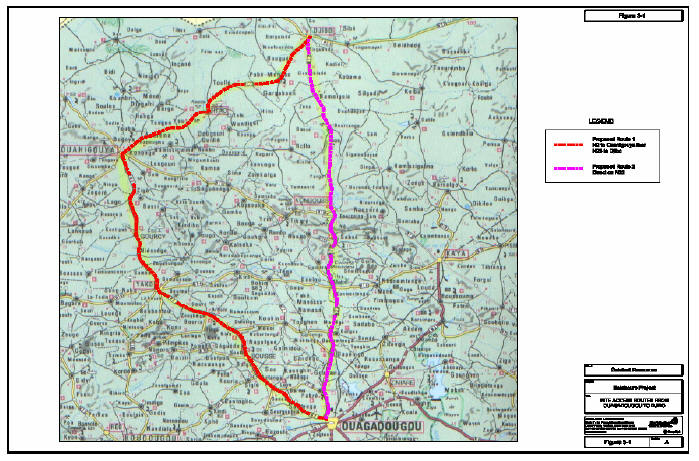

| 20.2.1 | Option A1 - Ouagadougou to Djibo, via Ouahigouya | 148 | ||

| 20.2.2 | Option A2 - Ouagadougou to Djibo, via Kongoussi | 149 | ||

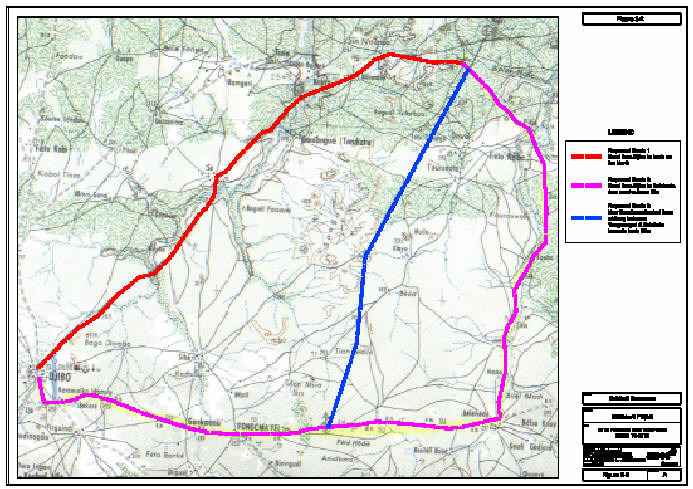

| 20.3 | Secondary Routes | 149 | ||

| 20.3.1 | Option B1 - Djibo to Inata, via Bouro Village | 149 | ||

| 20.3.2 | Option B2 - Djibo to Inata, via Belehede | 150 | ||

| 20.3.3 | Option B3 - Djibo to Inata, via central route | 151 | ||

| 20.3.4 | Discussion & Recommendations | 152 | ||

| 20.4 | Camp Accommodation and Facilities | 153 | ||

| 20.4.1 | Kitchen and Catering Facilities | 154 | ||

| 20.4.2 | Recreational Facilities | 154 | ||

| 20.4.3 | Laundry | 154 | ||

| 20.4.4 | Septic Tank and Sewage System | 154 | ||

| 20.5 | Mine Support Facilities | 155 | ||

| 20.5.1 | Administration Building | 155 | ||

| 20.5.2 | Workshop and Plant Stores | 155 | ||

| 20.5.3 | Fuel and Lubrication storage and distribution | 155 | ||

| 20.5.4 | Sewage Disposal | 156 | ||

| 20.5.5 | Explosives Magazine Facility | 156 | ||

| 20.6 | Sanitary Landfill | 157 | ||

| Page 9 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 20.7 | Power & Telecommunications | 157 | ||

| 20.7.1 | Power | 157 | ||

| 20.7.2 | Communications | 158 | ||

| 20.8 | Tailings | 158 | ||

| 20.8.1 | Tailings Storage | 158 | ||

| 20.9 | Water Management | 158 | ||

| 20.9.1 | General | 158 | ||

| 20.9.2 | Flood Attenuation | 159 | ||

| 20.9.3 | Return Water System | 159 | ||

| 20.9.4 | Diversion Structures | 159 | ||

| 20.9.5 | TMF Preliminary Water Balance | 160 | ||

| 20.10 | Water Abstraction Options | 163 | ||

| 20.10.1 | Groundwater Aquifer | 164 | ||

| 20.10.2 | Surface Impoundments | 164 | ||

| 20.10.3 | Recommendation | 168 | ||

| 20.11 | Capital Costs | 168 | ||

| 20.12 | Operating Costs | 172 | ||

| 21 | MANPOWER | 174 | ||

| 21.1 | General & Administration | 174 | ||

| 21.2 | Ouagadougou Office | 175 | ||

| 21.3 | Capital Costs | 175 | ||

| 21.4 | Operating Costs | 175 | ||

| 22 | ENVIRONMENTAL CONSIDERATIONS | 176 | ||

| 22.1 | Environmental study requirements | 176 | ||

| Page 10 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| 23 | CONSTRUCTION MANAGEMENT AND SCHEDULE | 178 | |

| 23.1 | Schedule | 178 | |

| 23.2 | Capital Costs | 179 | |

| 24 | CAPITAL AND OPERATING COST ESTIMATES | 181 | |

| 24.1 | Capital Costs | 181 | |

| 24.2 | Operating Costs | 183 | |

| 24.3 | Sustaining Capital | 185 | |

| 25 | MARKETS AND CONTRACTS | 186 | |

| 26 | INTERPRETATION AND CONCLUSIONS | 187 | |

| 26.1 | Exploration and Resource Potential | 187 | |

| 26.2 | Data Adequacy and Reliability | 187 | |

| 27 | RECOMMENDATIONS | 188 | |

| 28 | REFERENCES AND SOURCES OF INFORMATION | 189 | |

| 29 | SIGNATURE PAGE | 190 | |

| 30 | CERTIFICATES | 191 | |

| 30.1 | GBM - CERTIFICATE OF QUALIFICATION - Michael Short | 191 | |

| 30.2 | GBM - CERTIFICATE OF QUALIFICATION -Alex Mitchell | 192 | |

| 30.3 | AMEC - CERTIFICATE OF QUALIFICATION - Ciaran Molloy | 193 | |

| 30.4 | RSG Global - CERTIFICATE OF QUALIFIED PERSON - Harry Warries | 194 | |

| 30.5 | SOCREGE - CERTIFICATE OF QUALIFIED PERSON - Hubert Chailan | 195 | |

| Page 11 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

LIST OF FIGURES

| Figure 1-1 : Belahouro Permit - Corner Points | 18 |

| Figure 1-2 : Location Plan of the Belahoura Permit Area | 19 |

| Figure 1-3 : Birimian Greenstone Facies | 20 |

| Figure 1-4 : Location and Geology Plan | 21 |

| Figure 1-5 : Proposed CIL Process Testwork | 23 |

| Figure 1-6 : Proposed Heap Leach Testwork | 24 |

| Figure 1-7 : Summary Resource Statement (30 September 2005) | 25 |

| Figure 4-1 : Location Plan of the Belahoura Project Area | 35 |

| Figure 4-2 : Tenement Schedule | 36 |

| Figure 5-1 : Monthly Climatological Summary for the Project Site | 38 |

| Figure 5-2 : Seismic Load Conditions | 41 |

| Figure 6-1 : Belahouro Project Exploration History | 43 |

| Figure 6-2 : Resolute Resource Estimate 2000 (Reported at a 1.0g/t Au Lower Cutoff Grade) | 45 |

| Figure 6-3 : Ore Quest Resource Estimate December 2004 | 45 |

| Figure 6-4 : Summary Resource Statement Inata Reported at a 0.5g/t Au Lower Cutoff Grade | 45 |

| Figure 6-5 : Summary Resource Statement Inata Reported at a 1.0g/t Au Lower Cutoff Grade | 46 |

| Figure 10-1 : Goldbelt Exploration Statistics (2004 to September 2005) | 52 |

| Figure 14-1 : Summary of Drilling Database Statistics Grouped by Drill Type | 71 |

| Figure 14-2 : Summary of Drilling Database Statistics Grouped by Company | 71 |

| Figure 14-3 : Summary of Drilling Database Statistics Grouped by Laboratory | 71 |

| Figure 16-1 : Gravity Cyanaidation Test Results on Inata Composites | 74 |

| Figure 17-1 : Summary Statistics by Grouped Domain (2m Composites Uncut, Gold Grade (g/t)) | 78 |

| Figure 17-2 : Summary of Upper Cuts including Pre and Post Application of High Grade Cap Sample | 79 |

| Figure 17-3 : Summary Statistics Bulk Density Data (reported as SG) | 79 |

| Figure 17-4 : Gold Variogram Models- Inata | 81 |

| Figure 17-5 : Block Model Parameters | 82 |

| Figure 17-6 : Sample Search Criteria | 83 |

| Figure 17-7 : Change of support Parameters - emulating a 5mE x 10mN x 5mRL SMU | 84 |

| Figure 17-8 : Inata Deposit - Confidence Levels of Key Criteria | 85 |

| Figure 17-9 : Grade Tonnage Report - Multiple Indicator Kriging | 86 |

| Figure 17-10 : Grade Tonnage Distribution Subdivided by N43-101 Resource Categories | 87 |

| Figure 18-1 : Source of Main Input Parameters | 90 |

| Figure 18-2 : Summary Mining Operating Costs | 90 |

| Figure 18-3 : Summary Notional Mining Fleet | 91 |

| Figure 18-4 : Pit Optimisation Options (Summary Whittle Four-X Input Parameters) | 92 |

| Page 12 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| Figure 18-5 : Summary of Pit Optimisation Results | 93 |

| Figure 18-6 : Summary Pit Optimisation Results CIL Scenarios | 104 |

| Figure 18-7 : Summary Pit Optimisation Results CIL and HL Combined Scenario | 106 |

| Figure 18-8 : Summary Mine Production Schedule | 108 |

| Figure 19-1 : Sample Data and Leach Extraction | 111 |

| Figure 19-2 : Preg-robbing Tests | 112 |

| Figure 19-3 : Total Gold Extraction (%) for CIL Tests | 112 |

| Figure 19-4 : Ore Types Bond Work Index | 113 |

| Figure 19-5 : Total Gold Extraction (%) for CIL Tests | 113 |

| Figure 19-6 : Total Gold Extraction (%) | 114 |

| Figure 19-7 : Heap Leach Pad: Preliminary Civil Works Programme (Double Stacking) | 124 |

| Figure 19-8 : Volumetric Calculations - Paddock TMF | 130 |

| Figure 19-9 : Cost Estimation - Paddock TMF Option | 130 |

| Figure 19-10 : Summary Processing Recoveries | 134 |

| Figure 19-11 : Capital Cost Estimate Summary Level 3. 2MTPA (Wet Tailings) | 135 |

| Figure 19-12 : Capital Cost Estimate Summary Level 3 2MTPA (Dry Stack) | 136 |

| Figure 19-13 : Processing Costs | 147 |

| Figure 20-1 : Cost Estimation - Road Option B1 | 150 |

| Figure 20-2 : Cost Estimation - Road Option B2 | 151 |

| Figure 20-3 : Cost Estimation - Road Option B3 | 152 |

| Figure 20-4 : Slurry TMF Preliminary Water Balance | 161 |

| Figure 20-5 : Dry Stack Preliminary Water Balance | 162 |

| Figure 20-6 : Cost Estimation - Water Supply Pipeline and Well field | 164 |

| Figure 20-7 : Cost Estimation - Sona Barrage 2200m long @ 5m high | 165 |

| Figure 20-8 : Cost Estimation - Bouro Barrage | 166 |

| Figure 22-1 : Required Environmental Studies | 176 |

| Figure 23-1 : Schedule | 179 |

| Figure 23-2 : Owner's Costs - Capital Cost Estimate Summary Level 3 | 179 |

| Figure 24-1 : Dry Tailings System - 2.0 MTPA Capital Cost Estimate: Summary Level 1 | 181 |

| Figure 24-2 : Wet Tailings System - 2.0 MTPA Capital Cost Estimate: Summary Level 1 | 181 |

| Figure 24-3 : Wet Tailings System - 1.5 MTPA Capital Cost Estimate: Summary Level 1 | 182 |

| Figure 31-1 : Inata Field Duplicates - All Data | 196 |

| Figure 31-2 : Inata Field Duplicates- Data Gt 0.1g/t | 197 |

| Figure 31-3 : Blank Data | 198 |

| Figure 31-4 : Standards Data | 199 |

| Figure 31-5 : Standards Data | 200 |

| Figure 31-6 : Standards Data | 201 |

| Page 13 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| Figure 31-7: Inata Pills-Data Augusts 2005 | 202 |

| Figure 31-8: Inata Pills-Data Augusts 2005 | 203 |

| Figure 31-9: Inata Pills-Data Augusts 2005 | 204 |

| Figure 31-10: Inata Pills-Data Augusts 2005 | 205 |

| Figure 31-11: Inata Pills-Data Augusts 2005 | 206 |

| Figure 31-12 : Inata Field Duplicates - August 2005 Data GT 0.1g/t | 207 |

| Figure 31-13 : Blank Data - August 2005 | 208 |

| Figure 31-14 : Standards Data - August 2005 | 209 |

| Figure 31-15 : Standards Data - August 2005 | 210 |

| Figure 31-16 : Standards Data - August 2005 - Outliners Removed | 210 |

| Figure 31-17 : Standards Data - August 2005 | 211 |

| Figure 31-18 : Standards Data - August 2005 | 212 |

| Figure 30-19 : Standards Data - August 2005 | 213 |

| Figure 31-20 : Standards Data - August 2005 | 214 |

| Figure 31-21 : Standards Data - August 2005 | 215 |

| Figure 31-22 : Standards Data - August 2005 | 216 |

| Figure 31-23 : Typical Sectional View of Regolith Domains Section 1589460N | 217 |

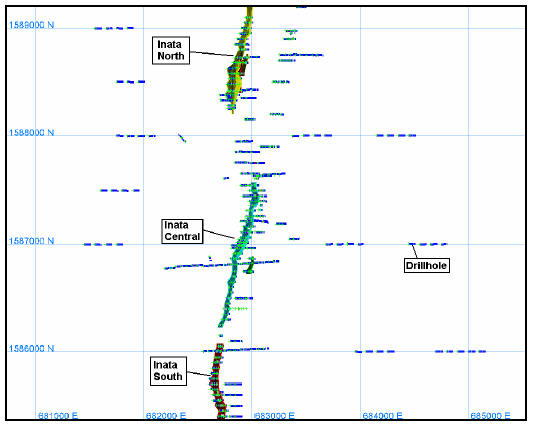

| Figure 31-24 : Plan View of Mineralized Domains | 217 |

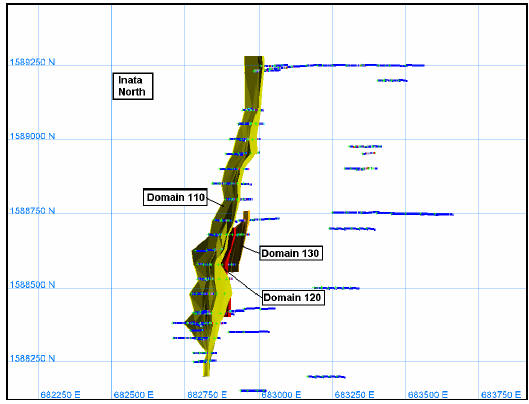

| Figure 31-25 : Plan View of Mineralized Domains Inata North | 218 |

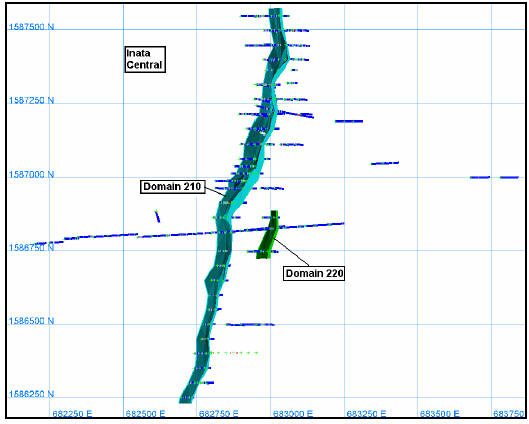

| Figure 31-26 : Plan View of Mineralized Domains Inata Central | 218 |

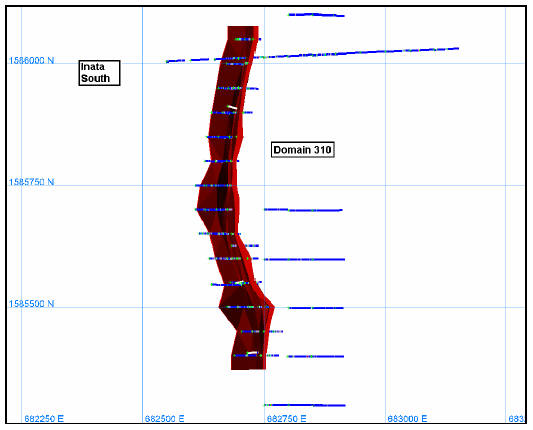

| Figure 31-27 : Plan View of Mineralized Domains Inata South | 219 |

| Figure 31-28 : Typical Cross Section (1588580N) of Interpreted Mineralization Domains Inata North | 219 |

| Figure 31-29 : Typical Cross Section (1586820N) of Interpreted Mineralization Domains Inata Central | 220 |

| Figure 31-30 : Typical Cross Section (1585600N) of Interpreted Mineralization Domains Inata South | 220 |

| Figure 31-31 : M Composites Log Probability Plot Domain 310 | 221 |

| Figure 31-32 : Mean Vs Contribution to Metal Plot Domain 310 | 221 |

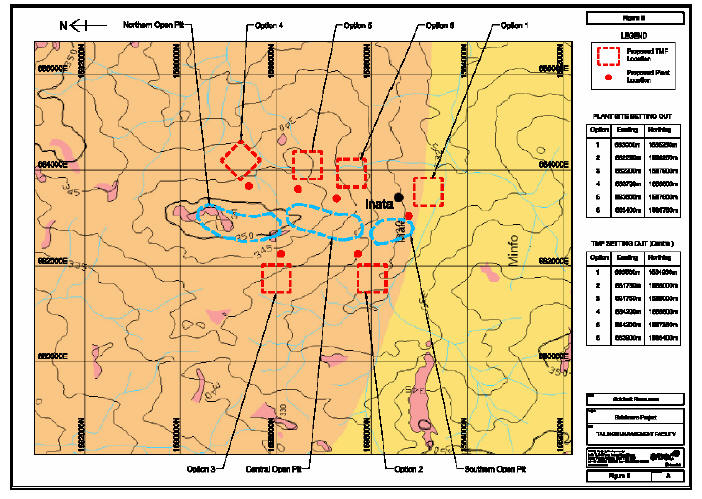

| Figure 31-33 : Tailings Management Facility Options | 222 |

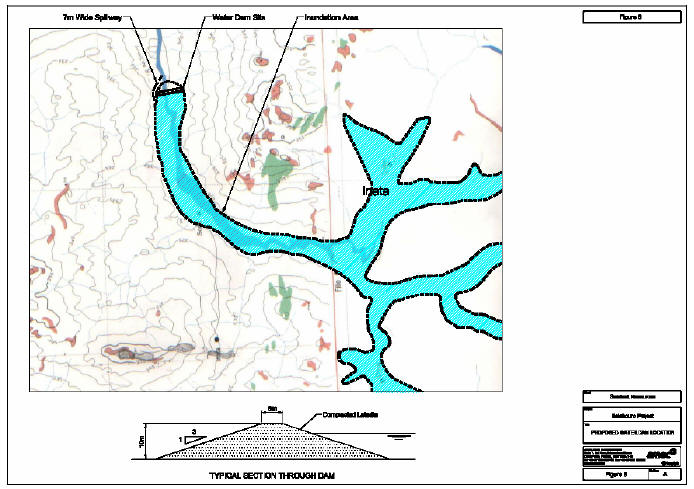

| Figure 31-34 : Sona Barrage | 223 |

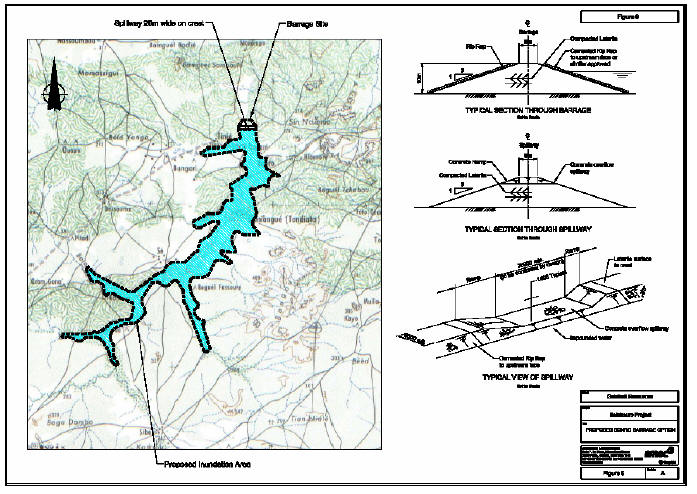

| Figure 31-35 : Bouro Barrage | 224 |

| Figure 31-36 : Primary Routes | 225 |

| Figure 31-37 : Secondary Routes | 226 |

| Figure 31-38 : Typical Road Details | 227 |

| Page 14 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

LIST OF DRAWINGS (Submitted Separately)

2Mtpa CIL Plant

0207 CRS 8001: PROCESS FLOW DIAGRAM - ORE INFEED

0207 CRS 8002: PROCESS FLOW DIAGRAM - CRUSHING AREA

0207 CRS 8003: PROCESS FLOW DIAGRAM - MILLING AREA

0207 CIL 8004: PROCESS FLOW DIAGRAM - CIL TANKS & THICKENER AREA

0207 STR 8005: PROCESS FLOW DIAGRAM - ACID WASH AREA

0207 STR 8006: PROCESS FLOW DIAGRAM - ELUTION AREA

0207 STR 8007: PROCESS FLOW DIAGRAM - ELECTROWINNING & SMELTING AREA

0207 CRG 8008: PROCESS FLOW DIAGRAM - CARBON REGENERATION AREA

0207 RGT 8009: PROCESS FLOW DIAGRAM - CYANIDE, CAUSTIC, FLOCCULANT & LIME

0207 RGT 8010: PROCESS FLOW DIAGRAM - AIR, OXYGEN & DIESEL SUPPLIES

0207 RGT 8011: PROCESS FLOW DIAGRAM - WATER DISTRIBUTION

1Mtpa CIL Plant

0207 CRS 8101: PROCESS FLOW DIAGRAM - ORE INFEED

0207 CRS 8102: PROCESS FLOW DIAGRAM - MILLING AREA

0207 CIL 8103: PROCESS FLOW DIAGRAM - CIL TANKS & THICKENER AREA

0207 STR 8104: PROCESS FLOW DIAGRAM - ACID WASH AREA

0207 STR 8105: PROCESS FLOW DIAGRAM - ELUTION AREA

0207 STR 8106: PROCESS FLOW DIAGRAM - ELECTROWINNING & SMELTING AREA

0207 CRG 8107: PROCESS FLOW DIAGRAM - CARBON REGENERATION AREA

| Page 15 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

0207 RGT 8108: PROCESS FLOW DIAGRAM - CYANIDE, CAUSTIC, FLOCCULANT & LIME

0207 RGT 8109: PROCESS FLOW DIAGRAM - AIR, OXYGEN & DIESEL SUPPLIES

0207 RGT 8110: PROCESS FLOW DIAGRAM - WATER DISTRIBUTION

1Mtpa Heap Leach Plant

0207 CRS 8201: PROCESS FLOW DIAGRAM -HEAP LEACH - ORE INFEED

0207 CRS 8202: PROCESS FLOW DIAGRAM - HEAP LEACH - CRUSHING AREA

0207 LCH 8203: PROCESS FLOW DIAGRAM - HEAP LEACH - WATER DISTRIBUTION

0207 CIP 8204: PROCESS FLOW DIAGRAM - HEAP LEACH - CARBON COLUMNS

0207 STR 8105: PROCESS FLOW DIAGRAM - ACID WASH AREA

0207 STR 8206: PROCESS FLOW DIAGRAM -HEAP LEACH - ELUTION AREA

0207 STR 8207: PROCESS FLOW DIAGRAM -HEAP LEACH - ELECTROWINNING & SMELTING AREA

0207 CRG 8208: PROCESS FLOW DIAGRAM - CARBON REGENERATION AREA

0207 RGT 8209: PROCESS FLOW DIAGRAM - CYANIDE, CAUSTIC, FLOCCULANT & LIME

0207 RGT 8210: PROCESS FLOW DIAGRAM - AIR & DIESEL SUPPLIES

0207 RGT 8211: PROCESS FLOW DIAGRAM - WATER DISTRIBUTION

0207GEN1206A PROPOSED SITE INFRASTRUCTURE - MORMOSSAL WATER DAM OPTION

0207GEN1207A PROPOSED SITE INFRASTRUCTURE- SONA DAM OPTION

| Page 16 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| APPENDICES | |

| 1- SUMMARY PIT OPTIMISATION MODEL DEVELOPMENT | 227 |

| 2 SUMMARY PIT OPTIMISATION MINING COSTS | 231 |

| 3 DETAILED PIT OPTIMISATION RESULTS-1 MTPA CIL OWNER OPERATED MINING | 234 |

| 4 DETAILED PIT OPTIMISATION RESULTS-1 MTPA CIL CONTRACT OPERATED MINING | 236 |

| 5 DETAILED PIT OPTIMISATION RESULTS-1.5 MTPA CIL | 238 |

| 6 DETAILED PIT OPTIMISATION RESULTS-2.0 MTPA CIL | 240 |

| 7 DETAILED PIT OPTIMISATION RESULTS-1.0 MTPA HL - NO AGGLOMERATION | 242 |

| 8 DETAILED PIT OPTIMISATION RESULTS-1.0 MTPA HL - WITH AGGLOMERATION | 244 |

| 9 DETAILED PIT OPTIMISATION RESULTS-1.5 MTPA HL - NO AGGLOMERATION | 246 |

| 10 DETAILED PIT OPTIMISATION RESULTS-1.5 MTPA HL - WITH AGGLOMERATION | 248 |

| 11 DETAILED PIT OPTIMISATION RESULTS-2.0 MTPA HL - NO AGGLOMERATION | 250 |

| 12 DETAILED PIT OPTIMISATION RESULTS-2.0 MTPA HL - WITH AGGLOMERATION | 252 |

| 13 DETAILED PIT OPTIMISATION RESULTS-COMBINED HL &CIL EXCLUDING HL AGGLOMERATION | 254 |

| 14 DETAILED PIT OPTIMISATION RESULTS-COMBINED HL &CIL INCLUDING HL AGGLOMERATION | 256 |

| 15 PLAN VIEW & X SECTIONS OF CUTBACKS USED FOR MINE PRODUCTION SCHEDULE | 258 |

| 16 ENVIRONMENTAL IMPACT STUDY BY SOCREGE (FRENCH VERSION) |

| Page 17 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

1 EXECUTIVE SUMMARY

1.1 Property Description

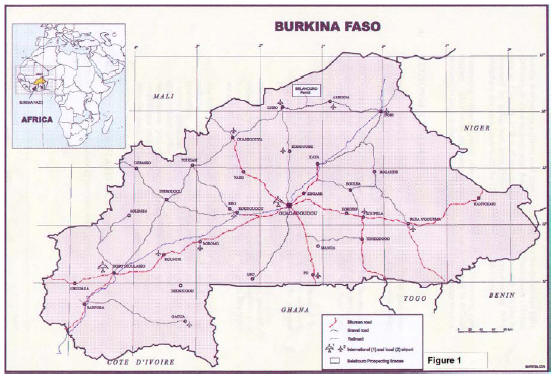

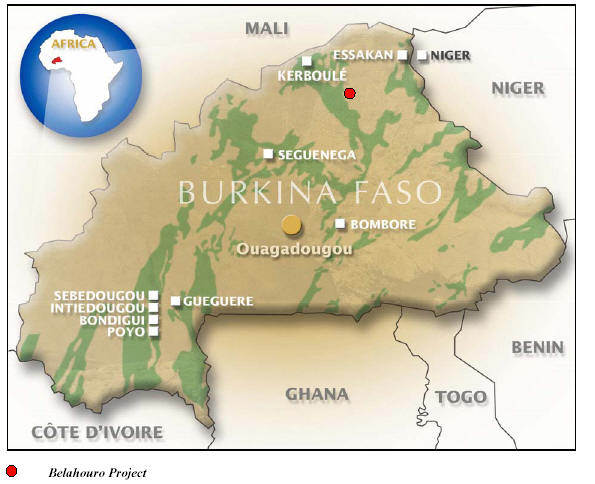

The project property is located within the Northern Region of the Republic of Burkina Faso, 220 km north north-east of Ouagadougou, close to the international boundary with Mali. The nearest town is Djibo which is 60km to the Southwest (see Figure 1-2).

The property covers an area of 1187 km2 of gently undulating land and has been subject to mineral exploration and artisanal workings for many years.

1.2 Exploration and Property History

The Belahouro Permit, licence no. 98-127, has an area of 1600km² and was granted to BHP Minerals International Exploration Inc on 3rd October 1994. The first renewal was granted on the 3rd October 1998, the second renewal, with a subsequent reduction in area, was granted on 3rd October 2001 and a third renewal, for a period of 1.5 years, was granted on 3rd October 2004. The Exploration Permit will expire on 3rd April 2006, however, Goldbelt will, in December 2005, submit an application for an Exploitation Permit for the Inata Project and in addition an Exploration Permit for the remaining Belahouro License Area.

Figure 1-1 : Belahouro Permit - Corner Points

| Coordinates Long/Lat (Clarke 1880) | UTM 30 WGS 84 | |||

| Corners | ||||

| Latitude North | Longitude West | Northing | Easting | |

| A | 14°30'07'' | 1°23'43'' | 1604000 | 673000 |

| B | 14°30'07'' | 1°06'23'' | 1604000 | 704000 |

| C | 14°25'00'' | 1°06'23'' | 1595000 | 704000 |

| D | 14°25'00'' | 0°55'00'' | 1595000 | 725000 |

| E | 14°17'20'' | 0°55'00'' | 1580000 | 725000 |

| F | 14°17'20'' | 1°29'00'' | 1580000 | 664000 |

| G | 14°22'36'' | 1°29'00'' | 1590000 | 664000 |

| H | 14°22'36'' | 1°28'10'' | 1590000 | 665000 |

| I | 14°28'16'' | 1°28'10'' | 1601000 | 665000 |

| J | 14°28'16'' | 1°23'45'' | 1601000 | 673000 |

| Page 18 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

1.2.1 Location and Access

The Belahouro permit lies close to the Mali-Burkina Faso border in the northernmost part of Burkina Faso. The central part of the permit lies approximately 220 km NNE of the capital, Ouagadougou and the nearest large city is Dijbo, 60 km to the South-West.

Access is by gravel road from Ouagadougou to Kongoussi and Djibo (200 km) or by bitumen road from Ouagadougou to Ouahigouya (180km) then to Djibo by 110 km of gravel road. The Belahouro camp site can be accessed by driving east from Djibo along the Dori Road, for approximately 60 km, then north along a gravel road for 18 km to the village of Belahouro.

Crossing the permit is possible along village tracks or through open country as most areas are open grassland or low shrub. Access to large drainages is difficult due to dense vegetation and deep drainage erosion.

Figure 1-2 : Location Plan of the Belahouro Permit Area

| Page 19 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

1.3 Geology and Mineralization

Figure 1-3 : Birimian Greenstone Facies

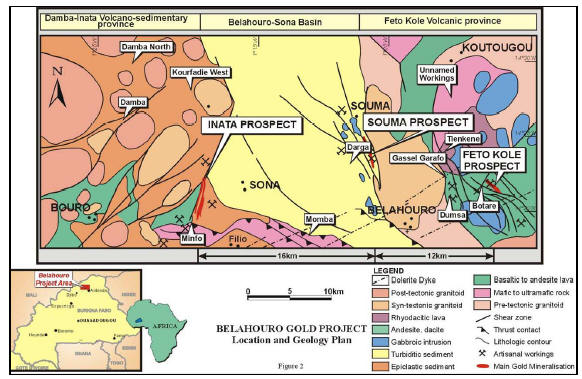

The Belahouro Project is located in the western portion of the Birimian Djibo Greenstone Belt. The belt has undergone regional lower greenschist metamorphism and is comprised of intermediate to mafic volcano-sedimentary successions and syn to post-kinematic granite and gabbro intrusions. Further emplacement of dolerite and felsic-porphyry has also occurred during and after mineralizing events.

Gold within the Belahouro Project is exclusively associated with mesothermal vein style mineralization, entirely consistent with the majority of Archaean and Proterozoic terrains worldwide, including the Birimian Series of West Africa. This style of mineralization is generally associated with regionally metamorphosed terrains that have experienced considerable deformation. As such, the deposits are invariably strongly structurally controlled, with the dominance of structural control increasing proportionally with metamorphic grade.

The principal gold mineralization within the Belahouro Project is confined to the Inata and the Fete Kole and Souma trends. The three Inata deposits (North, Central and South) are located over a strike length of 4km. The deposits appear to be related to the same mineralizing event and are associated with shearing. The Inata

| Page 20 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

Central and Inata South deposits occur on the same mineralized zone, separated by intermittent low grades and cross-faults. Inata North lies some 300m west of the Inata Central-South trend. The shear zone encompassing the Inata deposits strikes north-northeast and dips steeply to the west-northwest. Gold occurs as free grains and sulphides associated with quartz veins or silicified rocks.

The Damba-Inata volcano-sedimentary province lies within the western third of the tenure. The Belahouro-Sona Basin occupies the central third, whilst the Feto Kole volcanic province is located in the eastern third.

The Damba-Inata volcano-sedimentary province is dominated by metasediments (epiclastics) with lesser basaltic to andesitic volcanics. The province contains multiple granitoid intrusions. The regional foliation trend is north-east.

Figure 1-4 : Location and Geology Plan

The Belahouro-Sona basin is dominated by metasediments, generally turbiditic, with minor intermediate volcaniclastics. The southern part is traversed by an east-west shear zone. South of this zone, lithotypes are andesites, shales and chert.

The Fete Kole volcanic province is a complex of rhyodacitic, dacitic, andesitic and basaltic volcanics with associated pyroclastics and epiclastics. Within the volcanics, both pre-tectonic and syn to post tectonic

| Page 21 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

granitoids occur. The last major intrusive phase is a differentiated gabbro complex. The gabbro has intruded mainly into the volcanic package. At the base of the gabbro, titaniferous and vanadiferous magnetite banding can be found. Associated ultramafic units also occur within the gabbro and volcanic package.

1.4 Metallurgical Testing

Further Metallurgical test work is being carried out to further investigate and confirm the amenability of the ore to either CIL and/or Heap leach possibilities. The test work will produce accurate predictions on Bond Work Index and recoveries, hence processing costs can be reduced and pit optimizations can be rerun with a good probability in increasing the resource model.

1.4.1 Metallurgical Test Work for Belahouro - CIL Process

Samples were taken from the three Inata Deposits as follows:

| North Inata Deposit - | 2 reverse circulation samples and 2 diamond cores |

| Central Inata Deposit | 1 reverse circulation sample and 1 diamond core |

| South Inata Deposit - | 1 reverse circulation sample |

1.4.1.1 Comminution test work proposed for diamond cores,

Sort core into mineralogical zones : Oxide, Transition, Fresh (3 holes, 3 zones per hole, total of 9 drill core composites)

Select 3 pieces of each zone for Unconfined Compressive Strength test, 3 pieces for Apparent Specific Gravity

Stage crush balance to nominally -19mm

Blend and split :

(a) 10kg for Bond abrasion index

(b) 15kg for Bond rod mill work index

(c) 12kg for Bond ball mill work index

| Page 22 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

1.4.1.2 Cyanide leach testwork proposed for RC drill chips samples

Sort RC chips into mineralogical zones: Oxide, Transition, Fresh (4 holes, 3 zones per hole, total of 12 composites).

Stage crush to 100% passing 2mm

Blend and split to source 1kg charges.

Figure 1-5 : Proposed CIL Process Testwork

| 2 x 500gram | 3 x 1 kg | 1 x 1 kg | 1 x 1kg |

|

Head Assay |

Grind Test |

Comparative Direct vs CIL |

Optimum Grind Leaches |

|

|

|

Leach |

|

|

Au x 2, Ag, total and |

|

|

|

|

sulphide S |

|

|

|

|

25 element ICP scan |

Determine Grind Times |

P80 passing 75 micron |

Direct or CIL |

|

Total & organic C |

P80 passing 150 micron |

|

P80 passing 150 micron |

|

Hg, Sb, Te |

P80 passing 106 micron |

40% solids |

P80 passing 106 micron |

|

True specific gravity |

P80 passing 75 micron |

pH 10 - 10.5 (lime) |

P80 passing 75 micron |

|

Mineralogy |

P80 passing 38 micron |

0.1% NaCN initial |

P80 passing 38 micron |

|

|

|

maintain 500ppm |

|

|

|

|

Oxygen sparged |

|

|

|

|

For CIL add 20gpl carbon |

40% solids |

|

|

|

Samples at 2, 4, 8, 24, |

ph 10 - 10.5 (lime) |

|

|

|

48hrs (Au) |

|

|

|

|

Residue Au x 2 |

0.1% NaCN initial |

|

|

|

|

maintain 500ppm |

|

|

|

|

Oxygen sparged |

|

|

|

|

For CIL add 20gpl carbon |

|

|

|

|

Samples at 2, 4, 8, 24, |

|

|

|

|

48hrs (Au) |

|

|

|

|

Residue Au x 2 |

|

|

|

|

Size assay residue (Au) |

Additional test work,

Oxygen uptake rate (optimum P80, direct or CIL leach)

Pulp viscosity measurement (optimum P80)

Effect of dosing with kerosene to counteract pregrobbing behaviour

| Page 23 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

Optimum NaCN concentration at optimum P80 (e.g. 0.2 / 0.1%, 0.05 / 0.025%, compared to 0.1 / 0.05%)

Gravity recoverable gold content (mill 5kg to optimum P80, centrifugal concentrator, amalgamate concentrate, assay products)

Vendor application : settling / thickening characteristics, filtration characteristics (suggest Oxide, Transition, Fresh composites)

Confirmatory test work : use composites based on mining schedules (to be defined)

1.4.2 Metallurgical Test Work for Belahouro Project - Heap Leach

Blend and split sub samples for evaluation

Stage crush sub samples to achieve three designated P100's (50mm, 25mm, 12mm)

Blend and split each P100 size to source sub samples for evaluation

Figure 1-6 : Proposed Heap Leach Testwork

|

Head size assay(5kg) |

Fine grind leach(1kg) |

Coarse particle Leach (3kg) |

Cement agglomeration /percolation |

Column leach Tests (50kg) |

|

From top size to 2mm |

Stage crush to -2mm |

At each of three P100'S |

3 Cement doses(5kg each) |

Optimum crush size |

|

Allow for 6 fractions(Au) |

Fine grind to nom P80 75micron |

40% solids |

Determine percolation rate |

Agglomerate if required |

|

|

48hour leach, 500 ppm NaCn, time series |

Ph 10-10.5 (lime, maintained) |

|

30 Day leach |

|

|

Assay residue Au |

500ppmNaCN (maintained) |

|

5 day week irrigation |

|

|

|

Solns at 2, 4, 8, 24, 48, 72, 96, 120hrs (Au) |

|

Contact solution with carbon |

|

|

|

Size assay residue as per head |

|

Preg & barren solution assays |

|

|

|

|

|

Leach residue size assay |

| Page 24 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

1.5 Mineral Resources

Resource estimates for the Belahouro Gold Project (Inata) have been generated by RSG Global on the basis of analytical results available up to 30 September 2005. The resource models were derived via geological and modelling of the individual mineralized zones. Estimation involved the application of Multiple Indicator Kriging (MIK). Technique selection was based on the quantity and spacing of available data, and the interpreted controls on, and styles of, mineralization under review.

RSG Global also completed a detailed assessment of all analytical quality control data applied in resource estimation. At the time of resource estimation, no material bias had been identified, and the analytical precision for both standards and field duplicate data generally lie within accepted industry limits for mesothermal vein gold deposits.

The summarised Resource Statement in Figure 1-7 has been determined as at 30 September 2005 and reported in accordance with Canadian National Instrument 43-101, Standards of Disclosure for Mineral Projects of February 2001 (the Instrument) and the classifications adopted by CIM Council in August 2000. Furthermore, the resource classification is also consistent with the Australasian Code for the Reporting of Mineral Resources and Ore Reserves of December 2004 (the Code) as prepared by the Joint Ore Reserves Committee of the Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Mineral Council of Australia (JORC).

Figure 1-7 : Summary Resource Statement (30 September 2005)

Grade Tonnage Report - Multiple Indicator Kriging

Selective Mining Unit 5m E x10m N x 5m RL 30th September 2005

| Cutoff | Indicated | Inferred | ||||

| Grade | Tonnage (t) | Au g/t | ozs | Tonnage (t) | Au g/t | ozs |

| 0.4 | 15,836,000 | 1.9 | 945,000 | 5,593,000 | 1.3 | 236,000 |

| 0.5 | 15,043,000 | 1.9 | 933,000 | 4,869,000 | 1.4 | 226,000 |

| 0.7 | 13,121,000 | 2.1 | 895,000 | 3,923,000 | 1.6 | 207,000 |

| 1.0 | 10,297,000 | 2.5 | 818,000 | 2,811,000 | 2.0 | 177,000 |

| 1.5 | 6,964,000 | 3.1 | 686,000 | 1,600,000 | 2.5 | 129,000 |

The bulk density of the rock has been estimated as follows:-

Oxide 2.1 t/m3

Transition 2.5 t/m3

| Page 25 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

Primary 2.7 t/m3

1.5.1 Pit Optimisation & Sensitivity

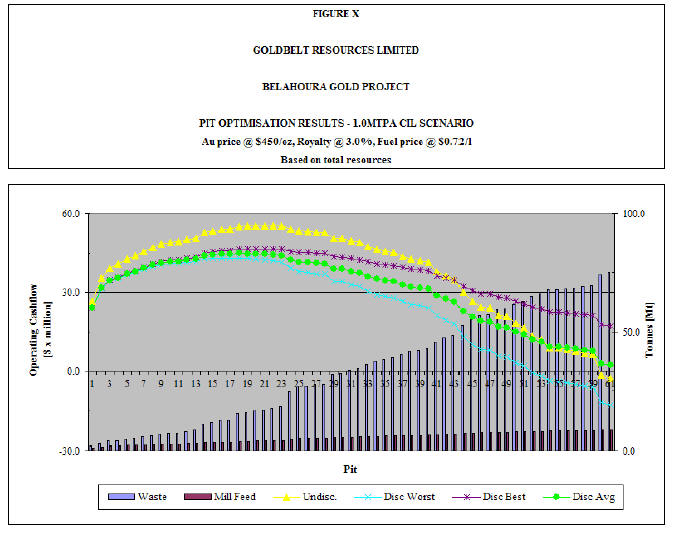

A summary of the principal pit optimisation results, based on the total resource and the maximum undiscounted cashflow is shown in Figure 1-8.

Figure 1-8 : Summary of Pit Optimisations

| Item | CIL Only | HL Only | CIL and HL | ||||||||||

| Combined | |||||||||||||

| Unit |

Owner Mining 1 |

Contract Mining | No Agglomeration |

With Agglomeration |

HL(N) 2 | HL(A) 3 | |||||||

| Throughput |

Mtpa |

1.0 |

1.0 |

1.5 |

2.0 |

1.0 |

1.5 |

2.0 |

1.0 |

1.5 |

2.0 |

1.0 / 1.0 |

1.0 / 1.0 |

| Base of pit |

mRL |

155 |

200 |

200 |

180 |

235 |

230 |

230 |

235 |

235 |

235 |

200 |

200 |

| Total material |

Mt |

46.5 |

20.5 |

23.2 |

30.1 |

13.0 |

15.3 |

15.8 |

10.8 |

12.2 |

13.0 |

21.8 |

20.6 |

| Waste |

Mt |

39.9 |

16.7 |

18.7 |

24.9 |

9.3 |

11.2 |

11.5 |

7.8 |

8.8 |

9.4 |

17.0 |

16.5 |

| Strip ratio |

w:o |

6.0 |

4.4 |

4.1 |

4.8 |

2.5 |

2.7 |

2.7 |

2.6 |

2.6 |

2.5 |

3.6 |

4.0 |

| Mill Feed |

Mt |

6.6 |

3.8 |

4.5 |

5.2 |

3.7 |

4.1 |

4.2 |

3.0 |

3.4 |

3.7 |

2.6 / 1.3 |

3.7 / 0.4 |

| Grade |

g/t |

2.7 |

2.8 |

2.6 |

2.6 |

2.4 |

2.4 |

2.3 |

2.7 |

2.6 |

2.4 |

3.0 / 1.0 |

2.8 / 0.9 |

| Recovered gold |

koz |

539 |

324 |

355 |

406 |

167 |

181 |

184 |

149 |

160 |

167 |

335 |

329 |

The base case of 1.0 Mtpa CIL, owner operated mining fleet scenario was based on the latest testwork from November and includes increasing the pit slope angles by 40to 50in the oxide and primary ores.

Further sensitivity analysis demonstrated that a $50 /oz (11%) change in the gold price represents a 27% change in the undiscounted operating cashflow.

Increasing the overall pit wall slope angle for oxide ores from 380to 450resulted in a 4% decrease in the cash cost. In the current resource models, the pit shells do not materially extend into the primary rock, therefore increasing the wall angles does not have a material effect on the optimum pit shell.

An indicative mining schedule was developed through Whittle Four-X.

____________________________________

1 Includes updated metallurgical and geotechnical parameters derived from

preliminary 2005 testwork.

2 Heap leach without agglomeration

3 Heap leach with agglomeration

| Page 26 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

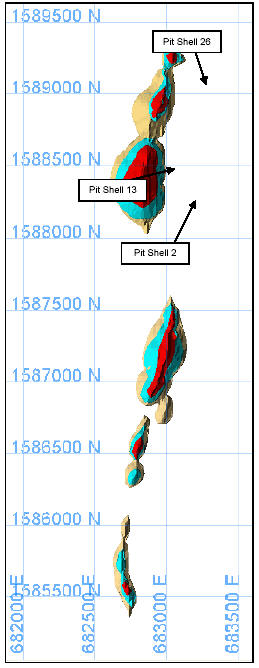

For the purposes of this mining study , pit shell 26 of the 1.0 Mtpa CIL, owner mining scenario was selected as the basis for mine production scheduling, the results are indicated in Figure 1-9.

Figure 1-9 : Pit Shell 26 Scheduling

| Total | Low Grade | Strip | Potential Mill Feed | Gold | |||||

| Period | Material | Waste 1 | Tonnes | Grade | Ratio | Tonnes | Grade | Insitu | Rec |

| Yr | Mt | Mt | Mt | g/t | w:o | Mt | g/t | koz | koz |

| 1 | 5.3 | 4.3 | 0.2 | 0.7 | 4.3 | 1.0 | 2.5 | 81.5 | 77.4 |

| 2 | 9.2 | 8.2 | 0.2 | 0.7 | 8.2 | 1.0 | 2.6 | 83.0 | 78.8 |

| 3 | 9.5 | 8.5 | 0.3 | 0.7 | 8.5 | 1.0 | 2.6 | 82.1 | 78.0 |

| 4 | 9.5 | 8.5 | 0.3 | 0.7 | 8.5 | 1.0 | 2.8 | 89.5 | 85.0 |

| 5 | 9.5 | 8.5 | 0.3 | 0.7 | 8.6 | 1.0 | 2.4 | 75.6 | 71.6 |

| 6 | 8.3 | 7.3 | 0.3 | 0.7 | 7.3 | 1.0 | 2.1 | 68.5 | 64.9 |

| 7 | 3.2 | 2.2 | 0.1 | 0.7 | 2.2 | 1.0 | 3.2 | 102.0 | 93.6 |

| 8 | 1.0 | 0.5 | 0.0 | 0.7 | 1.2 | 0.4 | 3.0 | 41.9 | 37.8 |

| Totals | 55.4 | 48.0 | 1.6 | 0.7 | 6.5 | 7.4 | 2.6 | 624.1 | 587.0 |

1.6 Mining Operations

It was assumed that the Belahouro Gold Project mine will selectively mined from a conventional open pit by either owner operated or contract mining.

Drilling and blasting will be performed on 5m high benches, with blasted material excavated by backhoe excavators in two discrete flitches, each nominally of 2.5m height.

The use of RC drilling, assays every 2.5m sample and interpretation of the results by mine geologists are the primary methods of grade control envisaged for the Project. Further investigations may be undertaken later to optimise sample length and drill pattern to ensure appropriate statistical methodologies can be utilised to minimise dilution and maximise ore extraction.

A notional drilling pattern of 10 m x 5 m was adopted for the study, with 115% of the expected ore zones assumed to be grade control drilled, to ensure sufficient overlap into adjacent low grade or waste such that ore is not missed. All RC holes are assumed to be drilled at a 60º angle.

The mining equipment which is considered to be suitable for the Project would include 80 t to 180 t backhoe excavators and off-highway haul trucks with a payload capacity of between 65 t to 92 t.

____________________________________

1 Waste is inclusive of low grade material.

| Page 27 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

The size of equipment would be dependent on the required ore mining selectivity and the final selected ore mining rate. It is recommended that a bench height optimisation study be carried out to assess mining dilution and recovery control in relation to mining costs.

1.7 Mineral Processing Plant

The mineral processing plant, described in more detail in section 19 of this Report, uses the Carbon in Leach process commonly employed in West Africa, however, the Heap Leach process has also been considered for the lower grade ore. Due consideration has been taken to the water requirement of the plant and a dry tailings disposal system has been considered along with co deposition of waste rock, as an alternative to the more traditional wet tailings system.

1.8 Mine Overhead

Mining will be carried out either as an owner operated or as a contract mining scenario. The costs of the mine management have been included in the mine operating costs.

1.9 Manpower

The manpower requirements have been estimated using the minimum of expatriate labour and only in strategic posts with a local subordinate who will in time take over the post.

1.10 Environmental Considerations

A pre-feasibility level environmental study was carried out by SRK in April 1999 for the joint venture between BHP and Resolute Limited. An environmental base line study and an environmental impact assessment (EIA) has been carried out by Socrege SA of Burkina Faso (see Appendix 16). The EIA is a legislative requirement of the Burkinabe Government prior to the issuing of a mining permit.

| Page 28 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

1.10.1 Water Supply

The supply of water for the plant is critical and as such considerable effort has been made to ascertain robust solutions. Four solutions have been considered in depth in conjunction with a water saving plant design in terms of tailings disposal. Three of the solutions are barrages in the Sona, Bouro and Mormossal areas, the fourth is a bore field some 40 km away in the Ninga area.

Each solution has its own set of implications both environmentally and financially, which are discussed in the body of the report.

The barrages are subject to the predicted rainfall and will affect a considerable area along with both major and minor villages. The bore field is in unproven water reserves and may affect the ecology of the area.

1.11 Capital and Operating Cost Estimates

The Cost Estimates have been prepared on the basis of installing new and proven equipment and ore throughputs of 2Mtpa, 1.5Mtpa and 1Mtpa have been considered as requested by Goldbelt. Written quotations have been obtained for major items of equipment; otherwise, current prices from the GBM database were employed. The uncertainty of the Bond Work Index has had a major impact both on size of mill and size of power station impacting on processing costs and capital costs. This will be clarified by the ongoing metallurgical test work and should provide grounds for reductions in the costs.

1.12 Markets and Contracts

The gold will be sold directly to the refiners with revenue raised at that point. There are no forward sales envisaged at this time and would only be undertaken as part of a financing package where forward sales of gold would be a lender requirement.

1.13 Conclusions and Recommendations

Current exploration has confirmed the significant potential of the Belahouro Project. Recent observations and current exploration models indicate that the known mineralization may represent the periphery of a larger mineralized system. Significant potential exists to identify open resources on the Souma trend. In addition,

| Page 29 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

the Fete Kole Trend represents a significant exploration target albeit that the geological controls on mineralization are complex and to date poorly understood. The controls on the Inata Deposits mineralization are generally well understood allowing effective targeting for future exploration programs, including logical step out drilling which has the potential to extend the known resources north of Inata North and south from the Inata South deposit.

High quality data has been collected by Goldbelt in recent exploration phases. The analytical accuracy and precision of assaying is high and suitable for resource estimation. Insufficient bulk density data is currently available to allow high confidence density stratification. This is considered a short coming of the current database and has precluded the classification of Measured Resources.

Infill drilling has confined the presence and continuity of analous zones of mineralization at Inata. While significant short scale variability exists in the gold grades, the 25m or better spaced drill fences are considered to appropriate to allow high confidence resource definition consistent with the Measured and Indicated Mineral Resource categories. The implication of the moderate short scale variability in mining and grade control is that a high quality grade control drilling will be required to enable selective grade control practises. It is likely that a high density of drilling, for example an 8m x 5m pattern, will also be required for adequate ore demarcation.

RSG Global's approach in defining broader mineralization zones for estimation that are based on a nominal 0.3g/t Au lower cut off grade and geology is considered appropriate for this style of vein hosted mesothermal gold deposit when open cut mining is considered. Opportunity exists to constrain higher grade shoots based on an elevated lower cut off grade at Inata North and to a lesser extent Inata Central. In these areas, potential exists to target underground mining.

The interpretation mineralization interpretation is consistent with the geological interpretation constructed on site and further refined by RSG Global. Refinement of the geological model is important as detailed scheduling maybe dependant on geological features. For example, optimum process performance may be dependant on the ability to blend ore types which have associated hydroscopic clays (viscosity complications) or are dominated by carbonaceous shales that have preg robbing characteristics.

Based on the completed study, the Consultants recommend the following works be undertaken :

Additional bulk density data is collected for the Inata deposits. The density data should be collected such that a suitable spatial, weathering, and lithological spread of information is available to enable a robust density model construction.

Step out drilling is completed to extend or close of the Inata North and Inata South trends.

| Page 30 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

Additional drilling is focused on the Souma trend and Minfo prospects which have the potential to augment the resource and reserve base at Belahouro.

If not already available, a suite of multi-element assays be collected. This can readily be achieved by assay of umpire assay pulps.

Ongoing refinement of the geological model is completed.

A bench height study is undertaken to ascertain the optimum bench heights.

Further metallurgical test work is carried out to establish meaning full parameters.

Further investigation is carried out to establish the optimum water supply to the mine.

Further investigation is carried out to establish the optimum road alignment to the mine.

| Page 31 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

2 INTRODUCTION AND TERMS OF REFERENCE

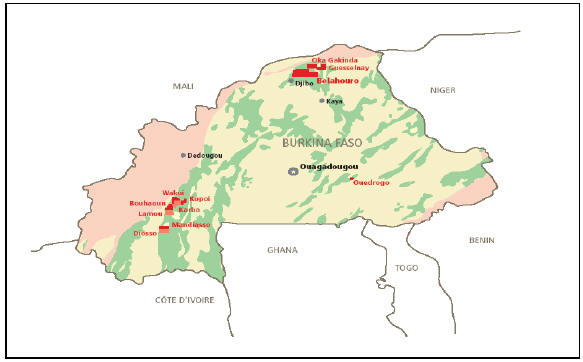

This Technical Review, prepared and compiled by GBM ("the Consultants"), provides a summary of the findings of the Belahouro Gold Project technical analysis undertaken by RSG (Global) in June and July 2005 and drilling data compiled up to November 2005. The Review provides Goldbelt Resources with the options available to them for further treatment of the resource and the necessary data for the compilation of their application for an exploitation permit to the Burkinabe Government. The Belahouro Project, located in Burkina Faso, contains several gold deposits.

This Review has been prepared generally in accordance with the requirements of National Instrument 43-101 (NI 43-101), Companion Policy 43-101CP and form 43-101FI of the Ontario Securities Commission (OSC) and Canadian Securities Administrators (CSA). It is not however intended to be a submission to those commissions.

All monetary values expressed in this document will be in United States of America Dollars (US$). The following Exchange Rates have been used :

GBP 1 = $1.757

Euro 1 = $1.1918

ZAR 1 = $0.1464

CFA 1 = $0.0018

2.1 Principal Sources of Information

In addition to site visits made by the Consultants, extensive information for the report was provided by Goldbelt Management in terms of previous reports and studies by independent operators and other consultants.

GBM have made all reasonable attempts to verify this information and have sent a draft of this report to Goldbelt with a written request to make comments and rectify any erroneous statements made.

| Page 32 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

3 DISCLAIMER

The Consultants are not qualified to provide extensive comment on legal issues associated with the Belahouro Gold Project and included in Section 4 of this Review.

The assessment of the mining aspects of the Belahouro Project, included in Sections 17 and 18 of this review, is based entirely on information and reports provided by independent mining consultants upon whom GBM has relied.

Similarly, the Consultants are not qualified to provide extensive comment on hydrological, environmental and geotechnical issues associated with the properties referred to in this Review. Assessment of these aspects has relied heavily on information provided by Goldbelt, along with reports previously prepared by other independent consultants.

No warranty or guarantee, be it express or implied, is made by the Consultants with respect to the completeness or accuracy of the legal aspects, metallurgy, processing and scheduled mill feed referred to in this document. The consultants do not accept any responsibility or liability in any way whatsoever to any person or entity in respect of these parts of this document, or any errors in or omissions from it, whether arising from negligence or any other basis in law whatsoever.

| Page 33 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

4 PROPERTY DESCRIPTION AND LOCATION

4.1 Background Information on Burkina Faso

Burkina Faso is landlocked and bordered by Benin (306 km border length), Cote d'Ivoire (584 km), Ghana (549 km), Mali (1,000 km), Niger (628 km), Togo (126 km). Burkina Faso has a land area of 274,200km2, comprised of a generally flat to dissected undulating plains and hills in the west and southeast. Natural resources include manganese, limestone, copper, nickel, bauxite marble, phosphates and salt. Burkina Faso's population is estimated at 13.9 million (2005) and is made up of several ethnic groups dominated by the Mossi (over 40%). French is the official national language. Burkina Faso gained its independence from France in 1960.

Burkina Faso is one of the poorest countries in the world, has few natural resources and a fragile soil. About 90% of the population is engaged in (mainly subsistence) agriculture, which is vulnerable to variations in rainfall. Cotton is the key crop. Industry remains dominated by government-controlled corporations. Following the African franc currency devaluation in January 1994 the government updated its development program in conjunction with international agencies, and exports and economic growth have increased. Maintenance of macroeconomic progress depends on continued low inflation, reduction in the trade deficit, and reforms designed to encourage private investment. The bitter internal crisis in neighbouring Cote d'Ivoire continues to restrict trade and industrial prospects and deepens the need for international assistance.

Many observers consider that the gold potential of Burkina Faso is significantly under-developed, however, the low level of investment in exploration and general lack of infrastructure have historically hampered development within the gold sector. Regardless, interest (albeit it somewhat subdued) in the mining and exploration sector has continued at the hands of both major and junior companies alike.

| Page 34 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

4.2 Project Location

The Belahouro Project is located approximately 220km north northeast of Ouagadougou, the capital of Burkina Faso, at a latitude of 11º 40' N and longitude of 13º 00' N, 2º 00' W (see Figure 4-1).

Figure 4-1 : Location Plan of the Belahouro Project Area

4.3 Land Area

The Belahouro Gold Project comprises one large permit covering an aggregate area of 1,187km2 as shown in Figure 4-2 below. The concession boundaries have not been legally surveyed, but are described by latitude and longitude via decree.

| Page 35 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

|

Figure 4-2 : Tenement Schedule |

||||

|

Permit Name |

Licence Type/Number |

Area |

Date Extension Granted |

Expiry |

|

Belahouro |

2003-081/2003-091 |

1,187km2 |

4 October 2004 |

April 3, 2006 |

|

Total |

|

1,187km2 |

|

|

RSG Global has not independently verified, nor is it qualified to independently verify, the legal status of the mineral properties in Burkina Faso in which Goldbelt is understood to have an interest. In preparing this review, RSG Global has assumed that the properties are lawfully accessible for evaluation and mineral production.

4.4 Mining Claim Description

The Belahouro Permit has been granted by the Burkina Faso government and consists of one large permit, approximately 1,187km2 in size located between 14º 17'20" to 14º 30'07"N latitude and 0º 55'00" to 1º28'10"W longitude in the northern region of Burkina Faso (Figure 4-2). The permit has been granted to the company by the Ministère des Mines, de l'Energie et des Carrières and cannot be contested by any other company. The government maintains a 10% carried interest in all permits issued although not until the Exploitation Stage.

The Belahouro Permit is a permit which allows the company to carry out all types of exploration provided certain reporting conditions and fee payments are maintained with the Ministère des Mines, de l'Energie et des Carrières. All exploration permits granted in Burkina Faso are for an in initial three-year period after which the permit can be renewed for two additional three-year extensions. After the second three-year period, the company must reduce the area of the exploration permit by 25%. After the third three-year period, the exploration permit must convert to an exploitation licence unless other arrangements for extension or grant of a new exploration permit are made.

The original Belahouro exploration licence of 1600 km2 in size was granted in October 1994 and further renewed for another three years in October 1998. As per the requirements in Burkina Faso, the 2nd renewal was granted in October 2001 with the mandatory 25% reduction to in size to 1187km2. On 11 November, 2004, the Belahouro permit was granted an extension of the expiry date until 03 April, 2006.

| Page 36 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

4.5 Agreements and Encumbrances

GBM & RSG Global are not qualified to provide significant comment on legal matters pertaining to the Belahouro Project, however advice provided by Goldbelt Limited suggests that the mineral properties comprising the Belahouro Gold Project are subject to a third party agreement. The BHP Royalty agreement (2.5% of gross sales) is now owned by International Royalty Limited.

4.6 Environmental Liabilities

GBM & RSG Global are not aware, nor have we been made aware, of any significant environmental liability associated with the Belahouro Project.

4.7 Permits

All resources and areas of more significant exploration potential defined to date lie within the Belahouro Permit. The Permit provides Goldbelt Resources the right to explore for minerals, however further permitting would be required prior to mine under the general mining code (Law No 023/97/II/AN) of Burkina Faso.

| Page 37 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

5.1 Property Access and Freight Routing

The project property is located within the Northern Region of the Republic of Burkina Faso, 220 km North Northeast of Ouagadougou, close to the international boundary with Mali. The nearest town is Djibo which is 60km to the Southwest, see Figure 1-2.

The property access is more fully detailed in section 20.1 and requires the building of 35 km of access road between site and the road connecting Djibo and Belehede which is a laterite surfaced all weather road.

Freight routing is by sea in containership to the Ghanaian port of Tema and then by road transport up through Ghana into Burkina Faso on to site via Ouagadougou.

5.2 Physiography and Climate

The general topography is slightly undulating and the vegetation is generally savannah type with acacia and the occasional baobab tree. Very little subsistence farming is evident with the exception of migratory grazing of goats and cattle.

The regional climate is strongly influenced by the Sahara and is defined as a semi-tropical environment of soudanien type characterised by one distinct dry season and one well defined rainy season from June to September. During November to January, the Harmattan Wind mobilises fine dust from the Sahara creating cool and dry conditions. A summary of the meteorological data used for the Belahouro Project site pre-feasibility project is presented in Figure 5-1. All data is summarised from Ouahiqouya only.

Figure 5-1 : Monthly Climatological Summary for the Project Site

| Precipitation | Evaporation 1 | Temperature 2 | Wind 3 | ||||||||

| Month | (1978-96) | (1961-94) | (1925-94) | (1961-94) | |||||||

| (mm) | Wettest | Driest | (mm) | (Deg C) | (m/s) | ||||||

| Ave | Max 4 | Min 5 | (1988) | (1993) | Average | Max | Min | Max | Min | Ave | |

| Jan | 0 | 0 | 0 | 0 | 0 | 238 | 343 | 183 | 33 | 14 | 1.5 |

| Feb | 0 | 0 | 0 | 0 | 0 | 260 | 370 | 210 | 36 | 16 | 1.5 |

| __________________________ |

| 1 Incomplete Record |

| 2 Incomplete Record |

| 3 Incomplete Record |

| 4 Maximum rainfall averaged over the 10 wettest years for all stations |

| 5 Minimum rainfall averaged over the 10 driest years for all stations |

| Page 38 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

| Precipitation | Evaporation 1 | Temperature 2 | Wind 3 | ||||||||

| Month | (1978-96) | (1961-94) | (1925-94) | (1961-94) | |||||||

| (mm) | (mm) | (Deg C) | (m/s) | ||||||||

| Ave | Max 4 | Min 5 | Wettest | Driest | Average | Max | Min | Max | Min | Ave | |

| (1988) | (1993) | ||||||||||

| Mar | 2 | 14 | 0 | 0 | 0 | 329 | 453 | 261 | 39 | 21 | 1.6 |

| April | 7 | 42 | 0 | 25 | 1 | 336 | 442 | 282 | 42 | 25 | 1.5 |

| May | 19 | 78 | 0 | 0 | 3 | 325 | 382 | 251 | 41 | 27 | 1.8 |

| June | 58 | 100 | 19 | 71 | 60 | 270 | 326 | 167 | 39 | 26 | 2.1 |

| July | 114 | 233 | 46 | 163 | 48 | 211 | 296 | 115 | 35 | 24 | 1.8 |

| Aug | 161 | 300 | 30 | 293 | 132 | 166 | 238 | 71 | 33 | 23 | 1.2 |

| Sept | 57 | 177 | 0 | 47 | 60 | 169 | 223 | 83 | 35 | 23 | 1.0 |

| Oct | 5 | 28 | 0 | 0 | 16 | 229 | 270 | 176 | 39 | 23 | 0.8 |

| Nov | 0 | 0 | 0 | 0 | 0 | 236 | 306 | 194 | 37 | 18 | 1.1 |

| Dec | 0 | 3 | 0 | 0 | 0 | 228 | 319 | 179 | 34 | 15 | 1.2 |

| Totals | 423 | 599 | 320 | 2996 | |||||||

5.3 Geology

5.3.1 Regional Geology

The Belahouro Project, Inata Prospect, is located within western environs of the Djibo greenstone belt, which comprises volcanic, volcano-detrital and sedimentary formations intruded by syn to post tectonic granitoids, impacted by metamorphism.

A detailed analysis of the regional geology is currently outside the scope of this report and the reader is directed to former pre-feasibility studies for the site.

5.3.2 Local Geology

The Inata mineralization is located within the Birimian Group of rocks of the Proterozoic age, close to the contact zone between the Turbiditic and Epiclastic sediments (see Figure 1-3). An east-west section through Inata suggests that a coarse to fine grained epiclastics passes to a sedimentary association comprising black shales, pelites and chert bands. The contact zone between the volcano-sediments and sediments is underlined by a silicified shear zone.

| Page 39 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

Preliminary pit geotechnical work was completed by George, Orr and Associates Pty Ltd in August 1999, a summary of which is provided in their report 'Belahouro Gold Project, Burkina Faso, Inata North and Inata Central Deposits - Preliminary Geotechnical Assessment'.

In summary, the oxide rock mass is extensively sheared and is expected to be highly weathered and dry. The wall rocks were judged to be of 'very poor' to 'poor' quality, reflecting on the weak nature of the rock and the presence of numerous structural geological defects.

Further geotechnical work is required for a full feasibility level study.

The overall slope angles used in this study range from 38º to 55º.

5.4 Hydrology and Hydrogeology

No definitive geohydrological records on aquifer and ground water elevations are available for the concession area, with the exception of first strike water levels reported within exploration boreholes.

Ground water elevations within the environs of the open pit are related to the macro/micro geological relief and are reported to be deeper than 80 m. Although local river alignments were in flood during the recent site visit, the average standing water ground level from well observations appears to be approximately 20 m below ground level.

5.5 Seismicity

There are no known seismic risk assessment studies for the area of the Belahouro Project. However, the map of seismic risk for Africa describes the project area as a zone of low seismic risk with seismic acceleration factors lower than 0.04g.

Contemporary practice requires that major structures are designed to resist the Operating Basic Earthquake (OBE) and Maximum Credible Earthquake (MCE). Based on this and in comparison with seismic risk assessments for projects located in areas of similar seismic risk in other regions of Africa (Ghana), the values shown in the Figure 5-2 below will be used for the different loading conditions in the stability analyses of the dam embankments.

The Maximum Credible Earthquake (MCE) has not been defined. It is recommended that a site specific seismic hazard assessment is undertaken for the project prior to detailed design.

| Page 40 of 261 |

|

|

| Project Report | |

| Date : 2nd December 2005 | GBM Proposal No. : GBM-0207 |

| Document No. : 0207-PFS-001E.doc | Revision No. : 7 |

| Project Title : Analysis of Technical Criteria for the Belahouro Gold Mine Project on behalf of Goldbelt Resources Ltd | |

Figure 5-2 : Seismic Load Conditions

|

|

Maximum Ground | Design Ground | Minimum Acceptable |

|

Design Case |

Acceleration | Acceleration 1 | Safety Factor |

|

Static |

0.00 g | 0.00 g | 1.50 |

|

Pseudo Static - OBE 2 |

0.03 g | 0.02 g | 1.25 |

|

Pseudo Static - MCE 3 |

n-d | n-d | 1.00 |

5.6 Local Resources and Infrastructure.

Over 80% of the population of Burkina Faso are engaged in subsistence agriculture and nomadic stock keeping. A significant proportion of the male labour force migrates annually to neighbouring countries, particularly Ghana and Cote d'Ivoire, for seasonal employment. Most workers are employed in the agriculture sector in growing peanuts, shea nuts, cotton, millet, corn rice, sesame sorghum and tending livestock. Burkina Faso exports cotton, animal products and gold and imports machinery, food products and petroleum.

Belahouro is the largest permanent village located approximately 30km east of the Inata project. A number of nomadic communities exist in the surrounding district. These communities survive on subsistence farming and small artisan gold mining operations. The artisan workings are based on outcropping mineralization and the reworking of anomalous laterite gravels.

As is common in most of the countries in this part of West Africa, regional infrastructure in Burkina Faso is poor, with few sealed roads and limited power distribution. Water, during the dry season in Belahouro, is only available from limited water bores operated by hand pumps. Village housing is a combination of mud huts and portable straw huts.

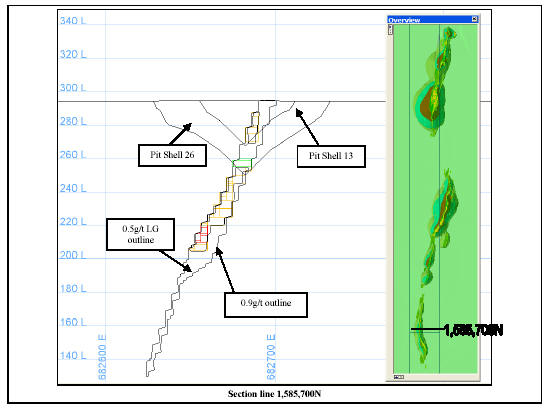

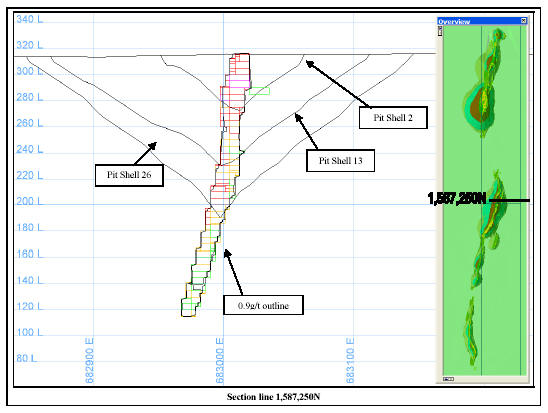

The Goldbelt central camp situated near the Belahouro village has 2 generators, comfortable accommodation for up to 40 people, a 30,000 litre diesel storage and a permanent supply of borehole water.